-

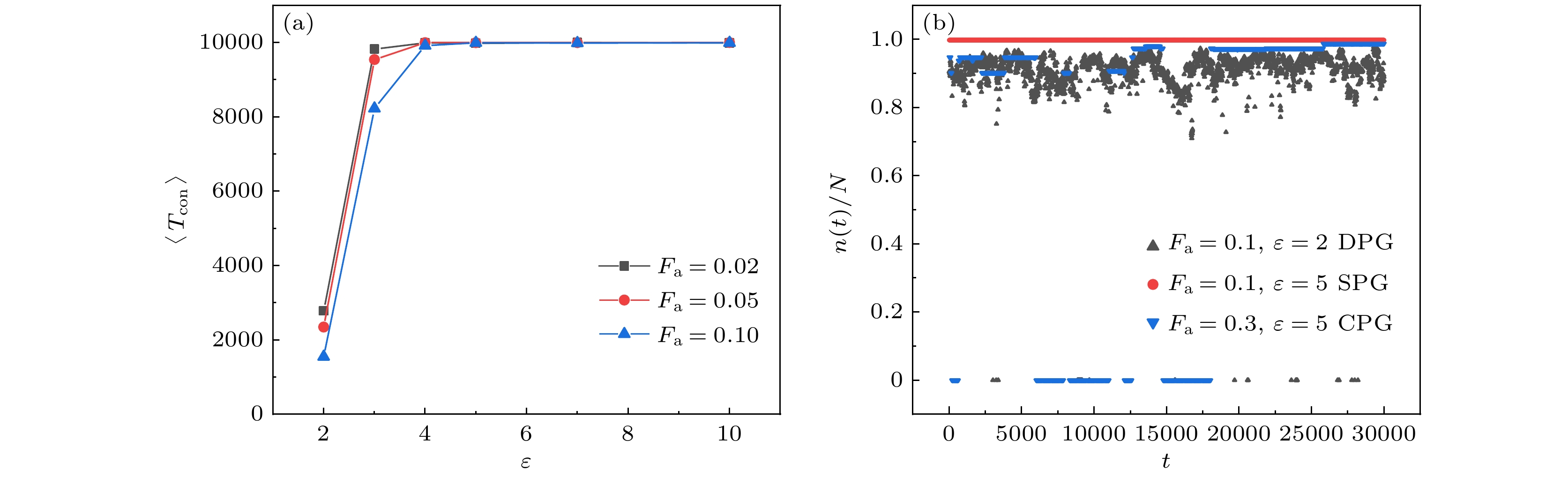

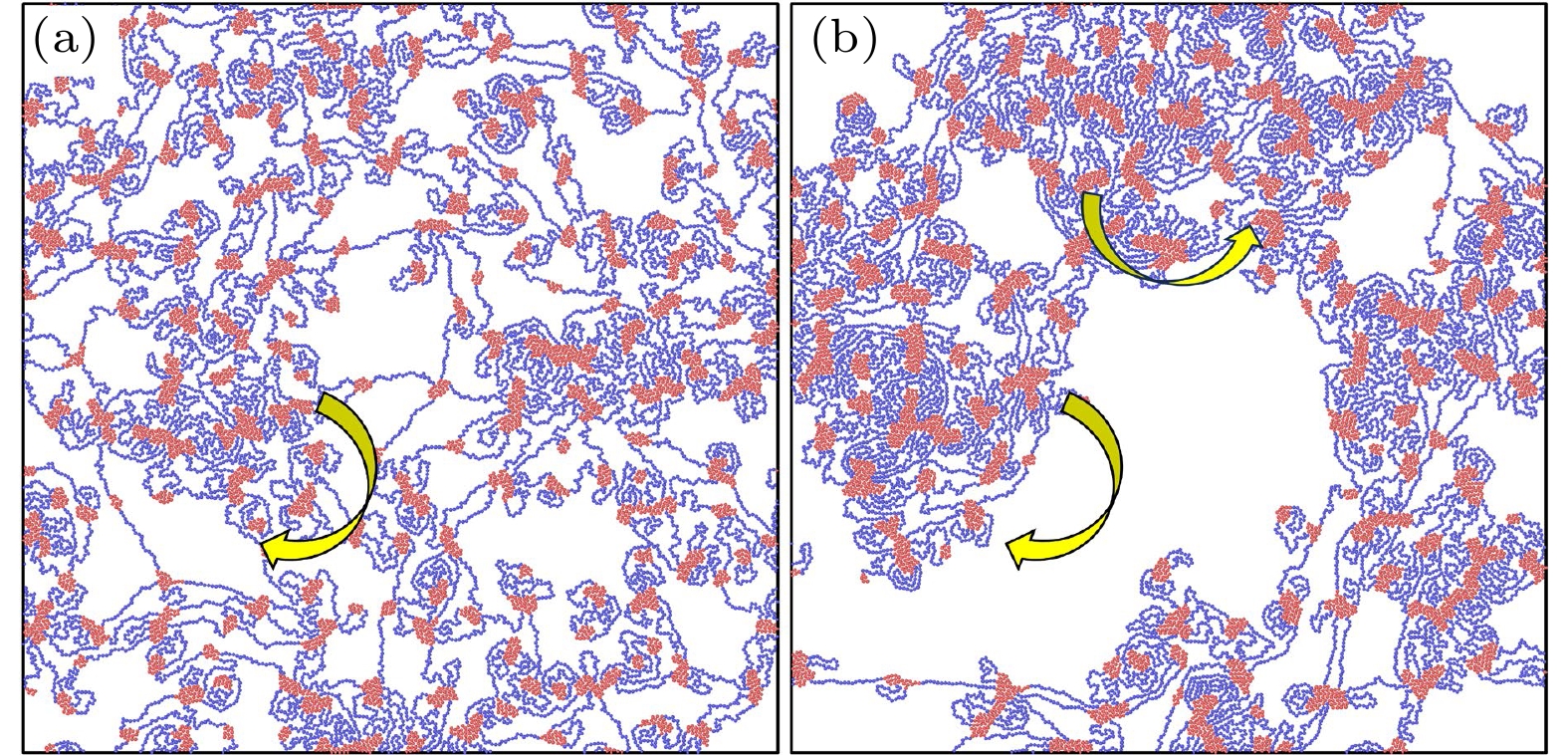

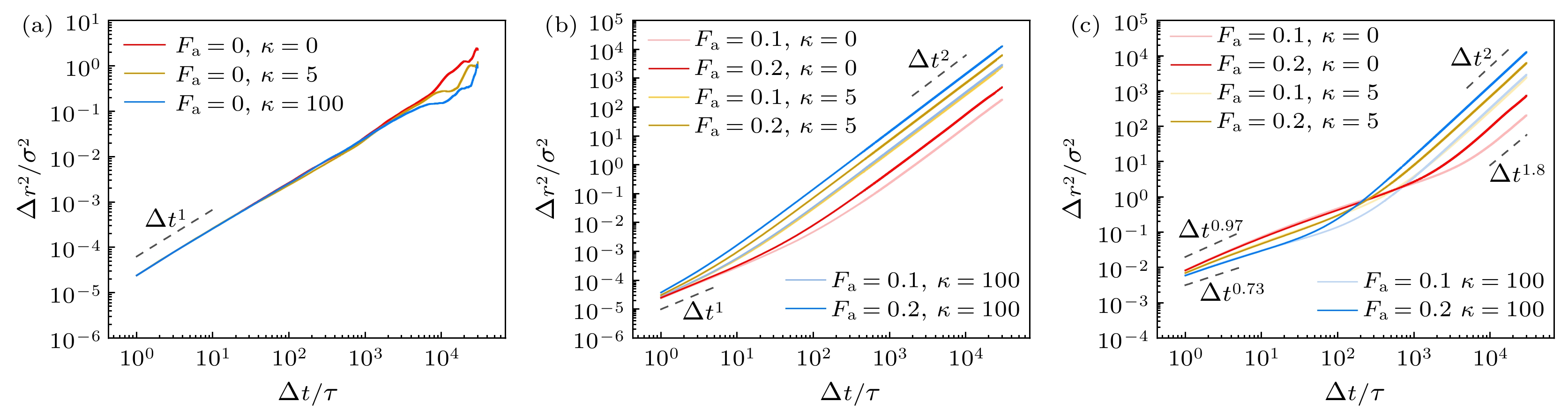

活性物质的自推进特征引发了许多非平衡自组织现象, 而聚合物链的构象自由度可以使链产生独特的平衡自组装行为, 这激发了活性物质与聚合物物理的交叉研究. 本文通过分子动力学模拟, 研究了自驱动活性对ABA 型三嵌段共聚物凝胶化转变的调控. 研究结果表明活性嵌段共聚物凝胶的塌缩源于自驱动活性引起的网络链运动, 活性越大则凝胶网络越容易产生大直径空洞. 在凝胶网络的拓扑缺陷方面, 当A嵌段之间吸引强度较大时, 环链比例随活性力增强而增大, 吸引强度较小时情况则相反. 交联点的分支数随活性的变化除了受到吸引强度的影响, 还与链刚性有关. 在动力学方面, 活性聚合物的定向运动会引发稳定聚合物凝胶整体的反常扩散. 本文的研究有助于增进对活性聚合物集体行为的认识, 为高分子活性材料的设计和应用提供了新的思路.The self-propulsion of active matter leads to many non-equilibrium self-organization phenomena, and the conformational freedom of polymer chains can produce unique equilibrium self-assembly behaviors, which stimulates cross-disciplinary research between active matter and polymer physics. In this work, we use molecular dynamics simulations to investigate the modulation of self-propulsion activity on the gel transition of ABA triblock copolymers. The research results indicate that under different active forces and attractive strengths, the gel states formed by ABA copolymers can be divided into three types: stable polymer gels with stable percolation paths and uniform spatial distribution, dynamic polymer gels with constantly changing percolation path and strand conformation, and collapsed polymer gels aggregating into large percolating clusters. The spatial uniformity of active gels is related not only to the concentration fluctuation during the formation of the network, but also to the inconsistent movement of the network chains caused by the activity, which is manifested in the rotation of crosslinking points in the flexible system and the directional movement of the bundles along their contour directions in the semi-flexible and rigid systems. In terms of topological conformation of polymer networks, when the attractive strength between A blocks is strong, the proportion of loop increases with the active force increasing. When attractive strength is weak, inter- and intra-chain binding are unstable, and the conformation is easily changed by the activity drive, noise and other chain collisions, so the proportion of loop decreases with the active force increasing. The branching number of crosslinking points varies with active force, which is not only affected by the attraction strength, but also related to the rigidity of the network chain. Generally, the branch number of crosslinking points in semi-flexible networks is larger than that in flexible and rigid networks. In addition, the directional motion of active polymers induces anomalous diffusion in stable polymer gels. This study contributes to the understanding of the collective behavior of active polymers and serves as a guide for designing and implementing active polymeric materials.

-

Keywords:

- active matter /

- ABA triblock copolymer /

- non-equilibrium system /

- polymer gel

[1] Deseigne J, Dauchot O, Chaté H 2010 Phys. Rev. Lett. 105 098001

Google Scholar

Google Scholar

[2] Vicsek T, Zafeiris A 2012 Phys. Rep. 517 71

Google Scholar

Google Scholar

[3] Liu L, Shi G, Thirumalai D, Hyeon C 2018 PLoS Comput. Biol. 14 e1006617

Google Scholar

Google Scholar

[4] Liu K, Patteson A E, Banigan E J, Schwarz J M 2021 Phys. Rev. Lett. 126 158101

Google Scholar

Google Scholar

[5] Weber C A, Suzuki R, Schaller V, Aranson I S, Bausch A R, Frey E 2015 Proc. Natl. Acad. Sci. U. S. A. 112 10703

Google Scholar

Google Scholar

[6] Kučera O, Gaillard J, Guérin C, Théry M, Blanchoin L 2022 Proc. Natl. Acad. Sci. U.S.A. 119 e2209522119

Google Scholar

Google Scholar

[7] Li H, Shi X Q, Huang M, Chen X, Xiao M, Liu C, Chaté H, Zhang H P 2019 Proc. Natl. Acad. Sci. U. S. A. 116 777

Google Scholar

Google Scholar

[8] Auer G K, Oliver P M, Rajendram M, Lin T Y, Yao Q, Jensen G J, Weibel D B 2019 mBio 10 00210

Google Scholar

Google Scholar

[9] Selander E, Jakobsen H H, Lombard F, Kiørboe T 2011 Proc. Natl. Acad. Sci. U. S. A. 108 4030

Google Scholar

Google Scholar

[10] Deblais A, Prathyusha K R, Sinaasappel R, Tuazon H, Tiwari I, Patil V P, Bhamla M S 2023 Soft Matter 19 7057

Google Scholar

Google Scholar

[11] Nishiguchi D, Iwasawa J, Jiang H R, Sano M 2018 New J. Phys. 20 015002

Google Scholar

Google Scholar

[12] Duman Ö, Isele-Holder R E, Elgeti J, Gompper G 2018 Soft Matter 14 4483

Google Scholar

Google Scholar

[13] Ndlec F J, Surrey T, Maggs A C, Leibler S 1997 Nature 389 305

Google Scholar

Google Scholar

[14] Schaller V, Weber C, Semmrich C, Frey E, Bausch A R 2010 Nature 467 73

Google Scholar

Google Scholar

[15] Huber L, Suzuki R, Krüger T, Frey E, Bausch A R 2018 Science 361 255

Google Scholar

Google Scholar

[16] Sanchez T, Chen D T N, DeCamp S J, Heymann M, Dogic Z 2012 Nature 491 431

Google Scholar

Google Scholar

[17] Doostmohammadi A, Ignés-Mullol J, Yeomans J M, Sagués F 2018 Nat. Commun. 9 3246

Google Scholar

Google Scholar

[18] Backouche F, Haviv L, Groswasser D, Bernheim-Groswasser A 2006 Phys. Biol. 3 264

Google Scholar

Google Scholar

[19] Chew W X, Henkin G, Nédélec F, Surrey T 2023 iScience 26 106063

Google Scholar

Google Scholar

[20] Faluweki M K, Goehring L 2022 J. R. Soc. Interface 19 20220268

Google Scholar

Google Scholar

[21] Faluweki M K, Cammann J, Mazza M G, Goehring L 2023 Phys. Rev. Lett. 131 158303

Google Scholar

Google Scholar

[22] Sugi T, Ito H, Nishimura M, Nagai K H 2019 Nat. Commun. 10 683

Google Scholar

Google Scholar

[23] Li Y Q, Sun Z Y, Shi T F, An L J 2004 J. Chem. Phys. 121 1133

Google Scholar

Google Scholar

[24] Tanaka F, Koga T 2001 BCSJ 74 201

Google Scholar

Google Scholar

[25] Hu H X, Shen Y F, Wang C, Luo M B 2022 Soft Matter 18 8820

Google Scholar

Google Scholar

[26] Han H, Joo S, Sakaue T, Jeon J H 2023 J. Chem. Phys. 159 024901

Google Scholar

Google Scholar

[27] Jiao Y, Wang J, Tian W D, Chen K 2023 Soft Matter 19 5468

Google Scholar

Google Scholar

[28] Bianco V, Locatelli E, Malgaretti P 2018 Phys. Rev. Lett. 121 217802

Google Scholar

Google Scholar

[29] Gu Y, Zhao J, Johnson J A 2020 Angew. Chem. Int. Ed. 59 5022

Google Scholar

Google Scholar

[30] Torquato S, Avellaneda M 1991 J. Chem. Phys. 95 6477

Google Scholar

Google Scholar

[31] Agrawal S, Galmarini S, Kröger M 2023 Phys. Rev. E 107 015307

Google Scholar

Google Scholar

[32] Hosono N, Masubuchi Y, Furukawa H, Watanabe T 2007 J. Chem. Phys. 127 164905

Google Scholar

Google Scholar

[33] Pereyra R G, Al-Maadeed M A, Carignano M A 2017 Express Polym. Lett. 11 199

Google Scholar

Google Scholar

[34] Di Lorenzo F, Seiffert S 2015 Polym. Chem. 6 5515

Google Scholar

Google Scholar

[35] Anand S K, Singh S P 2018 Phys. Rev. E 98 042501

Google Scholar

Google Scholar

[36] Head D A, Gompper G, Briels W J 2011 Soft Matter 7 3116

Google Scholar

Google Scholar

[37] Córdoba A 2018 J. Phys. Chem. B 122 4267

Google Scholar

Google Scholar

[38] Köhler S, Schaller V, Bausch A R 2011 Nat. Mater 10 462

Google Scholar

Google Scholar

-

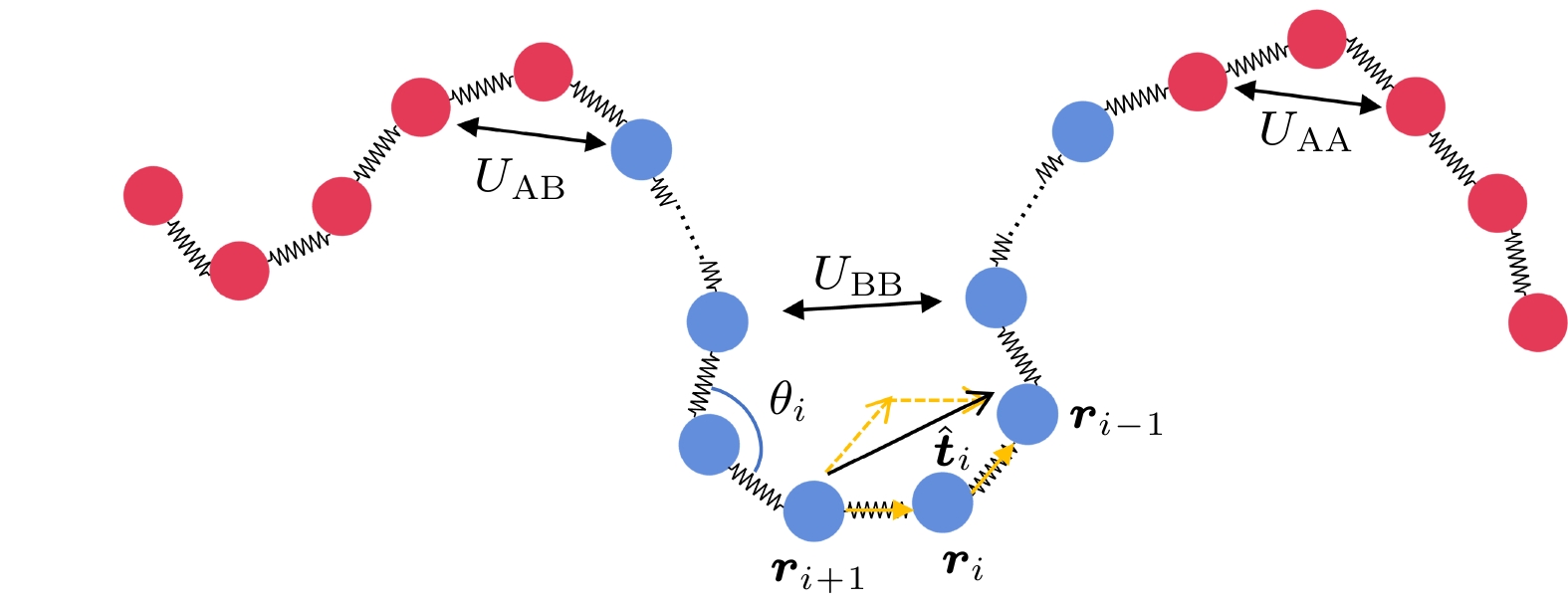

图 1 单体非键相互作用和活性力示意图, 红色圆形表示A单体, 蓝色圆形表示B单体, 中间嵌段的一些B单体在图中被省略

Fig. 1. Schematic diagram of non-bonding interactions and active forces of particles, with red circles representing type A monomers and blue circles representing type B monomers, some B monomers in the middle block are omitted in the diagram.

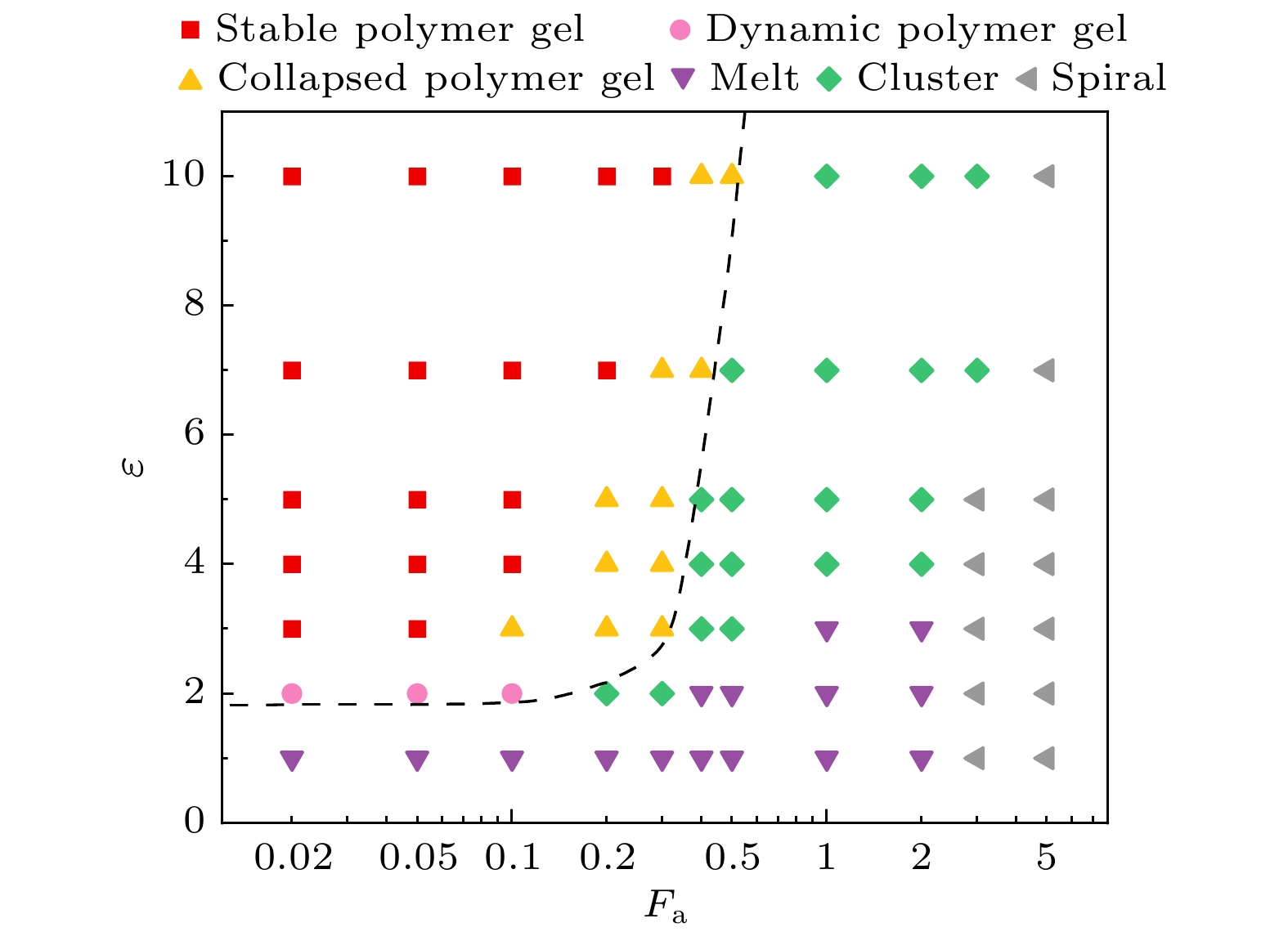

图 2 柔性活性ABA嵌段共聚物的相图, 虚线是各种凝胶态和非凝胶态粗略的分界线, 左侧表示凝胶态, 右侧为非凝胶态

Fig. 2. Phase diagram of flexible active ABA block copolymer. The dotted line is the rough dividing line between the various gel states and non-gel states, with the left part representing the gel state and the right part representing the non-gel state.

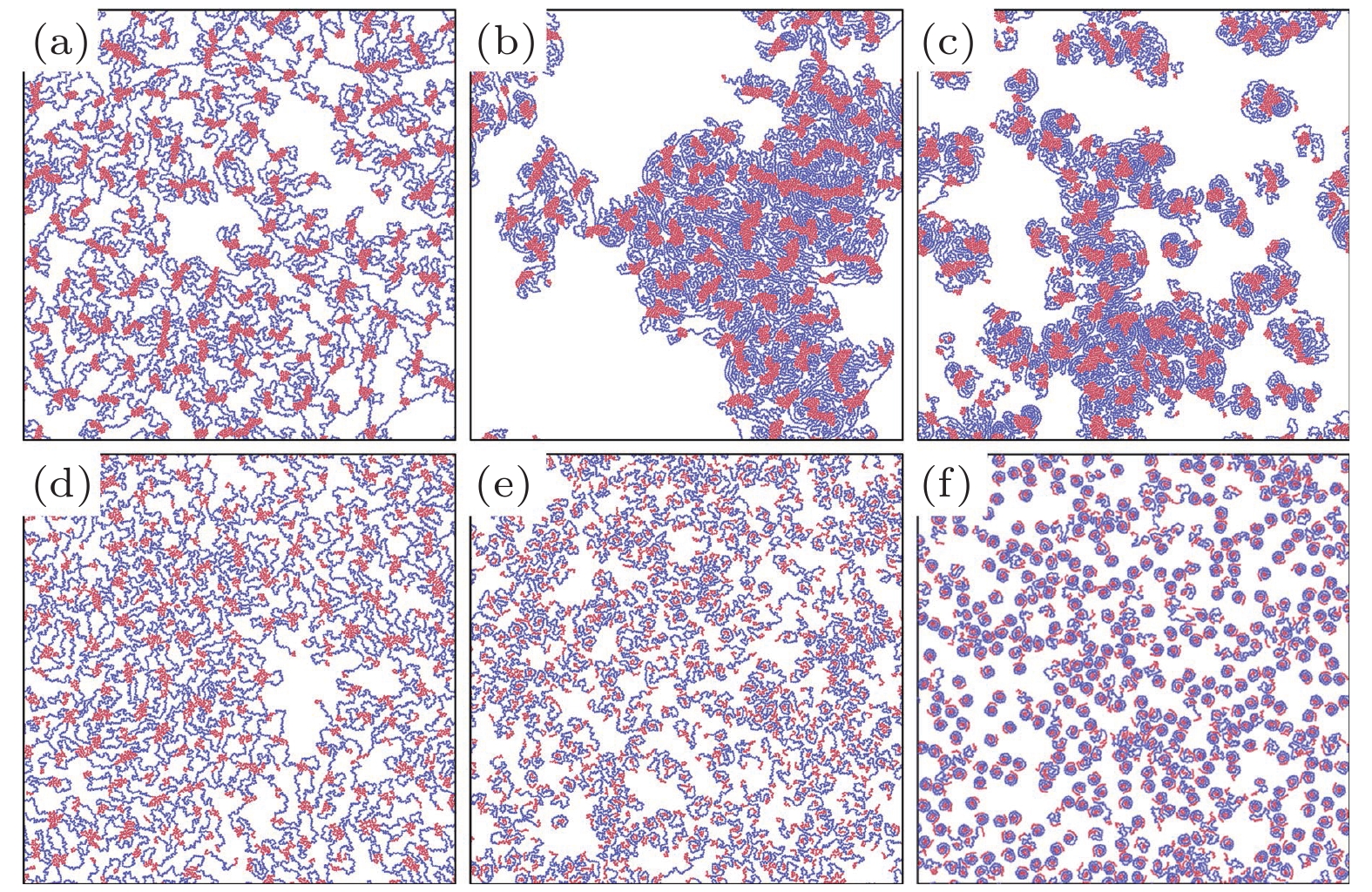

图 3 柔性活性ABA嵌段共聚物典型相的模拟快照 (a) 稳态聚合物凝胶; (b) 塌缩聚合物凝胶; (c) 团簇态; (d) 动态聚合物凝胶; (e) 熔融态; (f) 螺旋态

Fig. 3. Simulated snapshot of typical phase of flexible active ABA block copolymer: (a) Stable polymer gel; (b) collapsed polymer gel; (c) cluster state; (d) dynamic polymer gel; (e) melt state; (f) spiral state.

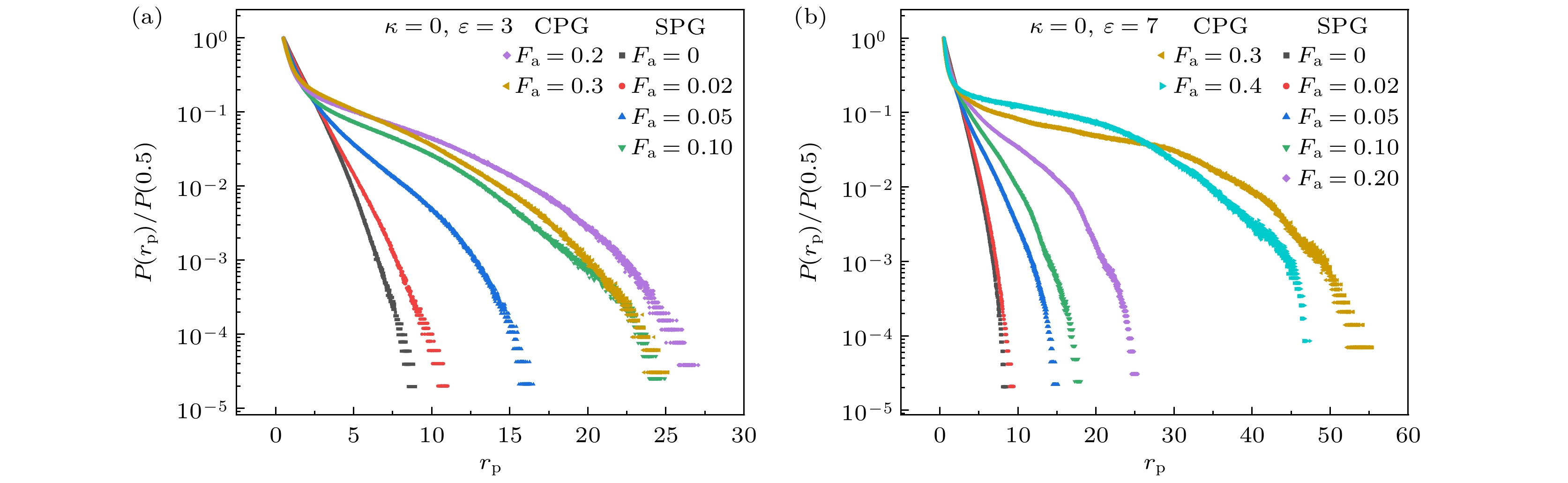

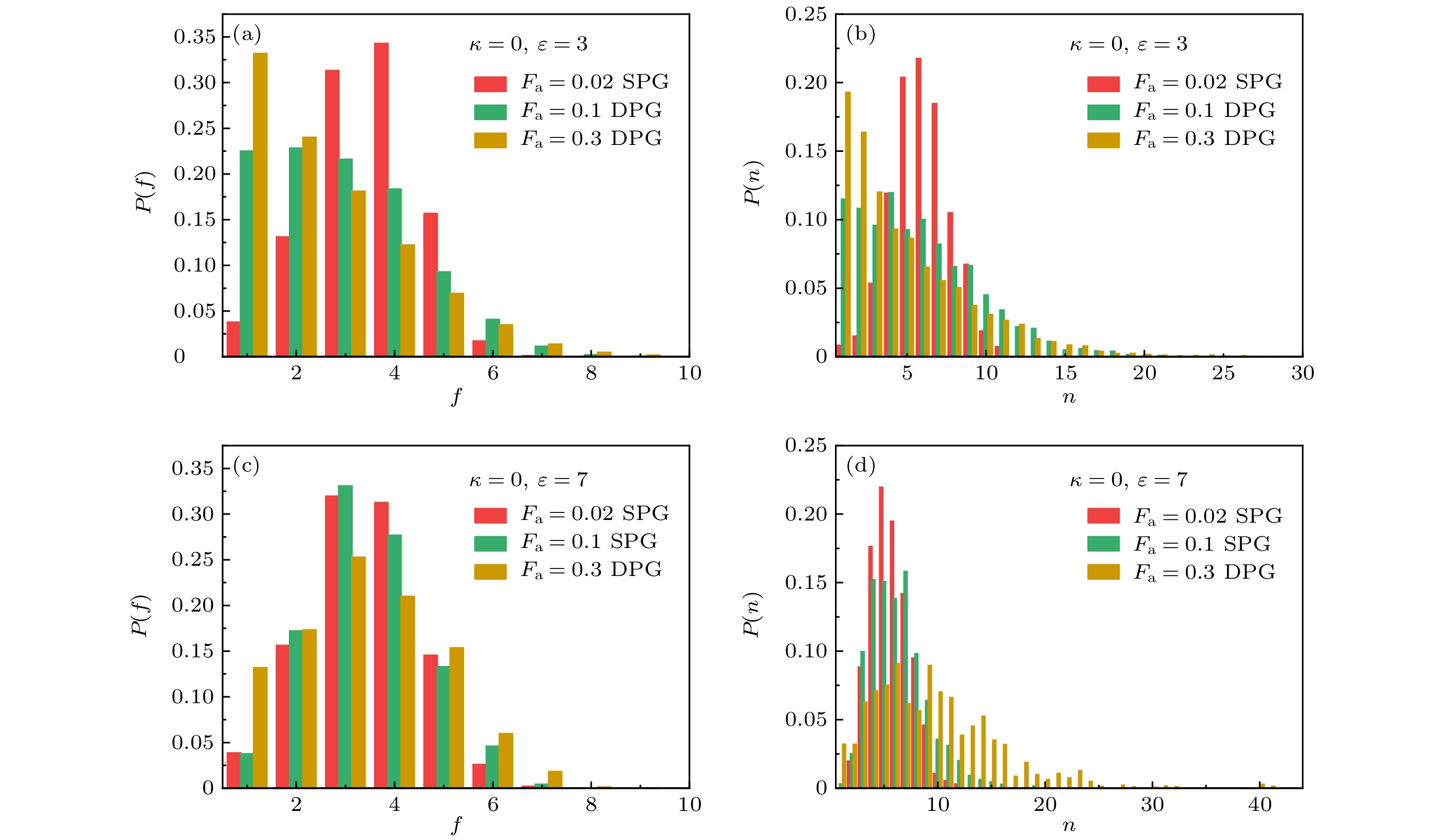

图 7 不同吸引强度下网络链三种构象的比例 (a) $\varepsilon = 7$; (b) $\varepsilon = 3$; (c)两种吸引强度的塌缩聚合物凝胶中, 环链比例随时间的变化

Fig. 7. The proportions of the three conformations of the network chain with different attraction strength: (a) $\varepsilon = 7$; (b) $\varepsilon = 3$; (c) the proportion of loop chains in two collapsed polymer gels with different attractive strengths as a function of time.

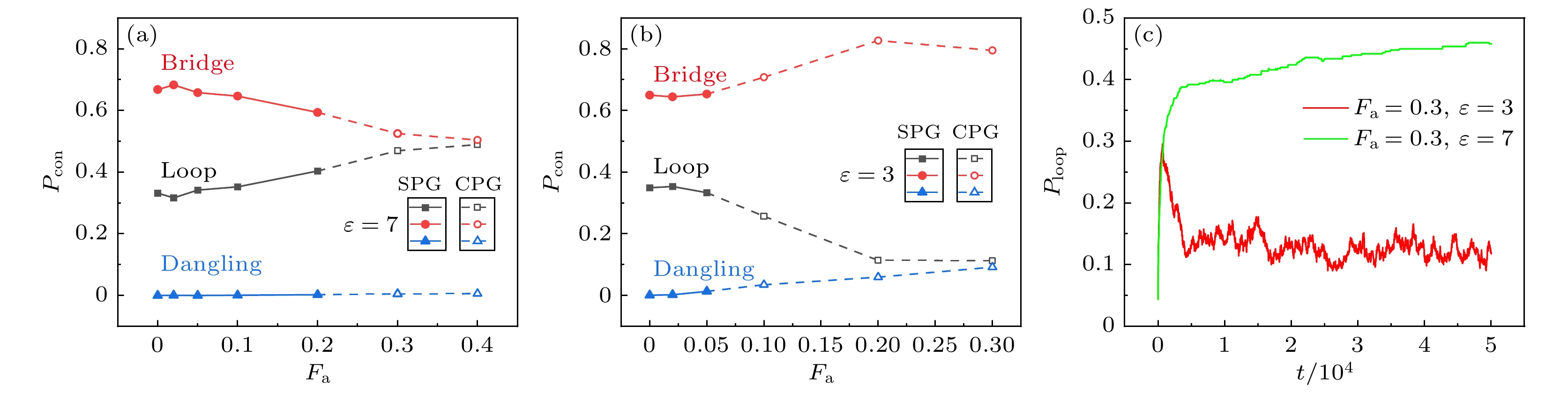

图 8 当$\varepsilon = 3$时, 3种活性下 (a)交联点的分支数分布和(b)交联点的尺寸分布, 红色表示稳定聚合物凝胶, 黄色和绿色表示塌缩; 当$\varepsilon = 7$时, 3种活性下(c)交联点的分支数分布和(d)交联点的尺寸分布

Fig. 8. When $\varepsilon = 3$, (a) the distribution of the branch number and (b) the size distribution of the crosslinker under the three activities; when $\varepsilon = 7$, (c) the distribution of the branch number and (d) the size distribution of the crosslinker under the three activities

-

[1] Deseigne J, Dauchot O, Chaté H 2010 Phys. Rev. Lett. 105 098001

Google Scholar

Google Scholar

[2] Vicsek T, Zafeiris A 2012 Phys. Rep. 517 71

Google Scholar

Google Scholar

[3] Liu L, Shi G, Thirumalai D, Hyeon C 2018 PLoS Comput. Biol. 14 e1006617

Google Scholar

Google Scholar

[4] Liu K, Patteson A E, Banigan E J, Schwarz J M 2021 Phys. Rev. Lett. 126 158101

Google Scholar

Google Scholar

[5] Weber C A, Suzuki R, Schaller V, Aranson I S, Bausch A R, Frey E 2015 Proc. Natl. Acad. Sci. U. S. A. 112 10703

Google Scholar

Google Scholar

[6] Kučera O, Gaillard J, Guérin C, Théry M, Blanchoin L 2022 Proc. Natl. Acad. Sci. U.S.A. 119 e2209522119

Google Scholar

Google Scholar

[7] Li H, Shi X Q, Huang M, Chen X, Xiao M, Liu C, Chaté H, Zhang H P 2019 Proc. Natl. Acad. Sci. U. S. A. 116 777

Google Scholar

Google Scholar

[8] Auer G K, Oliver P M, Rajendram M, Lin T Y, Yao Q, Jensen G J, Weibel D B 2019 mBio 10 00210

Google Scholar

Google Scholar

[9] Selander E, Jakobsen H H, Lombard F, Kiørboe T 2011 Proc. Natl. Acad. Sci. U. S. A. 108 4030

Google Scholar

Google Scholar

[10] Deblais A, Prathyusha K R, Sinaasappel R, Tuazon H, Tiwari I, Patil V P, Bhamla M S 2023 Soft Matter 19 7057

Google Scholar

Google Scholar

[11] Nishiguchi D, Iwasawa J, Jiang H R, Sano M 2018 New J. Phys. 20 015002

Google Scholar

Google Scholar

[12] Duman Ö, Isele-Holder R E, Elgeti J, Gompper G 2018 Soft Matter 14 4483

Google Scholar

Google Scholar

[13] Ndlec F J, Surrey T, Maggs A C, Leibler S 1997 Nature 389 305

Google Scholar

Google Scholar

[14] Schaller V, Weber C, Semmrich C, Frey E, Bausch A R 2010 Nature 467 73

Google Scholar

Google Scholar

[15] Huber L, Suzuki R, Krüger T, Frey E, Bausch A R 2018 Science 361 255

Google Scholar

Google Scholar

[16] Sanchez T, Chen D T N, DeCamp S J, Heymann M, Dogic Z 2012 Nature 491 431

Google Scholar

Google Scholar

[17] Doostmohammadi A, Ignés-Mullol J, Yeomans J M, Sagués F 2018 Nat. Commun. 9 3246

Google Scholar

Google Scholar

[18] Backouche F, Haviv L, Groswasser D, Bernheim-Groswasser A 2006 Phys. Biol. 3 264

Google Scholar

Google Scholar

[19] Chew W X, Henkin G, Nédélec F, Surrey T 2023 iScience 26 106063

Google Scholar

Google Scholar

[20] Faluweki M K, Goehring L 2022 J. R. Soc. Interface 19 20220268

Google Scholar

Google Scholar

[21] Faluweki M K, Cammann J, Mazza M G, Goehring L 2023 Phys. Rev. Lett. 131 158303

Google Scholar

Google Scholar

[22] Sugi T, Ito H, Nishimura M, Nagai K H 2019 Nat. Commun. 10 683

Google Scholar

Google Scholar

[23] Li Y Q, Sun Z Y, Shi T F, An L J 2004 J. Chem. Phys. 121 1133

Google Scholar

Google Scholar

[24] Tanaka F, Koga T 2001 BCSJ 74 201

Google Scholar

Google Scholar

[25] Hu H X, Shen Y F, Wang C, Luo M B 2022 Soft Matter 18 8820

Google Scholar

Google Scholar

[26] Han H, Joo S, Sakaue T, Jeon J H 2023 J. Chem. Phys. 159 024901

Google Scholar

Google Scholar

[27] Jiao Y, Wang J, Tian W D, Chen K 2023 Soft Matter 19 5468

Google Scholar

Google Scholar

[28] Bianco V, Locatelli E, Malgaretti P 2018 Phys. Rev. Lett. 121 217802

Google Scholar

Google Scholar

[29] Gu Y, Zhao J, Johnson J A 2020 Angew. Chem. Int. Ed. 59 5022

Google Scholar

Google Scholar

[30] Torquato S, Avellaneda M 1991 J. Chem. Phys. 95 6477

Google Scholar

Google Scholar

[31] Agrawal S, Galmarini S, Kröger M 2023 Phys. Rev. E 107 015307

Google Scholar

Google Scholar

[32] Hosono N, Masubuchi Y, Furukawa H, Watanabe T 2007 J. Chem. Phys. 127 164905

Google Scholar

Google Scholar

[33] Pereyra R G, Al-Maadeed M A, Carignano M A 2017 Express Polym. Lett. 11 199

Google Scholar

Google Scholar

[34] Di Lorenzo F, Seiffert S 2015 Polym. Chem. 6 5515

Google Scholar

Google Scholar

[35] Anand S K, Singh S P 2018 Phys. Rev. E 98 042501

Google Scholar

Google Scholar

[36] Head D A, Gompper G, Briels W J 2011 Soft Matter 7 3116

Google Scholar

Google Scholar

[37] Córdoba A 2018 J. Phys. Chem. B 122 4267

Google Scholar

Google Scholar

[38] Köhler S, Schaller V, Bausch A R 2011 Nat. Mater 10 462

Google Scholar

Google Scholar

计量

- 文章访问数: 875

- PDF下载量: 75

- 被引次数: 0

下载:

下载: