-

金属-半导体异质结 (MSJ) 是研发新型器件的基础. 本文考虑利用不同相的金属H-和T-NbS2与半导体GeS2组成不同的二维范德瓦耳斯MSJ, 并对它们的结构稳定性、电子特性以及电接触性质进行深入研究, 重点在探索MSJ电接触性质对不同相金属的依赖关系. 计算的结合能、声子谱、AIMD模拟以及力学性质研究表明, 两异质结高度稳定, 可实验制备, 且用于电子器件设计可行. 本征态H-NbS2/GeS2和T-NbS2/GeS2异质结分别形成了p型肖特基接触和准n型欧姆接触. 同时发现它们的肖特基势垒高度 (SBH) 和电接触类型可以通过外加电场和双轴应变来有效调控. 例如, 对于H-NbS2/GeS2异质结, 无论施加正/负电场或平面双轴压缩, 均能实现欧姆接触, 而T-NbS2/GeS2异质结, 仅在施加负电场时, 才能实现欧姆接触, 但需要的负电场很低, 平面双轴拉伸能导致其实现准欧姆接触. 也就是说, 当以半导体GeS2单层为场效应晶体管沟道材料, 与不同相的金属NbS2接触形成MSJ时, 其界面肖特基势垒有明显区别, 且在不同情形 (本征或物理调控) 中各有优势. 所以, 本研究对于理解H(T)-NbS2/GeS2异质结电接触的物理机制具有重要意义, 特别是为如何选择合适金属电极以研发高性能电子器件提供了理论参考.Metal-semiconductor heterojunction (MSJ) is the basis for developing novel devices. Here, we consider different two-dimensional van der Waals MSJs consisting of different-phase metals H- and T-NbS2 and semiconductor GeS2, and conduct an in-depth study of their structural stabilities, electronic and electrical contact properties, with an emphasis on exploring the dependence of the electrical contact properties of the MSJs on the different phases of metals. Calculation results of their binding energy, phonon spectra, AIMD simulations, and mechanical properties show that both heterojunctions are highly stable, which implies that it is possible to prepare them experimentally and feasible to use them for designing electronic devices. The intrinsic H-NbS2/GeS2 and T-NbS2/GeS2 heterojunctions form p-type Schottky contacts and quasi-n-type Ohmic contacts, respectively. It is also found that their Schottky barrier heights (SBHs) and electrical contact types can be effectively modulated by an applied electric field and biaxial strain. For example, for the H-NbS2/GeS2 heterojunction, Ohmic contact can be achieved regardless of applying a positive/negative electric field or planar biaxial compression, while for the T-NbS2/GeS2 heterojunction, Ohmic contact can be achieved only at a very low negative electric field. The planar biaxial stretching can achieve quasi-Ohmic contact. In other words, when the semiconductor GeS2 monolayer is used as the channel material of the field effect transistor and contacts different metal NbS2 monolayers to form the MSJ, the interfacial Schottky barriers are distinctly different, and each of them has its own advantages in different situations (intrinsic or physically regulated). Therefore, this study is of great significance for understanding the physical mechanism of the electrical contact behaviors for H(T)-NbS2/GeS2 heterojunction, especially for providing the theoretical reference for selecting suitable metal electrodes for the development of high-performance electronic devices.

-

Keywords:

- metal-semiconductor heterojunction /

- Schottky barrier /

- Schottky contact /

- Ohmic contact /

- physical field modulation

[1] Novoselov K S, Mishchenko A, Carvalho A, Castro Neto A 2016 Science 353 aac9439

Google Scholar

Google Scholar

[2] Han J N, Cao S G, Li Z H, Zhang Z H 2022 J. Phys. D: Appl. Phys. 56 045002

Google Scholar

Google Scholar

[3] Xu Y H, Han J N, Li Z H, Zhang Z H 2023 J. Phys. D: Appl. Phys. 56 365504

Google Scholar

Google Scholar

[4] Pierucci D, Henck H, Avila J, Balan A, Naylor C H, Patriarche G, Dappe Y J, Silly M G, Sirotti F, Johnson A C 2016 Nano Lett. 16 4054

Google Scholar

Google Scholar

[5] Chen J Z, Ma G B, Gong B X, Deng C Y, Zhang M, Guo K X, Cui R R, Wu Y K, Lü M L, Wang X 2023 Nanomaterials 13 429

Google Scholar

Google Scholar

[6] Wang J G, Ma F C, Sun M T 2017 RSC Adv. 7 16801

Google Scholar

Google Scholar

[7] Cai Y Q, Zhang G, Zhang Y W 2015 J. Phys. Chem. C 119 13929

Google Scholar

Google Scholar

[8] Yu L L, Lee Y H, Ling X., Santos E J, Shin Y C, Lin Y X, Dubey M, Kaxiras E, Kong J, Wang H, Palacios T 2014 Nano Lett. 14 3055

Google Scholar

Google Scholar

[9] Sinha S, Zhu T S, France-Lanord A, Sheng Y W, Grossman J C, Porfyrakis K, Warner J H 2020 Nat. Commun. 11 823

Google Scholar

Google Scholar

[10] Mohanta M K, Rawat A, Jena N, Dimple, Ahammed R, Sarkar A D 2020 ACS Appl. Mater. Interfaces. 12 3114

Google Scholar

Google Scholar

[11] Ahammed R, Rawat A, Jena N, Dimple, Mohanta M K, Sarkar A D 2020 Appl. Surf. Sci. 499 143894

Google Scholar

Google Scholar

[12] Hong X P, Kim J, Shi S F, Zhang Y, Jin C H, Sun Y H, Tongay S, Wu J Q, Zhang Y F, Wang F 2014 Nat. Nanotechnol. 9 682

Google Scholar

Google Scholar

[13] Rivera P, Seyler K L, Yu H Y, Schaibley J R, Yan J Q, Mandrus D G, Yao W, Xu D 2016 Science 351 688

Google Scholar

Google Scholar

[14] Paul Inbaraj C R, Mathew R J, Ulaganathan R K, Sankar R, Kataria M, Lin H Y, Cheng H Y, Lin K H, Lin H L, Liao Y M, Chou F C, Chen Y T, Lee C H, Chen Y F 2020 ACS Appl. Mater. 12 26213

Google Scholar

Google Scholar

[15] Kataria M, Yadav K, Cai S Y, Liao Y M, Lin H I, Shen T L, Chen Y H, Chen Y T, Wang W H, Chen Y F 2018 ACS Nano 12 9596

Google Scholar

Google Scholar

[16] Liu Y, Guo J, Zhu E B, Liao L, Lee S J, Ding M N, Shakir I, Gambin V, Huang Y, Duan X F 2018 Nature 557 696

Google Scholar

Google Scholar

[17] Kim C, Moon I, Lee D, Choi M S, Ahmed F, Nam S, Cho Y, Shin H J, Park S, Yoo W 2017 ACS Nano 11 1588

Google Scholar

Google Scholar

[18] Chen X, Wang D K, Wang T, Yang Z Y, Zou X M, Wang P, Luo W J, Li Q, Liao L, Hu W D 2019 ACS Appl. Mater. 11 33188

Google Scholar

Google Scholar

[19] Zheng S, Lu H C, Liu H, Liu D M, Robertson J 2019 Nanoscale 11 4811

Google Scholar

Google Scholar

[20] Allain A, Kang J, Banerjee K, Kis A 2015 Nat. Mater. 14 1195

Google Scholar

Google Scholar

[21] Zhang W X, Yin Y, He C 2020 Phys. Chem. Chem. Phys. 22 26231

Google Scholar

Google Scholar

[22] Wang X L, Feng W, Shen C, Sun Z H, Qi H B, Yang M, Liu Y H, Wu Y C, Wu X Q 2021 Front. Mater. 8 709757

Google Scholar

Google Scholar

[23] Nandi P, Rawat A, Ahammed R, Jena N, De Sarkar A 2021 Nanoscale 13 5460

Google Scholar

Google Scholar

[24] Chen H, Keiser C, Du S X, Gao H J, Sutter P, Sutter E 2017 Phys. Chem. Chem. Phys. 19 32473

Google Scholar

Google Scholar

[25] Gao R L, Yong Y L, Yuan X B, Hu S, Hou Q H, Kuang Y M 2022 ACS Omega 7 46440

Google Scholar

Google Scholar

[26] Ruan X Y, Xiong R, Cui Z, Wen C L, Ma J J, Wang B T, Sa B S 2022 Materials 15 4016

Google Scholar

Google Scholar

[27] Mao Y L, Zhang G H 2020 Physica B Condens. Matter 581 411673

Google Scholar

Google Scholar

[28] Zhang Z P, Yang P F, Hong M, Jiang S L, Zhao G C, Shi J P, Xie Q, Zhang Y F 2019 Nanotechnology 30 182002

Google Scholar

Google Scholar

[29] Shin H G, Yoon H S, Kim J S, Kim M, Lim J Y, Yu S, Park J H, Yi Y, Kim T, Jun S C, Im S 2018 Nano Lett. 18 1937

Google Scholar

Google Scholar

[30] Kim Y, Kwon K C, Kang S, Kim C, Kim T H, Hong S P, Park S Y, Suh J M, Choi M J, Han S 2019 ACS Sens. 4 2395

Google Scholar

Google Scholar

[31] Zhou J H, Shen Y H, Lü F, Zhang W Y, Lin F X, Zhang W S, Wang K, Luo H, Wang Q, Yang H 2022 Adv. Funct. Mater. 32 2204495

Google Scholar

Google Scholar

[32] Brandbyge M, Mozos J L, Ordejón P, Taylor J, Stokbro K 2002 Phys. Rev. B 65 165401

Google Scholar

Google Scholar

[33] Li Z H, Han J N, Cao S G, Zhang Z H, Deng X Q 2023 Phys. Rev. B 108 184413

Google Scholar

Google Scholar

[34] 何鑫, 李鑫焱, 李景辉, 张振华 2022 71 218503

Google Scholar

Google Scholar

He X, Li X Y, Li J H, Zhang Z H 2022 Acta Phys. Sin. 71 218503

Google Scholar

Google Scholar

[35] Li X Y, Li Z H, Han J N, Cao S G, Zhang Z H 2024 Phys. Chem. Chem. Phys. 26 4218

Google Scholar

Google Scholar

[36] Yi Y, Han J N, Li Z H, Cao S G, Zhang Z H 2024 Phys. Chem. Chem. Phys. 26 5045

Google Scholar

Google Scholar

[37] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[38] Troullier N, Martins J L 1991 Phys. Rev. B 43 1993

Google Scholar

Google Scholar

[39] Soler J M, Artacho E, Gale J D, García A, Junquera J, Ordejón P, Sánchez-Portal D 2002 J. Phys. Condens Matter 14 2745

Google Scholar

Google Scholar

[40] Grimme S 2006 J. Comput. Chem. 27 1787

Google Scholar

Google Scholar

[41] Ding X, Zhang S, Zhao M, Xiang Y, Zhang K H, Zu X, Li S, Qiao L 2019 Phys. Rev. Appl. 12 064061

Google Scholar

Google Scholar

[42] Jelver L, Larsen P M, Stradi D, Stokbro K, Jacobsen K W 2017 Phys. Rev. B 96 085306

Google Scholar

Google Scholar

[43] Xia J L, Gu Y X, Mai J, Hu T Y, Wang Q K, Xie C, Wu Y K, Wang X 2023 Heliyon 9 e20619

Google Scholar

Google Scholar

[44] Vu T V, Hieu N V, Phuc H V, Hieu N N, Bui H D, Idrees M, Amin B, Nguyen C V 2020 Appl. Surf. Sci. 507 145036

Google Scholar

Google Scholar

[45] Nguyen S T, Huong T T T, Ca N X, Nguyen C Q 2024 Nanoscale Adv. 6 1565

Google Scholar

Google Scholar

[46] Wang Q H, Li H, Si L N, Dou Z L, Yan H J, Yang Y, Liu F B 2023 Mater. Today Commun. 35 10572

Google Scholar

Google Scholar

[47] Wang F F, Yuan J, Zhang Z F, Ding X L, Gu C J, Yan S B, Sun J H, Jiang T, Wu Y F, Zhou J 2023 Phys. Rev. B 108 075416

Google Scholar

Google Scholar

[48] Mohanta M K, Kishore A, Sarkar A D 2020 Nanotechnology 31 495208

Google Scholar

Google Scholar

[49] Cadelano E, Palla P L, Giordano S, Colombo L 2010 Phys. Rev. B 82 235414

Google Scholar

Google Scholar

[50] Li Y Q, Wang X Y, Zhu S Y, Tang D S, He Q W, Wang X C 2022 J. Mater. Chem. C 10 12132

Google Scholar

Google Scholar

[51] Gupta A, Sakthivel T, Seal S 2015 Prog. Mater Sci. 73 44

Google Scholar

Google Scholar

[52] Booth T J, Blake P, Nair R R, Jiang D, Hill E W, Bangert U, Bleloch A, Gass M, Novoselov K S, Katsnelson M I 2008 Nano Lett. 8 2442

Google Scholar

Google Scholar

[53] Zhang W X, Shi C H, He C, Bai M 2020 J. Solid State Chem. 289 121511

Google Scholar

Google Scholar

[54] Zheng J S, Li E L, Ma D M, Cui Z, Peng T, Wang X L 2019 Phys. Status Solidi B 256 1900161

Google Scholar

Google Scholar

[55] Li Z H, Han J N, Cao S G, Zhang Z H 2023 Appl. Surf. Sci. 614 156095

Google Scholar

Google Scholar

[56] Nguyen C V, Idrees M, Phuc H V, Hieu N N, Binh N T, Amin B, Vu T V 2020 Phys. Rev. B 101 235419

Google Scholar

Google Scholar

-

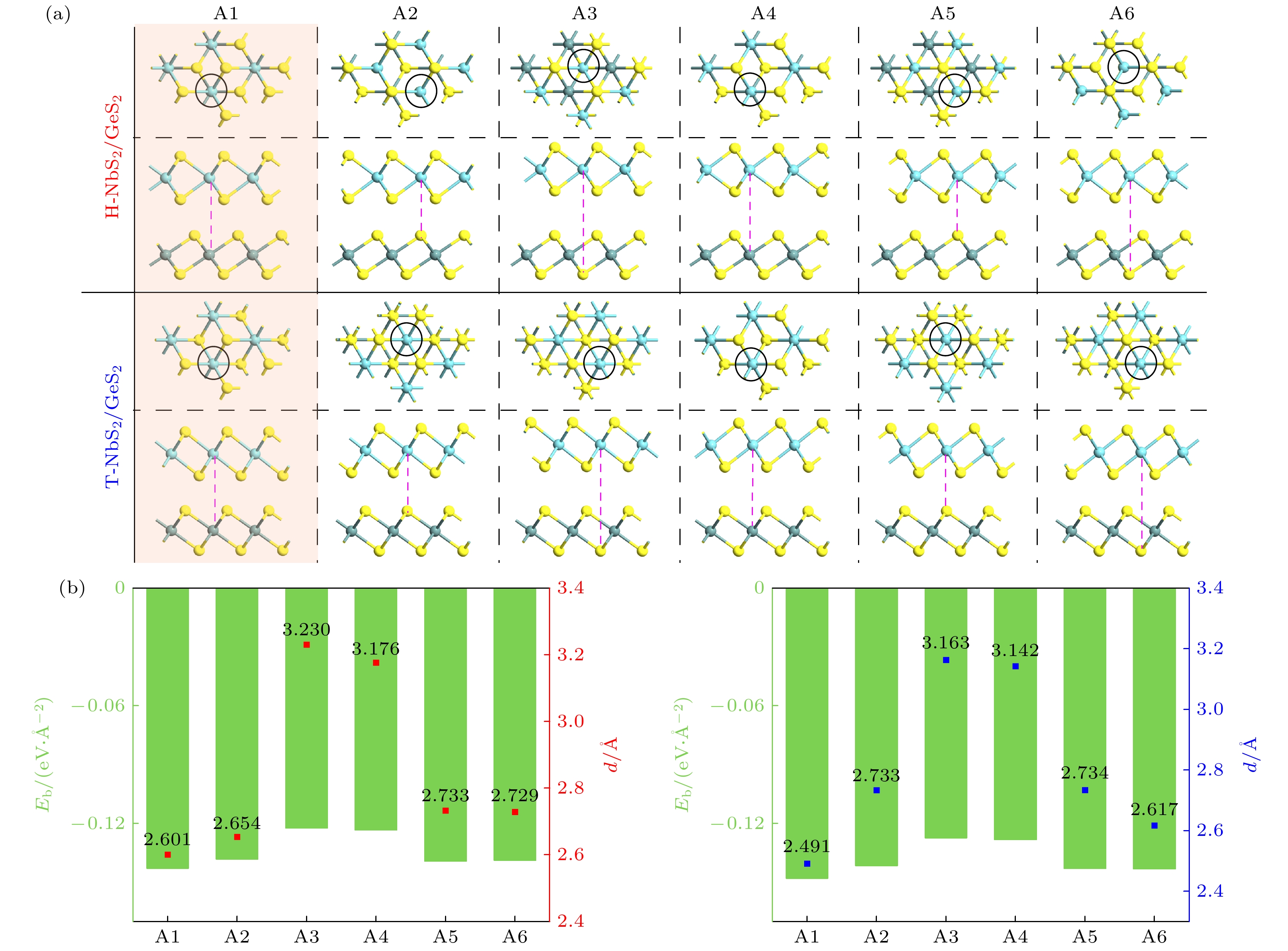

图 2 (a) H-NbS2/GeS2 (上图) 和T-NbS2/GeS2 (下图) 的6种堆垛方式A1—A6, 图中两个橙色阴影区域为最稳堆垛结构; (b) 6种堆垛方式的H-NbS2/GeS2 (左图) 和T-NbS2/GeS2 (右图) 的优化层间距及对应的结合能

Fig. 2. (a) Six stacking modes A1-A6 for H-NbS2/GeS2 (top panel) and T-NbS2/GeS2 (bottom panel), with the two orange shaded regions in the figure showing the most stable stacking structures; (b) optimized interlayer spacing and corresponding binding energy of H-NbS2/GeS2 (left panel) and T-NbS2/GeS2 (right panel) for the six stacking modes.

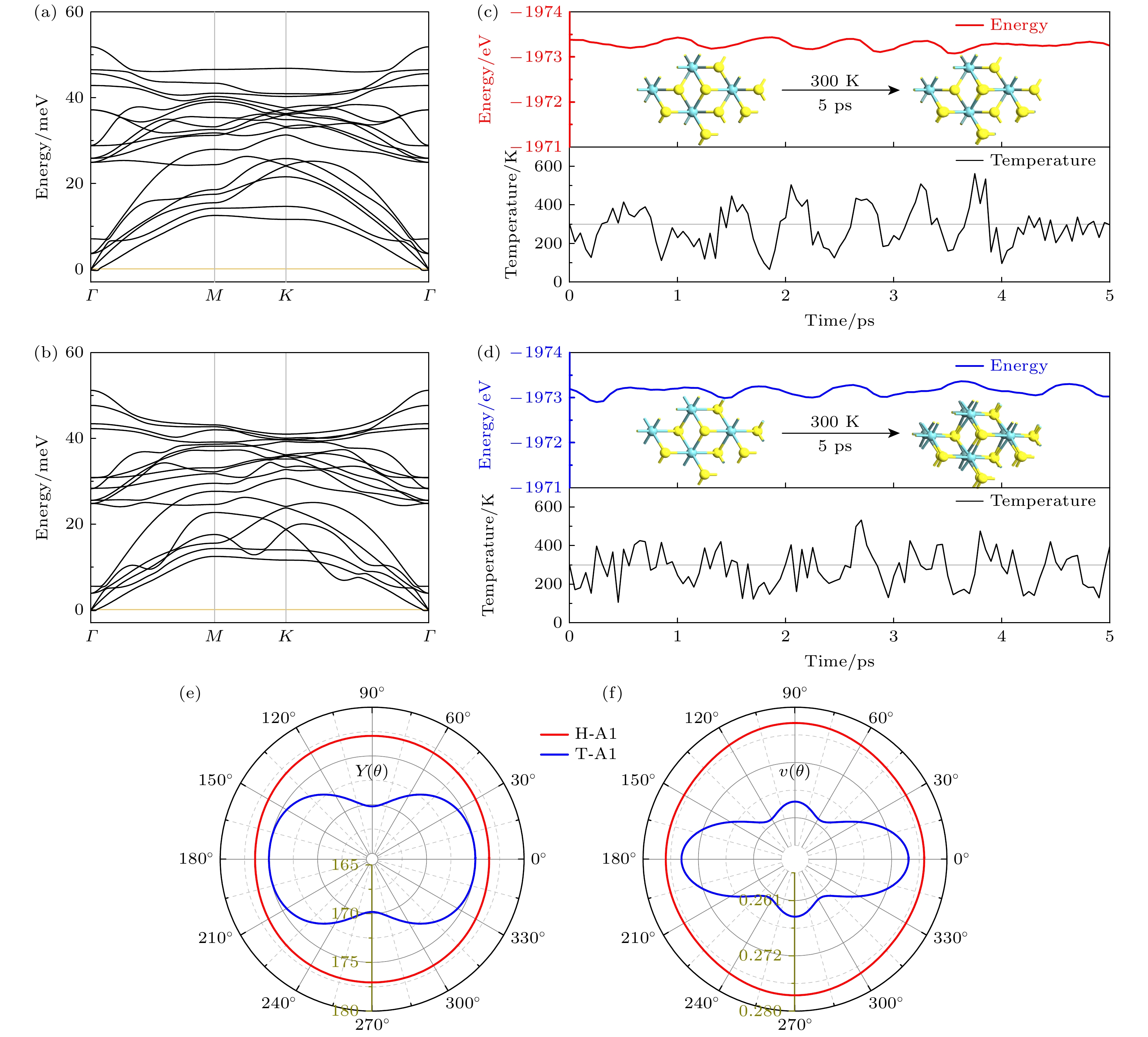

图 3 (a) H-A1和(b) T-A1的声子谱. (c) H-A1和(d) T-A1 300 K的AIMD模拟. H-A1和T-A1的 (e) 杨氏模量Y和 (f) 泊松比v随面内角$\theta $的变化

Fig. 3. Phonon spectra of (a) H-A1 and (b) T-A1. AIMD simulations at 300 K of (c) H-A1 and (d) T-A1. Variation of (e) Young’s modulus Y and (f) Poisson’s ratio v with the in-plane angle for H-A1 and T-A1.

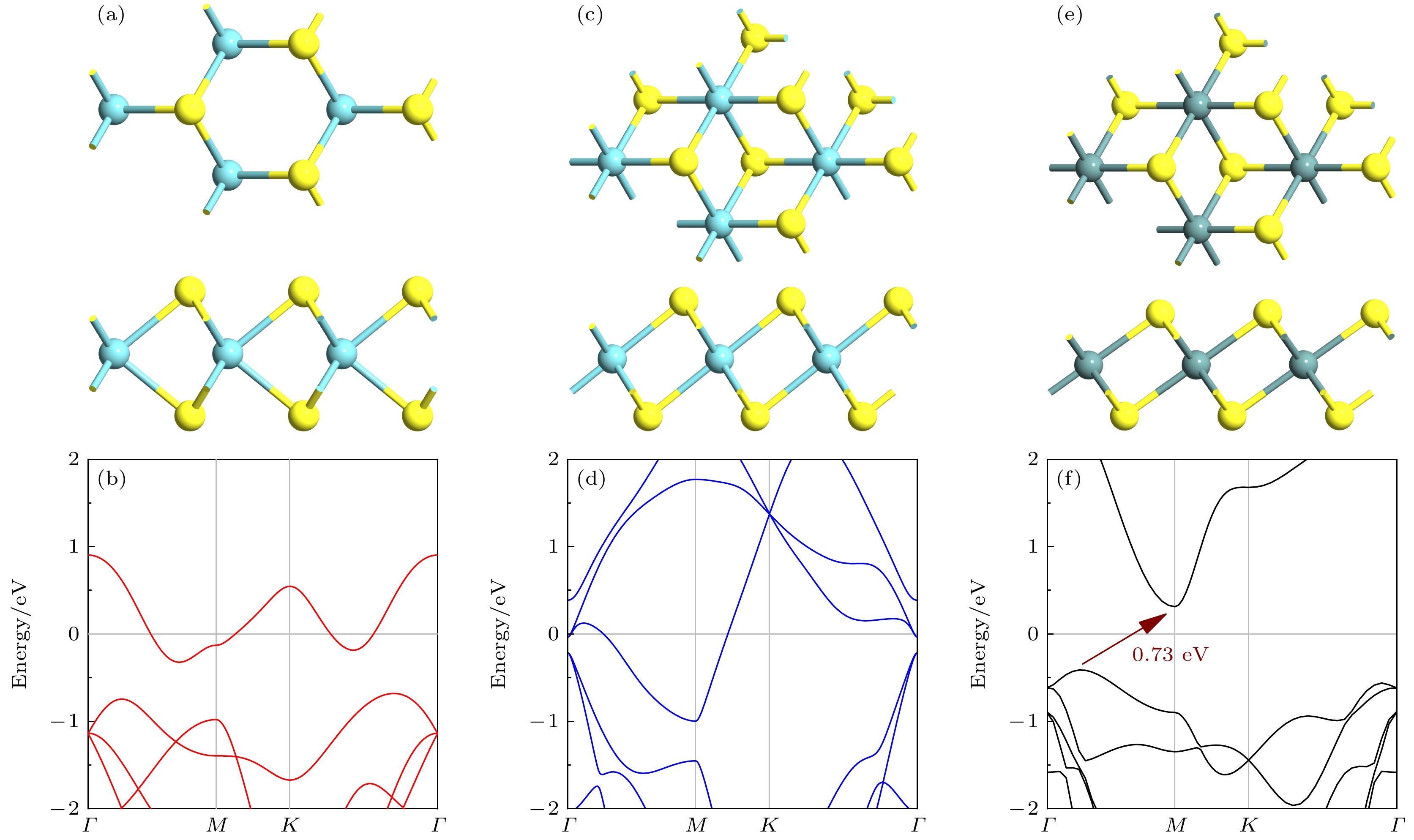

图 4 异质结投影能带结构 (a) H-A1, (b) T-A1. 沿z轴方向的电荷密度差及三维电荷密度差 (c) H-A1, (d) T-A1; 插图中红色和蓝色分别代表电子积累和消耗, 等值面设为0.0005 e/Å3

Fig. 4. Projected band structures of heterojunctions: (a) H-A1; (b) T-A1. Charge density difference along the z-axis direction and three-dimensional charge density difference: (c) H-A1; (d) T-A1, where the red and blue in the inset represent electron accumulation and depletion, respectively, and the isosurfaces are set to 0.0005 e/Å3.

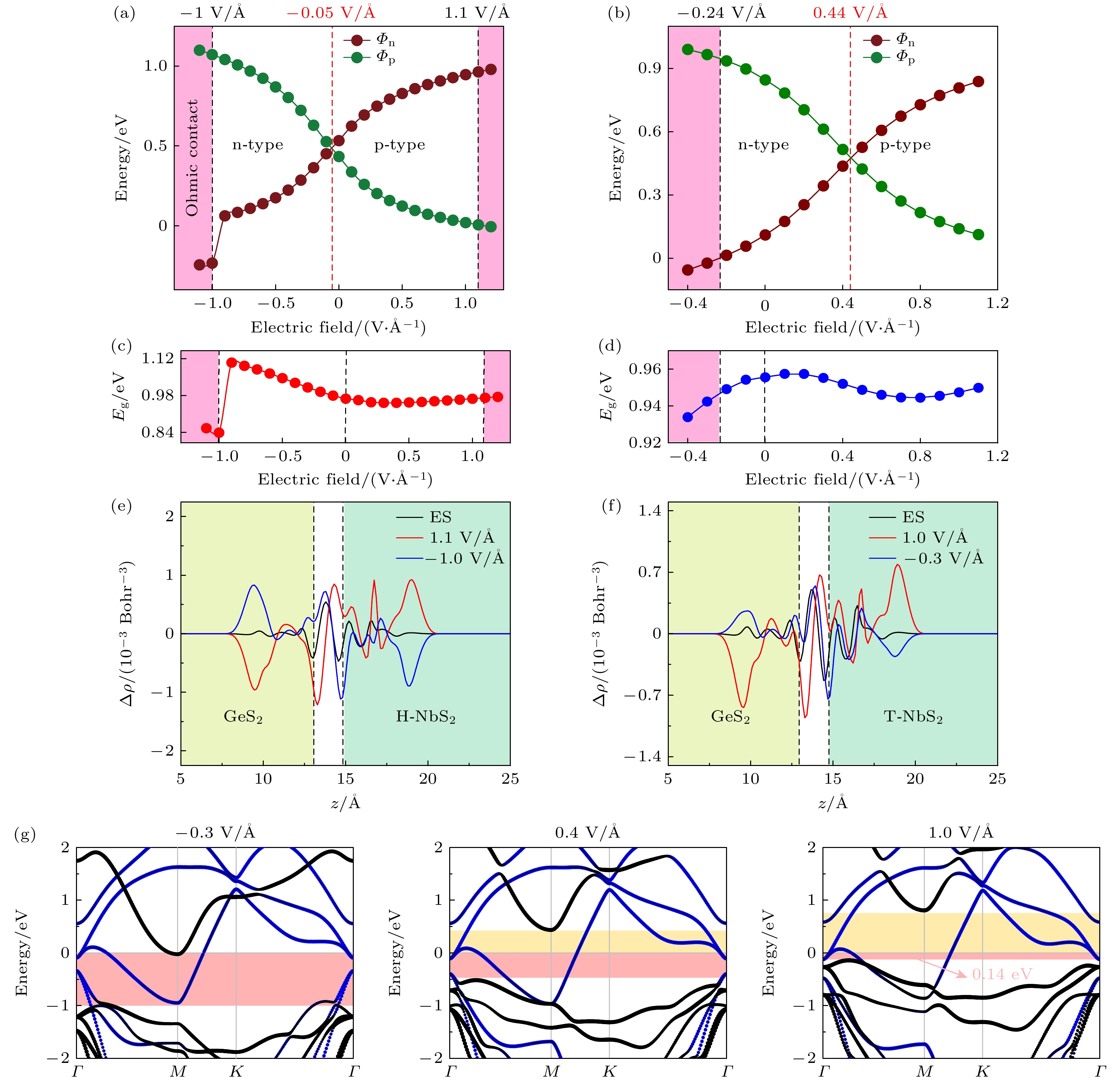

图 5 外电场调制效应, 肖特基势垒高度与电场的关系 (a) H-A1; (b) T-A1. 异质结中GeS2单层的带隙与电场的关系 (c) H-A1; (d) T-A1. 不同电场下异质结沿z轴方向的电荷密度差 (e) H-A1; (f) T-A1. (g) T-A1的投影能带结构随外电场变化情况, 其中蓝色表示T-NbS2层的贡献, 黑色表示GeS2层的贡献, 上下两个方框分别表示Φn和Φp

Fig. 5. External electric field modulation effect, Schottky barrier height versus electric field: (a) H-A1; (b) T-A1. Band gap of GeS2 monolayer in heterojunction versus electric field: (c) H-A1; (d) T-A1. Difference in charge density of heterojunction along z-axis with different electric fields: (e) H-A1; (f) T-A1. (g) Variation of the projected energy-band structure with the external electric field for T-A1, where the blue denotes the contribution of T-NbS2 layer, and the black denotes the contribution of GeS2 layer, and top and bottom boxes indicate Φn and Φp, respectively.

图 6 双轴应变调控效应, 肖特基势垒高度与双轴应变的关系 (a) H-A1; (b) T-A1. 异质结中GeS2单层的带隙与双轴应变的关系(c) H-A1; (d) T-A1. 不同双轴应变下异质结沿z轴方向的电荷密度差 (e) H-A1; (f) T-A1. (g) H-A1在不同双轴应变下的投影能带结构, 其中红色表示H-NbS2层的贡献, 黑色表示GeS2层的贡献, 上下两个方框分别表示Φn和Φp

Fig. 6. Biaxial strain modulation effect, Schottky barrier height versus biaxial strain: (a) H-A1; (b) T-A1. Band gap of GeS2 monolayer in heterojunction versus biaxial strain: (c) H-A1; (d) T-A1. Difference in charge density of heterojunction along z-axis for different biaxial strains: (e) H-A1; (f) T-A1. (g) Projected band structures of H-A1 under different biaxial strains, where the red denotes the contribution of the H-NbS2 layer, and the black denotes the contribution of the GeS2 layer, and the upper and lower boxes denote Φn and Φp, respectively.

-

[1] Novoselov K S, Mishchenko A, Carvalho A, Castro Neto A 2016 Science 353 aac9439

Google Scholar

Google Scholar

[2] Han J N, Cao S G, Li Z H, Zhang Z H 2022 J. Phys. D: Appl. Phys. 56 045002

Google Scholar

Google Scholar

[3] Xu Y H, Han J N, Li Z H, Zhang Z H 2023 J. Phys. D: Appl. Phys. 56 365504

Google Scholar

Google Scholar

[4] Pierucci D, Henck H, Avila J, Balan A, Naylor C H, Patriarche G, Dappe Y J, Silly M G, Sirotti F, Johnson A C 2016 Nano Lett. 16 4054

Google Scholar

Google Scholar

[5] Chen J Z, Ma G B, Gong B X, Deng C Y, Zhang M, Guo K X, Cui R R, Wu Y K, Lü M L, Wang X 2023 Nanomaterials 13 429

Google Scholar

Google Scholar

[6] Wang J G, Ma F C, Sun M T 2017 RSC Adv. 7 16801

Google Scholar

Google Scholar

[7] Cai Y Q, Zhang G, Zhang Y W 2015 J. Phys. Chem. C 119 13929

Google Scholar

Google Scholar

[8] Yu L L, Lee Y H, Ling X., Santos E J, Shin Y C, Lin Y X, Dubey M, Kaxiras E, Kong J, Wang H, Palacios T 2014 Nano Lett. 14 3055

Google Scholar

Google Scholar

[9] Sinha S, Zhu T S, France-Lanord A, Sheng Y W, Grossman J C, Porfyrakis K, Warner J H 2020 Nat. Commun. 11 823

Google Scholar

Google Scholar

[10] Mohanta M K, Rawat A, Jena N, Dimple, Ahammed R, Sarkar A D 2020 ACS Appl. Mater. Interfaces. 12 3114

Google Scholar

Google Scholar

[11] Ahammed R, Rawat A, Jena N, Dimple, Mohanta M K, Sarkar A D 2020 Appl. Surf. Sci. 499 143894

Google Scholar

Google Scholar

[12] Hong X P, Kim J, Shi S F, Zhang Y, Jin C H, Sun Y H, Tongay S, Wu J Q, Zhang Y F, Wang F 2014 Nat. Nanotechnol. 9 682

Google Scholar

Google Scholar

[13] Rivera P, Seyler K L, Yu H Y, Schaibley J R, Yan J Q, Mandrus D G, Yao W, Xu D 2016 Science 351 688

Google Scholar

Google Scholar

[14] Paul Inbaraj C R, Mathew R J, Ulaganathan R K, Sankar R, Kataria M, Lin H Y, Cheng H Y, Lin K H, Lin H L, Liao Y M, Chou F C, Chen Y T, Lee C H, Chen Y F 2020 ACS Appl. Mater. 12 26213

Google Scholar

Google Scholar

[15] Kataria M, Yadav K, Cai S Y, Liao Y M, Lin H I, Shen T L, Chen Y H, Chen Y T, Wang W H, Chen Y F 2018 ACS Nano 12 9596

Google Scholar

Google Scholar

[16] Liu Y, Guo J, Zhu E B, Liao L, Lee S J, Ding M N, Shakir I, Gambin V, Huang Y, Duan X F 2018 Nature 557 696

Google Scholar

Google Scholar

[17] Kim C, Moon I, Lee D, Choi M S, Ahmed F, Nam S, Cho Y, Shin H J, Park S, Yoo W 2017 ACS Nano 11 1588

Google Scholar

Google Scholar

[18] Chen X, Wang D K, Wang T, Yang Z Y, Zou X M, Wang P, Luo W J, Li Q, Liao L, Hu W D 2019 ACS Appl. Mater. 11 33188

Google Scholar

Google Scholar

[19] Zheng S, Lu H C, Liu H, Liu D M, Robertson J 2019 Nanoscale 11 4811

Google Scholar

Google Scholar

[20] Allain A, Kang J, Banerjee K, Kis A 2015 Nat. Mater. 14 1195

Google Scholar

Google Scholar

[21] Zhang W X, Yin Y, He C 2020 Phys. Chem. Chem. Phys. 22 26231

Google Scholar

Google Scholar

[22] Wang X L, Feng W, Shen C, Sun Z H, Qi H B, Yang M, Liu Y H, Wu Y C, Wu X Q 2021 Front. Mater. 8 709757

Google Scholar

Google Scholar

[23] Nandi P, Rawat A, Ahammed R, Jena N, De Sarkar A 2021 Nanoscale 13 5460

Google Scholar

Google Scholar

[24] Chen H, Keiser C, Du S X, Gao H J, Sutter P, Sutter E 2017 Phys. Chem. Chem. Phys. 19 32473

Google Scholar

Google Scholar

[25] Gao R L, Yong Y L, Yuan X B, Hu S, Hou Q H, Kuang Y M 2022 ACS Omega 7 46440

Google Scholar

Google Scholar

[26] Ruan X Y, Xiong R, Cui Z, Wen C L, Ma J J, Wang B T, Sa B S 2022 Materials 15 4016

Google Scholar

Google Scholar

[27] Mao Y L, Zhang G H 2020 Physica B Condens. Matter 581 411673

Google Scholar

Google Scholar

[28] Zhang Z P, Yang P F, Hong M, Jiang S L, Zhao G C, Shi J P, Xie Q, Zhang Y F 2019 Nanotechnology 30 182002

Google Scholar

Google Scholar

[29] Shin H G, Yoon H S, Kim J S, Kim M, Lim J Y, Yu S, Park J H, Yi Y, Kim T, Jun S C, Im S 2018 Nano Lett. 18 1937

Google Scholar

Google Scholar

[30] Kim Y, Kwon K C, Kang S, Kim C, Kim T H, Hong S P, Park S Y, Suh J M, Choi M J, Han S 2019 ACS Sens. 4 2395

Google Scholar

Google Scholar

[31] Zhou J H, Shen Y H, Lü F, Zhang W Y, Lin F X, Zhang W S, Wang K, Luo H, Wang Q, Yang H 2022 Adv. Funct. Mater. 32 2204495

Google Scholar

Google Scholar

[32] Brandbyge M, Mozos J L, Ordejón P, Taylor J, Stokbro K 2002 Phys. Rev. B 65 165401

Google Scholar

Google Scholar

[33] Li Z H, Han J N, Cao S G, Zhang Z H, Deng X Q 2023 Phys. Rev. B 108 184413

Google Scholar

Google Scholar

[34] 何鑫, 李鑫焱, 李景辉, 张振华 2022 71 218503

Google Scholar

Google Scholar

He X, Li X Y, Li J H, Zhang Z H 2022 Acta Phys. Sin. 71 218503

Google Scholar

Google Scholar

[35] Li X Y, Li Z H, Han J N, Cao S G, Zhang Z H 2024 Phys. Chem. Chem. Phys. 26 4218

Google Scholar

Google Scholar

[36] Yi Y, Han J N, Li Z H, Cao S G, Zhang Z H 2024 Phys. Chem. Chem. Phys. 26 5045

Google Scholar

Google Scholar

[37] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[38] Troullier N, Martins J L 1991 Phys. Rev. B 43 1993

Google Scholar

Google Scholar

[39] Soler J M, Artacho E, Gale J D, García A, Junquera J, Ordejón P, Sánchez-Portal D 2002 J. Phys. Condens Matter 14 2745

Google Scholar

Google Scholar

[40] Grimme S 2006 J. Comput. Chem. 27 1787

Google Scholar

Google Scholar

[41] Ding X, Zhang S, Zhao M, Xiang Y, Zhang K H, Zu X, Li S, Qiao L 2019 Phys. Rev. Appl. 12 064061

Google Scholar

Google Scholar

[42] Jelver L, Larsen P M, Stradi D, Stokbro K, Jacobsen K W 2017 Phys. Rev. B 96 085306

Google Scholar

Google Scholar

[43] Xia J L, Gu Y X, Mai J, Hu T Y, Wang Q K, Xie C, Wu Y K, Wang X 2023 Heliyon 9 e20619

Google Scholar

Google Scholar

[44] Vu T V, Hieu N V, Phuc H V, Hieu N N, Bui H D, Idrees M, Amin B, Nguyen C V 2020 Appl. Surf. Sci. 507 145036

Google Scholar

Google Scholar

[45] Nguyen S T, Huong T T T, Ca N X, Nguyen C Q 2024 Nanoscale Adv. 6 1565

Google Scholar

Google Scholar

[46] Wang Q H, Li H, Si L N, Dou Z L, Yan H J, Yang Y, Liu F B 2023 Mater. Today Commun. 35 10572

Google Scholar

Google Scholar

[47] Wang F F, Yuan J, Zhang Z F, Ding X L, Gu C J, Yan S B, Sun J H, Jiang T, Wu Y F, Zhou J 2023 Phys. Rev. B 108 075416

Google Scholar

Google Scholar

[48] Mohanta M K, Kishore A, Sarkar A D 2020 Nanotechnology 31 495208

Google Scholar

Google Scholar

[49] Cadelano E, Palla P L, Giordano S, Colombo L 2010 Phys. Rev. B 82 235414

Google Scholar

Google Scholar

[50] Li Y Q, Wang X Y, Zhu S Y, Tang D S, He Q W, Wang X C 2022 J. Mater. Chem. C 10 12132

Google Scholar

Google Scholar

[51] Gupta A, Sakthivel T, Seal S 2015 Prog. Mater Sci. 73 44

Google Scholar

Google Scholar

[52] Booth T J, Blake P, Nair R R, Jiang D, Hill E W, Bangert U, Bleloch A, Gass M, Novoselov K S, Katsnelson M I 2008 Nano Lett. 8 2442

Google Scholar

Google Scholar

[53] Zhang W X, Shi C H, He C, Bai M 2020 J. Solid State Chem. 289 121511

Google Scholar

Google Scholar

[54] Zheng J S, Li E L, Ma D M, Cui Z, Peng T, Wang X L 2019 Phys. Status Solidi B 256 1900161

Google Scholar

Google Scholar

[55] Li Z H, Han J N, Cao S G, Zhang Z H 2023 Appl. Surf. Sci. 614 156095

Google Scholar

Google Scholar

[56] Nguyen C V, Idrees M, Phuc H V, Hieu N N, Binh N T, Amin B, Vu T V 2020 Phys. Rev. B 101 235419

Google Scholar

Google Scholar

计量

- 文章访问数: 3471

- PDF下载量: 131

- 被引次数: 0

下载:

下载: