-

本文采用匹配渐近法和多重变量法, 基于深胞晶生长的定常解, 在考虑了各向异性界面动力学后, 导出胞晶界面扰动振幅变化率满足的色散关系式及界面形态满足的量子化条件, 研究在各向异性界面动力学的影响下定向凝固过程中深胞晶生长界面形态的稳定性. 结果表明, 考虑了各向异性界面动力学的深胞晶体生长的定向凝固系统包含两种整体不稳定机制: 整体振荡不稳定机制和低频不稳定机制. 通过稳定性分析发现, 低阶近似下各向异性界面动力学对整体振荡不稳定机制有着显著影响, 随着各向异性界面动力学参数的增大, 中性模式产生强振荡的枝晶结构的整体振荡不稳定区域减小. 同时, 界面动力学各向异性参数对系统整体波动不稳定性的影响随着界面动力学参数的增大而增大.

In this paper, based on the steady solution of deep cellular crystal growth, the matching asymptotic method and multiple variable method are used to obtain the dispersion relation and the quantization condition of the interfacial morphology in directional solidification process when the interfacial dynamics is anisotropic. The stability of interfacial morphology of deep cell growth during directional solidification under the influence of anisotropic interfacial dynamics is studied. The mathematical model of the oriented solidification system is established, and the overall ground state solution of the constant cellular growth is taken as the ground state, and the unsteady state solution of the deep cellular growth is expressed as the superposition of the ground state solution and the perturbation dynamics solution when the stability analysis is carried out. The thermodynamic conditions in the mathematical model of the problem constitute a regenerative problem together with the boundary conditions. The asymptotic solution of the cellular crystal growth when $\varepsilon \to 0$ can be found by dividing the cellular crystal growth region into an outer region far from the root and a region near the root, with an asymptotic solution found in the external region and the root region, respectively, and then matching them to obtain a consistent and effective asymptotic solution in the whole region. The asymptotic solution of the model in the external region is derived to obtain a first-order approximation of the eigenvalues. The inner solutions are matched with the outer solutions based on the vicinity of the singularity to obtain the global solutions and quantization conditions of the system, and finally the stability analysis is conducted. The results show that the directional solidification system of deep cellular crystal growth considering anisotropic interfacial kinetics contains two global instability mechanisms: global oscillation instability and low-frequency instability. The stability analysis shows that the anisotropic interfacial kinetics has a significant effect on the global oscillatory instability mechanism in the low order approximation. With the increase of the anisotropic interfacial kinetics parameter${\beta _4}$ , the global oscillatory instability region$\left( {{\text{Os}}{\text{.U}}} \right)$ of the dendrite structure with strong oscillation in neutral mode decreases. At the same time, the influence of interfacial dynamic anisotropy parameters on the overall oscillation instability of the system increases with interfacial dynamic parameters increasing.-

Keywords:

- deep cellular crystal growth /

- interface kinetics /

- stability

[1] McFadden G B, Coriell S R 1984 Physica D 12 253

Google Scholar

Google Scholar

[2] Hurle D 1993 Handbook of Crystal Growth (Vol. 1) (New York: Elsevier Science Publishers) pp899–1073

[3] Mullins W W, Sekerka R F 1963 Appl. Phys. 34 323

Google Scholar

Google Scholar

[4] Mullins W W, Sekerka R F 1964 Appl. Phys. 35 444

[5] Langer J S 1980 Rev. Mod. Phys. 52 1

Google Scholar

Google Scholar

[6] Pelcé P, Pumir A 1985 J. Cryst. Growth 73 337

Google Scholar

Google Scholar

[7] Dombre T, Haankim V 1987 Phys. Rev. A 36 2811

Google Scholar

Google Scholar

[8] Pelcé P 1988 Dynamics of Curved Fronts (New York: Academic Press) pp327–340

[9] Karma A, Pelcé P 1990 Phys. Rev. A 41 6741

[10] Benamar M, Bouissou P, Pelcé P 1988 J. Cryst. Growth 92 97

Google Scholar

Google Scholar

[11] Xu J J 1991 Phys. Rev. A 43 930

Google Scholar

Google Scholar

[12] Xu J J 1991 Eur. J. Appl. Math. 2 105

Google Scholar

Google Scholar

[13] Xu J J 1996 Phys. Rev. E 53 5323

[14] Trivedi R, Seetharaman V, Eshelman M A 1991 Metall. Mater. Trans. A 22 585

Google Scholar

Google Scholar

[15] Coriell S R, Sekerka R G 1976 J. Cryst. Growth 34 157

Google Scholar

Google Scholar

[16] Young G W, Davis S H, Brattkus K 1987 J. Cryst. Growth 83 560

Google Scholar

Google Scholar

[17] 袁训锋 2014 铸造技术 35 1773

Yuan X F 2014 Foundry Technol. 35 1773

[18] Zheng G J, Chen M W, Yang C M, Liu N 2022 Chin. J. Phys. 78 155

Google Scholar

Google Scholar

[19] Zheng G J, Chen M W, Yang C M, Wang Z D 2022 Chin. J. Phys. 77 10

Google Scholar

Google Scholar

[20] Chen K X, Demange G, Cui X, Wang Z D, Pang X L, Patte R, Mao H H, Chen X H, Shi R J, Zapolsky H 2024 Acta Mater. 270 119874

Google Scholar

Google Scholar

[21] Pelcé P 1988 Dynamics of Curved Fronts (New York: Academic Press) pp155–174

[22] 陈明文, 陈奕臣, 张文龙, 刘秀敏, 王自东 2014 63 038101

Google Scholar

Google Scholar

Chen M W, Chen Y C, Zhang W L, Liu X M, Wang Z D 2014 Acta Phys. Sin. 63 038101

Google Scholar

Google Scholar

[23] Xu J J, Chen Y Q 2011 Phys. Rev. E 83 041601

[24] 钮迪, 蒋晗 2022 71 168101

Google Scholar

Google Scholar

Niu D, Jiang H 2022 Acta Phys. Sin. 71 168101

Google Scholar

Google Scholar

-

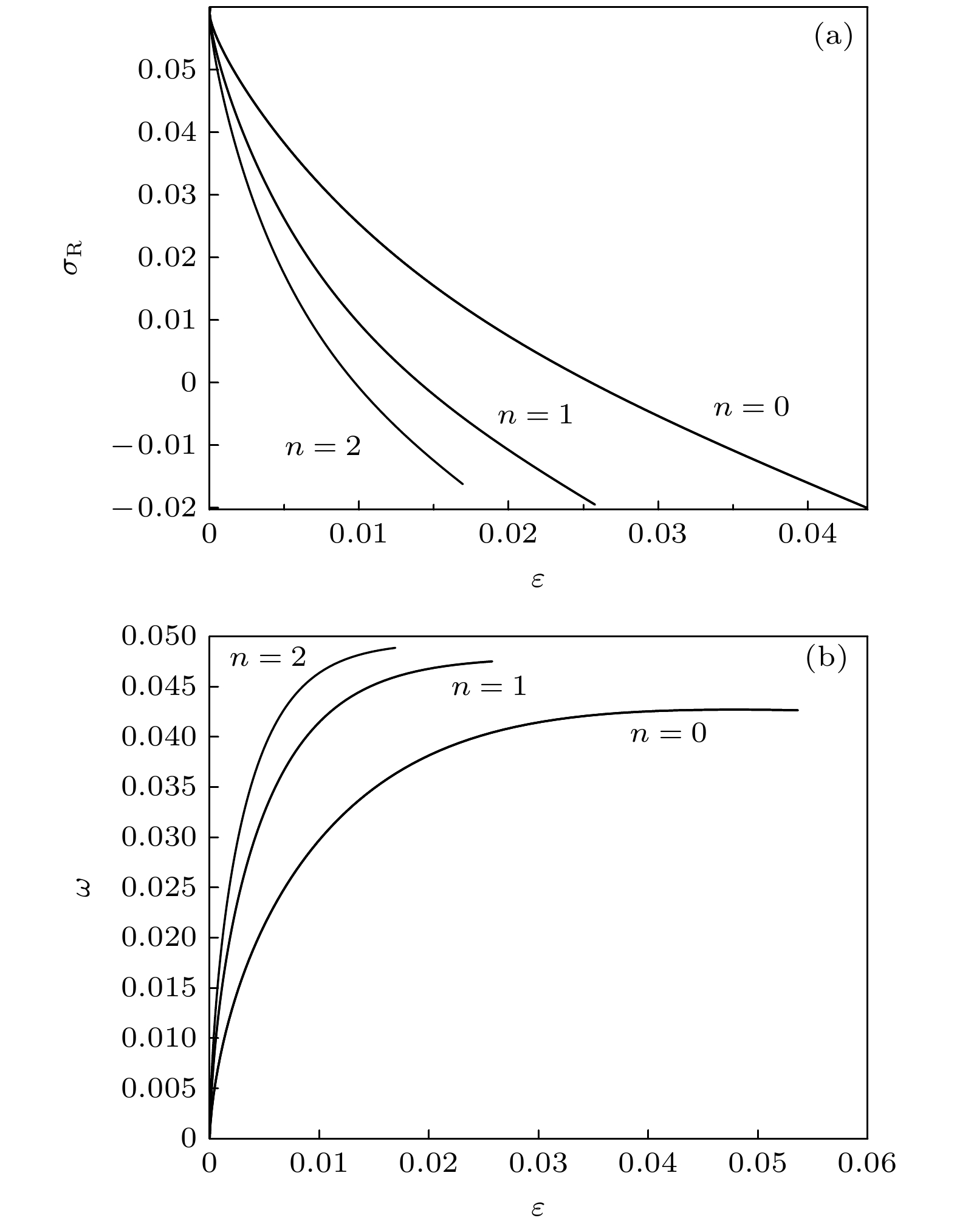

图 5 GTW-S中性模式曲线. 参数分别为$V = 16{\text{ μm/s}}, {\text{ }}{C_\infty } = $$ 1.2{\text{%}}, ~{G_T} = $ $78 \times {10^{ - 4}}{\text{ K/μm}},\; {\text{ }}{\varepsilon _{\text{c}}} = 0.5338 \times {10^{ - 2}},\; {\text{ }}M $= $0.09552,\; {\text{ }}k = 0.29, \;{\text{ }}{m_*} = 1, \;{\text{ }}{G_{\text{c}}} = 0.14485 \times {10^{ - 4}}, \;{\text{ }}{\lambda _G} $= $ 0.4989, {\text{ }}E = 0.25, {\text{ }}{\beta _4} = 0.6$ (a) 首级近似[24]; (b) 一级近似

Fig. 5. The neutral curves of the GTW-S-modes for the case $V = 16{\text{ μm/s, }}\;{C_\infty } = 1.2{\text{%}},\; {\text{ }}{G_T}= 78 \;\times\; {10^{ - 4}}{\text{ K/μm}}, $ ${\varepsilon _{\text{c}}} = $$ 0.5338 \times {10^{ - 2}},\; {\text{ }}M = 0.09552,\; {\text{ }}k = 0.29, $ ${\text{ }}{m_*} = 1, {\text{ }}{G_{\text{c}}} = $$ 0.14485 \times {10^{ - 4}}, $ ${\lambda _G} = 0.4989, {\text{ }}E = 0.25, {\text{ }}{\beta _4} = 0.6$: (a) Leading-order approximation[24]; (b) first-order approximation.

图 6 一级近似下的GTW-S中性模式曲线$\left( {n = 0} \right)$. 参数分别为${C_\infty } = 1.2{\text{%}}, {\text{ }}{G_T} =78 \times {10^{ - 4}}{\text{ K/μm}}, {\text{ }}V = 16{\text{ μm/s}},$ $ {\varepsilon _{\text{c}}} = 0.5338 \times {10^{ - 2}}, {\text{ }}M = 0.09552, {\text{ }}{G_{\text{c}}} = 0.14485 \times {10^{ - 4}} $, $k=0.29$, ${\lambda _G} = 0.4989$, $E = 0.25, {\text{ }}{m_*} = 5 $

Fig. 6. The neutral curves of the GTW-S-modes $(n = 0)$in the first-order approximation for the case ${C_\infty } = 1.2{\text{%}}$, ${G_T} = 78 \times {10^{ - 4}}{\text{ K/μm}}$, $V = 16\;{\text{μm/s}}$, ${\varepsilon _{\text{c}}} = 0.005338$, $M= $$ 0.09552$, ${G_{\text{c}}} = 0.14485 \times {10^{ - 4}}$, $k = 0.29,\; {\lambda _G} = 0.4989$, $E= 0.25, \; {m_*} = 5 $

图 7 一级近似下的GTW-S中性模式曲线$\left( {n = 0} \right)$. 参数分别为${C_\infty }= 1.2{\text{%}}, {G_T} = 78 \times {10^{ - 4}}{\text{ K/μm, }}V = 16{\text{ μm/s }}, {\varepsilon _{\text{c}}} =$ $ 0.5338 \times {10^{ - 2}}, {\text{ }}M = 0.09552, {\text{ }}{G_{\text{c}}} $ = $0.14485 \times {10^{ - 4}},\; {\text{ }}k = $$ 0.29{, }\;{\lambda _G} = 0.4989,\; {\text{ }}E = 0.25$

Fig. 7. The neutral curves of the GTW-S-modes $(n = 0)$in the first-order approximation. The case ${C_\infty } = 1.2{\text{%}}$, $ {G_T} = $$ 78 \times {10^{-4}}{\text{ K/μm}}, \; V = 16\;{\text{μm/s}}, \;{\varepsilon _{\text{c}}} = 0.005338,\; M = 0.09552$, ${G_{\text{c}}} = 0.14485 \times {10^{ - 4}}, \;k = 0.29, \;\lambda_G = 0.4989,$ E = 0.25

-

[1] McFadden G B, Coriell S R 1984 Physica D 12 253

Google Scholar

Google Scholar

[2] Hurle D 1993 Handbook of Crystal Growth (Vol. 1) (New York: Elsevier Science Publishers) pp899–1073

[3] Mullins W W, Sekerka R F 1963 Appl. Phys. 34 323

Google Scholar

Google Scholar

[4] Mullins W W, Sekerka R F 1964 Appl. Phys. 35 444

[5] Langer J S 1980 Rev. Mod. Phys. 52 1

Google Scholar

Google Scholar

[6] Pelcé P, Pumir A 1985 J. Cryst. Growth 73 337

Google Scholar

Google Scholar

[7] Dombre T, Haankim V 1987 Phys. Rev. A 36 2811

Google Scholar

Google Scholar

[8] Pelcé P 1988 Dynamics of Curved Fronts (New York: Academic Press) pp327–340

[9] Karma A, Pelcé P 1990 Phys. Rev. A 41 6741

[10] Benamar M, Bouissou P, Pelcé P 1988 J. Cryst. Growth 92 97

Google Scholar

Google Scholar

[11] Xu J J 1991 Phys. Rev. A 43 930

Google Scholar

Google Scholar

[12] Xu J J 1991 Eur. J. Appl. Math. 2 105

Google Scholar

Google Scholar

[13] Xu J J 1996 Phys. Rev. E 53 5323

[14] Trivedi R, Seetharaman V, Eshelman M A 1991 Metall. Mater. Trans. A 22 585

Google Scholar

Google Scholar

[15] Coriell S R, Sekerka R G 1976 J. Cryst. Growth 34 157

Google Scholar

Google Scholar

[16] Young G W, Davis S H, Brattkus K 1987 J. Cryst. Growth 83 560

Google Scholar

Google Scholar

[17] 袁训锋 2014 铸造技术 35 1773

Yuan X F 2014 Foundry Technol. 35 1773

[18] Zheng G J, Chen M W, Yang C M, Liu N 2022 Chin. J. Phys. 78 155

Google Scholar

Google Scholar

[19] Zheng G J, Chen M W, Yang C M, Wang Z D 2022 Chin. J. Phys. 77 10

Google Scholar

Google Scholar

[20] Chen K X, Demange G, Cui X, Wang Z D, Pang X L, Patte R, Mao H H, Chen X H, Shi R J, Zapolsky H 2024 Acta Mater. 270 119874

Google Scholar

Google Scholar

[21] Pelcé P 1988 Dynamics of Curved Fronts (New York: Academic Press) pp155–174

[22] 陈明文, 陈奕臣, 张文龙, 刘秀敏, 王自东 2014 63 038101

Google Scholar

Google Scholar

Chen M W, Chen Y C, Zhang W L, Liu X M, Wang Z D 2014 Acta Phys. Sin. 63 038101

Google Scholar

Google Scholar

[23] Xu J J, Chen Y Q 2011 Phys. Rev. E 83 041601

[24] 钮迪, 蒋晗 2022 71 168101

Google Scholar

Google Scholar

Niu D, Jiang H 2022 Acta Phys. Sin. 71 168101

Google Scholar

Google Scholar

计量

- 文章访问数: 2391

- PDF下载量: 62

- 被引次数: 0

下载:

下载: