-

镍基高温合金GH4742具有优异的机械性能, 而晶粒尺寸是影响其性能的关键因素. 基于物理模型的超声背散射法可以实现晶粒尺寸高效和准确的评价, 但受限于复杂模型或多角度声束测量. 因此, 本文提出了一种只需单向测量的背散射系数法, 且无需考虑测量系统等无关因素的影响. 基于独立散射模型, 推导了只与材料相关的背散射系数; 利用空间相关函数描述了晶粒尺寸与背散射系数的关系; 采用参考信号剔除干扰因素的影响, 实现实验背散射系数的快速提取. 制备三组不同晶粒尺寸的GH4742试块进行相控阵超声实验和平均晶粒尺寸评价, 并与金相法结果进行对比. 结果表明本文方法得到的晶粒度与金相法结果最大相对误差为–22.7%, 最小相对误差为–3.7%.

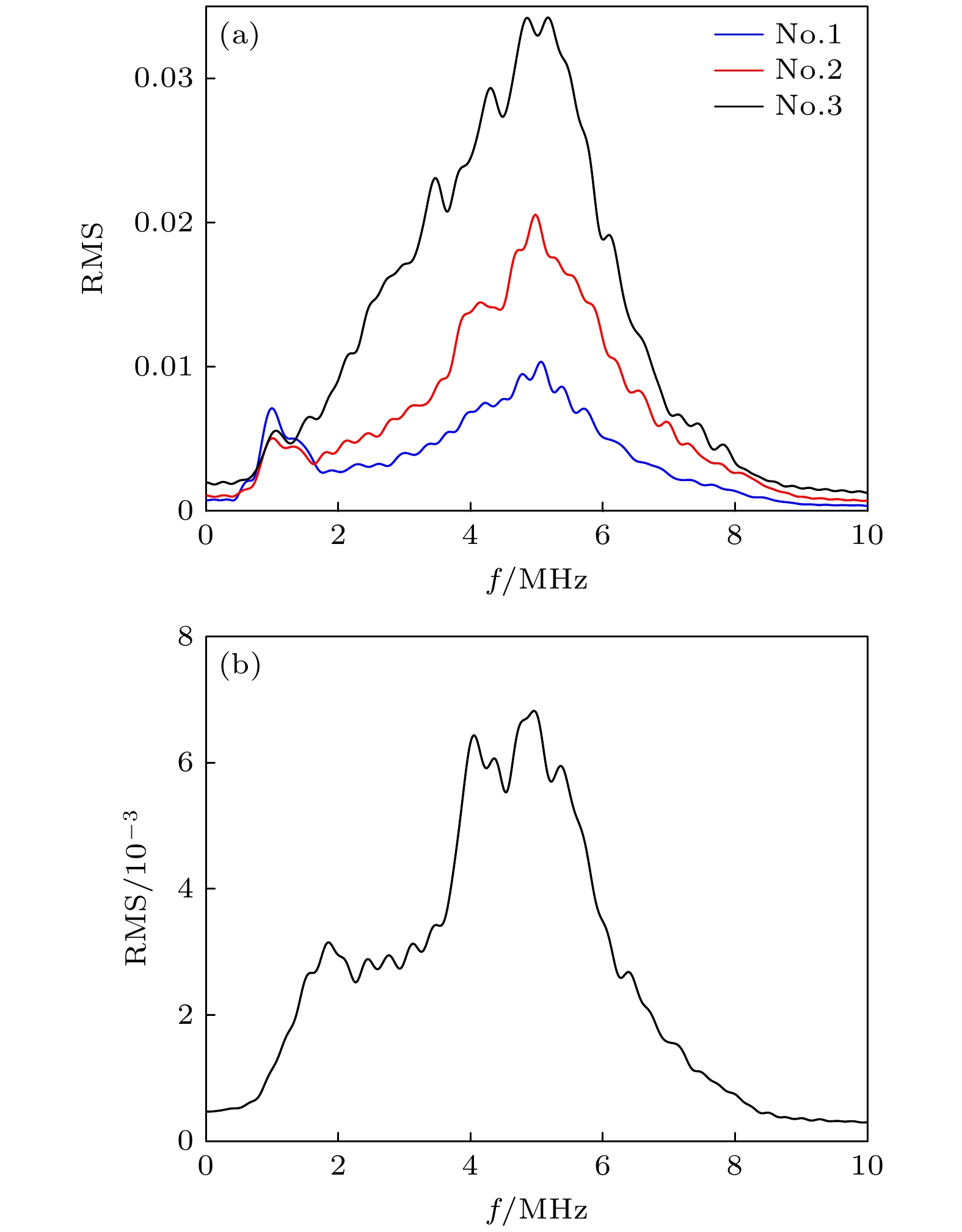

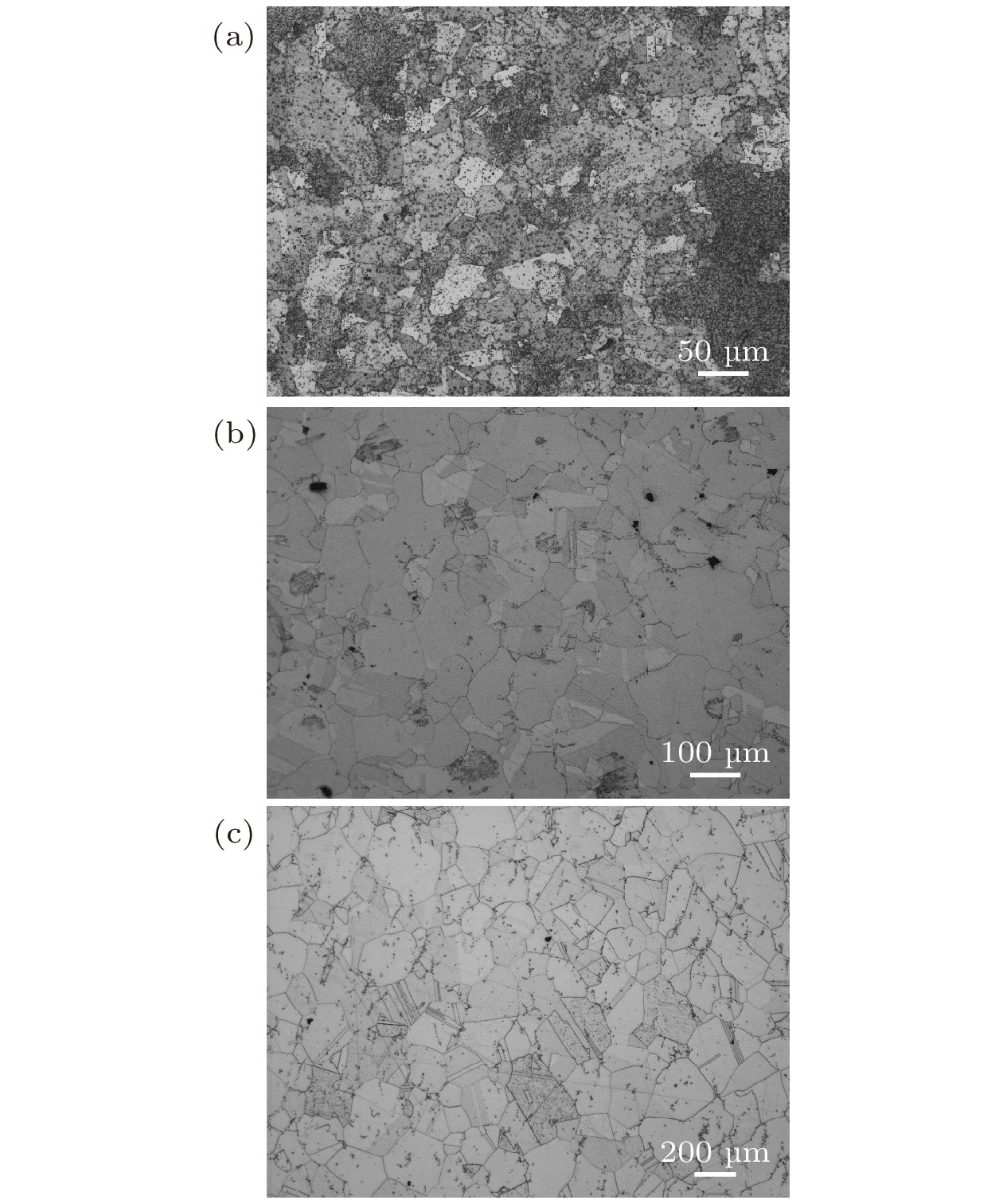

GH4742 nickel-based superalloy exhibits excellent mechanical properties, and grain size is a key factor affecting its performance. A physical model-based ultrasonic backscattering method makes grain size measurement accurate and efficient. Nevertheless, it is constrained by complex models or multiple measurements taken from various beam angles. As a result, a backscattering coefficient method that requires only a single measurement for grain size evaluation is proposed. In contrast to the existing methods, the proposed method solely focuses on the backscattering coefficient component of the backscattering signal. It effectively eliminates the influence of unrelated factors, such as the measurement system and the acoustic field, through the utilization of reference signals. The independent scattering model is employed to derive the backscattering coefficient, which solely pertains to the material itself. The relationship between grain size and backscattering coefficient is described by using a spatial correlation function. To consider the irrelevant factors, an experimental measurement method is developed by using the reference signals. Through numerical calculation and analysis, it has been observed that the backscattering coefficient is closely related to the frequency. When the product of the wavenumber and the grain size is significantly greater than 1 ( $ ka\gg 1 $ ), a Stochastic scattering limit is reached. Conversely, when$ ka\ll 1 $ , a Rayleigh scattering limit is observed. Furthermore, the backscattering coefficient is directly proportional to the grain size. As a general trend, larger grain sizes result in higher backscattering coefficient.Three sets of GH4742 specimens with different grain sizes are prepared for phased array ultrasound experiments. It can be observed that the experimental backscattering coefficients, root mean square (RMS) values, and the amplitude trend of time domain signal are consistent. To perform grain size inversion, the backscattering coefficients in the effective bandwidth range of the probe are selected. By utilizing the least-square method, the theoretical backscattering coefficient is employed to fit the curves of the experimental backscattering coefficients. The evaluation results are compared with those obtained by metallographic analysis. The results show that the grain sizes obtained by the proposed method have a maximum relative error of –22.7% and a minimum relative error of –3.7%. -

Keywords:

- ultrasonic evaluation /

- backscattering coefficient /

- GH4742 /

- grain size

[1] Cruzado A, Lucarini S, Lorca J, Segurado J 2018 Int. J. Fatigue 113 236

Google Scholar

Google Scholar

[2] Lehto P, Remes H, Saukkonen T, Hänninen H, Romanoff J 2014 Mater. Sci. Eng. A 592 28

Google Scholar

Google Scholar

[3] 秦鹤勇, 李振团, 赵光普, 张文云, 张晓敏 2023 材料研究学报 37 502

Google Scholar

Google Scholar

Qin H Y, Li Z T, Zhao G P, Zhang W Y, Zhang X M 2023 Chin. J. Mater. Res. 37 502

Google Scholar

Google Scholar

[4] He K, Chen N F, Wang C J, Wei L S, Chen J K 2018 Cryst. Res. Technol. 53 1700157

Google Scholar

Google Scholar

[5] Toth L S, Biswas S, Gu C, Beausir B 2013 Mater. Charact. 84 67

Google Scholar

Google Scholar

[6] Aghaie-Khafri M, Honarvar F, Zanganeh S 2012 J. Nondest. Eval. 31 191

Google Scholar

Google Scholar

[7] Homa L, Cherry M, Wertz J 2021 Inverse Probl. 37 065004

Google Scholar

Google Scholar

[8] 金士杰, 王志诚, 田鑫, 孙旭, 林莉 2023 航空学报 44 231

Google Scholar

Google Scholar

Jin S J, Wang Z C, Tian X, Sun X, Lin L 2023 Acta Aeronaut. Astronaut. Sin. 44 231

Google Scholar

Google Scholar

[9] 朱琦, 许多, 张元军, 李玉娟, 王文, 张海燕 2022 71 244301

Google Scholar

Google Scholar

Zhu Q, Xu D, Zhang Y J, Li Y J, Wang W, Zhang H Y 2022 Acta Phys. Sin. 71 244301

Google Scholar

Google Scholar

[10] Liu Y, Tian Q, Guan X F 2021 NDT&E Int. 122 102479

Google Scholar

Google Scholar

[11] 李珊, 李雄兵, 宋永锋, 陈超 2018 67 234301

Google Scholar

Google Scholar

Li S, Li X B, Song Y F, Chen C 2018 Acta Phys. Sin. 67 234301

Google Scholar

Google Scholar

[12] 东蕊, 刘成成, 蔡勋兵, 邵留磊, 李博艺, 他得安 2019 68 184301

Google Scholar

Google Scholar

Dong R, Liu C C, Cai X B, Shao L L, Li B Y, Ta D A 2019 Acta Phys. Sin. 68 184301

Google Scholar

Google Scholar

[13] Yu L X, Guo Y M, Margetan F J, Thompson R B 2001 Rev. Prog. Quant. Nondestruct. Eval. 20 1330

Google Scholar

Google Scholar

[14] Zhang F Z, Wang C S, Wu Y S, Zhou L Z, Tian Q 2022 Mater. Sci. Eng. A 832 142488

Google Scholar

Google Scholar

[15] Margetan F J, Yu L X, Thompson R B 2005 Rev. Prog. Quant. Nondestruct. Eval. 24 1300

Google Scholar

Google Scholar

[16] Rokhlin S I, Sha G F, Li J, Pilchak A L 2021 Ultrasonics 115 106433

Google Scholar

Google Scholar

[17] Liu Y, Tian Q, Yu P, He J J, Guan X F 2022 NDT E Int. 129 102634

Google Scholar

Google Scholar

[18] Ghoshal G, Turner J A, Weaver R L 2007 J. Acoust. Soc. Am. 122 2009

Google Scholar

Google Scholar

[19] Arguelles A P, Kube C M, Hu P, Turner J A 2016 T J. Acoust. Soc. Am. 140 1570

Google Scholar

Google Scholar

[20] Wydra A, Chertov A, Maev R G, Kube C M, Du H L, Turner J A 2015 Res. Nondestruct. Eval. 26 225

Google Scholar

Google Scholar

[21] Rose J H 1991 Rev. Prog. Quant. Nondestruct. Eval. 10B 1715

Google Scholar

Google Scholar

[22] Margetan F J, Gray T, Thompson R B 1991 Rev. Prog. Quant. Nondestruct. Eval. 10B 1721

Google Scholar

Google Scholar

[23] Kube C M, Turner J A 2015 Wave Motion 27 182

Google Scholar

Google Scholar

[24] Weaver R L 1990 J. Mech. Phys. Solids 38 55

Google Scholar

Google Scholar

[25] Stanke F E 1986 J. Acoust. Soc. Am. 80 1479

Google Scholar

Google Scholar

[26] 杜金辉, 吕旭东, 董建新, 孙文儒, 毕中南, 赵光普, 邓群, 崔传勇, 马惠萍, 张北江 2019 金属学报 55 1115

Google Scholar

Google Scholar

Du J H, Lü X D, Dong J X, Sun W R, Bi Z N, Zhao G P, Deng Q, Cui C Y, Ma H P, Zhang B J 2019 Acta Metallurg. Sin. 55 1115

Google Scholar

Google Scholar

[27] Haldipur P, Margetan F J, Thompson R B 2004 Rev. Prog. Quant. Nondestructive Eval. 23 1061

Google Scholar

Google Scholar

-

图 4 不同频率下背散射幅值与晶粒尺寸关系 (a) 0—100 MHz; (b) 0—20 MHz. 其他参数: $ {c}_{11}=250\;{\mathrm{G}}{\mathrm{P}}{\mathrm{a}} $, $ {c}_{12}= $$ 160\;{\mathrm{G}}{\mathrm{P}}{\mathrm{a}} $, $ {c}_{44}=118\;{\mathrm{G}}{\mathrm{P}}{\mathrm{a}} $, $ \rho =8240\;{\mathrm{k}}{\mathrm{g}}/{{\mathrm{m}}}^{3} $

Fig. 4. Backscattering amplitude versus grain sizes in different frequencies: (a) 0–100 MHz; (b) 0–20 MHz, where $ {c}_{11} = $$ 250\;{\mathrm{G}}{\mathrm{P}}{\mathrm{a}} $, $ {c}_{12} = 160\;{\mathrm{G}}{\mathrm{P}}{\mathrm{a}} $, $ {c}_{44} = 118\;{\mathrm{G}}{\mathrm{P}}{\mathrm{a}} $, $ \rho = 8240\;{\mathrm{k}}{\mathrm{g}}/{{\mathrm{m}}}^{3} $

表 1 GH4742化学组成成分

Table 1. Chemical composition of GH4742.

成分 Ti Cr Mo Co Nb Mn Fe C Al B Ni 质量分数% 2.52 14.0 5.12 9.95 2.6 0.2 0.5 0.06 2.54 0.01 Bal. 表 2 晶粒尺寸测量结果对比

Table 2. Comparison of grain size measured by micrographs and backscattering coefficient.

试块 金相法 金相法晶粒度 背散射

系数法背散射系数

法晶粒度No.1 55 μm 5.4 58 μm 5.2 No.2 77 μm 4.4 103 μm 3.6 No.3 163 μm 2.2 200 μm 1.7 -

[1] Cruzado A, Lucarini S, Lorca J, Segurado J 2018 Int. J. Fatigue 113 236

Google Scholar

Google Scholar

[2] Lehto P, Remes H, Saukkonen T, Hänninen H, Romanoff J 2014 Mater. Sci. Eng. A 592 28

Google Scholar

Google Scholar

[3] 秦鹤勇, 李振团, 赵光普, 张文云, 张晓敏 2023 材料研究学报 37 502

Google Scholar

Google Scholar

Qin H Y, Li Z T, Zhao G P, Zhang W Y, Zhang X M 2023 Chin. J. Mater. Res. 37 502

Google Scholar

Google Scholar

[4] He K, Chen N F, Wang C J, Wei L S, Chen J K 2018 Cryst. Res. Technol. 53 1700157

Google Scholar

Google Scholar

[5] Toth L S, Biswas S, Gu C, Beausir B 2013 Mater. Charact. 84 67

Google Scholar

Google Scholar

[6] Aghaie-Khafri M, Honarvar F, Zanganeh S 2012 J. Nondest. Eval. 31 191

Google Scholar

Google Scholar

[7] Homa L, Cherry M, Wertz J 2021 Inverse Probl. 37 065004

Google Scholar

Google Scholar

[8] 金士杰, 王志诚, 田鑫, 孙旭, 林莉 2023 航空学报 44 231

Google Scholar

Google Scholar

Jin S J, Wang Z C, Tian X, Sun X, Lin L 2023 Acta Aeronaut. Astronaut. Sin. 44 231

Google Scholar

Google Scholar

[9] 朱琦, 许多, 张元军, 李玉娟, 王文, 张海燕 2022 71 244301

Google Scholar

Google Scholar

Zhu Q, Xu D, Zhang Y J, Li Y J, Wang W, Zhang H Y 2022 Acta Phys. Sin. 71 244301

Google Scholar

Google Scholar

[10] Liu Y, Tian Q, Guan X F 2021 NDT&E Int. 122 102479

Google Scholar

Google Scholar

[11] 李珊, 李雄兵, 宋永锋, 陈超 2018 67 234301

Google Scholar

Google Scholar

Li S, Li X B, Song Y F, Chen C 2018 Acta Phys. Sin. 67 234301

Google Scholar

Google Scholar

[12] 东蕊, 刘成成, 蔡勋兵, 邵留磊, 李博艺, 他得安 2019 68 184301

Google Scholar

Google Scholar

Dong R, Liu C C, Cai X B, Shao L L, Li B Y, Ta D A 2019 Acta Phys. Sin. 68 184301

Google Scholar

Google Scholar

[13] Yu L X, Guo Y M, Margetan F J, Thompson R B 2001 Rev. Prog. Quant. Nondestruct. Eval. 20 1330

Google Scholar

Google Scholar

[14] Zhang F Z, Wang C S, Wu Y S, Zhou L Z, Tian Q 2022 Mater. Sci. Eng. A 832 142488

Google Scholar

Google Scholar

[15] Margetan F J, Yu L X, Thompson R B 2005 Rev. Prog. Quant. Nondestruct. Eval. 24 1300

Google Scholar

Google Scholar

[16] Rokhlin S I, Sha G F, Li J, Pilchak A L 2021 Ultrasonics 115 106433

Google Scholar

Google Scholar

[17] Liu Y, Tian Q, Yu P, He J J, Guan X F 2022 NDT E Int. 129 102634

Google Scholar

Google Scholar

[18] Ghoshal G, Turner J A, Weaver R L 2007 J. Acoust. Soc. Am. 122 2009

Google Scholar

Google Scholar

[19] Arguelles A P, Kube C M, Hu P, Turner J A 2016 T J. Acoust. Soc. Am. 140 1570

Google Scholar

Google Scholar

[20] Wydra A, Chertov A, Maev R G, Kube C M, Du H L, Turner J A 2015 Res. Nondestruct. Eval. 26 225

Google Scholar

Google Scholar

[21] Rose J H 1991 Rev. Prog. Quant. Nondestruct. Eval. 10B 1715

Google Scholar

Google Scholar

[22] Margetan F J, Gray T, Thompson R B 1991 Rev. Prog. Quant. Nondestruct. Eval. 10B 1721

Google Scholar

Google Scholar

[23] Kube C M, Turner J A 2015 Wave Motion 27 182

Google Scholar

Google Scholar

[24] Weaver R L 1990 J. Mech. Phys. Solids 38 55

Google Scholar

Google Scholar

[25] Stanke F E 1986 J. Acoust. Soc. Am. 80 1479

Google Scholar

Google Scholar

[26] 杜金辉, 吕旭东, 董建新, 孙文儒, 毕中南, 赵光普, 邓群, 崔传勇, 马惠萍, 张北江 2019 金属学报 55 1115

Google Scholar

Google Scholar

Du J H, Lü X D, Dong J X, Sun W R, Bi Z N, Zhao G P, Deng Q, Cui C Y, Ma H P, Zhang B J 2019 Acta Metallurg. Sin. 55 1115

Google Scholar

Google Scholar

[27] Haldipur P, Margetan F J, Thompson R B 2004 Rev. Prog. Quant. Nondestructive Eval. 23 1061

Google Scholar

Google Scholar

计量

- 文章访问数: 3467

- PDF下载量: 221

- 被引次数: 0

下载:

下载: