-

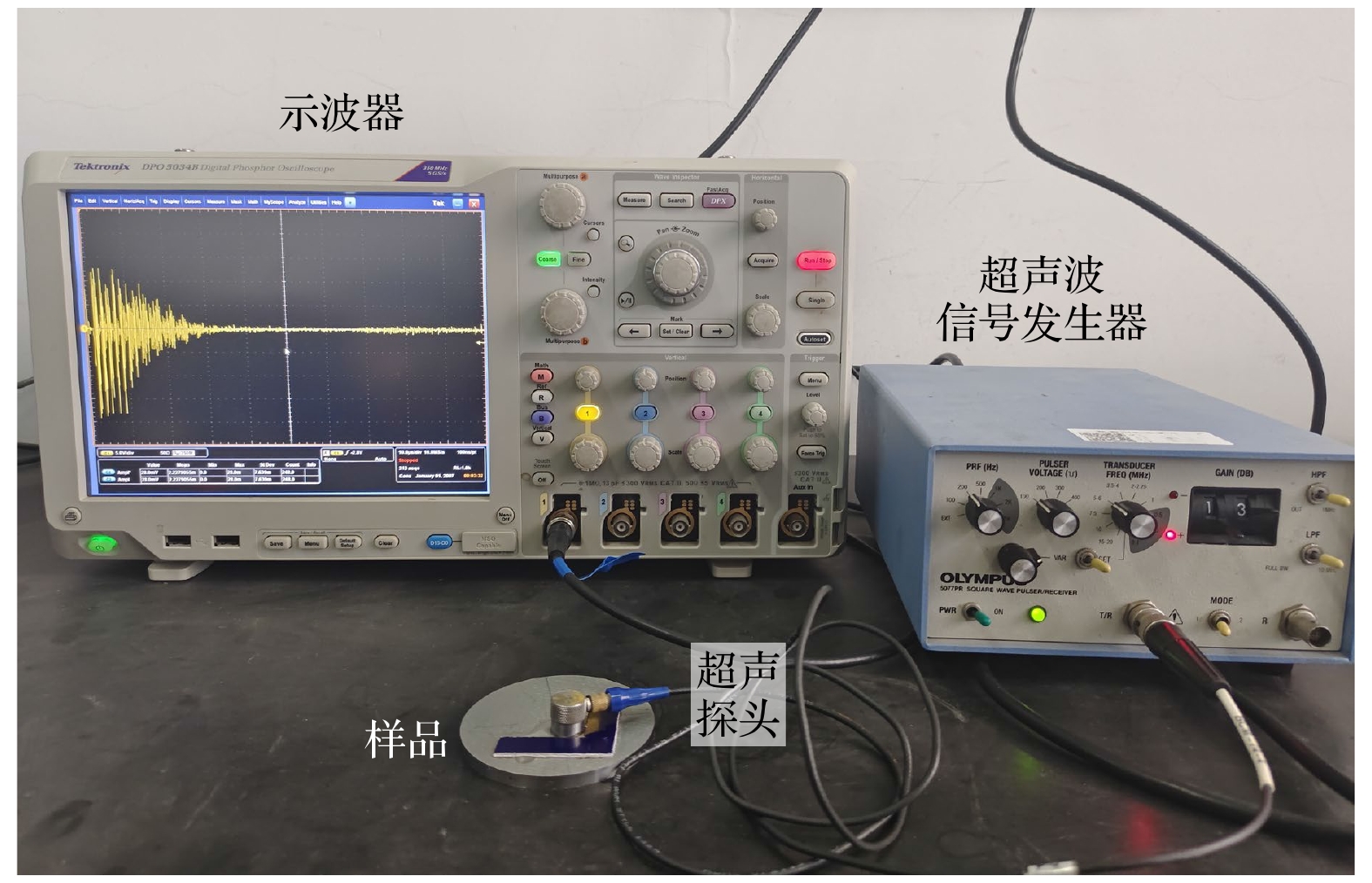

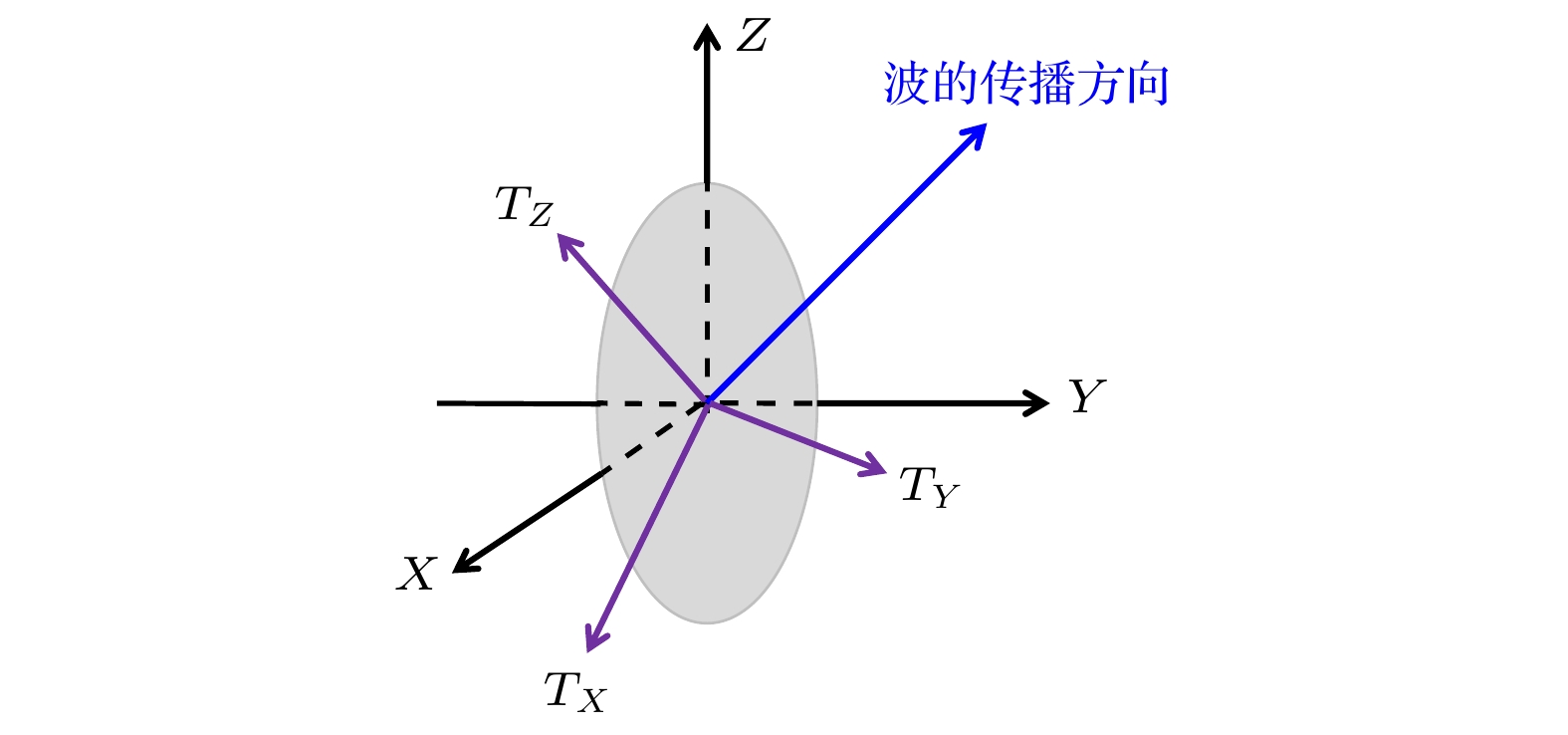

超声波识别在国防、军事、航空航天、核设施等高科技领域具有重要的应用价值. 利用超声波可以实现对个体金属材料的识别, 但现有研究侧重于识别材料超声信号差异的算法, 缺乏识别机理. 本文以2A12铝合金为例, 利用6个晶粒在尺寸、形状、排布方向以及排列顺序不同时, 建立了10个2A12铝合金微结构的初级模型, 以此类比多晶金属材料的复杂微观结构. 利用Comsol有限元软件仿真计算了金属材料不同微观结构中的超声波时域信号, 并将回波信号中的的背向散射信号提取为超声指纹. 定义了特征差异Q, 量化了具有不同微结构的散射模型间的超声指纹的差异. 结果表明, 微观结构的细微变化也会导致超声信号出现差异, 其中晶粒尺寸的变化对信号的影响更为显著. 随后提出了超声识别算法, 并对4块形状完全一致的2A12铝合金样品进行了识别实验. 识别结果表明, 利用超声指纹可以准确识别出目标样品, 且各样品间的超声指纹有显著区别. 最后对样品进行了扫描电子显微镜实验, 所得电子显微镜图片显示了各样品真实微观结构的形貌与差异, 证实了所建立的超声散射模型的有效性.Ultrasonic identification has an important application value for national defense, military affairs, aerospace, nuclear facilities and other high-tech fields. Ultrasonic waves can be used to identify any metal material. At present, the researches focus on algorithms for identifying the difference in ultrasonic signal among materials, but the study on the corresponding identification theory is lacking. In this work, 10 primary models of the microstructure of 2A12 aluminum alloy are established as analogies to the complex microstructures of polycrystalline metallic materials. The grains of these models are different from each other in size, separation distance, shape, arrangement directions and orders. The time-domain ultrasonic echo signals of different microstructures are calculated by making use of the finite element method. The grass-like signals between two echoes are ultrasonic backscattering signals, which are sensitive to any change of microstructure. The backscattering signals between the primary echo and the secondary echo in the ultrasonic echo time domain signals are extracted as ultrasonic fingerprints. The feature difference Q is defined to quantify the difference in ultrasonic fingerprint of each sample. The results show that the slight variation in microstructure will lead to difference in ultrasonic signal, and the difference caused by the variation in grain size is more distinct. And then, an ultrasonic identification algorithm is proposed, and the identification experiments are conducted on four 2A12 aluminum alloy samples with the same shape. The identification results show that the target sample can be accurately identified by using ultrasonic fingerprints and the ultrasonic fingerprints of the target sample are distinctly different from those of the other samples. The microstructure morphologies of the samples are examined by using scanning electron microscopy (SEM). The SEM results show that there are significant differences in grain size, separation distance and densification between samples although they are the same material. The features of the microstructure in the proposed ultrasonic scattering model in this work are confirmed by the actual y micromorphologies observed in the SEM images. The identification experiments and SEM results demonstrate that the established ultrasonic scattering model is effective. This work can provide a reference for theoretically studying ultrasonic identification and present an idea for developing some new identification algorithms in future.

-

Keywords:

- ultrasonic scattering /

- microstructure /

- polycrystalline materials /

- ultrasonic identification /

- finite element methods

[1] Yang L Y, Turner J A, Li Z 2007 J. Acoust. Soc. Am. 121 50

Google Scholar

Google Scholar

[2] Ghoshal G, Turner J A 2009 IEEE Trans. Ultrason. Ferrelectr. Freq. Control 56 1419

Google Scholar

Google Scholar

[3] Huang M, Sha G, Huthwaite P, Rokhlin S I, Lowe M J S 2021 J. Acoust. Soc. Am. 149 2377

Google Scholar

Google Scholar

[4] Thompson R B, Margetan F J, Haldipur P, Yu L, Wasan H 2008 Wave Motion 45 655

Google Scholar

Google Scholar

[5] Huntington H B 1950 J. Acoust. Soc. Am. 22 362

Google Scholar

Google Scholar

[6] Lobkis O I, Rokhlin S I 2010 Appl. Phys. Lett. 96 161905

Google Scholar

Google Scholar

[7] Li J, Rokhlin S I 2015 Wave Motion 58 145

Google Scholar

Google Scholar

[8] Song Y F, Kube C M, Turner J A, Li X 2017 Ultrasonics 80 58

Google Scholar

Google Scholar

[9] Yang L, Li J, Rokhlin S I 2013 Wave Motion 50 1283

Google Scholar

Google Scholar

[10] Li J, Yang L, Rokhlin S I 2014 Ultrasonics 54 1789

Google Scholar

Google Scholar

[11] 贾晓菲, 何亮 2014 中国科学: 物理学 力学 天文学 44 185

Google Scholar

Google Scholar

Jia X F, He L 2014 Sci. Sin. Phys. Mech. Astron. 44 185

Google Scholar

Google Scholar

[12] 李珊, 李雄兵, 宋永锋, 陈超 2018 67 234301

Google Scholar

Google Scholar

Li S, Li X B, Song Y F, Chen C 2018 Acta Phys. Sin. 67 234301

Google Scholar

Google Scholar

[13] Yang L, Rokhlin S I 2013 J. Nondestr. Eval. 32 142

Google Scholar

Google Scholar

[14] Li J, Rokhlin S I 2016 Int. J. Solids Struct. 78–79 110

Google Scholar

Google Scholar

[15] Hu P, Turner J A 2015 J. Acoust. Soc. Am. 137 321

Google Scholar

Google Scholar

[16] Liu Y, Tian Q, Yu P, He J, Guan X 2022 NDT and E Int. 129 102634

Google Scholar

Google Scholar

[17] Thompson B R 2002 Top. Appl. Phys. 84 233

Google Scholar

Google Scholar

[18] Good M S, Simpkins B E, Kirihara J L, Skorpik R J, Willett J A 2003 Ultrasonic Intrinsic Tagging for Nuclear Disarmament: A Proof-of-Concept Test (Richland: Pacific Northwest National Laboratory) PNNL-14462

[19] 刘小荣, 贺西平, 张宏普, 贺升平, 尼涛, 崔东, 卢康 2016 科学通报 61 844

Google Scholar

Google Scholar

Liu X R, He X P, Zhang H P, He S P, Ni T, Cui D, Lu K 2016 Chin. Sci. Bull. 61 844

Google Scholar

Google Scholar

[20] 安笑笑, 贺西平, 卢康 2018 电子学报 46 1737

Google Scholar

Google Scholar

An X X, He X P, Lu K 2018 Acta Electron. Sin. 46 1737

Google Scholar

Google Scholar

[21] Liu Y, He X P, He S P 2023 Acoust. Phys. 69 574

Google Scholar

Google Scholar

[22] Du H 2022 Ultrasonics 119 106633

Google Scholar

Google Scholar

[23] Yang L, Li J, Lobkis O I, Rokhlin S I 2012 J. Nondestr. Eval. 31 270

Google Scholar

Google Scholar

[24] Rokhlin S I, Sha G, Li J, Pilchak A L 2021 Ultrasonics 115 106433

Google Scholar

Google Scholar

[25] Yang L, Lobkis O I, Rokhlin S I 2011 Ultrasonics 51 697

Google Scholar

Google Scholar

[26] Lobkis O I, Yang L, Li J, Rokhlin S I 2012 Ultrasonics 52 694

Google Scholar

Google Scholar

-

表 1 模型参数

Table 1. Model parameters of the models.

A B C D E F G H I J 排列顺序 HSV

HSVVHS

VHSHSV

HSVHHH

HHHSSS

SSSHSV

HSVVSH

VSHHSV

HSVVHS

HSVVVV

VVV间距1/μm 900 900 1300 900 900 900 900 600 900 900 间距2/μm 800 800 500 800 800 800 800 500 800 800 RCL/μm 10 10 10 10 10 10 10 10 10 10 RCS/μm 5 5 5 5 5 5 5 5 5 5 RHL/μm 300 300 300 300 300 200 300 300 300 300 RHS/μm 150 150 150 150 150 100 150 150 150 150 RS/μm 200 200 200 200 200 100 200 200 200 200 RVL/μm 300 300 300 300 300 200 300 300 300 300 RVS/μm 200 200 200 200 200 100 200 200 200 200 表 2 各模型间特征差异

Table 2. Feature differences of each model.

编号 A B C D E F G H I J A 4.2043 0.2362 0.6463 1.3433 6.3421 2.3561 2.4869 2.7060 2.8057 B 4.2043 3.9681 3.5580 2.8610 2.1378 1.8482 1.7174 1.4983 1.3986 C 0.2362 3.9681 0.4100 1.1071 6.1059 2.1199 2.2507 2.4698 2.5695 D 0.6463 3.5580 0.4100 0.6971 5.6958 1.7098 1.8406 2.0598 2.1595 E 1.3433 2.8610 1.1071 0.6971 4.9988 1.0127 1.1436 1.3627 1.4624 F 6.3421 2.1378 6.1059 5.6958 4.9988 3.9860 3.8552 3.6360 3.5364 G 2.3561 1.8482 2.1199 1.7098 1.0127 3.9860 0.1308 0.3500 0.4497 H 2.4869 1.7174 2.2507 1.8406 1.1436 3.8552 0.1308 0.2191 0.3188 I 2.7060 1.4983 2.4698 2.0598 1.3627 3.6360 0.3500 0.2191 0.0997 J 2.8057 1.3986 2.5695 2.1595 1.4624 3.5364 0.4497 0.3188 0.0997 表 3 超声指纹识别结果

Table 3. Identification results of the ultrasonic fingerprints.

1 2 3 ······ 7 阈值 超出阈值次数 Pk (1#) 1.1474 0.8247 0.7687 ······ 0.7652 1.0362 1 Pk (2#) 4.3000 4.3018 4.3559 ······ 4.4523 7 Pk (3#) 4.5489 4.5639 4.5547 ······ 4.6969 7 Pk (4#) 3.8497 3.4267 3.5947 ······ 3.7984 7 -

[1] Yang L Y, Turner J A, Li Z 2007 J. Acoust. Soc. Am. 121 50

Google Scholar

Google Scholar

[2] Ghoshal G, Turner J A 2009 IEEE Trans. Ultrason. Ferrelectr. Freq. Control 56 1419

Google Scholar

Google Scholar

[3] Huang M, Sha G, Huthwaite P, Rokhlin S I, Lowe M J S 2021 J. Acoust. Soc. Am. 149 2377

Google Scholar

Google Scholar

[4] Thompson R B, Margetan F J, Haldipur P, Yu L, Wasan H 2008 Wave Motion 45 655

Google Scholar

Google Scholar

[5] Huntington H B 1950 J. Acoust. Soc. Am. 22 362

Google Scholar

Google Scholar

[6] Lobkis O I, Rokhlin S I 2010 Appl. Phys. Lett. 96 161905

Google Scholar

Google Scholar

[7] Li J, Rokhlin S I 2015 Wave Motion 58 145

Google Scholar

Google Scholar

[8] Song Y F, Kube C M, Turner J A, Li X 2017 Ultrasonics 80 58

Google Scholar

Google Scholar

[9] Yang L, Li J, Rokhlin S I 2013 Wave Motion 50 1283

Google Scholar

Google Scholar

[10] Li J, Yang L, Rokhlin S I 2014 Ultrasonics 54 1789

Google Scholar

Google Scholar

[11] 贾晓菲, 何亮 2014 中国科学: 物理学 力学 天文学 44 185

Google Scholar

Google Scholar

Jia X F, He L 2014 Sci. Sin. Phys. Mech. Astron. 44 185

Google Scholar

Google Scholar

[12] 李珊, 李雄兵, 宋永锋, 陈超 2018 67 234301

Google Scholar

Google Scholar

Li S, Li X B, Song Y F, Chen C 2018 Acta Phys. Sin. 67 234301

Google Scholar

Google Scholar

[13] Yang L, Rokhlin S I 2013 J. Nondestr. Eval. 32 142

Google Scholar

Google Scholar

[14] Li J, Rokhlin S I 2016 Int. J. Solids Struct. 78–79 110

Google Scholar

Google Scholar

[15] Hu P, Turner J A 2015 J. Acoust. Soc. Am. 137 321

Google Scholar

Google Scholar

[16] Liu Y, Tian Q, Yu P, He J, Guan X 2022 NDT and E Int. 129 102634

Google Scholar

Google Scholar

[17] Thompson B R 2002 Top. Appl. Phys. 84 233

Google Scholar

Google Scholar

[18] Good M S, Simpkins B E, Kirihara J L, Skorpik R J, Willett J A 2003 Ultrasonic Intrinsic Tagging for Nuclear Disarmament: A Proof-of-Concept Test (Richland: Pacific Northwest National Laboratory) PNNL-14462

[19] 刘小荣, 贺西平, 张宏普, 贺升平, 尼涛, 崔东, 卢康 2016 科学通报 61 844

Google Scholar

Google Scholar

Liu X R, He X P, Zhang H P, He S P, Ni T, Cui D, Lu K 2016 Chin. Sci. Bull. 61 844

Google Scholar

Google Scholar

[20] 安笑笑, 贺西平, 卢康 2018 电子学报 46 1737

Google Scholar

Google Scholar

An X X, He X P, Lu K 2018 Acta Electron. Sin. 46 1737

Google Scholar

Google Scholar

[21] Liu Y, He X P, He S P 2023 Acoust. Phys. 69 574

Google Scholar

Google Scholar

[22] Du H 2022 Ultrasonics 119 106633

Google Scholar

Google Scholar

[23] Yang L, Li J, Lobkis O I, Rokhlin S I 2012 J. Nondestr. Eval. 31 270

Google Scholar

Google Scholar

[24] Rokhlin S I, Sha G, Li J, Pilchak A L 2021 Ultrasonics 115 106433

Google Scholar

Google Scholar

[25] Yang L, Lobkis O I, Rokhlin S I 2011 Ultrasonics 51 697

Google Scholar

Google Scholar

[26] Lobkis O I, Yang L, Li J, Rokhlin S I 2012 Ultrasonics 52 694

Google Scholar

Google Scholar

计量

- 文章访问数: 5099

- PDF下载量: 116

- 被引次数: 0

下载:

下载: