-

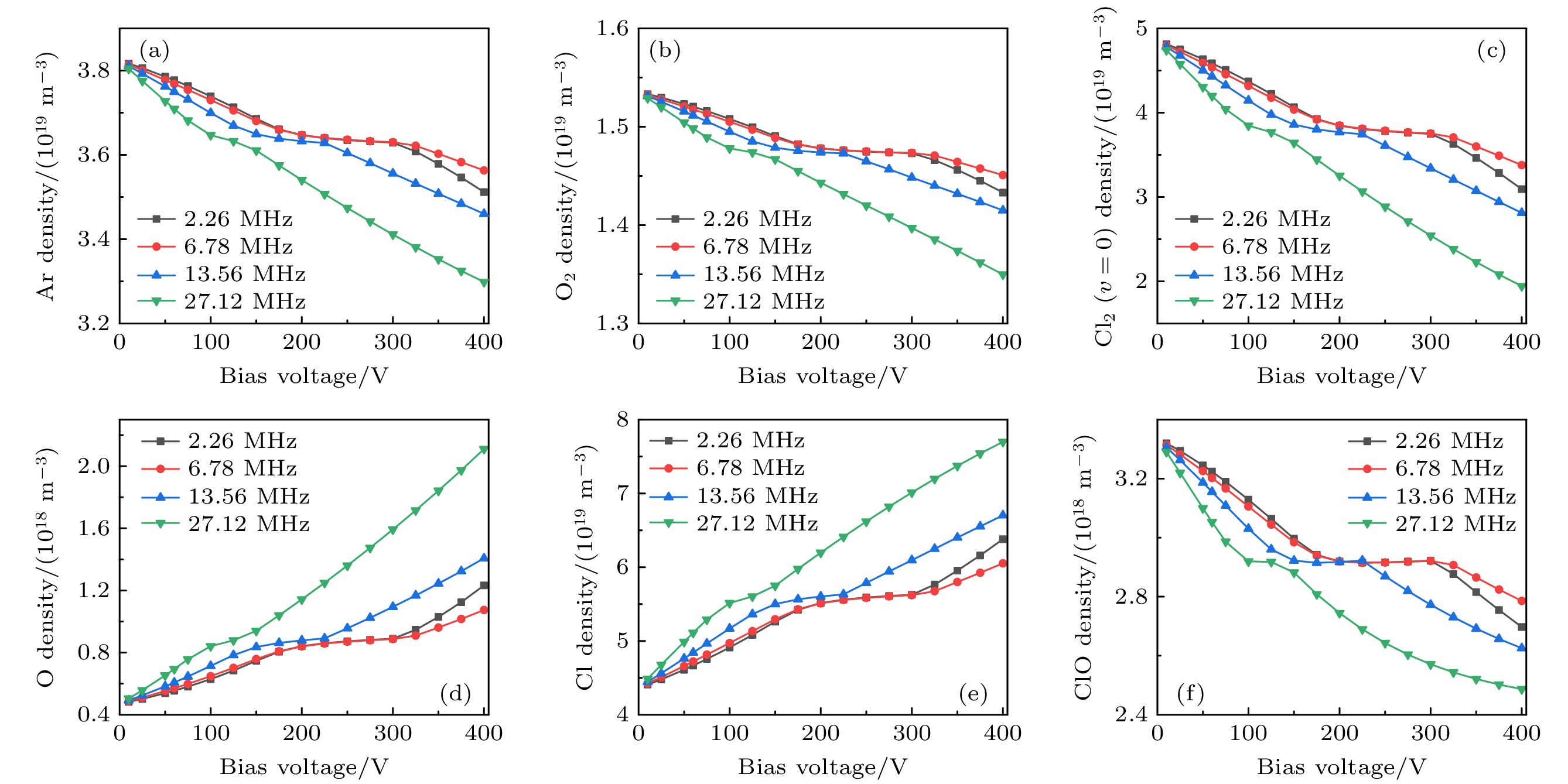

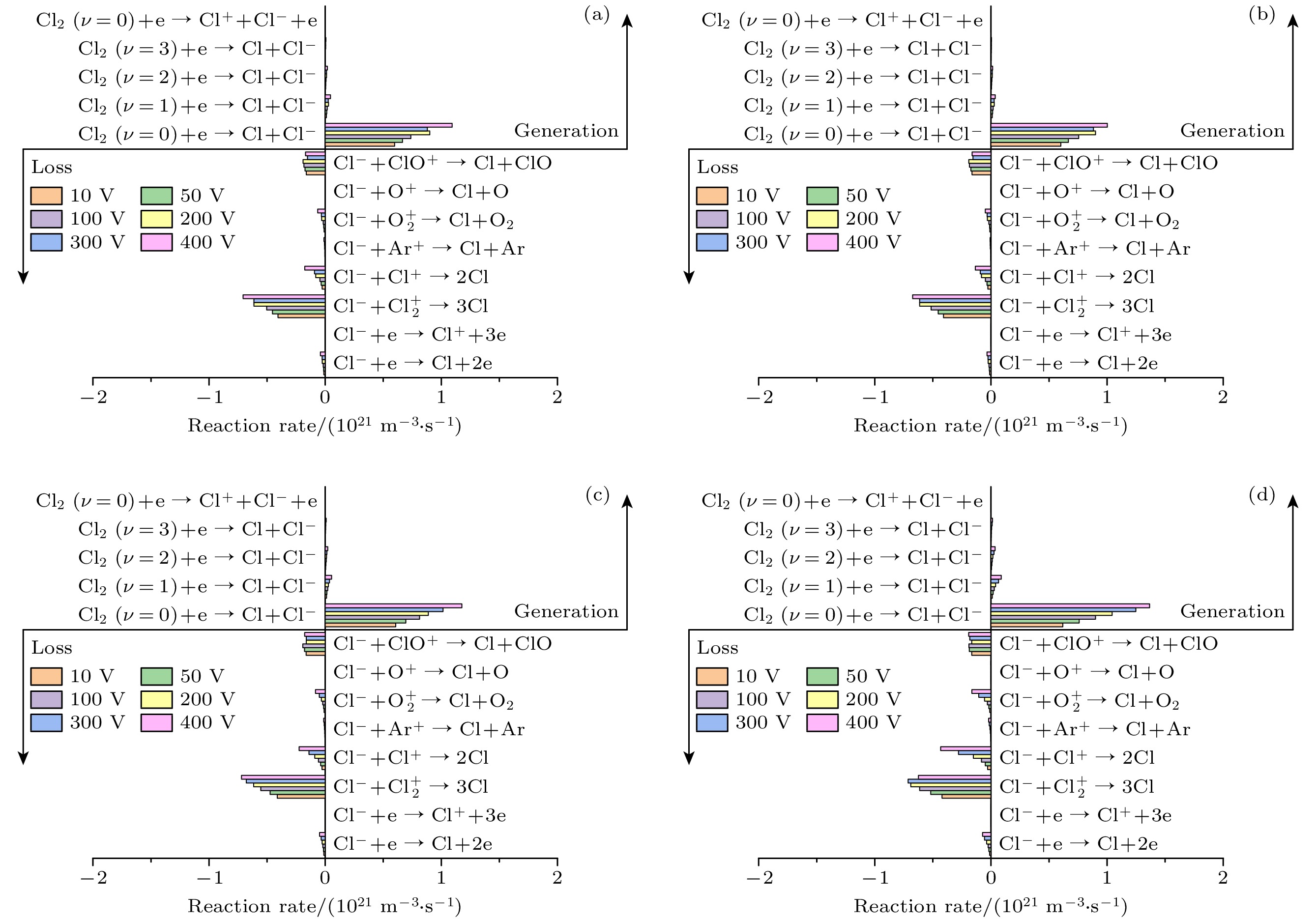

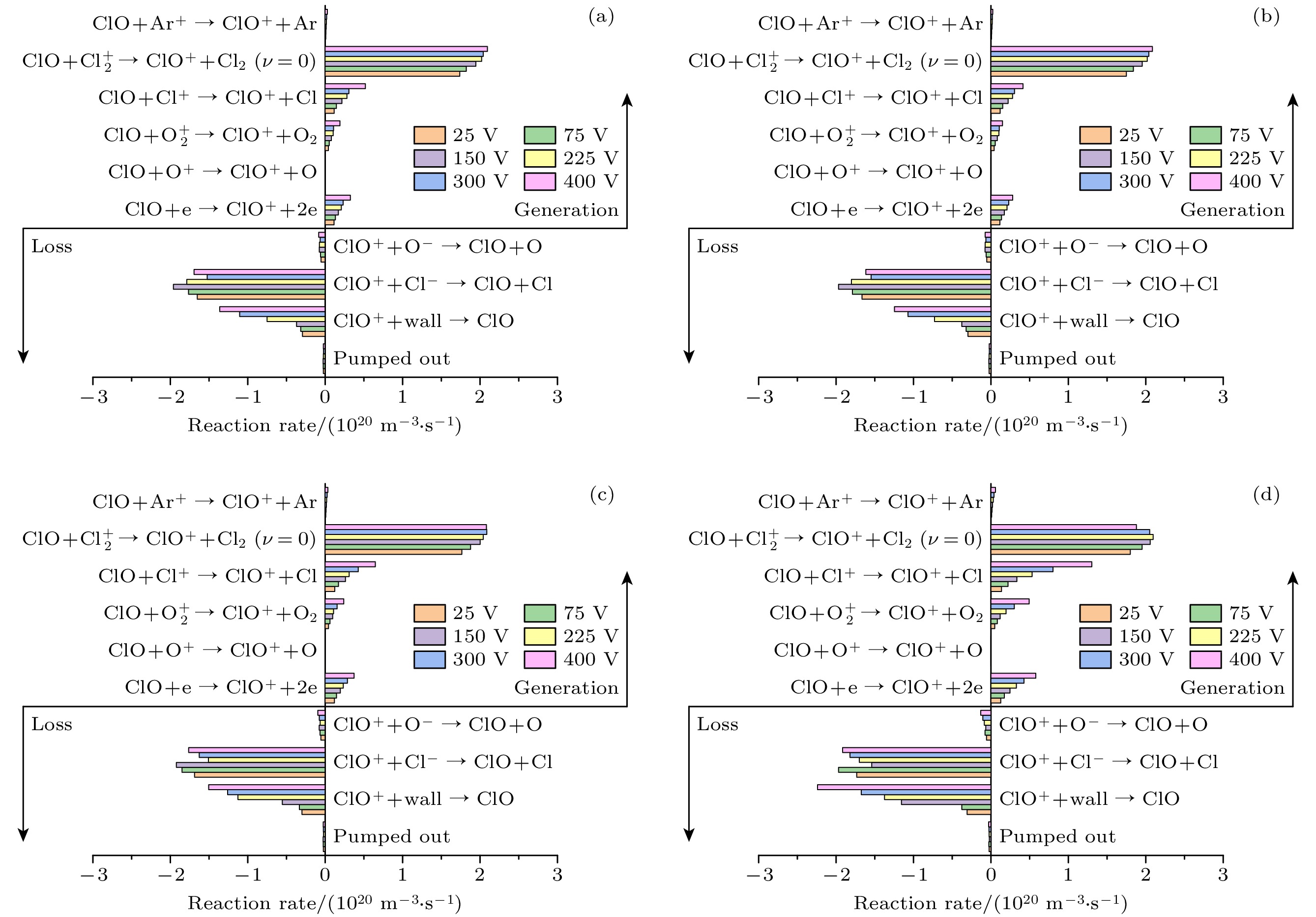

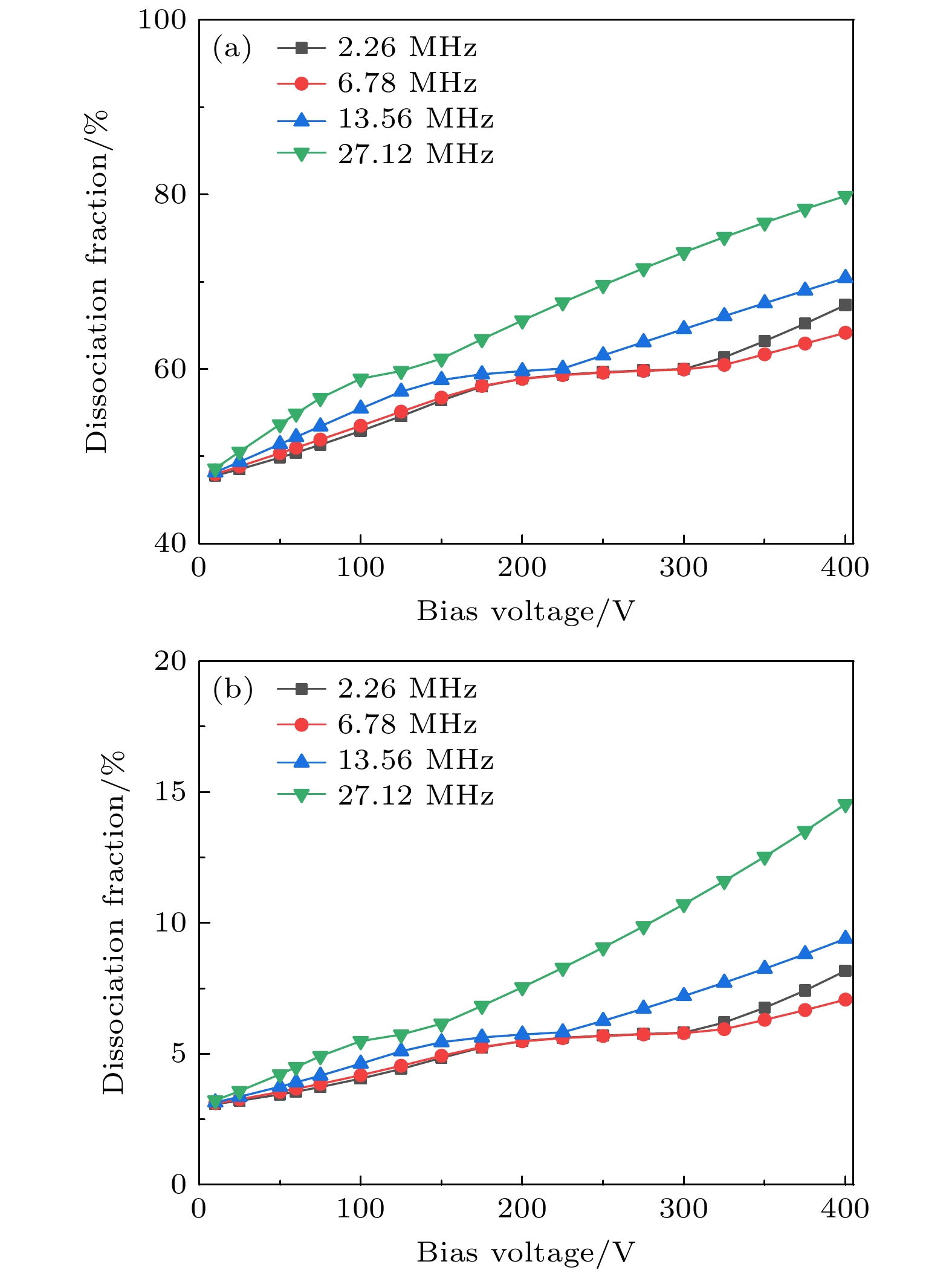

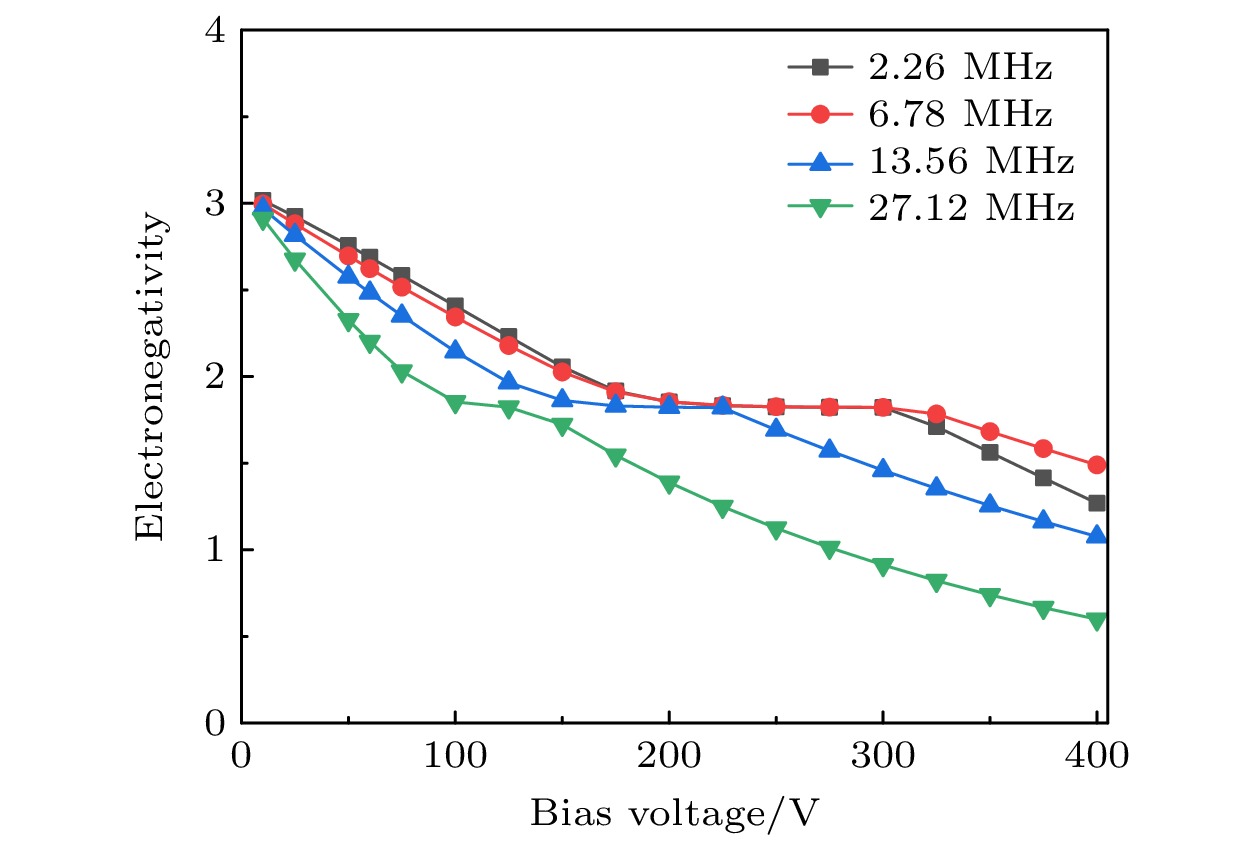

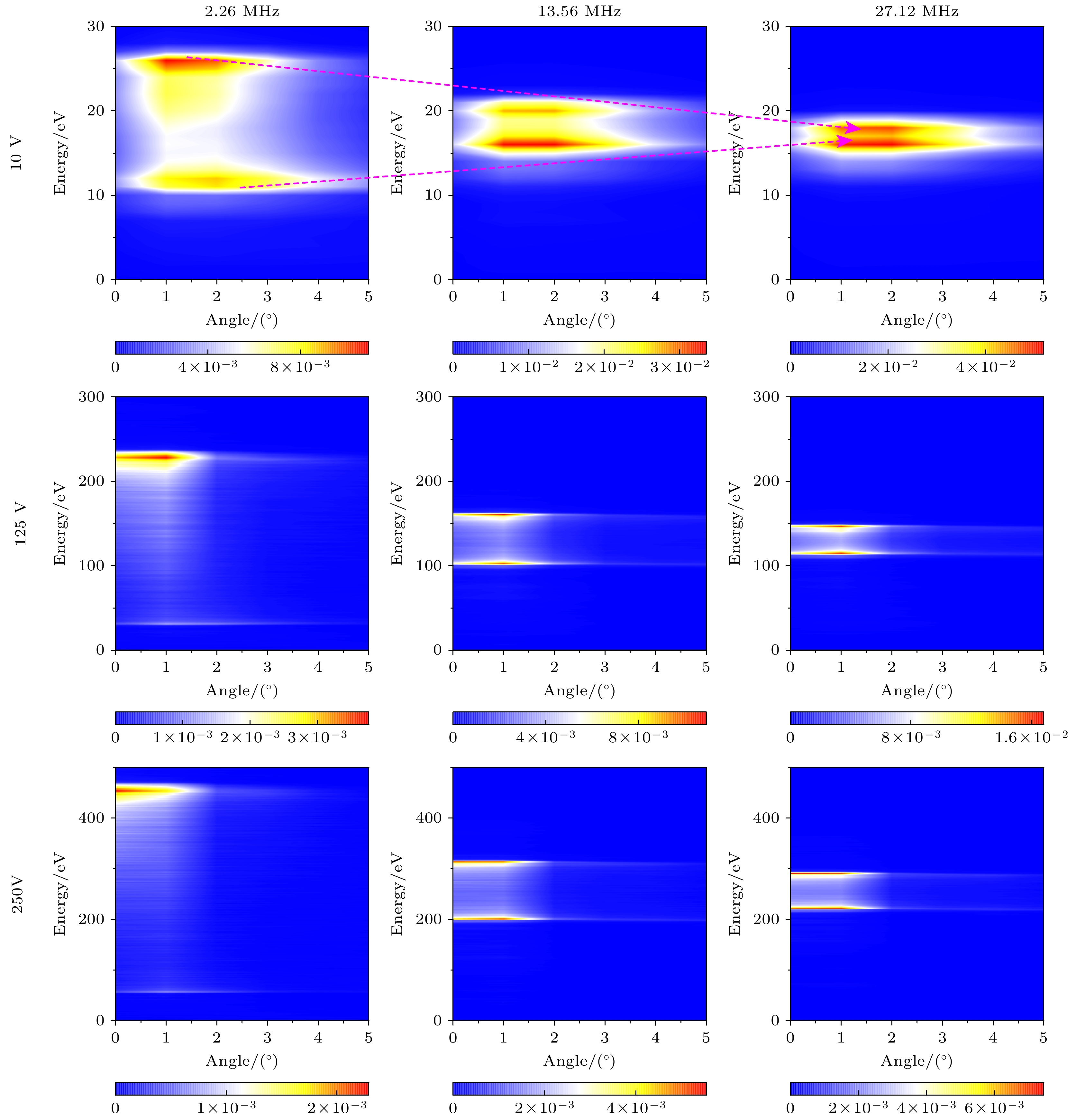

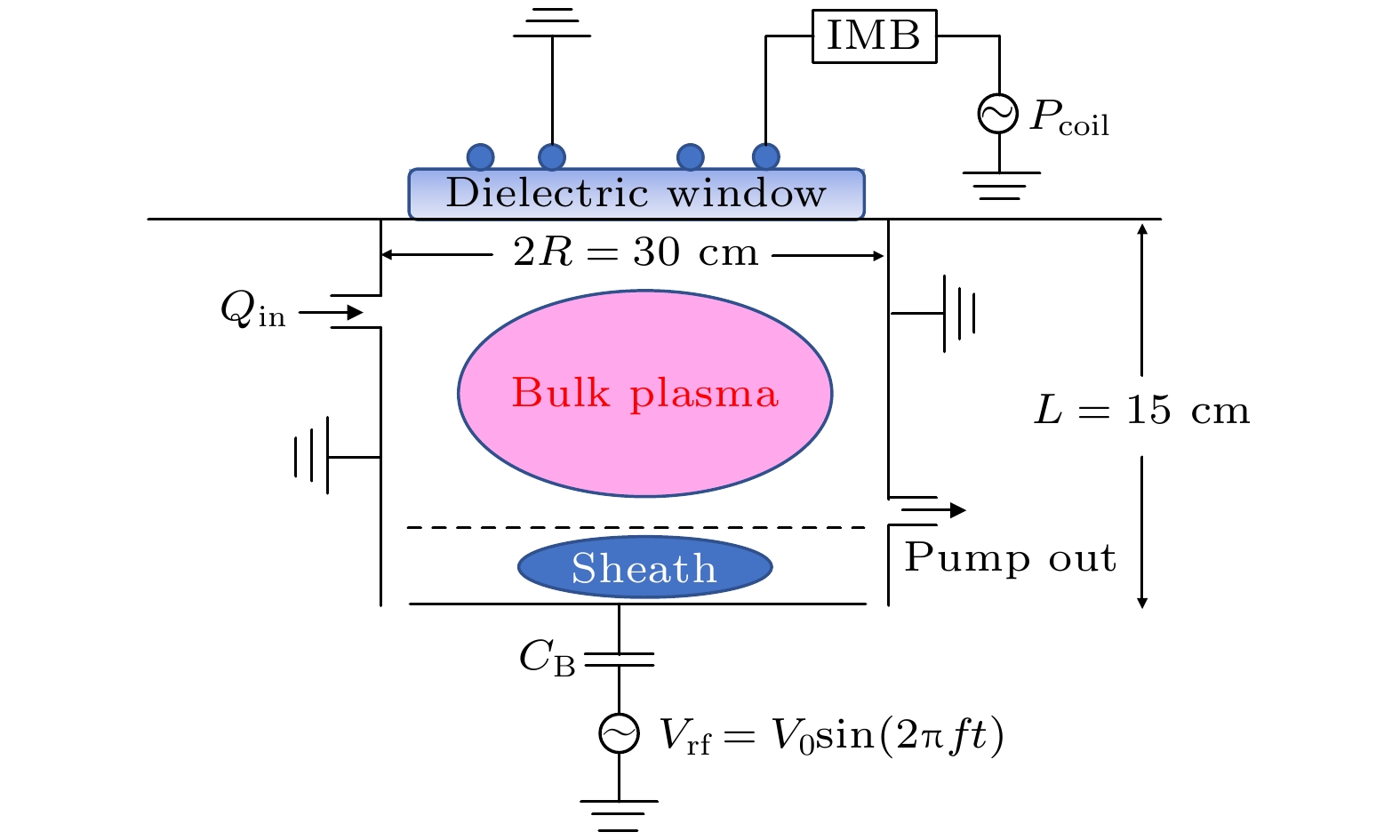

在刻蚀工艺中, 通常会在感性耦合等离子体源的下极板上施加偏压源, 以实现对离子能量和离子通量的独立调控. 本文采用整体模型双向耦合一维流体鞘层模型, 在Ar/O2/Cl2放电中, 研究了偏压幅值和频率对等离子体特性及离子能量角度分布的影响. 研究结果表明: 当偏压频率为2.26 MHz时, 随着偏压的增加, 除了Cl–离子和ClO+离子的密度先增加后降低最后再增加外, 其余带电粒子、O原子和Cl原子的密度都是先增加后基本保持不变最后再增加. 当偏压频率为13.56和27.12 MHz时, 除了Cl–离子和

$ {\text{Cl}}_2^ + $ 离子外, 其余粒子密度随偏压的演化趋势与低频结果相似. 随着偏压频率的提高, 在低偏压范围内(<200 V), 由于偏压源对等离子体加热显著增加, 导致了带电粒子、O原子和Cl原子的密度增加; 而在高偏压范围内(>300 V), 由于偏压源对等离子体加热先减弱后增强, 导致除了$ {\text{Cl}}_2^ + $ 离子和Cl–离子外, 其余带电粒子、O原子和Cl原子的密度都是先下降后增加的. 此外, 随着偏压频率的增加, 离子能量分布中的高能峰和低能峰彼此靠近, 离子能峰间距变窄, 并最终变成单峰结构. 本文的结论对于优化等离子体刻蚀工艺具有重要意义.In the etching process, a bias source is usually applied to the substrate of the inductively coupled plasma (ICP) to realize independent modulation of the ion energy and ion flux. In this work, a hybrid model, i.e. a global model combined bi-directionally with a fluid sheath model, is employed to investigate the plasma properties and ion energy distribution function (IEDF) in biased inductively coupled Ar/O2/Cl2 plasmas. The results indicate that at a bias frequency of 2.26 MHz, the Cl– ion density and ClO+ ion density first increase with bias voltage rising, and then they decrease, and finally they rise again, which is different from the densities of other charged species, such as O and Cl atoms. At the bias frequency of 13.56 MHz and 27.12 MHz, except Cl– and$ {\text{Cl}}_2^ + $ ions, the evolutions of other species densities with bias voltage are similar to the results at lower bias frequency. The evolution of the species densities with bias frequency depends on the bias voltage. For instance, in the low bias voltage range (< 200 V), the densities of charges species, O and Cl atoms increase with bias frequency increasing due to a significant increase in the heating of the plasma by the bias source. However, when the bias voltage is high, say, higher than 300 V, except$ {\text{Cl}}_2^ + $ and Cl– ions, the densities of other charged species, O and Cl atoms first decrease with bias frequency increasing and then they increase due to a decrease and then an increase in the heating of the plasma by the bias source. In addition, as the bias frequency increases, the peak separation of IEDF becomes narrow, the high energy peak and low energy peak approach each other and they almost merge into one peak at high bias frequency. The results obtained in this work are of significant importance in improving the etching process.-

Keywords:

- inductively coupled plasma /

- bias source /

- hybrid model /

- ion energy /

- ion flux

[1] Efremov A M, Kim D P, Kim C I 2004 IEEE Trans. Plasma Sci. 32 1344

Google Scholar

Google Scholar

[2] Efremov A M, Kim D P, Kim C I 2003 J. Vac. Sci. Technol., A 21 1568

Google Scholar

Google Scholar

[3] Bogaerts A, Neyts E, Gijbels R, Van Der Mullen J 2002 Spectrochim Acta, Part B 57 609

Google Scholar

Google Scholar

[4] Choi S K, Kim D P, Kim C I, Chang E G 2001 J. Vac. Sci. Technol., A 19 1063

Google Scholar

Google Scholar

[5] Lee Y J, Han H R, Lee J, Yeom G Y 2000 Surf. Coat. Technol. 131 257

Google Scholar

Google Scholar

[6] Wen D Q, Liu W, Gao F, Lieberman M A, Wang Y N 2016 Plasma Sources Sci. Technol. 25 045009

Google Scholar

Google Scholar

[7] Wen D, Zhang Y, Lieberman M A, Wang Y 2017 Plasma Processes Polym. 14 1600100

Google Scholar

Google Scholar

[8] Zhang Y R, Gao F, Li X C, Bogaerts A, Wang Y N 2015 J. Vac. Sci. Technol., A 33 061303

Google Scholar

Google Scholar

[9] Lee H C, Lee M H, Chung C W 2010 Appl. Phys. Lett. 96 071501

Google Scholar

Google Scholar

[10] Lee H C, Chung C W 2012 Appl. Phys. Lett. 101 244104

Google Scholar

Google Scholar

[11] Lee H C, Bang J Y, Chung C W 2011 Thin Solid Films 519 7009

Google Scholar

Google Scholar

[12] Lee C, Lieberman M A 1995 J. Vac. Sci. Technol., A 13 368

Google Scholar

Google Scholar

[13] Gudmundsson J T 2004 J. Phys. D: Appl. Phys. 37 2073

Google Scholar

Google Scholar

[14] Jung J, Kim M S, Park J, Lim C M, Hwang T W, Seo B J, Chung C W 2023 Phys. Plasmas 30 023504

Google Scholar

Google Scholar

[15] Tong L, Zhang Y R, Huang J W, Zhao M L, Wen D Q, Song Y H, Wang Y N 2021 Phys. Plasmas 28 053512

Google Scholar

Google Scholar

[16] Tong L, Zhao M L, Zhang Y R, Song Y H, Wang Y N 2023 J. Phys. D: Appl. Phys. 56 365202

[17] Khater M H, Overzet L J 2004 Plasma Sources Sci. Technol. 13 466

Google Scholar

Google Scholar

[18] Dai Z L, Zhang S Q, Wang Y N 2013 Vacuum 89 197

Google Scholar

Google Scholar

[19] Zhang S Q, Dai Z L, Song Y H, Wang Y N 2014 Vacuum 99 180

Google Scholar

Google Scholar

[20] Levko D, Raja L L 2022 J. Vac. Sci. Technol., B 40 052205

Google Scholar

Google Scholar

[21] Levko D, Upadhyay R R, Suzuki K, Raja L L 2023 J. Vac. Sci. Technol., A 41 012205

Google Scholar

Google Scholar

[22] Malyshev M V, Donnelly V M, Colonell J I, Samukawa S 1999 J. Appl. Phys. 86 4813

Google Scholar

Google Scholar

[23] Malyshev M V, Donnelly V M 2000 Plasma Sources Sci. Technol. 9 353

Google Scholar

Google Scholar

[24] Donnelly V M, Malyshev M V 2000 Appl. Phys. Lett. 77 2467

Google Scholar

Google Scholar

[25] Malyshev M V, Donnelly V M 2001 J. Appl. Phys. 90 1130

Google Scholar

Google Scholar

[26] Malyshev M V, Fuller N C M, Bogart K H A, Donnelly V M, Herman I P 2000 J. Appl. Phys. 88 2246

Google Scholar

Google Scholar

[27] Malyshev M V, Donnelly V M 2000 J. Appl. Phys. 88 6207

Google Scholar

Google Scholar

[28] Malyshev M V, Donnelly V M 2000 J. Appl. Phys. 87 1642

Google Scholar

Google Scholar

[29] Thorsteinsson E G, Gudmundsson J T 2010 Plasma Sources Sci. Technol. 19 015001

Google Scholar

Google Scholar

[30] Thorsteinsson E G, Gudmundsson J T 2010 J. Phys. D: Appl. Phys. 43 115201

Google Scholar

Google Scholar

[31] Thorsteinsson E G, Gudmundsson J T 2010 J. Phys. D: Appl. Phys. 43 115202

Google Scholar

Google Scholar

[32] Thorsteinsson E G, Gudmundsson J T 2010 Plasma Sources Sci. Technol. 19 055008

Google Scholar

Google Scholar

[33] Gudmundsson J T, Hjartarson A T, Thorsteinsson E G 2012 Vacuum 86 808

Google Scholar

Google Scholar

[34] Zhang Y R, Zhao Z Z, Xue C, Gao F, Wang Y N 2019 J. Phys. D: Appl. Phys. 52 295204

[35] Liu W, Wen D Q, Zhao S X, Gao F, Wang Y N 2015 Plasma Sources Sci. Technol. 24 025035

Google Scholar

Google Scholar

[36] 范惠泽, 刘凯, 黄永清, 蔡世伟, 任晓敏, 段晓峰, 王琦, 刘昊, 吴瑶, 费嘉瑞 2017 真空科学与技术学报 37 286

Google Scholar

Google Scholar

Fan H Z, Liu K, Huang Y Q, Cai S W, Ren X M, Duan X F, Wang Q, Liu H, Wu Y, Fei J R 2017 Chin. J. Vac. Sci. Technol. 37 286

Google Scholar

Google Scholar

[37] Smith S A, Lampert W V, Rajagopal P, Banks A D, Thomson D, Davis R F 2000 J. Vac. Sci. Technol., A 18 879

Google Scholar

Google Scholar

[38] Lee J M, Chang K M, Lee I H, Park S J 2000 J. Vac. Sci. Technol., B 18 1409

Google Scholar

Google Scholar

[39] Taube A, Kamiński M, Ekielski M, et al. 2021 Mater. Sci. Semicond. Process. 122 105450

Google Scholar

Google Scholar

[40] Chung C W, Chung I 2000 J. Vac. Sci. Technol., A 18 835

Google Scholar

Google Scholar

[41] Park J S, Kim T H, Choi C S, Hahn Y B 2002 Korean J. Chem. Eng. 19 486

Google Scholar

Google Scholar

[42] Kwon K H, Efremov A, Yun S J, Chun I, Kim K 2014 Thin Solid Films 552 105

Google Scholar

Google Scholar

[43] Kang S, Efremov A, Yun S J, Son J, Kwon K H 2013 Plasma Chem. Plasma Process. 33 527

Google Scholar

Google Scholar

[44] Tinck S, Boullart W, Bogaerts A 2009 J. Phys. D: Appl. Phys. 42 095204

Google Scholar

Google Scholar

[45] Tinck S, Boullart W, Bogaerts A 2011 Plasma Sources Sci. Technol. 20 045012

Google Scholar

Google Scholar

[46] Tinck S, Bogaerts A, Shamiryan D 2011 Plasma Processes Polym. 8 490

Google Scholar

Google Scholar

[47] Hsu C C, Coburn J W, Graves D B 2006 J. Vac. Sci. Technol., A 24 1

Google Scholar

Google Scholar

[48] Efremov A, Amirov I, Izyumov M 2023 Vacuum 207 111664

Google Scholar

Google Scholar

[49] Hsu C C, Nierode M A, Coburn J W, Graves D B 2006 J. Phys. D: Appl. Phys. 39 3272

Google Scholar

Google Scholar

[50] Schulze J, Schüngel E, Czarnetzki U 2012 Appl. Phys. Lett. 100 024102

Google Scholar

Google Scholar

[51] Ahr P, Schüngel E, Schulze J, Tsankov T V, Czarnetzki U 2015 Plasma Sources Sci. Technol. 24 044006

Google Scholar

Google Scholar

[52] Lieberman M A, Lichtenberg A J 2005 Principles of Plasma Discharges and Materials Processing (Hoboken, NJ, USA: John Wiley & Sons, Inc.) p268

[53] 张钰如, 高飞, 王友年 2021 70 095206

Google Scholar

Google Scholar

Zhang Y R, Gao F, Wang Y N A 2021 Acta Phys. Sin. 70 095206

Google Scholar

Google Scholar

[54] Yang W, Zhao S X, Wen D Q, Liu W, Liu Y X, Li X C, Wang Y N 2016 J. Vac. Sci. Technol., A 34 031305

Google Scholar

Google Scholar

[55] Toneli D A, Pessoa R S, Roberto M, Gudmundsson J T 2015 J. Phys. D: Appl. Phys. 48 325202

Google Scholar

Google Scholar

[56] Proto A 2021 Ph. D. Dissertation (Iceland: University of Iceland

[57] Stafford L, Khare R, Guha J, Donnelly V M, Poirier J S, Margot J 2009 J. Phys. D: Appl. Phys. 42 055206

Google Scholar

Google Scholar

[58] Guha J, Donnelly V M 2009 J. Appl. Phys. 105 113307

Google Scholar

Google Scholar

[59] Boyd R L F, Thomson J B 1959 Proc. R. Soc. London, Ser. A 252 102

Google Scholar

Google Scholar

[60] Kokkoris G, Goodyear A, Cooke M, Gogolides E 2008 J. Phys. D: Appl. Phys. 41 195211

Google Scholar

Google Scholar

[61] Dai Z L, Wang Y N, Ma T C 2002 Phys. Rev. E 65 036403

Google Scholar

Google Scholar

[62] Dai Z L, Wang Y N 2004 Phys. Rev. E 69 036403

Google Scholar

Google Scholar

[63] Dai Z L, Wang Y N 2002 Phys. Rev. E 66 026413

Google Scholar

Google Scholar

[64] Dai Z L, Wang Y N 2002 J. Appl. Phys. 92 6428

Google Scholar

Google Scholar

[65] Dai Z L, Wang Y N 2003 Surf. Coat. Technol. 165 224

Google Scholar

Google Scholar

[66] Wen D Q, Zhang Q Z, Jiang W, Song Y H, Bogaerts A, Wang Y N 2014 J. Appl. Phys. 115 233303

Google Scholar

Google Scholar

[67] Hong Y H, Kim T W, Kim B S, Lee M Y, Chung C W 2022 Plasma Sources Sci. Technol. 31 075008

Google Scholar

Google Scholar

[68] Huang S, Gudmundsson J T 2013 Plasma Sources Sci. Technol. 22 055020

Google Scholar

Google Scholar

[69] Hennad A, Yousfi M 2010 J. Phys. D: Appl. Phys. 44 025201

Google Scholar

Google Scholar

[70] Manenschijn A, Janssen G C A M, Van Der Drift E, Radelaar S 1991 J. Appl. Phys. 69 1253

Google Scholar

Google Scholar

[71] Hayden C, Gahan D, Hopkins M B 2009 Plasma Sources Sci. Technol. 18 025018

Google Scholar

Google Scholar

[72] Gahan D, Dolinaj B, Hopkins M B 2008 Rev. Sci. Instrum. 79 033502

Google Scholar

Google Scholar

[73] Edelberg E A, Aydil E S 1999 J. Appl. Phys. 86 4799

Google Scholar

Google Scholar

[74] Edelberg E A, Perry A, Benjamin N, Aydil E S 1999 J. Vac. Sci. Technol., A 17 506

Google Scholar

Google Scholar

[75] Edelberg E A, Perry A, Benjamin N, Aydil E S 1999 Rev. Sci. Instrum. 70 2689

Google Scholar

Google Scholar

-

图 5 不同偏压频率下, 带电粒子密度随偏压幅值的变化 (a) Ar+; (b) $ {\text{O}}_2^ + $; (c) O+; (d) O–; (e) $ {\text{Cl}}_2^ + $; (f) Cl+; (g) Cl–; (h) ClO+; (i) 电子密度

Fig. 5. Evolutions of the densities of charged species with bias voltage for different bias frequencies: (a) Ar+; (b) $ {\text{O}}_2^ + $; (c) O+; (d) O–; (e) $ {\text{Cl}}_2^ + $; (f) Cl+; (g) Cl–; (h) ClO+; (i) electron density.

表 1 Ar/O2/Cl2混合气体放电中考虑的粒子

Table 1. Plasma species considered in Ar/O2/Cl2 discharges.

基态中性粒子 Ar, O2, O3, O, Cl2 (ν = 0), Cl, ClO 激发态中性

粒子Arm, Arr, Ar(4p), O2(a), O(D),

Cl2 (ν = 1), Cl2 (ν = 2), Cl2 (ν = 3)正离子 Ar+, $ {\text{O}}_2^ + $, O+, $ {\text{Cl}}_2^ + $, Cl+, ClO+ 负离子/电子 O–, Cl–, e No. Reaction ${\gamma _l}$ 1 ${\text{Cl + wall }} \to {\text{ }}\dfrac{{1}}{{2}}{\text{C}}{{\text{l}}_{2}}\left( {\nu = {0}} \right)$ 方程(3) 2 ${\text{Cl + wall }} \to {\text{ }}\dfrac{{1}}{{2}}{\text{ClO}}$ 方程(4) 3 ${\text{O + wall }} \to {\text{ }}\dfrac{{1}}{{2}}{{\text{O}}_{2}}$ 0.09 4 ${\text{O}}\left( {\text{D}} \right){\text{ + wall }} \to {\text{ }}\dfrac{{1}}{{2}}{{\text{O}}_{2}}$ 0.09 5 ${\text{C}}{{\text{l}}_{2}}\left( \nu \right){\text{ + wall }} \to {\text{ C}}{{\text{l}}_{2}}\left( {\nu - {1}} \right)$ 1 6 ${{\text{O}}_{2}}\left( {\text{a}} \right){\text{ + wall }} \to {\text{ }}{{\text{O}}_{2}}$ 0.007 7 ${\text{O}}\left( {\text{D}} \right){\text{ + wall }} \to {\text{ O}}$ 0.1 8 ${\text{A}}{{\text{r}}^ * }{\text{ + wall }} \to {\text{ Ar}}$ 1 表 3 偏压频率为13.56 MHz时, 不同偏压幅值下的时间平均鞘层厚度和鞘层电压降

Table 3. Time-averaged sheath thickness and voltage drop across the sheath for different bias voltage amplitudes, at bias frequency of 13.56 MHz.

25 V 50 V 75 V 100 V 125 V 150 V 175 V 200 V ${\bar d_{\text{s}}}{\text{ /mm}}$ 4.67 4.75 4.79 4.80 4.81 4.85 4.93 5.03 ${\bar V_{\text{s}}}{\text{ /V}}$ 31.32 55.47 79.98 104.63 129.34 154.1 178.88 203.70 -

[1] Efremov A M, Kim D P, Kim C I 2004 IEEE Trans. Plasma Sci. 32 1344

Google Scholar

Google Scholar

[2] Efremov A M, Kim D P, Kim C I 2003 J. Vac. Sci. Technol., A 21 1568

Google Scholar

Google Scholar

[3] Bogaerts A, Neyts E, Gijbels R, Van Der Mullen J 2002 Spectrochim Acta, Part B 57 609

Google Scholar

Google Scholar

[4] Choi S K, Kim D P, Kim C I, Chang E G 2001 J. Vac. Sci. Technol., A 19 1063

Google Scholar

Google Scholar

[5] Lee Y J, Han H R, Lee J, Yeom G Y 2000 Surf. Coat. Technol. 131 257

Google Scholar

Google Scholar

[6] Wen D Q, Liu W, Gao F, Lieberman M A, Wang Y N 2016 Plasma Sources Sci. Technol. 25 045009

Google Scholar

Google Scholar

[7] Wen D, Zhang Y, Lieberman M A, Wang Y 2017 Plasma Processes Polym. 14 1600100

Google Scholar

Google Scholar

[8] Zhang Y R, Gao F, Li X C, Bogaerts A, Wang Y N 2015 J. Vac. Sci. Technol., A 33 061303

Google Scholar

Google Scholar

[9] Lee H C, Lee M H, Chung C W 2010 Appl. Phys. Lett. 96 071501

Google Scholar

Google Scholar

[10] Lee H C, Chung C W 2012 Appl. Phys. Lett. 101 244104

Google Scholar

Google Scholar

[11] Lee H C, Bang J Y, Chung C W 2011 Thin Solid Films 519 7009

Google Scholar

Google Scholar

[12] Lee C, Lieberman M A 1995 J. Vac. Sci. Technol., A 13 368

Google Scholar

Google Scholar

[13] Gudmundsson J T 2004 J. Phys. D: Appl. Phys. 37 2073

Google Scholar

Google Scholar

[14] Jung J, Kim M S, Park J, Lim C M, Hwang T W, Seo B J, Chung C W 2023 Phys. Plasmas 30 023504

Google Scholar

Google Scholar

[15] Tong L, Zhang Y R, Huang J W, Zhao M L, Wen D Q, Song Y H, Wang Y N 2021 Phys. Plasmas 28 053512

Google Scholar

Google Scholar

[16] Tong L, Zhao M L, Zhang Y R, Song Y H, Wang Y N 2023 J. Phys. D: Appl. Phys. 56 365202

[17] Khater M H, Overzet L J 2004 Plasma Sources Sci. Technol. 13 466

Google Scholar

Google Scholar

[18] Dai Z L, Zhang S Q, Wang Y N 2013 Vacuum 89 197

Google Scholar

Google Scholar

[19] Zhang S Q, Dai Z L, Song Y H, Wang Y N 2014 Vacuum 99 180

Google Scholar

Google Scholar

[20] Levko D, Raja L L 2022 J. Vac. Sci. Technol., B 40 052205

Google Scholar

Google Scholar

[21] Levko D, Upadhyay R R, Suzuki K, Raja L L 2023 J. Vac. Sci. Technol., A 41 012205

Google Scholar

Google Scholar

[22] Malyshev M V, Donnelly V M, Colonell J I, Samukawa S 1999 J. Appl. Phys. 86 4813

Google Scholar

Google Scholar

[23] Malyshev M V, Donnelly V M 2000 Plasma Sources Sci. Technol. 9 353

Google Scholar

Google Scholar

[24] Donnelly V M, Malyshev M V 2000 Appl. Phys. Lett. 77 2467

Google Scholar

Google Scholar

[25] Malyshev M V, Donnelly V M 2001 J. Appl. Phys. 90 1130

Google Scholar

Google Scholar

[26] Malyshev M V, Fuller N C M, Bogart K H A, Donnelly V M, Herman I P 2000 J. Appl. Phys. 88 2246

Google Scholar

Google Scholar

[27] Malyshev M V, Donnelly V M 2000 J. Appl. Phys. 88 6207

Google Scholar

Google Scholar

[28] Malyshev M V, Donnelly V M 2000 J. Appl. Phys. 87 1642

Google Scholar

Google Scholar

[29] Thorsteinsson E G, Gudmundsson J T 2010 Plasma Sources Sci. Technol. 19 015001

Google Scholar

Google Scholar

[30] Thorsteinsson E G, Gudmundsson J T 2010 J. Phys. D: Appl. Phys. 43 115201

Google Scholar

Google Scholar

[31] Thorsteinsson E G, Gudmundsson J T 2010 J. Phys. D: Appl. Phys. 43 115202

Google Scholar

Google Scholar

[32] Thorsteinsson E G, Gudmundsson J T 2010 Plasma Sources Sci. Technol. 19 055008

Google Scholar

Google Scholar

[33] Gudmundsson J T, Hjartarson A T, Thorsteinsson E G 2012 Vacuum 86 808

Google Scholar

Google Scholar

[34] Zhang Y R, Zhao Z Z, Xue C, Gao F, Wang Y N 2019 J. Phys. D: Appl. Phys. 52 295204

[35] Liu W, Wen D Q, Zhao S X, Gao F, Wang Y N 2015 Plasma Sources Sci. Technol. 24 025035

Google Scholar

Google Scholar

[36] 范惠泽, 刘凯, 黄永清, 蔡世伟, 任晓敏, 段晓峰, 王琦, 刘昊, 吴瑶, 费嘉瑞 2017 真空科学与技术学报 37 286

Google Scholar

Google Scholar

Fan H Z, Liu K, Huang Y Q, Cai S W, Ren X M, Duan X F, Wang Q, Liu H, Wu Y, Fei J R 2017 Chin. J. Vac. Sci. Technol. 37 286

Google Scholar

Google Scholar

[37] Smith S A, Lampert W V, Rajagopal P, Banks A D, Thomson D, Davis R F 2000 J. Vac. Sci. Technol., A 18 879

Google Scholar

Google Scholar

[38] Lee J M, Chang K M, Lee I H, Park S J 2000 J. Vac. Sci. Technol., B 18 1409

Google Scholar

Google Scholar

[39] Taube A, Kamiński M, Ekielski M, et al. 2021 Mater. Sci. Semicond. Process. 122 105450

Google Scholar

Google Scholar

[40] Chung C W, Chung I 2000 J. Vac. Sci. Technol., A 18 835

Google Scholar

Google Scholar

[41] Park J S, Kim T H, Choi C S, Hahn Y B 2002 Korean J. Chem. Eng. 19 486

Google Scholar

Google Scholar

[42] Kwon K H, Efremov A, Yun S J, Chun I, Kim K 2014 Thin Solid Films 552 105

Google Scholar

Google Scholar

[43] Kang S, Efremov A, Yun S J, Son J, Kwon K H 2013 Plasma Chem. Plasma Process. 33 527

Google Scholar

Google Scholar

[44] Tinck S, Boullart W, Bogaerts A 2009 J. Phys. D: Appl. Phys. 42 095204

Google Scholar

Google Scholar

[45] Tinck S, Boullart W, Bogaerts A 2011 Plasma Sources Sci. Technol. 20 045012

Google Scholar

Google Scholar

[46] Tinck S, Bogaerts A, Shamiryan D 2011 Plasma Processes Polym. 8 490

Google Scholar

Google Scholar

[47] Hsu C C, Coburn J W, Graves D B 2006 J. Vac. Sci. Technol., A 24 1

Google Scholar

Google Scholar

[48] Efremov A, Amirov I, Izyumov M 2023 Vacuum 207 111664

Google Scholar

Google Scholar

[49] Hsu C C, Nierode M A, Coburn J W, Graves D B 2006 J. Phys. D: Appl. Phys. 39 3272

Google Scholar

Google Scholar

[50] Schulze J, Schüngel E, Czarnetzki U 2012 Appl. Phys. Lett. 100 024102

Google Scholar

Google Scholar

[51] Ahr P, Schüngel E, Schulze J, Tsankov T V, Czarnetzki U 2015 Plasma Sources Sci. Technol. 24 044006

Google Scholar

Google Scholar

[52] Lieberman M A, Lichtenberg A J 2005 Principles of Plasma Discharges and Materials Processing (Hoboken, NJ, USA: John Wiley & Sons, Inc.) p268

[53] 张钰如, 高飞, 王友年 2021 70 095206

Google Scholar

Google Scholar

Zhang Y R, Gao F, Wang Y N A 2021 Acta Phys. Sin. 70 095206

Google Scholar

Google Scholar

[54] Yang W, Zhao S X, Wen D Q, Liu W, Liu Y X, Li X C, Wang Y N 2016 J. Vac. Sci. Technol., A 34 031305

Google Scholar

Google Scholar

[55] Toneli D A, Pessoa R S, Roberto M, Gudmundsson J T 2015 J. Phys. D: Appl. Phys. 48 325202

Google Scholar

Google Scholar

[56] Proto A 2021 Ph. D. Dissertation (Iceland: University of Iceland

[57] Stafford L, Khare R, Guha J, Donnelly V M, Poirier J S, Margot J 2009 J. Phys. D: Appl. Phys. 42 055206

Google Scholar

Google Scholar

[58] Guha J, Donnelly V M 2009 J. Appl. Phys. 105 113307

Google Scholar

Google Scholar

[59] Boyd R L F, Thomson J B 1959 Proc. R. Soc. London, Ser. A 252 102

Google Scholar

Google Scholar

[60] Kokkoris G, Goodyear A, Cooke M, Gogolides E 2008 J. Phys. D: Appl. Phys. 41 195211

Google Scholar

Google Scholar

[61] Dai Z L, Wang Y N, Ma T C 2002 Phys. Rev. E 65 036403

Google Scholar

Google Scholar

[62] Dai Z L, Wang Y N 2004 Phys. Rev. E 69 036403

Google Scholar

Google Scholar

[63] Dai Z L, Wang Y N 2002 Phys. Rev. E 66 026413

Google Scholar

Google Scholar

[64] Dai Z L, Wang Y N 2002 J. Appl. Phys. 92 6428

Google Scholar

Google Scholar

[65] Dai Z L, Wang Y N 2003 Surf. Coat. Technol. 165 224

Google Scholar

Google Scholar

[66] Wen D Q, Zhang Q Z, Jiang W, Song Y H, Bogaerts A, Wang Y N 2014 J. Appl. Phys. 115 233303

Google Scholar

Google Scholar

[67] Hong Y H, Kim T W, Kim B S, Lee M Y, Chung C W 2022 Plasma Sources Sci. Technol. 31 075008

Google Scholar

Google Scholar

[68] Huang S, Gudmundsson J T 2013 Plasma Sources Sci. Technol. 22 055020

Google Scholar

Google Scholar

[69] Hennad A, Yousfi M 2010 J. Phys. D: Appl. Phys. 44 025201

Google Scholar

Google Scholar

[70] Manenschijn A, Janssen G C A M, Van Der Drift E, Radelaar S 1991 J. Appl. Phys. 69 1253

Google Scholar

Google Scholar

[71] Hayden C, Gahan D, Hopkins M B 2009 Plasma Sources Sci. Technol. 18 025018

Google Scholar

Google Scholar

[72] Gahan D, Dolinaj B, Hopkins M B 2008 Rev. Sci. Instrum. 79 033502

Google Scholar

Google Scholar

[73] Edelberg E A, Aydil E S 1999 J. Appl. Phys. 86 4799

Google Scholar

Google Scholar

[74] Edelberg E A, Perry A, Benjamin N, Aydil E S 1999 J. Vac. Sci. Technol., A 17 506

Google Scholar

Google Scholar

[75] Edelberg E A, Perry A, Benjamin N, Aydil E S 1999 Rev. Sci. Instrum. 70 2689

Google Scholar

Google Scholar

计量

- 文章访问数: 4726

- PDF下载量: 317

- 被引次数: 0

下载:

下载: