-

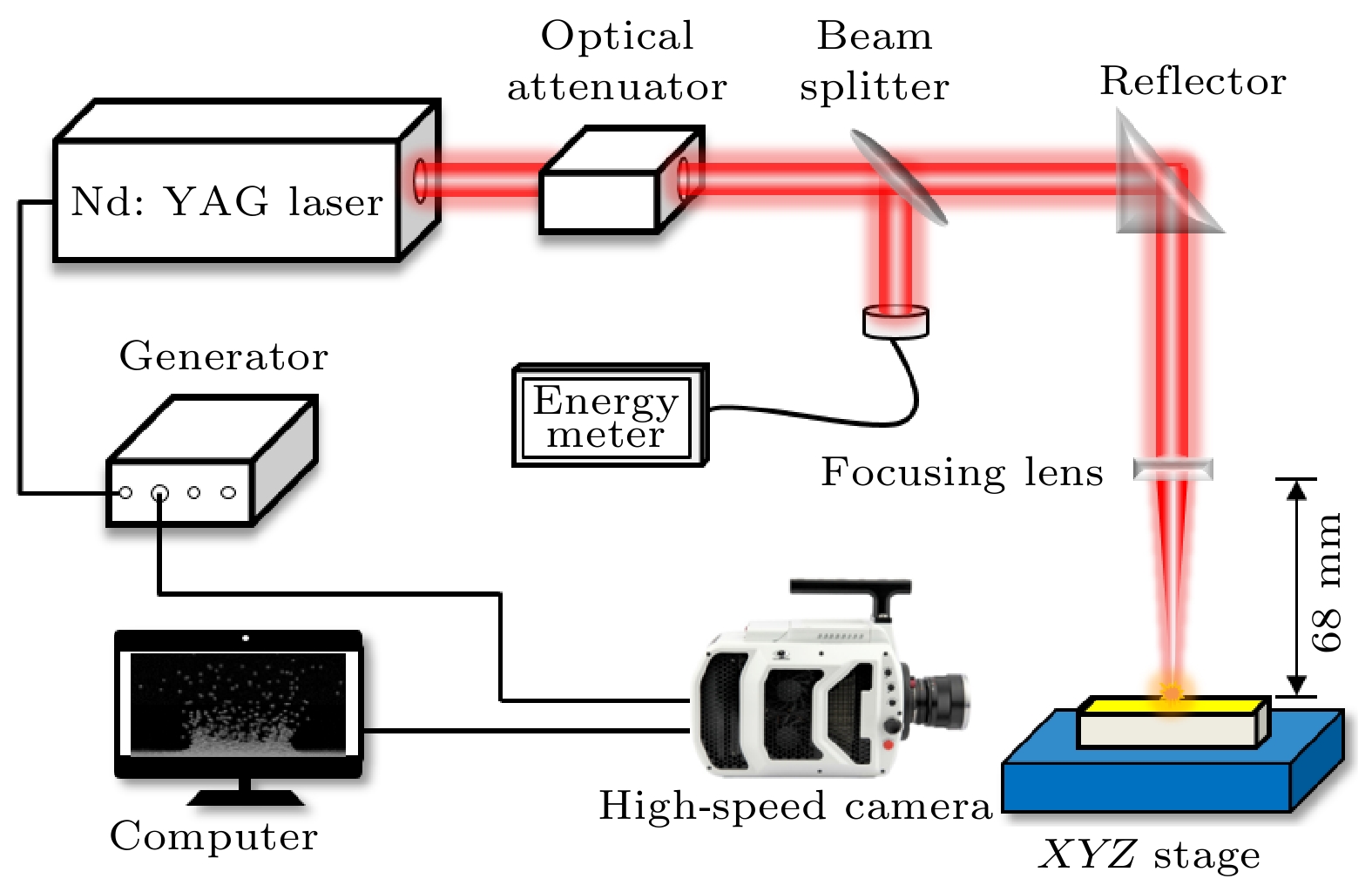

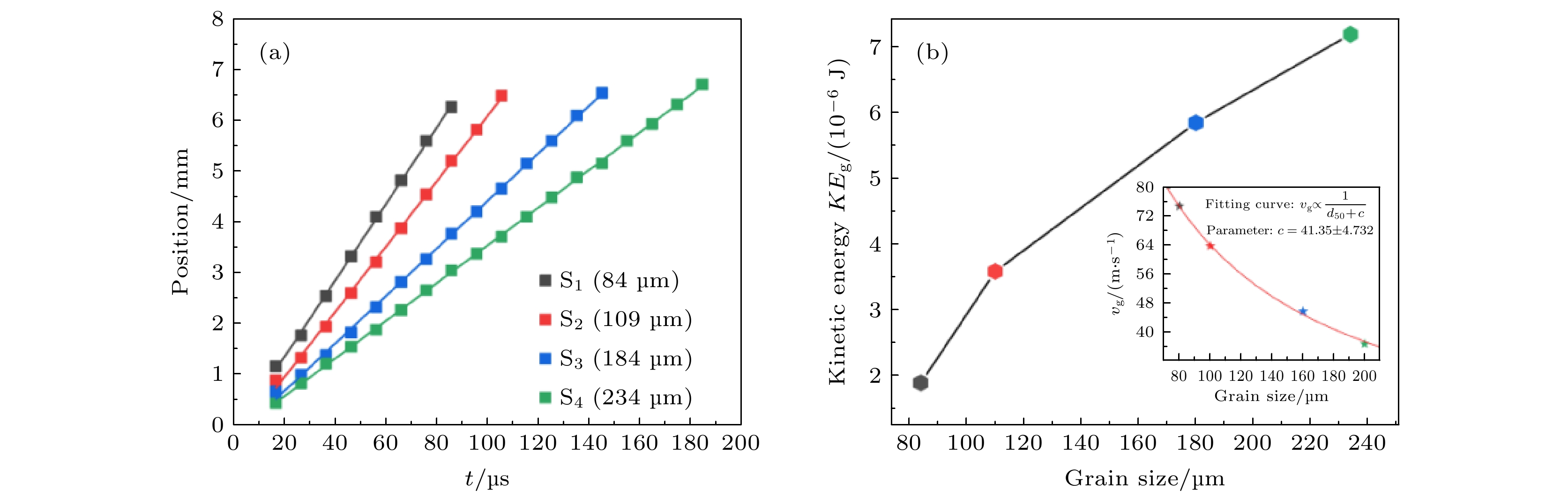

激光脉冲辐照材料靶面产生的等离子体的演化过程会对靶面施加一脉冲式冲击压. 当被辐照的靶材为离散颗粒堆积物时, 激光冲击压在靶面能够驱动颗粒发生溅射现象. 本文选用中值直径分别为84, 109, 184, 234 μm且具有窄粒径分布的干燥石英砂堆积形成离散颗粒靶, 并采用波长为1064 nm的Nd: YAG 纳秒激光脉冲与其相互作用产生的冲击压驱动石英颗粒发生溅射, 同时通过高速摄像机记录溅射过程, 研究了粒径对激光驱动颗粒溅射动力学特征的影响. 通过分析高速影像发现, 激光驱动的颗粒溅射在时间尺度上可以分为两个特征明显的过程, 即持续百微秒垂直于靶面方向的快速早期溅射过程和持续几十毫秒扇形颗粒帘结构的慢速后期溅射过程. 前者对应的颗粒出射动能呈现出了随粒径的增加而增大的趋势, 后者对应的沿径向扩张的帘底直径D随时间

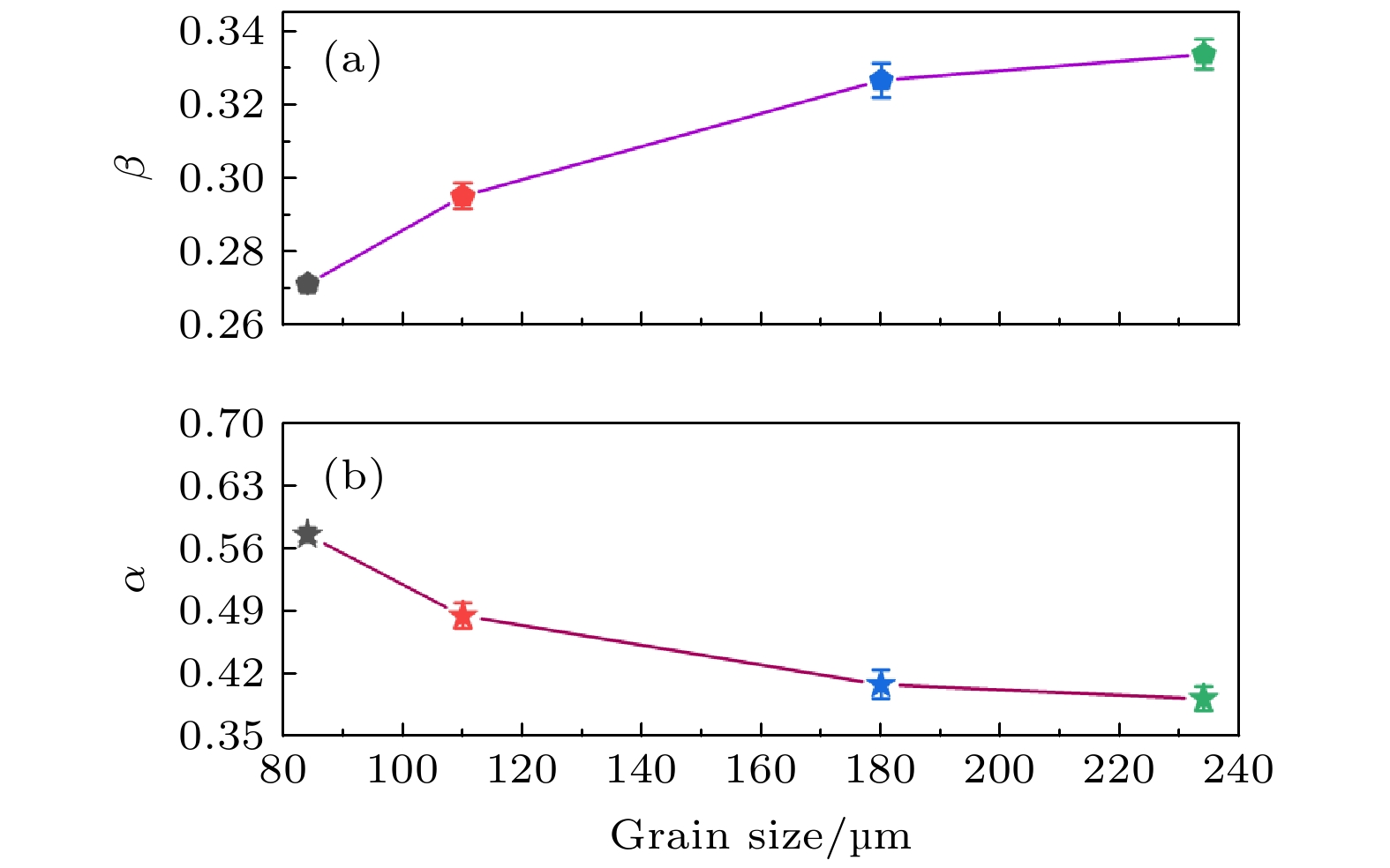

$ t $ 的演化规律遵循点源模型的描述$ : {D\left(t\right)=\alpha t}^{\beta } $ , 系数$ \mathrm{\alpha } $ 的拟合值随粒径的增加而减小, 幂指数$ \beta $ 的拟合值却呈现出了随粒径增加而增大的趋势. 通过细致考虑粒径依赖的颗粒在气流中的冲量耦合效率, 以及粒径依赖的激光与颗粒靶相互作用产生的等离子体特征, 对以上实验观察给予了合理的解释. 本研究加深了人们对激光驱动颗粒溅射机理的认识.When intense laser pulse irradiates a target surface, the energetic processes of generation and expansion of laser-induced plasma will affect a localized pressure impulse around the irradiation zone. As a result, pulsed laser ablating granular target can drive a physical phenomenon of grain ejection. In this work, taking dry glass beads with different grain sizes as an example of granular targets and using high-speed video camera, we experimentally investigate the grain-size dependent dynamics of grain ejection driven by nanosecond laser pulses. The measured video sequences clearly exhibit that the laser-driven grain ejection process can be separated into two regimes: early-stage fast ejecting process and later-stage slow ejecting process. We find that there exists an obvious grain size effect on the kinetic energy of grains in the early-stage ejecting process. In addition, the temporal evolution of transient ejection of a curtain diameter$ D\left(t\right) $ corresponding to the later-stage ejecting process obeys the well-known “point source” law,$ {D\left(t\right)=\alpha t}^{\beta } $ , where both parameters$ \alpha $ and$ \beta $ depend on grain size. The observations mentioned above can be reasonably explained by considering the grain size dependent efficiency of impulse coupling between grain and plasma flow and plasma features generated by interaction of laser pulse with granular targets. These experimental results improve the understanding of the mechanism of laser-driven grain ejection.-

Keywords:

- laser ablation /

- granular material /

- grain ejection /

- grain size

[1] Sedov L I 1946 Appl. Math. Mech. 10 241

[2] Schmidt R M, Housen K R 1987 Int. J. Impact Eng. 5 543

Google Scholar

Google Scholar

[3] Holsapple K A, Schmidt R M 1979 Lunar Planet Sci. 10 2757

[4] Holsapple K A 1980 Lunar Planet Sci. 11 2379

[5] Gault D E, Wedekind J A 1977 Experimental Hypervelocity Impact into Quartz Sand-II, Effects of Gravitational Acceleration (New York: Impact & Explosion Cratering Planetary & Terrestrial Implications Proceedings of the Symposium on Planetary Cratering Mechanics) p1231

[6] Sedov L I 1959 Similarity and Dimensional Methods in Mechanics (4th Ed.) (New York: Academic Press) p377

[7] Holsapple K A, Schmidt R M 1987 J. Geophys. Res. 92 6350

Google Scholar

Google Scholar

[8] Holsapple K A 1993 Annu. Rev. Earth Planet. Sci. 21 333

Google Scholar

Google Scholar

[9] Amanda M, Walsh, Kristi E. Holloway, Piotr Habdas, John R, de Bruyn 2003 Phys. Rev. Lett. 91 104301

Google Scholar

Google Scholar

[10] Uehara J S, Ambroso M A, Ojha R P 2003 Phys. Rev. Lett. 90 194301

Google Scholar

Google Scholar

[11] Katsuragi H, Durian D J 2007 Nat. Phys. 3 420

Google Scholar

Google Scholar

[12] Pacheco-Vazquez F, Ruiz-Suarez J C 2011 Phys. Rev. Lett. 107 218001

Google Scholar

Google Scholar

[13] Ciamarra M P, Lara A H, Lee A T, Goldman D I, Vishik I, Swinney H L 2004 Phys. Rev. Lett. 92 194301

Google Scholar

Google Scholar

[14] Lohse D, Bergmann R, Mikkelsen R, et al. 2004 Phys. Rev. Lett. 93 198003

Google Scholar

Google Scholar

[15] Nordstrom K N, Lim E, Harrington M, Losert W 2014 Phys. Rev. Lett. 112 228002

Google Scholar

Google Scholar

[16] Clark A H, Kondic L, Behringer R P 2012 Phys. Rev. Lett. 109 238302

Google Scholar

Google Scholar

[17] Satoru Y, Koji W, Norihisa O, Takafumi M 2006 Icarus 183 215

Google Scholar

Google Scholar

[18] Marston J O, Li E Q, Thoroddsen S T 2012 J. Fluid Mech. 704 5

Google Scholar

Google Scholar

[19] Boudet J F, Amarouchene Y, Kellay H 2006 Phys. Rev. Lett. 96 158001

Google Scholar

Google Scholar

[20] Deboeuf S, Gondret P, Rabaud M 2009 Phys. Rev. E 79 041306

Google Scholar

Google Scholar

[21] Benusiglio A, Quéré D, Clanet C 2014 J. Fluid Mech. 752 123

Google Scholar

Google Scholar

[22] Pacheco-Vázquez F, Tacumá A, Marston J O 2017 Phys. Rev. E 96 032904

Google Scholar

Google Scholar

[23] Gao M, Liu X, Vanin L P, Sun T P, Cheng X 2018 AIChE J. 10 16063

Google Scholar

Google Scholar

[24] Marston J O, Pacheco-Vázquez F 2019 Phys. Rev. E 99 030901

Google Scholar

Google Scholar

[25] Bilger H R, Habib T 1985 Appl. Opt. 24 686

Google Scholar

Google Scholar

[26] Goldman D I, Umbahnowar P 2008 Phys. Rev. E 77 021308

Google Scholar

Google Scholar

[27] Li X L, Li Y J, Li S T, et al. 2021 Phys. Rev. Appl. 16 024017

Google Scholar

Google Scholar

[28] Li Y J, Li X L, Li ST, Zhou MJ, Qian D B, Chen L W, Yang J, Zhang S F, Ma X W 2021 J. Anal. Atom. Spectrom. 36 1969

Google Scholar

Google Scholar

[29] Yu L Y, Lu J D, Chen W, Wu G, Shen K, Feng W 2005 Plasma Sci. Technol. 7 3041

Google Scholar

Google Scholar

-

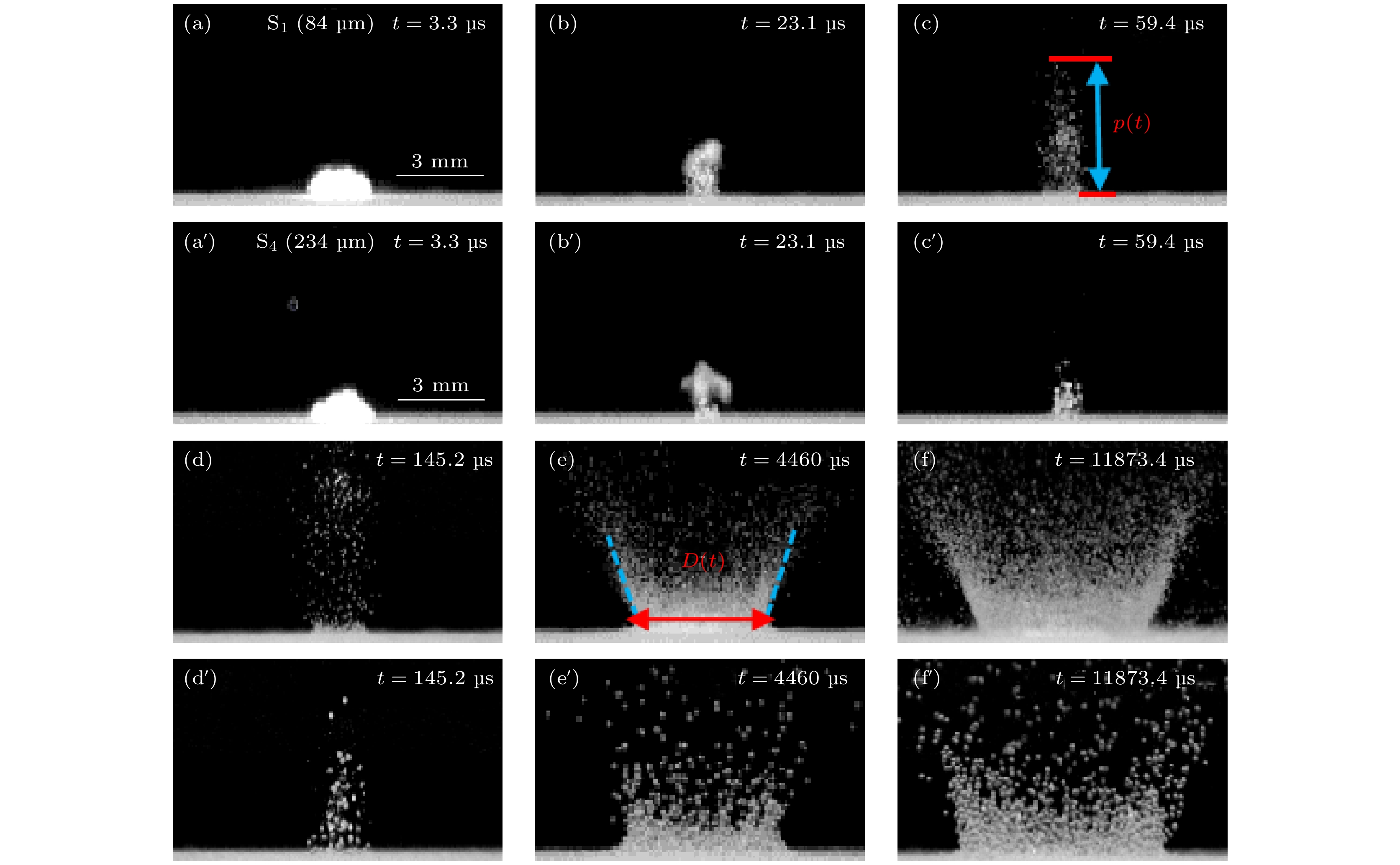

图 3 颗粒靶S1 (a)—(f)和S4 (a')—(f')对应的颗粒溅射时空影像. 图(c)中垂直于靶面的双箭头线段给出了早期颗粒溅射过程中最快颗粒位置的定义, 图(e)中平行于靶面的双箭头线段给出了对后期颗粒溅射过程中颗粒帘底直径的定义

Fig. 3. Temporal and spatial images of grain ejection corresponding to granular targets S1 (a)–(f) and S4 (a')–(f'). The definitions for the fastest gain position in the early-stage ejecting process and the ejecta curtain diameter crossponding to the later-srage ejecting process are shown in panel (c) and panel (e), respectively.

图 5 不同粒径的颗粒靶对应的后期颗粒溅射过程形成的颗粒帘底直径随时间的演化. 实线对应了采用点源模型方程

$ {D\left(t\right)=at}^{\beta } $ 拟合的结果. 插图展示了颗粒帘扩张速率随时间的演化Fig. 5. Ejecta curtain diameter corresponding to the later-stage ejecting process as a function of time. The solid lines show the fitting results with the point source model. The inset exhibits the speed of expanding ejecta curtain with time.

-

[1] Sedov L I 1946 Appl. Math. Mech. 10 241

[2] Schmidt R M, Housen K R 1987 Int. J. Impact Eng. 5 543

Google Scholar

Google Scholar

[3] Holsapple K A, Schmidt R M 1979 Lunar Planet Sci. 10 2757

[4] Holsapple K A 1980 Lunar Planet Sci. 11 2379

[5] Gault D E, Wedekind J A 1977 Experimental Hypervelocity Impact into Quartz Sand-II, Effects of Gravitational Acceleration (New York: Impact & Explosion Cratering Planetary & Terrestrial Implications Proceedings of the Symposium on Planetary Cratering Mechanics) p1231

[6] Sedov L I 1959 Similarity and Dimensional Methods in Mechanics (4th Ed.) (New York: Academic Press) p377

[7] Holsapple K A, Schmidt R M 1987 J. Geophys. Res. 92 6350

Google Scholar

Google Scholar

[8] Holsapple K A 1993 Annu. Rev. Earth Planet. Sci. 21 333

Google Scholar

Google Scholar

[9] Amanda M, Walsh, Kristi E. Holloway, Piotr Habdas, John R, de Bruyn 2003 Phys. Rev. Lett. 91 104301

Google Scholar

Google Scholar

[10] Uehara J S, Ambroso M A, Ojha R P 2003 Phys. Rev. Lett. 90 194301

Google Scholar

Google Scholar

[11] Katsuragi H, Durian D J 2007 Nat. Phys. 3 420

Google Scholar

Google Scholar

[12] Pacheco-Vazquez F, Ruiz-Suarez J C 2011 Phys. Rev. Lett. 107 218001

Google Scholar

Google Scholar

[13] Ciamarra M P, Lara A H, Lee A T, Goldman D I, Vishik I, Swinney H L 2004 Phys. Rev. Lett. 92 194301

Google Scholar

Google Scholar

[14] Lohse D, Bergmann R, Mikkelsen R, et al. 2004 Phys. Rev. Lett. 93 198003

Google Scholar

Google Scholar

[15] Nordstrom K N, Lim E, Harrington M, Losert W 2014 Phys. Rev. Lett. 112 228002

Google Scholar

Google Scholar

[16] Clark A H, Kondic L, Behringer R P 2012 Phys. Rev. Lett. 109 238302

Google Scholar

Google Scholar

[17] Satoru Y, Koji W, Norihisa O, Takafumi M 2006 Icarus 183 215

Google Scholar

Google Scholar

[18] Marston J O, Li E Q, Thoroddsen S T 2012 J. Fluid Mech. 704 5

Google Scholar

Google Scholar

[19] Boudet J F, Amarouchene Y, Kellay H 2006 Phys. Rev. Lett. 96 158001

Google Scholar

Google Scholar

[20] Deboeuf S, Gondret P, Rabaud M 2009 Phys. Rev. E 79 041306

Google Scholar

Google Scholar

[21] Benusiglio A, Quéré D, Clanet C 2014 J. Fluid Mech. 752 123

Google Scholar

Google Scholar

[22] Pacheco-Vázquez F, Tacumá A, Marston J O 2017 Phys. Rev. E 96 032904

Google Scholar

Google Scholar

[23] Gao M, Liu X, Vanin L P, Sun T P, Cheng X 2018 AIChE J. 10 16063

Google Scholar

Google Scholar

[24] Marston J O, Pacheco-Vázquez F 2019 Phys. Rev. E 99 030901

Google Scholar

Google Scholar

[25] Bilger H R, Habib T 1985 Appl. Opt. 24 686

Google Scholar

Google Scholar

[26] Goldman D I, Umbahnowar P 2008 Phys. Rev. E 77 021308

Google Scholar

Google Scholar

[27] Li X L, Li Y J, Li S T, et al. 2021 Phys. Rev. Appl. 16 024017

Google Scholar

Google Scholar

[28] Li Y J, Li X L, Li ST, Zhou MJ, Qian D B, Chen L W, Yang J, Zhang S F, Ma X W 2021 J. Anal. Atom. Spectrom. 36 1969

Google Scholar

Google Scholar

[29] Yu L Y, Lu J D, Chen W, Wu G, Shen K, Feng W 2005 Plasma Sci. Technol. 7 3041

Google Scholar

Google Scholar

计量

- 文章访问数: 6663

- PDF下载量: 73

- 被引次数: 0

下载:

下载: