-

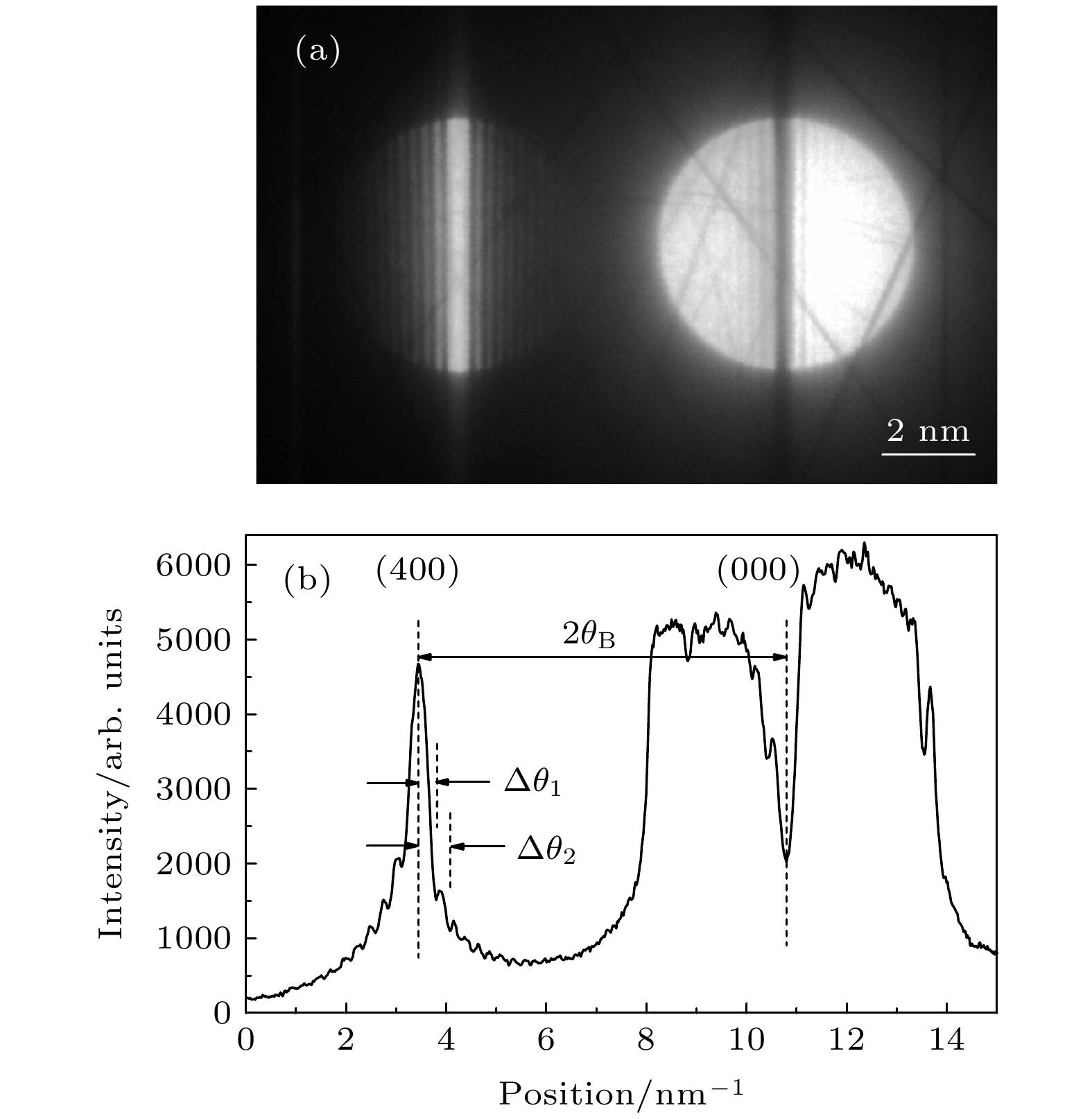

本文通过分析200 kV加速电压条件下, 单晶Si薄膜样品的透射电子显微镜(TEM)双束会聚束衍射(CBED) Kossel-Möllenstedt (K-M)花样, 测定了单晶Si薄膜样品的局部厚度和Si晶体(400)晶面的消光距离

$ {\xi }_{400} $ . 分析了影响测量不确定度的因素, 并运用一阶偏导的方法讨论了各个因素对测量不确定度的影响系数, 依据GB/T 27418-2017《测量不确定度评定与表示》对实验估计值进行了不确定度评定. 结论如下: 被测Si晶体局部厚度的实验估计值为239 nm, 其合成标准不确定度为5 nm, 相对标准不确定度为2.2%; 包含概率为0.95时, 包含因子为2.07, 扩展不确定度为11 nm; 加速电压为200 kV时, Si晶体(400)晶面的消光距离$ {\xi }_{400} $ 的实验估计值为194 nm, 合成标准不确定度为20 nm; 包含概率为0.85时, 包含因子为1.49, 扩展不确定度为30 nm. 影响试样厚度$ {t}_{0} $ 合成标准不确定度的主要因素是相机常数、加速电压和试样厚度; 影响消光距离$ \mathrm{\xi } $ 合成标准不确定度的主要因素是相机常数、加速电压和消光距离. 双束K-M花样测量数据的测量不确定度$ u\left({\Delta }{\theta }_{i}\right) $ 对消光距离不确定度的影响约是对试样厚度不确定度影响的${n}_{i}{\left( {\xi }/{t}\right)}^{3}$ ($ {n}_{i} $ 为正整数,$ {n}_{i} $ ≥1)倍, 对拟合直线斜率的不确定度的影响是对截距不确定度影响的$ {n}_{i} $ 倍. 如果试样有一定厚度, 即$ {n}_{i} $ >1, 则用TEM双束会聚束衍射K-M花样分析薄晶体厚度的不确定度较小, 而用此方法分析消光距离的不确定度较大.In this paper, the local thickness of single crystal Si film sample and the extinction distance$ {\xi }_{400} $ of the (400) plane of Si crystal are obtained by analyzing the double-beam converging beam diffraction (CBED) pattern of single crystal Si film sample under the 200 kV of accelerated voltage. The factors affecting the measurement uncertainty are analyzed, and the influence coefficients of each factor on the measurement uncertainty are discussed by using the concept of first-order partial derivative. The measurement uncertainty of thin crystal thickness and extinction distance are evaluated and expressed according to national standards GB/T 27418-2017. The conclusions are as follows. The local thickness of the measured Si crystal is estimated at 239 nm, the combined standard uncertainty is 5 nm, and the relative standard uncertainty is 2.2%. With the inclusion probability being 0.95, the coverage factor is 2.07 and the expanded uncertainty is 11 nm. With the accelerated voltage being 200 kV, the extinction distance of Si crystal (400) plane is estimated at 194 nm, the combined standard uncertainty of the extinction distance is 20 nm, and the relative standard uncertainty of the extinction distance is 10%. With the inclusion probability being 0.85, the coverage factor is 1.49 and the expanded uncertainty is 30 nm. The main factors that can affect the combined standard uncertainty of sample thickness t0 are camera constant, accelerating voltage and sample thickness, while the factors that influence the combined standard uncertainty of extinction distance are camera constant, accelerating voltage and extinction distance. The influence of the uncertainties of the measurement data of the Kossel-Möllenstedt pattern on the uncertainty of the extinction distance is${n}_{i}{\left( {\xi }/{t}\right)}^{3}$ times that on the sample thickness, and their influence on the slope of the fitting line is about$ {n}_{i} $ times that on the intercept of the line, where$ {n}_{i} $ is a positive integer and greater than or equal to 1. If the sample is not too thin, that is,$ {n}_{i} $ is greater than 1, then the uncertainty of crystal thickness will be smaller than the uncertainty of extinction distance.-

Keywords:

- convergent-beam electron diffraction /

- thickness measurement /

- extinction distance /

- uncertainty

[1] 时金安, 张庆华, 谷林 2017 电子显微学报 36 18

Google Scholar

Google Scholar

Shi J A, Zhang Q H, Gu L 2017 J. Chin. Electron Microsc. Soc. 36 18

Google Scholar

Google Scholar

[2] Heo Y U 2020 Appl. Microsc. 50 325

[3] 刘玉, 赵东山, 聂鑫, 陶红玉, 王建波, 桂嘉年 2012 电子显微学报 31 130

Google Scholar

Google Scholar

Liu Y, Zhao D S, Nie X, Tao H Y, Wang J B, Gui J N 2012 J. Chin. Electron Microsc. Soc. 31 130

Google Scholar

Google Scholar

[4] 娄艳芝 2021 电子显微学报 40 234

Lou Y Z 2021 J. Chin. Electron Microsc. Soc. 40 234

[5] Castro Riglos M V, Tolley A 2007 Appl. Surf. Sci. 254 420

Google Scholar

Google Scholar

[6] Zhu J, Tan P K, Tan H, Wang D D, Mai Z H 2015 J. Vac. Sci. Technol. , B 33 052209

Google Scholar

Google Scholar

[7] Delille D, Pantel R, Van Cappellen E 2001 Ultramicroscopy 87 5

Google Scholar

Google Scholar

[8] Spence J C H, Zuo J M 1992 Electron Microdiffraction (New York: Plenum Press) p86

[9] GB/T 20724-2021 微束分析薄晶体厚度的会聚束电子衍射测定方法

GB/T 20724-2021 Microbeam analysis—Method of Thickness Measurement for Thin Crystals by Convergent Beam Electron Diffraction (in Chinese)

[10] 叶恒强, 王元明 2003 (北京: 科学出版社) 第22页

Ye H Q, Wang Y M 2003 Progress on Transmission Electron Microscope (Beijing: Science Press) p22 (in Chinese)

[11] GB/T 27418-2017 测量不确定度评定与表示 第48, 49页

GB/T 27418-2017 Guide to the Evaluation and Expression of Uncertainty in Measurement pp48, 49 (in Chinese)

[12] JJF1059.1-2012 测量不确定度评定与表示 第19页

JJF1059.1-2012 Evaluation and Expression of Uncertainty in Measurement p19 (in Chinese)

[13] 赫什P, 豪伊·A, 尼科尔森R B, 帕施利D W, 惠兰M J 著 (刘安生, 李永洪 译)1983 薄晶体电子显微学 (北京: 科学出版社) 第111页

Hirsch P, Howie A, Nicholson R B, Pashley D W, Whelan M J (translated by Liu A S, Li Y H) 1983 Electron microscopy of thin crystals (Beijing: Science Press) p111 (in Chinese)

[14] Fultz B, Howe J 2008 Transmission Electron Microscopy and Diffractometry of Materials (New York: Springer Press) p237

[15] Vainshtein B K 1964 Structure Analysis by Electron Diffraction (York: Pergamon Press) p16

[16] Egerton R F 2016 Physical Principles of Electron microscopy (New York: Springer Press) p101

[17] Williams D B, Carter C B 2009 Transmission Electron Microscopy: A Textbook for Materials Science (New York: Springer Press) p14

[18] Zuo J M, Spence J C H 2017 Advanced Transission Electron Microscopy: Imaging and Diffraction in Anoscience (New York: Springer Press) p2

[19] 柳得橹, 权茂华, 吴杏芳 2018 电子显微分析实用方法 (北京: 中国质检出版社, 中国标准出版社) 第288—292页

Liu D L, Quan M H, Wu X F 2018 Practial Methods of Electron Microscopic Analysis (Beijing: China Quality and Standards Press) pp288–292 (in Chinese)

[20] 赫什P, 豪伊A, 尼科尔森R B, 帕施利D W, 惠兰M J 著 (刘安生, 李永洪 译) 1983 薄晶体电子显微学 (北京: 科学出版社) 第568—579页

Hirsch P, Howie A, Nicholson R B, Pashley D W, Whelan M J (translated by Liu A S, Li Y H) 1983 Electron Microscopy of Thin Crystals (Beijing: Science Press) pp568–579 (in Chinese)

-

表 1 K-M花样测量数据

Table 1. K-M pattern measurement data.

$ Z $ Data 1

/nm–1Data 2

/nm–1Data 3

/nm–1Ave.

/nm–1$ u\left(Z\right) $/nm–1 R 7.336 7.336 7.318 7.330 0.006 Δθ1 0.361 0.342 0.343 0.349 0.006 Δθ2 0.631 0.613 0.595 0.613 0.010 Δθ3 0.829 0.831 0.847 0.836 0.006 Δθ4 1.101 1.082 1.045 1.076 0.016 Δθ5 1.299 1.334 1.298 1.310 0.012 Δθ6 1.516 1.532 1.569 1.539 0.016 Δθ7 1.750 1.766 1.785 1.767 0.010 Δθ8 2.001 2.019 1.949 1.990 0.021 表 2 K-M花样测量结果的数据分析

Table 2. Data analysis of K-M pattern measurement results.

i $ {n}_{i} $ $ {n}_{i}^{-2} $ 数据1 数据2 数据3 平均值 $ {\mathit{s}}_{i} $

/nm–1$ {\left({\mathit{s}}_{i}/{n}_{i}\right)}^{2} $

/(10–5 nm–2)$ {\mathit{s}}_{i} $

/nm–1$ {\left({\mathit{s}}_{i}/{n}_{i}\right)}^{2} $

/(10–5 nm–2)$ {\mathit{s}}_{i} $

/nm–1$ {\left({\mathit{s}}_{i}/{n}_{i}\right)}^{2} $

/(10–5 nm–2)$\bar{s}_i$

/nm–1$(\bar{s}_i/n_i)^2$

/(10–5 nm–2)1 2 0.2500 0.0067 1.1239 0.0064 1.0087 0.0064 1.0146 0.0065 1.0484 2 3 0.1111 0.0117 1.5262 0.0114 1.4403 0.0111 1.3570 0.0114 1.4403 3 4 0.0625 0.0154 1.4817 0.0154 1.4889 0.0157 1.5468 0.0155 1.5057 4 5 0.040 0.0204 1.6727 0.0201 1.6155 0.0194 1.5069 0.0200 1.5976 5 6 0.0278 0.0241 1.6170 0.0248 1.7053 0.0241 1.6145 0.0243 1.6453 6 7 0.0204 0.0282 1.6180 0.0285 1.6524 0.0291 1.7331 0.0286 1.6675 7 8 0.0156 0.0325 1.6507 0.0328 1.6811 0.0332 1.7174 0.0328 1.6830 8 9 0.0123 0.0372 1.7053 0.0375 1.7361 0.0362 1.6178 0.0370 1.6860 表 3 直线拟合数据及相关分析结果

Table 3. Line fitting data and related analysis results.

$ k $

/(10–7 nm–2)$ u\left(k\right) $

/(10–7 nm–2)$ {\xi }_{400} $

/nm$ u\left({\xi }_{400}\right) $

/nmb

/(10–7 nm–2)$ u\left(b\right) $

/(10–7 nm–2)t

/nm$ u\left(t\right) $

/nm$ {t}_{0} $

/nm$ u\left({t}_{0}\right) $

/nm–266.105 9.703 194 3.534 171.376 0.982 242 0.692 239 0.685 表 4 薄晶体厚度的合成标准不确定度分析过程数据

Table 4. Combined standard uncertainty analysis process data of thin crystal thickness.

i $ {n}_{i} $ $ {\Delta }{\theta }_{i} $ $ \dfrac{\partial {t}_{0}}{\partial \xi } $ $ {\left[\dfrac{\partial {t}_{0}}{\partial \xi }\right]}^{2}{u}^{2}\left(\xi \right) $

/nm2$ \dfrac{\partial {t}_{0}}{\partial k} $

/(105 nm3)$ {\left[\dfrac{\partial {t}_{0}}{\partial k}\right]}^{2}{u}^{2}\left(k\right) $

/nm2$ \dfrac{\partial {t}_{0}}{\partial {\Delta }{\theta }_{i}} $

/(102 nm2)$ {\left[\dfrac{\partial {t}_{0}}{\partial {\Delta }{\theta }_{i}}\right]}^{2}{u}^{2}\left({\Delta }{\theta }_{i}\right) $

/nm2$ \dfrac{\partial {t}_{0}}{\partial {R}_{hkl}} $

/nm2$ {\left[\dfrac{\partial {t}_{0}}{\partial {R}_{hkl}}\right]}^{2}{u}^{2}\left({R}_{hkl}\right) $

/nm21 2 0.349 0.4789 2.865 17.445 2.865 –8.383 26.848 39.92 0.057 2 3 0.613 0.2129 0.566 7.753 0.566 –9.838 104.519 82.27 0.244 3 4 0.836 0.1197 0.179 4.361 0.179 –10.058 32.823 114.67 0.473 4 5 1.076 0.0766 0.073 2.791 0.073 –10.361 290.186 152.09 0.833 5 6 1.310 0.0532 0.035 1.938 0.035 –10.514 154.891 187.96 1.272 6 7 1.539 0.0391 0.019 1.424 0.019 –10.585 275.992 222.24 1.778 7 8 1.767 0.0299 0.011 1.090 0.011 –10.634 115.718 256.35 2.366 8 9 1.990 0.0237 0.007 0.861 0.007 –10.644 498.953 288.91 3.005 表 5 消光距离的合成标准不确定度分析过程数据

Table 5. Combined standard uncertainty analysis process data of extinction distance.

i $ {n}_{i} $ $ {\Delta }{\theta }_{i} $ $ \dfrac{\partial \xi }{\partial t} $ $ {\left[\dfrac{\partial \xi }{\partial t}\right]}^{2}{u}^{2}\left(t\right) $

/nm2$ \dfrac{\partial \xi }{\partial b} $

/(107 nm3)$ {\left[\dfrac{\partial \xi }{\partial b}\right]}^{2}{u}^{2}\left(b\right) $

/nm2$ \dfrac{\partial \xi }{\partial {\Delta }{\theta }_{i}} $

/(102 nm2)${\left[\dfrac{\partial \xi }{\partial {\Delta }{\theta }_{i} }\right]}^{2}{u}^{2} ({ {\Delta }{\bar\theta }_{i} } )$

/(102 nm2)$ \dfrac{\partial \xi }{\partial {R}_{hkl}} $

/(102 nm2)${\left[\dfrac{\partial \xi }{\partial {R}_{hkl} }\right]}^{2}{u}^{2}\left({\bar {R}_{hkl} }\right)$

/nm21 2 0.349 2.067 2.047 –1.457 2.047 –8.762 0.293 –0.417 0.063 2 3 0.613 4.651 10.363 –3.278 10.363 –15.405 2.563 –1.289 0.598 3 4 0.836 8.269 32.752 –5.828 32.752 –21.001 1.431 –2.394 2.064 4 5 1.076 12.921 79.962 –9.106 79.962 –27.041 19.767 –3.969 5.672 5 6 1.310 18.606 165.809 –13.113 165.809 –32.929 15.193 –5.887 12.475 6 7 1.539 25.325 307.182 –17.848 307.182 –38.676 36.847 –8.120 23.738 7 8 1.767 33.077 524.039 –23.312 524.039 –44.406 20.179 –10.705 41.252 8 9 1.990 41.863 839.410 –29.504 839.410 –50.001 110.117 –13.573 66.316 -

[1] 时金安, 张庆华, 谷林 2017 电子显微学报 36 18

Google Scholar

Google Scholar

Shi J A, Zhang Q H, Gu L 2017 J. Chin. Electron Microsc. Soc. 36 18

Google Scholar

Google Scholar

[2] Heo Y U 2020 Appl. Microsc. 50 325

[3] 刘玉, 赵东山, 聂鑫, 陶红玉, 王建波, 桂嘉年 2012 电子显微学报 31 130

Google Scholar

Google Scholar

Liu Y, Zhao D S, Nie X, Tao H Y, Wang J B, Gui J N 2012 J. Chin. Electron Microsc. Soc. 31 130

Google Scholar

Google Scholar

[4] 娄艳芝 2021 电子显微学报 40 234

Lou Y Z 2021 J. Chin. Electron Microsc. Soc. 40 234

[5] Castro Riglos M V, Tolley A 2007 Appl. Surf. Sci. 254 420

Google Scholar

Google Scholar

[6] Zhu J, Tan P K, Tan H, Wang D D, Mai Z H 2015 J. Vac. Sci. Technol. , B 33 052209

Google Scholar

Google Scholar

[7] Delille D, Pantel R, Van Cappellen E 2001 Ultramicroscopy 87 5

Google Scholar

Google Scholar

[8] Spence J C H, Zuo J M 1992 Electron Microdiffraction (New York: Plenum Press) p86

[9] GB/T 20724-2021 微束分析薄晶体厚度的会聚束电子衍射测定方法

GB/T 20724-2021 Microbeam analysis—Method of Thickness Measurement for Thin Crystals by Convergent Beam Electron Diffraction (in Chinese)

[10] 叶恒强, 王元明 2003 (北京: 科学出版社) 第22页

Ye H Q, Wang Y M 2003 Progress on Transmission Electron Microscope (Beijing: Science Press) p22 (in Chinese)

[11] GB/T 27418-2017 测量不确定度评定与表示 第48, 49页

GB/T 27418-2017 Guide to the Evaluation and Expression of Uncertainty in Measurement pp48, 49 (in Chinese)

[12] JJF1059.1-2012 测量不确定度评定与表示 第19页

JJF1059.1-2012 Evaluation and Expression of Uncertainty in Measurement p19 (in Chinese)

[13] 赫什P, 豪伊·A, 尼科尔森R B, 帕施利D W, 惠兰M J 著 (刘安生, 李永洪 译)1983 薄晶体电子显微学 (北京: 科学出版社) 第111页

Hirsch P, Howie A, Nicholson R B, Pashley D W, Whelan M J (translated by Liu A S, Li Y H) 1983 Electron microscopy of thin crystals (Beijing: Science Press) p111 (in Chinese)

[14] Fultz B, Howe J 2008 Transmission Electron Microscopy and Diffractometry of Materials (New York: Springer Press) p237

[15] Vainshtein B K 1964 Structure Analysis by Electron Diffraction (York: Pergamon Press) p16

[16] Egerton R F 2016 Physical Principles of Electron microscopy (New York: Springer Press) p101

[17] Williams D B, Carter C B 2009 Transmission Electron Microscopy: A Textbook for Materials Science (New York: Springer Press) p14

[18] Zuo J M, Spence J C H 2017 Advanced Transission Electron Microscopy: Imaging and Diffraction in Anoscience (New York: Springer Press) p2

[19] 柳得橹, 权茂华, 吴杏芳 2018 电子显微分析实用方法 (北京: 中国质检出版社, 中国标准出版社) 第288—292页

Liu D L, Quan M H, Wu X F 2018 Practial Methods of Electron Microscopic Analysis (Beijing: China Quality and Standards Press) pp288–292 (in Chinese)

[20] 赫什P, 豪伊A, 尼科尔森R B, 帕施利D W, 惠兰M J 著 (刘安生, 李永洪 译) 1983 薄晶体电子显微学 (北京: 科学出版社) 第568—579页

Hirsch P, Howie A, Nicholson R B, Pashley D W, Whelan M J (translated by Liu A S, Li Y H) 1983 Electron Microscopy of Thin Crystals (Beijing: Science Press) pp568–579 (in Chinese)

计量

- 文章访问数: 6542

- PDF下载量: 82

- 被引次数: 0

下载:

下载: