-

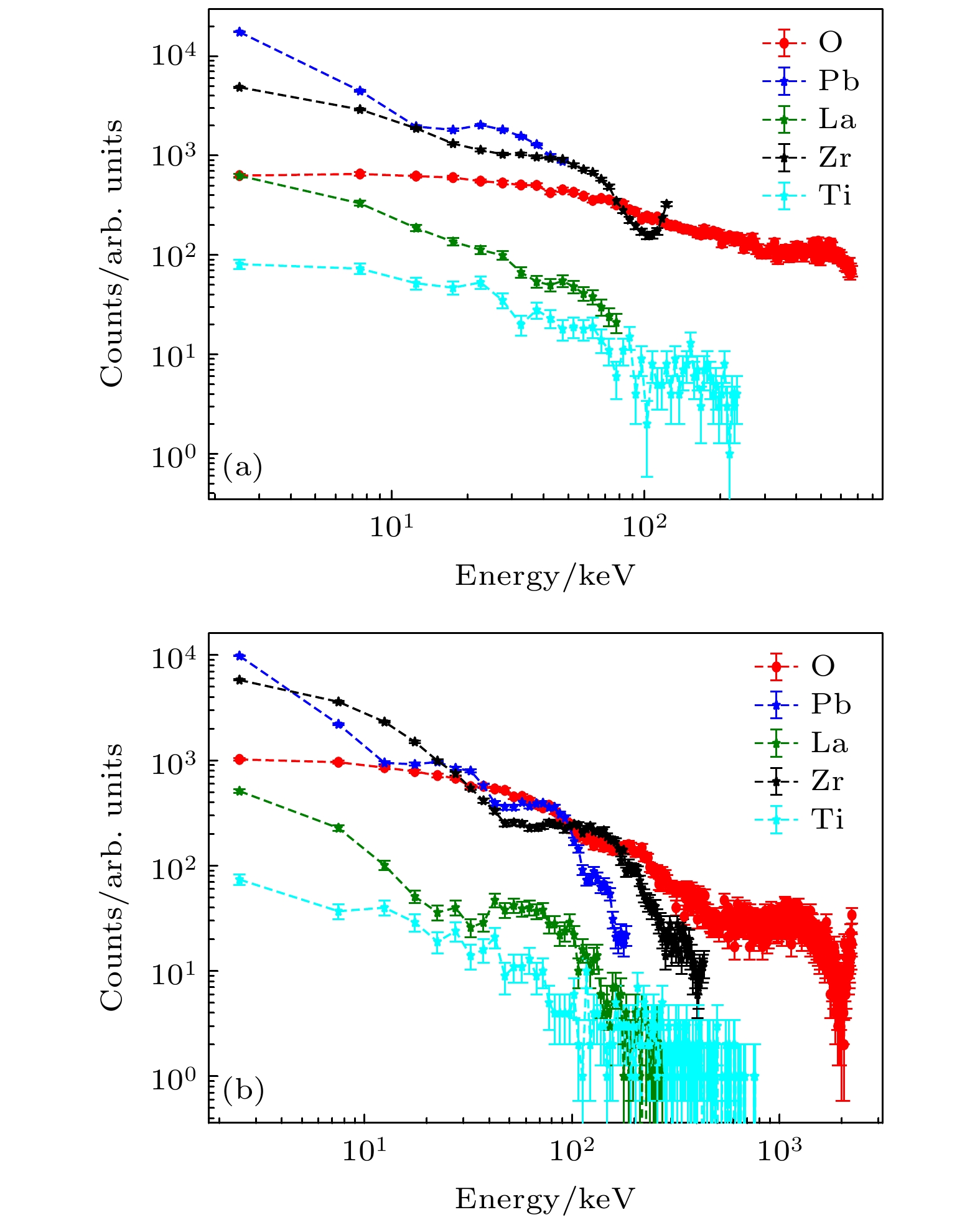

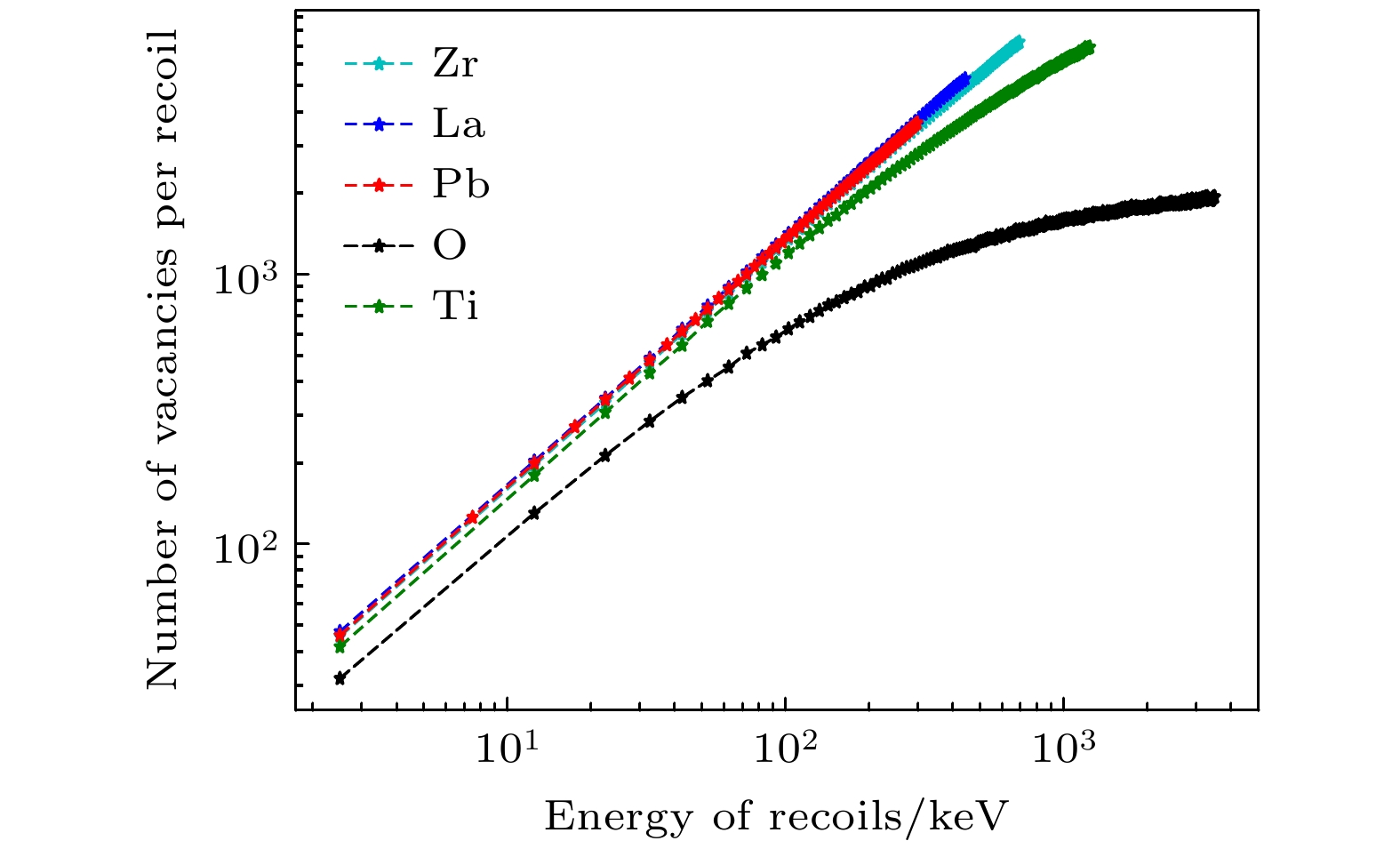

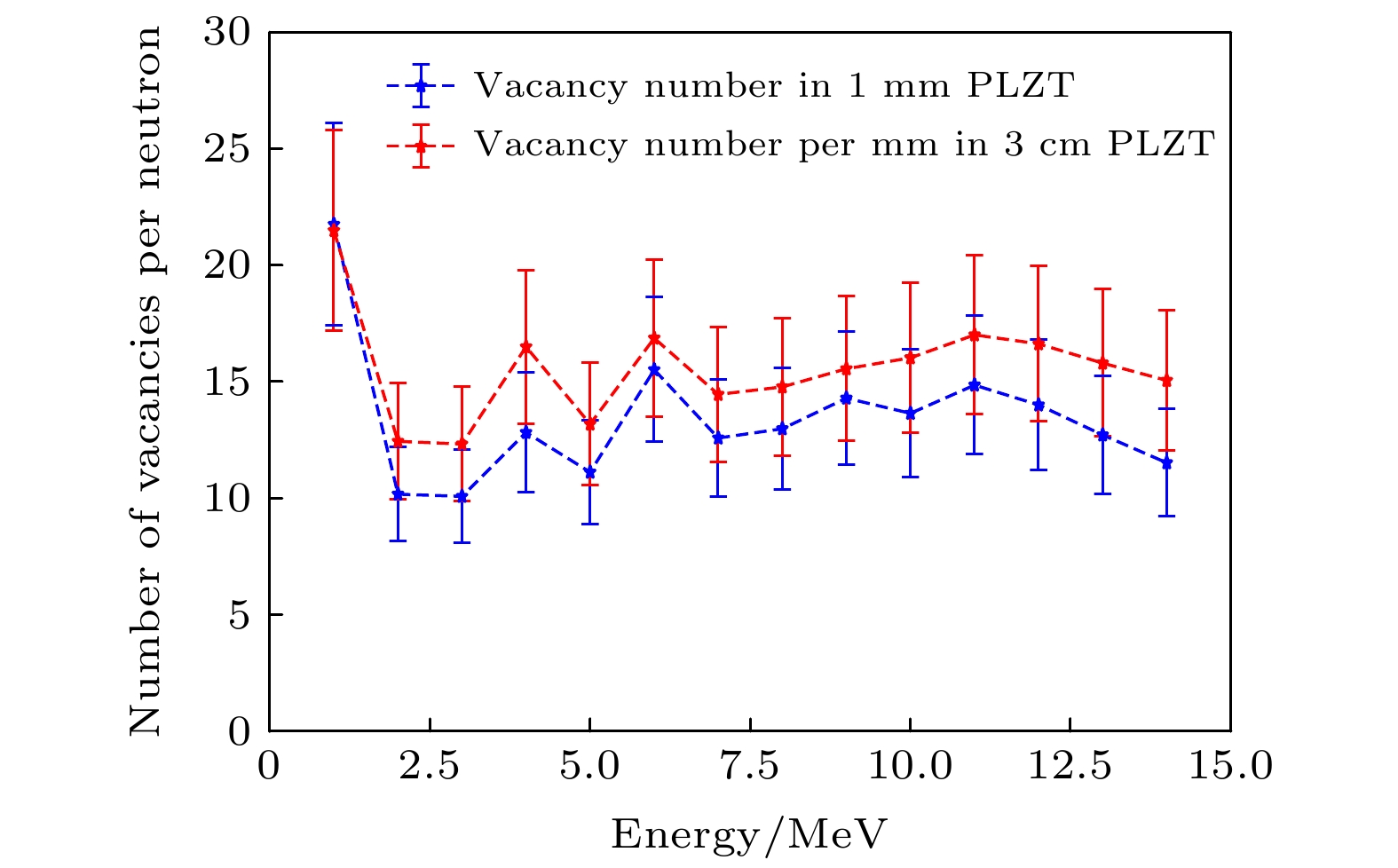

锆钛酸铅镧(Pb0.94La0.06Zr0.96Ti0.04O3, PLZT)具有良好的介电和储能性质, 是高效、高能量密度电容元件和存储器件的基体材料. 为研究该材料的中子辐照损伤, 首先基于Geant4程序包模拟了能量为1—14 MeV中子辐照锆钛酸铅镧(PLZT)材料产生的反冲原子能谱, 然后根据产生的反冲原子种类和最大能量, 利用二元碰撞方法模拟了不同能量的离子在PLZT中产生的位移损伤(包括空位和间隙原子), 最后根据反冲原子能谱和对应能量离子在材料中产生的缺陷数目计算了不同能量的中子在PLZT材料中产生缺陷浓度以及分布. 结果发现, 对于1—14 MeV能区的快中子而言, 其在厚度为3 cm的PLZT材料中产生的缺陷数目近似与中子能量无关, 约为460 ± 120 空位/中子. 辐照损伤在3 cm厚度内随深度的增加而略有减小, 总体变化小于50%, 该减小主要是由于中子的反散射导致. 本工作为计算中子在材料中的位移损伤提供了一种方法, 同时模拟结果可为研究PLZT基电子器件的中子辐照效应提供指导.Lead lanthanum zirconate titanate (PLZT) has a broad application prospect for energy storage devices with high energy density, since it possesses excellent dielectric and energy storage properties. To investigate the irradiation damage to the PLZT induced by neutrons with different energy, the primary energetic recoil spectra of each kind of element are first extracted from the transportation simulations of neutrons with energy ranging from 1 to 14 MeV, respectively. Then, the displacement damages (including vacancies and interstitial atoms) induced by each type of recoil with different energy are simulated based on the binary collision approximation method. Finally the number of defects in PLZT produced by neutrons with an energy range from 1 to 14 MeV is calculated based on the recoil energy spectra and the defect number produced by the recoils. The results show that the number of defects produced in the PLZT material with a thickness of 3 cm is approximately independent of the neutron energy for the fast neutrons with energy in a range from 1 to 14 MeV, even though the primary recoil energy spectra from neutrons with different energy are completely different. The average number of defects produced in 3-cm-thick PLZT is about 460 ± 120 vacancies/neutrons. For neutrons with energy ranging from 1 to 14 MeV, the produced defect concentration in PLZT decreases slightly with the depth increasing within a thickness of 3 cm. The difference in defect concentration in this 3 cm is in a range of 50%. This decrease is caused mainly by the fact that some of neutrons are back-scattered during transport. The average defect concentration produced by neutron irradiation in the PLZT with a thickness of 3 cm is slightly(~20%) higher than that in the PLZT with a thickness of 1 mm. The reason for the higher defect concentration in a thicker (3 cm) PLZT can be attributed to the following facts: (i) the (n, 2n) reactions between neutron and material can make the number of neutrons increase during transport; (ii) the scattering can make the path of neutron longer; (iii) the inelastic scattering can lead to a smallnumber of moderated neutrons, which have a slightly larger interaction cross section with materials. This indicates the damage produced in thick PLZT is quite complicated and closely related to the process of neutron transport. This work presents a method of calculating the displacement damage of neutrons in materials, and the simulation results can provide guidance for studying the neutron irradiation effects of PLZT-based electronic devices.

-

Keywords:

- lead lanthanum zirconate titanate /

- Monte Carlo simulations /

- neutron radiation damage /

- concentration of defects

[1] 谢飞, 臧航, 刘方, 何欢, 廖文龙, 黄煜 2020 69 192401

Google Scholar

Google Scholar

Xie F, Zang H, Liu F, He H, Liao W L, Huang Y 2020 Acta Phys. Sin. 69 192401

Google Scholar

Google Scholar

[2] Hazdra P, Záhlava V, Vobecký J 2014 Nucl. Instrum. Methods Phys. Res., Sect. B 327 124

Google Scholar

Google Scholar

[3] Sharma R K, Hazdra P, Popelka S 2015 IEEE Trans. Nucl. Sci. 62 534

Google Scholar

Google Scholar

[4] Rauls M B, Dong W, Huber J E, Lynch C S 2011 Acta Mater. 59 2713

Google Scholar

Google Scholar

[5] Kumar A, Prasad V V B, Raju K C J, James A R 2016 J. Alloys Compd. 654 95

Google Scholar

Google Scholar

[6] He H, Tan X 2007 J. Am. Ceram. Soc. 90 2090

Google Scholar

Google Scholar

[7] Hao X, Zhai J, Kong L B, Xu Z 2014 Prog. Mater. Sci. 63 1

Google Scholar

Google Scholar

[8] Haertling G H, Land C E 1971 J. Am. Ceram. Soc. 54 1

[9] Sternberg A, Krumina A, Sprogis A, Rubulis A, Grinvalds G, Shebanov L, Weber H W, Klima H, Schwabl H, Dindun S, Ulmanis U 1992 Ferroelectrics 126 233

Google Scholar

Google Scholar

[10] Bittner R, Humer K, Weber H W, Cakare L, Sternberg A, Lesnyh D. A, Kulikov D V, Trushin Y V 2002 Integr. Ferroelectr. 47 143

Google Scholar

Google Scholar

[11] Kulikov D V, Trushin Y V, Kharlamov V S, Bittner R, Schmidt A A 2000 Proc. SPIE 4348 264

[12] Sternberg A, Kundzins K, Zauls V, Aulika I, Akare L, Bittner R, Weber H, Humer K, Lesnyh D, Kulikov D 2004 J. Eur. Ceram. Soc. 24 1653

Google Scholar

Google Scholar

[13] Nordlund K, Zinkle S J, Sand A E, Granberg F, Averback R S, Stoller R E, Suzudo T, Malerba L, Banhart F, Weber W J, Willaime F, Dudarev S L, Simeone D 2018 J. Nucl. Mater. 512 450

Google Scholar

Google Scholar

[14] Nordlund K 2019 J. Nucl. Mater. 520 273

Google Scholar

Google Scholar

[15] Robinson M T, Torrens I M 1974 Phys. Rev. B 9 5008

Google Scholar

Google Scholar

[16] Zhang S, Nordlund K, Djurabekova F, Granberg F, Zhang Y, Wang T S 2017 Mater. Res. Lett. 5 433

Google Scholar

Google Scholar

[17] Djurabekova F G, Pugacheva T S, Umarov F F, Yugay S V 2000 International Conference on Ion Implantation Technology Proceedings. Ion Implantation Technology-2000 (Cat. No. 00EX432), 17–22 Sept. 2000 228

[18] Zhang S, Wang B W, Zhang L M, Liu N, Wang T S, Duan B H, Xu X G 2021 J. Phys. D:Appl. Phys. 54 245104

Google Scholar

Google Scholar

[19] Zhang S, Nordlund K, Djurabekova F, Zhang Y, Velisa G, Wang T S 2016 Phys. Rev. E 94 043319

Google Scholar

Google Scholar

[20] Zhang S, Pakarinen O H, Backholm M, Djurabekova F, Nordlund K, Keinonen J, Wang T S 2017 J. Phys.: Condens. Matter. 30 015403

[21] Bukonte L, Djurabekova F, Samela J, Nordlund K, Norris S A, Aziz M J 2013 Nucl. Instrum. Methods Phys. Res., Sect. B 297 23

Google Scholar

Google Scholar

[22] Klaver T P C, Zhang S, Nordlund K 2017 J. Nucl. Mater. 492 113

Google Scholar

Google Scholar

[23] Agostinelli S, Allison J, Amako K, et al. 2003 Nucl. Instrum. Methods Phys. Res. Sect. A 506 250

Google Scholar

Google Scholar

[24] Allison J, Amako K, Apostolakis J, et al. 2016 Nucl. Instrum. Methods Phys. Res., Sect. A 835 186

Google Scholar

Google Scholar

[25] Allison J, Amako K, Apostolakis J, et al. 2006 IEEE Trans. Nucl. Sci. 53 270

Google Scholar

Google Scholar

[26] Nuclear Energy Agency http://www.oecd-nea.org/dbdata/jeff/jeff33/

[27] Mendoza E, Cano-Ott D, Koi T, Guerrero C 2014 IEEE Trans. Nucl. Sci. 61 2357

Google Scholar

Google Scholar

[28] J. F. Ziegler, J. P. Biersack, Littmark U 1985 The Stopping and Range of Ions in Matter (Pergamon, New York: Pergamon Press)

[29] Ziegler J F http://www.srim.org/

[30] Chadwick M B, Herman M, Obložinský P, et al. 2011 Nucl. Data Sheets 112 2887

Google Scholar

Google Scholar

-

图 4 1—14 MeV中子辐照3 cm厚PLZT材料产生的反冲原子数目(对应左侧Y轴的红色点线)和未与材料发生作用的中子数目(对应右侧Y轴的蓝色点线)

Fig. 4. Number of recoils (corresponding to the red dotted line and the left Y-axis) and the number of neutrons without interaction(corresponding to the blue dotted line and the right Y-axis) during irradiation of neutrons with energies from 1 to 14 MeVin PLZT with a thickness of 3 cm.

-

[1] 谢飞, 臧航, 刘方, 何欢, 廖文龙, 黄煜 2020 69 192401

Google Scholar

Google Scholar

Xie F, Zang H, Liu F, He H, Liao W L, Huang Y 2020 Acta Phys. Sin. 69 192401

Google Scholar

Google Scholar

[2] Hazdra P, Záhlava V, Vobecký J 2014 Nucl. Instrum. Methods Phys. Res., Sect. B 327 124

Google Scholar

Google Scholar

[3] Sharma R K, Hazdra P, Popelka S 2015 IEEE Trans. Nucl. Sci. 62 534

Google Scholar

Google Scholar

[4] Rauls M B, Dong W, Huber J E, Lynch C S 2011 Acta Mater. 59 2713

Google Scholar

Google Scholar

[5] Kumar A, Prasad V V B, Raju K C J, James A R 2016 J. Alloys Compd. 654 95

Google Scholar

Google Scholar

[6] He H, Tan X 2007 J. Am. Ceram. Soc. 90 2090

Google Scholar

Google Scholar

[7] Hao X, Zhai J, Kong L B, Xu Z 2014 Prog. Mater. Sci. 63 1

Google Scholar

Google Scholar

[8] Haertling G H, Land C E 1971 J. Am. Ceram. Soc. 54 1

[9] Sternberg A, Krumina A, Sprogis A, Rubulis A, Grinvalds G, Shebanov L, Weber H W, Klima H, Schwabl H, Dindun S, Ulmanis U 1992 Ferroelectrics 126 233

Google Scholar

Google Scholar

[10] Bittner R, Humer K, Weber H W, Cakare L, Sternberg A, Lesnyh D. A, Kulikov D V, Trushin Y V 2002 Integr. Ferroelectr. 47 143

Google Scholar

Google Scholar

[11] Kulikov D V, Trushin Y V, Kharlamov V S, Bittner R, Schmidt A A 2000 Proc. SPIE 4348 264

[12] Sternberg A, Kundzins K, Zauls V, Aulika I, Akare L, Bittner R, Weber H, Humer K, Lesnyh D, Kulikov D 2004 J. Eur. Ceram. Soc. 24 1653

Google Scholar

Google Scholar

[13] Nordlund K, Zinkle S J, Sand A E, Granberg F, Averback R S, Stoller R E, Suzudo T, Malerba L, Banhart F, Weber W J, Willaime F, Dudarev S L, Simeone D 2018 J. Nucl. Mater. 512 450

Google Scholar

Google Scholar

[14] Nordlund K 2019 J. Nucl. Mater. 520 273

Google Scholar

Google Scholar

[15] Robinson M T, Torrens I M 1974 Phys. Rev. B 9 5008

Google Scholar

Google Scholar

[16] Zhang S, Nordlund K, Djurabekova F, Granberg F, Zhang Y, Wang T S 2017 Mater. Res. Lett. 5 433

Google Scholar

Google Scholar

[17] Djurabekova F G, Pugacheva T S, Umarov F F, Yugay S V 2000 International Conference on Ion Implantation Technology Proceedings. Ion Implantation Technology-2000 (Cat. No. 00EX432), 17–22 Sept. 2000 228

[18] Zhang S, Wang B W, Zhang L M, Liu N, Wang T S, Duan B H, Xu X G 2021 J. Phys. D:Appl. Phys. 54 245104

Google Scholar

Google Scholar

[19] Zhang S, Nordlund K, Djurabekova F, Zhang Y, Velisa G, Wang T S 2016 Phys. Rev. E 94 043319

Google Scholar

Google Scholar

[20] Zhang S, Pakarinen O H, Backholm M, Djurabekova F, Nordlund K, Keinonen J, Wang T S 2017 J. Phys.: Condens. Matter. 30 015403

[21] Bukonte L, Djurabekova F, Samela J, Nordlund K, Norris S A, Aziz M J 2013 Nucl. Instrum. Methods Phys. Res., Sect. B 297 23

Google Scholar

Google Scholar

[22] Klaver T P C, Zhang S, Nordlund K 2017 J. Nucl. Mater. 492 113

Google Scholar

Google Scholar

[23] Agostinelli S, Allison J, Amako K, et al. 2003 Nucl. Instrum. Methods Phys. Res. Sect. A 506 250

Google Scholar

Google Scholar

[24] Allison J, Amako K, Apostolakis J, et al. 2016 Nucl. Instrum. Methods Phys. Res., Sect. A 835 186

Google Scholar

Google Scholar

[25] Allison J, Amako K, Apostolakis J, et al. 2006 IEEE Trans. Nucl. Sci. 53 270

Google Scholar

Google Scholar

[26] Nuclear Energy Agency http://www.oecd-nea.org/dbdata/jeff/jeff33/

[27] Mendoza E, Cano-Ott D, Koi T, Guerrero C 2014 IEEE Trans. Nucl. Sci. 61 2357

Google Scholar

Google Scholar

[28] J. F. Ziegler, J. P. Biersack, Littmark U 1985 The Stopping and Range of Ions in Matter (Pergamon, New York: Pergamon Press)

[29] Ziegler J F http://www.srim.org/

[30] Chadwick M B, Herman M, Obložinský P, et al. 2011 Nucl. Data Sheets 112 2887

Google Scholar

Google Scholar

计量

- 文章访问数: 5436

- PDF下载量: 98

- 被引次数: 0

下载:

下载: