-

流动隐身衣因为可以显著降低指定目标的表面阻力而备受关注. 然而大多数传统流动隐身衣的设计参数为非均匀各向异性, 非均匀这一限制增加了制备流动隐身衣的难度. 为突破这种限制, 本文采用等效介质理论与积分中值定理, 将流动隐身衣所需的设计参数均匀化. 通过数值模拟验证了简化后的均匀流动隐身衣具有与非均匀流动隐身衣一样的隐身效果, 并且同样适用于多种流场. 这种简化方法不仅可以将非均匀流动隐身衣简化为均匀流动隐身衣, 更重要的是可以适用于其他领域, 如光学、声学、电磁学与热学等不同领域的超材料均匀化设计, 为降低超材料制备难度提供了新方法. 此外, 基于均匀流动隐身衣对不同流场的适用性, 首次设计了一种流动伪装装置, 该装置可以将原始物体所产生的流场伪装成由任意物体引起的期望流场, 为实现流动伪装提供了解决方案. 最后, 定量对比分析了流动隐身衣的隐身与减阻性能随着雷诺数增加的变化, 结果表明在非蠕动流时流动隐身衣仍然具有良好的隐身性能与较高的减阻效率.Hydrodynamic cloaks have attracted extensive attention because of their ability to significantly reduce the surface resistance of designated target. However, most of parameters of traditional hydrodynamic cloaks present inhomogeneous and anisotropy, which increases the challenge of manufacturing hydrodynamic cloaks for us. To overcome this limitation, equivalent medium theory and integral median theorem are used to homogenize the parameters of hydrodynamic cloaks. Numerical simulations verify that the simplified homogeneous hydrodynamic cloaks exhibit the equivalent cloaking effect as inhomogeneous hydrodynamic cloaks, which can be applied to different flow fields as well. This simplified method not only can simplify inhomogeneous hydrodynamic cloaks to homogeneous hydrodynamic cloaks, but also can be applied to other physical fields, such as optics, acoustics, electromagnetics, and thermodynamics among other areas for the homogenization of metamaterial design, providing a new method to relax the difficulty of metamaterial design. In addition, based on the applicability of homogeneous hydrodynamic cloaks to different flow fields, hydrodynamic camouflage devices are designed that can camouflage the flow fields generated by the original objects into fields caused by arbitrary objects, offering a scheme for achieving hydrodynamic camouflage. Finally, as Reynolds numbers increase, the cloaking and drag reduction performance of hydrodynamic cloaks are quantitatively compared and analyzed. The results show that hydrodynamic cloaks still exhibit high performance in cloaking and drag reduction in non-creeping flows.

-

Keywords:

- homogenized design /

- hydrodynamic cloaks /

- hydrodynamic camouflage /

- metamaterials

[1] Pendry J B, Schurig D, Smith D R 2006 Science 312 1780

Google Scholar

Google Scholar

[2] Schurig D, Mock J J, Justice B J, Cummer J B, Starr A F, Smith D R 2006 Science 314 977

Google Scholar

Google Scholar

[3] Liu R, Ji C, Mock J J, Chin J Y, Cui T J, Smith D R 2009 Science 323 366

Google Scholar

Google Scholar

[4] Han T, Qiu C W, Tang X 2010 Opt. Lett. 35 2642

Google Scholar

Google Scholar

[5] Chen H, Chan C T 2007 Appl. Phys. Lett. 91 183518

Google Scholar

Google Scholar

[6] Zhang S, Xia C, Fang N 2011 Phys. Rev. Lett. 106 024301

Google Scholar

Google Scholar

[7] Greenleaf A, Kurylev Y, Lassas M 2012 Proc. Natl. Acad. Sci. U.S.A. 109 10169

Google Scholar

Google Scholar

[8] 沈惠杰, 温激鸿, 郁殿龙, 蔡力, 温熙森 2012 61 134303

Google Scholar

Google Scholar

Shen H J, Wen J H, Yu D L, Cai L, Wen X S 2012 Acta Phys. Sin. 61 134303

Google Scholar

Google Scholar

[9] Zigoneanu L, Popa B I, Cummer S A 2014 Nat. Mater. 13 352

Google Scholar

Google Scholar

[10] 陆智淼, 蔡力, 温激鸿, 温熙森 2016 65 174301

Google Scholar

Google Scholar

Lu Z M, Cai L, Wen J H, Wen X S 2016 Acta Phys. Sin. 65 174301

Google Scholar

Google Scholar

[11] Fan C Z, Gao Y, Huang J P 2008 Appl. Phys. Lett. 92 251907

Google Scholar

Google Scholar

[12] Guenneau S, Amra C, Veynante D 2012 Opt. Express 20 8207

Google Scholar

Google Scholar

[13] 秦春雷, 杨晶晶, 黄铭 2014 63 194402

Google Scholar

Google Scholar

Qin C L, Yang J J, Huang M 2014 Acta Phys. Sin. 63 194402

Google Scholar

Google Scholar

[14] Li Y, Shen X, Wu Z, Huang J P, Chen Y X, Ni Y S, Huang J P 2015 Phys. Rev. Lett. 115 195503

Google Scholar

Google Scholar

[15] Shen X, Li Y, Jiang C, Huang J P 2016 Phys. Rev. Lett. 117 055501

Google Scholar

Google Scholar

[16] 夏舸, 杨立, 寇蔚, 杜勇成 2017 66 104401

Google Scholar

Google Scholar

Xia K, Yang L, Kou W, Du Y C 2017 Acta Phys. Sin. 66 104401

Google Scholar

Google Scholar

[17] Hu R, Zhou S, Li Y, Lei D Y, Luo X B, Qiu C W 2018 Adv. Mater. 30 1707237

Google Scholar

Google Scholar

[18] Wang B, Shih T M, Huang J P 2021 Appl. Therm. Eng. 190 116726

Google Scholar

Google Scholar

[19] Huang J P 2020 ES Energy Environ. 7 1

Google Scholar

Google Scholar

[20] Xu L J, Huang J P 2020 Chin. Phys. Lett. 37 080502

Google Scholar

Google Scholar

[21] Xu L J, Huang J P 2020 Chin. Phys. Lett. 37 120501

Google Scholar

Google Scholar

[22] Yang S, Wang J, Dai G L, Yang F B, Huang J P 2021 Phys. Rep. 908 1

Google Scholar

Google Scholar

[23] Xu L J, Yang S, Huang J P 2021 EPL 133 20006

Google Scholar

Google Scholar

[24] Wang H, Yao N Z, Wang B, Shih T M, Wang X S 2022 Appl. Therm. Eng. 206 118012

Google Scholar

Google Scholar

[25] Zhang S, Genov D A, Sun C, Zhang X 2008 Phys. Rev. Lett. 100 123002

Google Scholar

Google Scholar

[26] Greenleaf A, Kurylev Y, Lassas M, Uhlmann G 2008 Phys. Rev. Lett. 101 220404

Google Scholar

Google Scholar

[27] Bückmann T, Thiel M, Kadic M, Schittny R, Wegener M 2014 Nat. Commun. 5 1

[28] Bückmann T, Kadic M, Schittny R, Wegener M 2015 Proc. Natl. Acad. Sci. U.S.A. 112 4930

Google Scholar

Google Scholar

[29] Urzhumov Y A, Smith D R 2011 Phys. Rev. Lett. 107 074501

Google Scholar

Google Scholar

[30] Urzhumov Y A, Smith D R 2012 Phys. Rev. E 86 056313

Google Scholar

Google Scholar

[31] Li C Y, Xu L, Zhu L L, Zou S Y, Liu Q H, Wang Z Y, Chen H Y 2018 Phys. Rev. Lett. 121 104501

Google Scholar

Google Scholar

[32] Zou S Y, Xu Y D, Zatianina R, Li C Y, Liang X, Zhu L L, Zhang Y Q, Liu G H, Liu Q H, Chen H Y, Wang Z Y 2019 Phys. Rev. Lett. 123 074501

Google Scholar

Google Scholar

[33] Tay F, Zhang Y, Xu H, Goh H, Luo Y, Zhang B L 2019 arXiv: 1908.07169 [physics.app-ph]

[34] Park J, Youn J R, Song Y S 2019 Phys. Rev. Lett. 123 074502

Google Scholar

Google Scholar

[35] Park J, Youn J R, Song Y S 2019 Phys. Rev. Appl. 12 061002

Google Scholar

Google Scholar

[36] Park J, Youn J R, Song Y S 2021 Extreme Mech. Lett. 42 101061

Google Scholar

Google Scholar

[37] Wang B, Shih T M, Xu L J, Huang J P 2021 Phys. Rev. Appl. 15 034014

Google Scholar

Google Scholar

[38] Boyko E, Bacheva V, Eigenbrod M, Paratore F, D.Gat A, Hardt S, Bercovici M 2021 Phys. Rev. Lett. 126 184502

Google Scholar

Google Scholar

[39] Hele-Shaw 1898 Nature 58 520

[40] Park J, Song Y S 2020 J. Fluids Struct. 98 103136

Google Scholar

Google Scholar

-

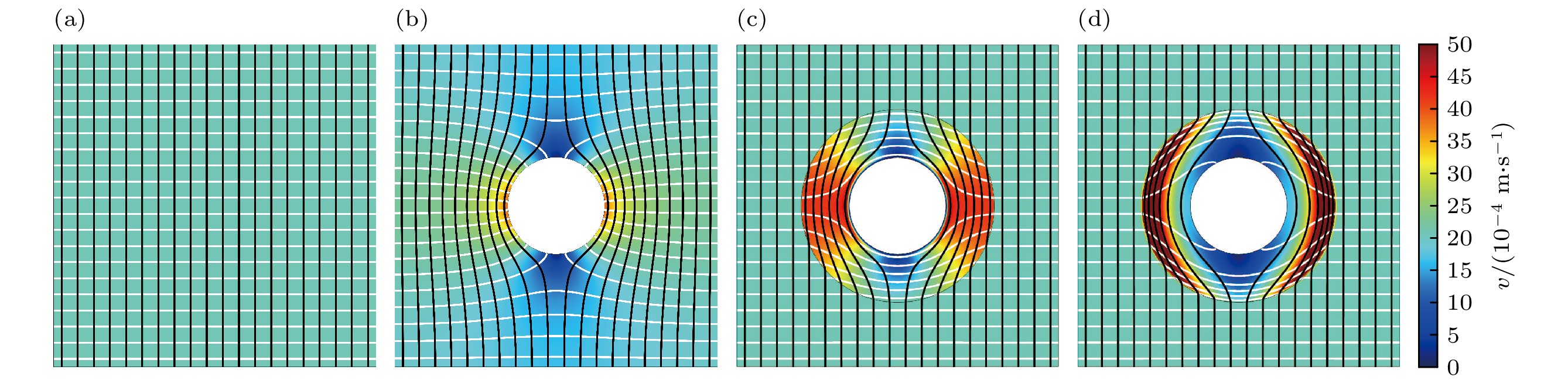

图 3 均匀流场下的速度分布图, 黑色线条为流线, 白色线条为等压线 (a) 不含障碍物; (b) 含障碍物; (c) 含障碍物与非均匀隐身衣; (d) 含障碍物与均匀隐身衣

Fig. 3. Velocity distributions superimposed with streamlines (black color) and isobars (white color) for uniform flow fields: (a) Obstacle absent; (b) obstacle existent; (c) obstacle and inhomogeneous cloak existent; (d) obstacle and homogeneous cloak existent

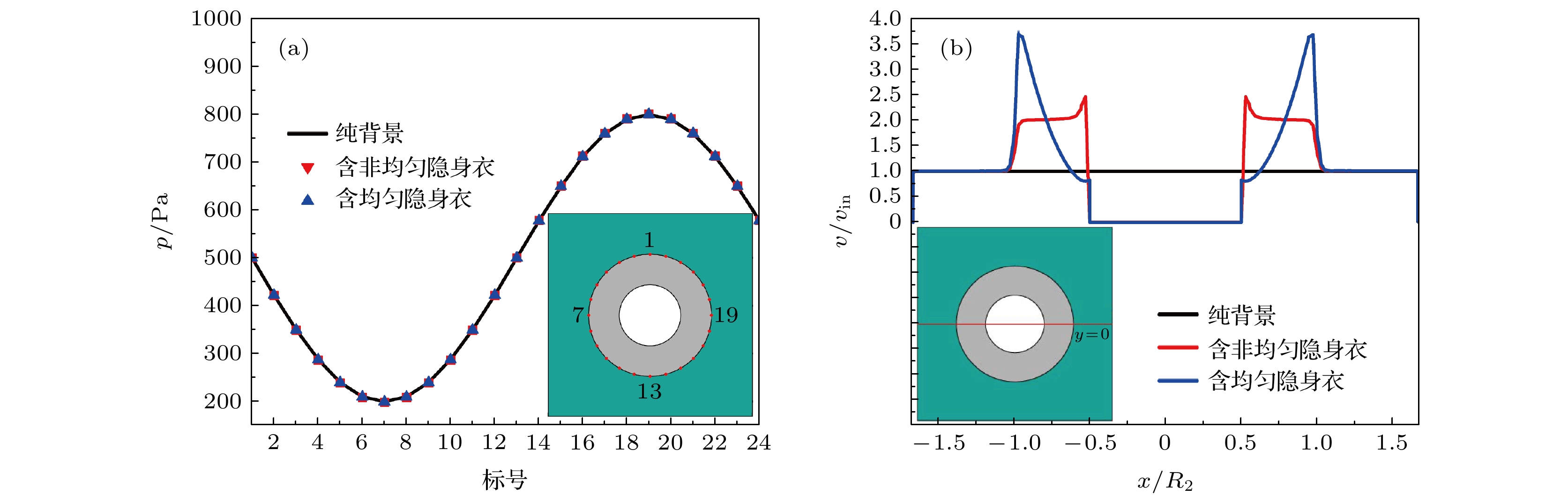

图 4 (a) 压强分布图, 黑色线条、红色三角形与蓝色三角形分别表示图3(a)、图3(c)与图3(d)在

$ r^{\prime}=R_2 $ 处的压强; (b) 速度分布图, 黑色线条、红色线条与蓝色线条分别表示图3(a)、图3(c)与图3(d)在$ y=0 $ 处的速度分布Fig. 4. (a) Pressure distributions. Black line, red triangle and blue triangle indicate the pressure at

$ r^{\prime}=R_2 $ in Fig. 3(a) (only background), Fig. 3(c) (with inhomogeneous cloaks) and Fig. 3(d) (with homogeneous cloaks) respectively. (b) Velocity distributions. Black line, red line and blue line indicate the velocity at$ y=0 $ in Fig. 3(a) (only background), Fig. 3(c) (with inhomogeneous cloaks) and Fig. 3(d) (with homogeneous cloaks) respectively图 5 非均匀流场下的速度分布图, 黑色线条为流线, 白色线条为等压线 (a) 不含障碍物; (b) 含障碍物与非均匀隐身衣; (c) 含障碍物与均匀隐身衣

Fig. 5. Velocity distributions superimposed with streamlines (black color) and isobars (white color) for non-uniform flow fields: (a) Obstacle absent; (b) obstacle and inhomogeneous cloak existent; (c) obstacle and homogeneous cloak existent

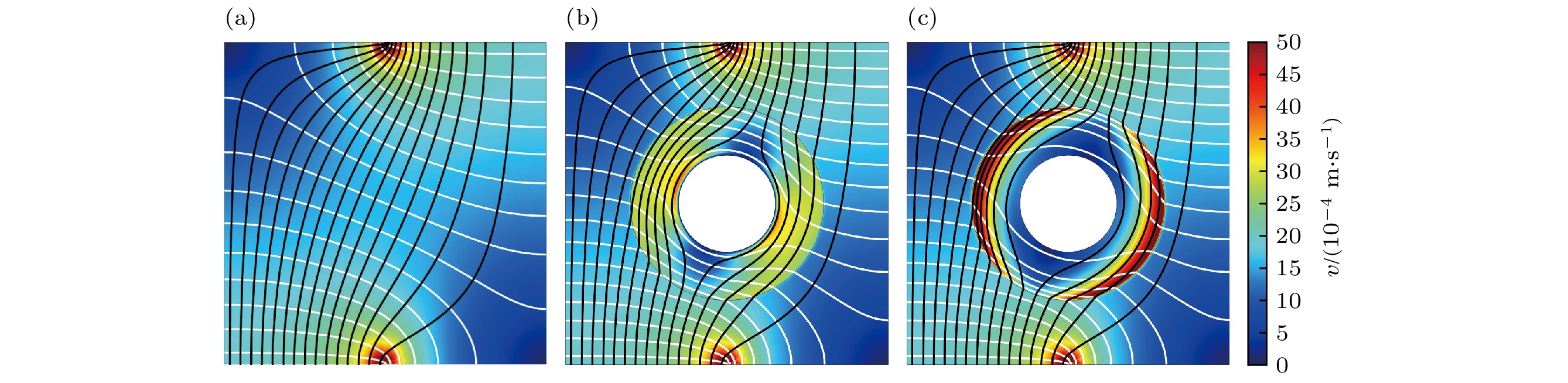

图 A1 流动伪装示意图 (a) 仅含障碍物; (b) 隐身状态; (c) 一个障碍物被伪装成两个; (d) 含两个障碍物. 从伪装图中可以看出, 图(c)红色虚线外的流场与图(d)两个目标物体的流场一致, 说明一个物体已经被隐藏并伪装成两个物体

Fig. A1. Schematic of hydrodynamic camouflage: (a) Only one obstacle exists; (b) cloaking; (c) one obstacle camouflaged as two obstacles; (d) two obstacles exist. As can be seen from the camouflage devices, the flow fields outside the red dashed line in panel (c) coincide with the flow fields of the two-target objects in panel (d), indicating that one object has been hidden and camouflaged as two objects

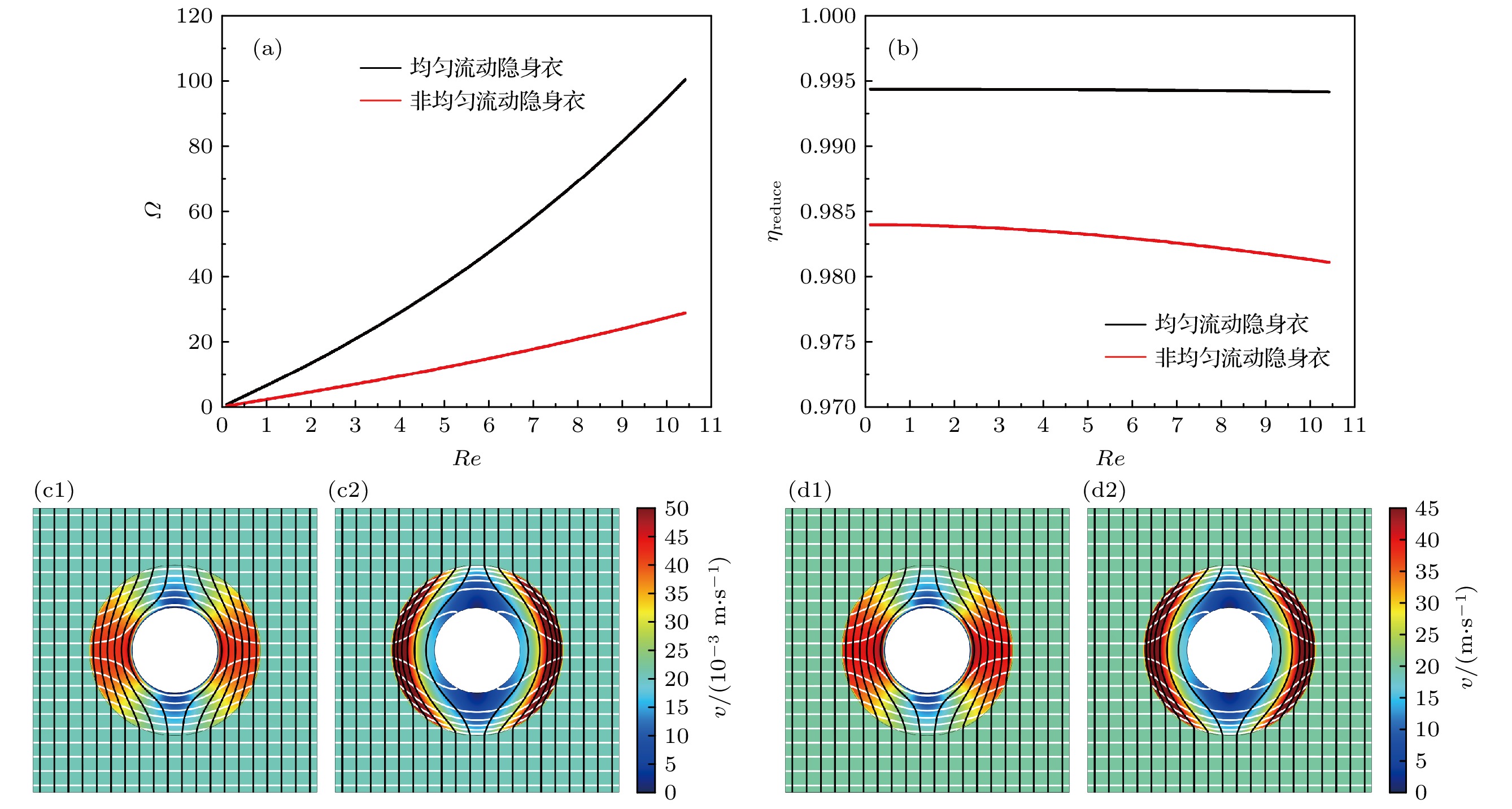

图 6 (a) 隐身效果, 其中Ω表示含隐身衣流场与纯背景流场的差异程度; (b) 减阻效果, 其中

$ \eta_{{\rm{reduce}}} $ 表示隐身衣的减阻程度; (c) 当流域雷诺数$ Re=1 $ 时, 非均匀流动隐身衣(c1)与均匀流动隐身衣(c2)的速度分布; (d) 当流域雷诺数$ Re=10 $ 时, 非均匀流动隐身衣(d1)与均匀流动隐身衣(d2)的速度分布Fig. 6. (a) Cloaking effects, in which Ω presents the difference between flow fields with cloaks and pure background flow fields; (b) Drag reduction effects, in which

$ \eta_{reduce} $ denotes the degree of drag reduction of cloaks; (c) Velocity distributions of inhomogeneous cloaks (c1) and homogeneous cloaks (c2) at$ Re = 1 $ ; (d) Velocity distributions of inhomogeneous cloaks (d1) and homogeneous cloaks (d2) at$ Re = 10 $ -

[1] Pendry J B, Schurig D, Smith D R 2006 Science 312 1780

Google Scholar

Google Scholar

[2] Schurig D, Mock J J, Justice B J, Cummer J B, Starr A F, Smith D R 2006 Science 314 977

Google Scholar

Google Scholar

[3] Liu R, Ji C, Mock J J, Chin J Y, Cui T J, Smith D R 2009 Science 323 366

Google Scholar

Google Scholar

[4] Han T, Qiu C W, Tang X 2010 Opt. Lett. 35 2642

Google Scholar

Google Scholar

[5] Chen H, Chan C T 2007 Appl. Phys. Lett. 91 183518

Google Scholar

Google Scholar

[6] Zhang S, Xia C, Fang N 2011 Phys. Rev. Lett. 106 024301

Google Scholar

Google Scholar

[7] Greenleaf A, Kurylev Y, Lassas M 2012 Proc. Natl. Acad. Sci. U.S.A. 109 10169

Google Scholar

Google Scholar

[8] 沈惠杰, 温激鸿, 郁殿龙, 蔡力, 温熙森 2012 61 134303

Google Scholar

Google Scholar

Shen H J, Wen J H, Yu D L, Cai L, Wen X S 2012 Acta Phys. Sin. 61 134303

Google Scholar

Google Scholar

[9] Zigoneanu L, Popa B I, Cummer S A 2014 Nat. Mater. 13 352

Google Scholar

Google Scholar

[10] 陆智淼, 蔡力, 温激鸿, 温熙森 2016 65 174301

Google Scholar

Google Scholar

Lu Z M, Cai L, Wen J H, Wen X S 2016 Acta Phys. Sin. 65 174301

Google Scholar

Google Scholar

[11] Fan C Z, Gao Y, Huang J P 2008 Appl. Phys. Lett. 92 251907

Google Scholar

Google Scholar

[12] Guenneau S, Amra C, Veynante D 2012 Opt. Express 20 8207

Google Scholar

Google Scholar

[13] 秦春雷, 杨晶晶, 黄铭 2014 63 194402

Google Scholar

Google Scholar

Qin C L, Yang J J, Huang M 2014 Acta Phys. Sin. 63 194402

Google Scholar

Google Scholar

[14] Li Y, Shen X, Wu Z, Huang J P, Chen Y X, Ni Y S, Huang J P 2015 Phys. Rev. Lett. 115 195503

Google Scholar

Google Scholar

[15] Shen X, Li Y, Jiang C, Huang J P 2016 Phys. Rev. Lett. 117 055501

Google Scholar

Google Scholar

[16] 夏舸, 杨立, 寇蔚, 杜勇成 2017 66 104401

Google Scholar

Google Scholar

Xia K, Yang L, Kou W, Du Y C 2017 Acta Phys. Sin. 66 104401

Google Scholar

Google Scholar

[17] Hu R, Zhou S, Li Y, Lei D Y, Luo X B, Qiu C W 2018 Adv. Mater. 30 1707237

Google Scholar

Google Scholar

[18] Wang B, Shih T M, Huang J P 2021 Appl. Therm. Eng. 190 116726

Google Scholar

Google Scholar

[19] Huang J P 2020 ES Energy Environ. 7 1

Google Scholar

Google Scholar

[20] Xu L J, Huang J P 2020 Chin. Phys. Lett. 37 080502

Google Scholar

Google Scholar

[21] Xu L J, Huang J P 2020 Chin. Phys. Lett. 37 120501

Google Scholar

Google Scholar

[22] Yang S, Wang J, Dai G L, Yang F B, Huang J P 2021 Phys. Rep. 908 1

Google Scholar

Google Scholar

[23] Xu L J, Yang S, Huang J P 2021 EPL 133 20006

Google Scholar

Google Scholar

[24] Wang H, Yao N Z, Wang B, Shih T M, Wang X S 2022 Appl. Therm. Eng. 206 118012

Google Scholar

Google Scholar

[25] Zhang S, Genov D A, Sun C, Zhang X 2008 Phys. Rev. Lett. 100 123002

Google Scholar

Google Scholar

[26] Greenleaf A, Kurylev Y, Lassas M, Uhlmann G 2008 Phys. Rev. Lett. 101 220404

Google Scholar

Google Scholar

[27] Bückmann T, Thiel M, Kadic M, Schittny R, Wegener M 2014 Nat. Commun. 5 1

[28] Bückmann T, Kadic M, Schittny R, Wegener M 2015 Proc. Natl. Acad. Sci. U.S.A. 112 4930

Google Scholar

Google Scholar

[29] Urzhumov Y A, Smith D R 2011 Phys. Rev. Lett. 107 074501

Google Scholar

Google Scholar

[30] Urzhumov Y A, Smith D R 2012 Phys. Rev. E 86 056313

Google Scholar

Google Scholar

[31] Li C Y, Xu L, Zhu L L, Zou S Y, Liu Q H, Wang Z Y, Chen H Y 2018 Phys. Rev. Lett. 121 104501

Google Scholar

Google Scholar

[32] Zou S Y, Xu Y D, Zatianina R, Li C Y, Liang X, Zhu L L, Zhang Y Q, Liu G H, Liu Q H, Chen H Y, Wang Z Y 2019 Phys. Rev. Lett. 123 074501

Google Scholar

Google Scholar

[33] Tay F, Zhang Y, Xu H, Goh H, Luo Y, Zhang B L 2019 arXiv: 1908.07169 [physics.app-ph]

[34] Park J, Youn J R, Song Y S 2019 Phys. Rev. Lett. 123 074502

Google Scholar

Google Scholar

[35] Park J, Youn J R, Song Y S 2019 Phys. Rev. Appl. 12 061002

Google Scholar

Google Scholar

[36] Park J, Youn J R, Song Y S 2021 Extreme Mech. Lett. 42 101061

Google Scholar

Google Scholar

[37] Wang B, Shih T M, Xu L J, Huang J P 2021 Phys. Rev. Appl. 15 034014

Google Scholar

Google Scholar

[38] Boyko E, Bacheva V, Eigenbrod M, Paratore F, D.Gat A, Hardt S, Bercovici M 2021 Phys. Rev. Lett. 126 184502

Google Scholar

Google Scholar

[39] Hele-Shaw 1898 Nature 58 520

[40] Park J, Song Y S 2020 J. Fluids Struct. 98 103136

Google Scholar

Google Scholar

计量

- 文章访问数: 4852

- PDF下载量: 71

- 被引次数: 0

下载:

下载: