-

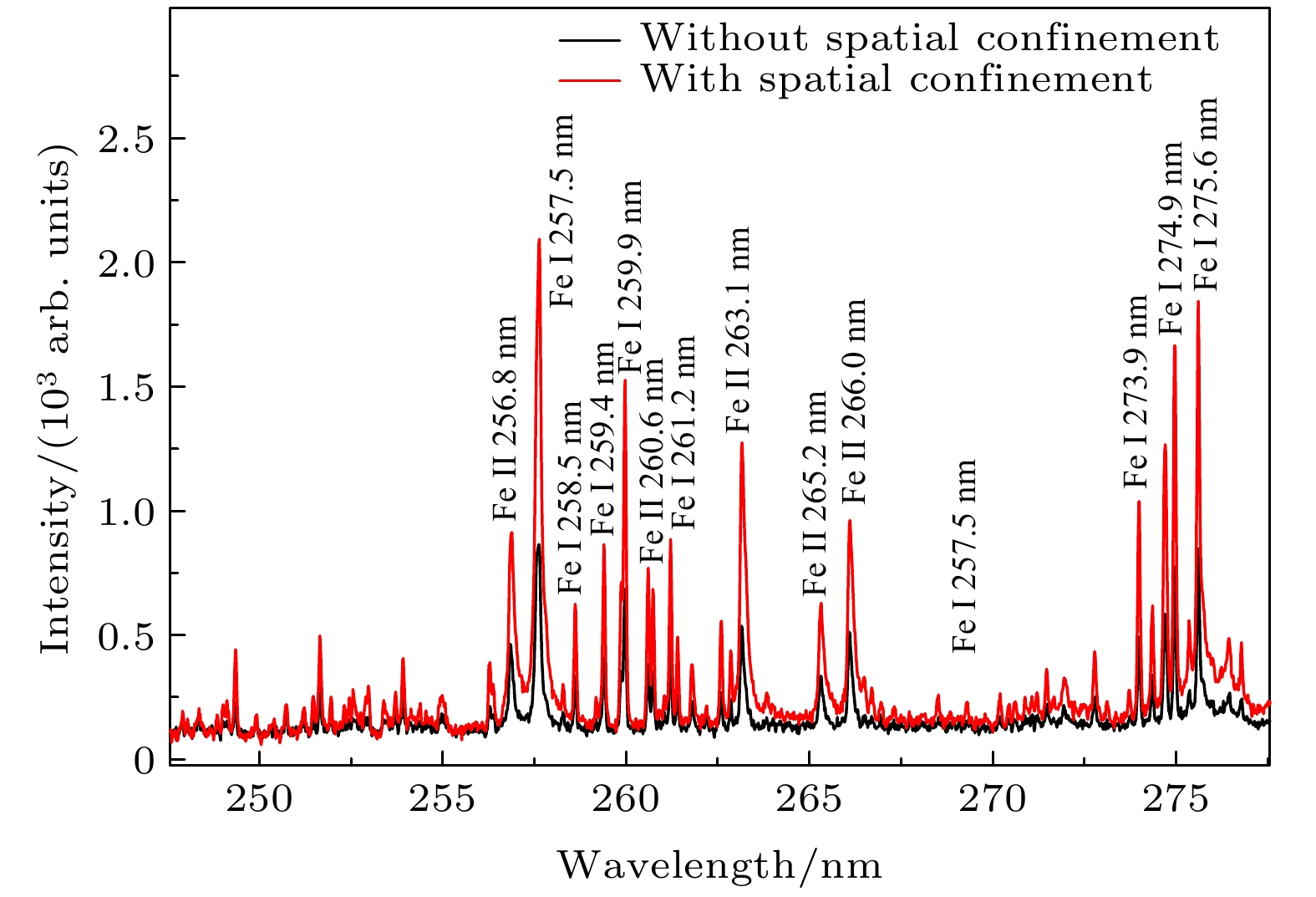

铝合金中Fe元素的含量直接影响合金的塑性、耐热性、强度及抗应力腐蚀性能, 其成分的定量分析是合金成分在线检测的重要环节. 为了提高铝合金中Fe元素定量分析精度, 把空间约束纳秒激光诱导击穿光谱技术与梯度下降法相结合. 通过采集激光诱导铝合金等离子体发射光谱, 发现在平板空间约束下的等离子体辐射强度有明显增强, 在间距为10 mm时的等离子体发射光谱增强约2.3倍. 分别利用内标法和梯度下降法建立定标模型, 对比两种模型的拟合系数、均方根误差和平均相对误差. 在平板约束条件下, 相比于内标法, 梯度下降法得到的Fe元素定量分析参数R2从95.22%提升到了99.22%, 训练集均方根误差从质量分数0.1409%下降到了0.0731%, 测试集均方根误差从质量分数0.1401%下降到了0.0756%, 平均相对误差从6.8893%下降到3.5521%. 与内标定标模型相比, 梯度下降定标模型的精确度和稳定性都有所提高, 空间约束LIBS结合梯度下降法可以有效地降低合金基体效应和自吸收效应对定量分析的影响.The concentration of Fe in aluminum alloy can affect the plasticity, heat resistance, strength and stress corrosion resistance of the alloy. The quantitative analysis of aluminum alloy composition is an important part of the online detection of alloy composition. To improve the quantitative analysis accuracy of Fe in aluminum alloy, the spatial confinement nanosecond laser-induced breakdown spectroscopy is combined with the gradient-descent method. By collecting laser-induced aluminum alloy plasma emission spectra, it is found that the plasma radiation intensity under the confinement of the plate space is significantly enhanced. The enhancement factor of the plasma emission spectrum with a plate spacing of 10 mm is 2.3. The internal standard method and the gradient descent method are used to establish the calibration models respectively, and the values of fitting coefficient (R2), root mean square error (RMSE) and average relative error (ARE) of the two models are compared. Without plate spatial confinement, the R2, RMSEC, RMSEP and ARE of the Fe element calculated by the internal standard method are 90.66%, 0.1903%, 0.1910% and 9.2220%, respectively. The R2, RMSEC, RMSEP and ARE of Fe element obtained by the gradient descent method are 97.12%, 0.1467% (weight concentration), 0.1124% (weight concentration) and 7.1373%, respectively. With the plate spatial confinement, the R2, RMSEC, RMSEP and ARE of Fe element calculated by the internal standard method are 95.22%, 0.1409% (weight concentration), 0.1401% (weight concentration), and 6.8893%, respectively. The R2, RMSEC, RMSEP and ARE of Fe element obtained by the gradient descent method are 99.22%, 0.0731% (weight concentration), 0.0756% (weight concentration) and 3.5521%, respectively. Comparing with the internal calibration model, the accuracy and stability of the gradient descent calibration model are improved. The spatial confinement LIBS combined with the gradient descent method can effectively reduce the influence of the alloy matrix effect and the self-absorption effect on the quantitative analysis.

-

Keywords:

- laser-induced breakdown spectroscopy /

- gradient descent /

- spatial confinement /

- aluminum alloy

[1] 张新明, 邓运来, 张勇 2015 金属学报 51 257271

Google Scholar

Google Scholar

Zhang M X, Deng Y L, Zhang Y 2015 Acta Metall. Sin. 51 257271

Google Scholar

Google Scholar

[2] Su R M, Xiao J, Jia Y X, Wang K N, Qu Y D 2019 Mater. Res. Express 6 126561

Google Scholar

Google Scholar

[3] Ye M Z 2015 Metall. Anal. 1924

[4] Cheng A Y, Yu J, Gao C L, Zhang L S 2020 IOP Conf. Ser. : Mater. Sci. Eng. 780 062059

[5] Lahmar L, Benamar M E A, Melzi M A, Melkaou C H, Mabdoua Y 2020 X‐Ray Spectrom. 49 313

Google Scholar

Google Scholar

[6] Zhao S Y, Gao X, Chen A M, Lin J Q 2020 Appl. Phys. B 126 7

Google Scholar

Google Scholar

[7] Feng J, Wang Z, West L, Li Z, Lu J 2011 Anal. Bioanal. Chem. 400 3261

Google Scholar

Google Scholar

[8] Cai L, Wang Z, Li C, Huang X, Zhao D, Ding H 2019 Rev. Sci. Instrum. 90 053503

Google Scholar

Google Scholar

[9] Lin X M, Sun H R, Gao X, Xu Y T, Wang Z X, Wang Y 2021 Spectrochim. Acta, Part B 180 106200

Google Scholar

Google Scholar

[10] Zeng Q, Pan C, Li C, Fei T, Ding X, Du X, Wang Q 2018 Spectrochim. Acta, Part B 142 68

Google Scholar

Google Scholar

[11] Guo L B, Zhang D, Sun L X, Yao S C, Zhang L, Wang Z Z, Wang Q Q, Ding H B, Lu Y, Hou Z Y, Wang Z 2021 Front. Phys. 16 22500

Google Scholar

Google Scholar

[12] Fu Y T, Gu W L, Hou Z Y, Muhammed S A, Li T Q, Wang Y, Wang Z 2021 Front. Phys. 16 22502

Google Scholar

Google Scholar

[13] Guo L B, Hao Z Q, Shen M, Xiong W, He X N, Xie Z Q, Gao M, Li X Y, Zeng X Y, Lu Y F 2013 Opt. Express 21 1818818195

Google Scholar

Google Scholar

[14] Li X W, Yin H L, Wang Z, Fu Y T, Li Z, Ni W D 2015 Spectrochim. Acta, Part B 111 102107

Google Scholar

Google Scholar

[15] Ren L, Hao X J, Tang H J, Sun Y K 2019 Results Phys. 15 102798

Google Scholar

Google Scholar

[16] Tian Y, Chen Q, Lin Y Q, Lu Y 2021 Spectrochim. Acta, Part B 175 106027

Google Scholar

Google Scholar

[17] Hao Z Q, Li C M, Shen M, Yang X Y 2015 Opt. Express 23 77957801

Google Scholar

Google Scholar

[18] Rao A, Jenkins P R, Auxier J, Shattan M B 2021 J. Anal. At. Spectrom. 36 399406

Google Scholar

Google Scholar

[19] Ni B Z, Chen X L, Fu H B, Wang J G 2014 Front. Phys. 9 439445

Google Scholar

Google Scholar

[20] Zhang Y Q, Sun C, Yue Z Q, Shabbir S, Xu W J, Wu M T, Zou L, Tan Y Q, Chen F Y, Yu J 2020 Opt. Express 28 32019

Google Scholar

Google Scholar

[21] Li T Q, Hou Z Y, Fu Y T, Yu J L, Gu W L, Wang Z 2019 Anal. Chim. Acta. 1058 3947

Google Scholar

Google Scholar

[22] Hinton G E 1989 Artif. Intell. 40 185234

[23] Zhao J K, Zhang R F, Zhou Z, Chen S 2021 Neurocomputing 438 184194

[24] Hao W 2021 Appl. Math. Lett. 112 106739

Google Scholar

Google Scholar

[25] Gao X, Liu L, Song C, Lin J Q 2015 J. Phys. D: Appl. Phys. 48 175205

Google Scholar

Google Scholar

[26] Zhang D, Chen A M, Wang X W, Wang Y, Sui L Z, Ke D, Li S Y, Jiang Y F, Jin M X 2018 Spectrochim. Acta, Part B 143 7177

Google Scholar

Google Scholar

[27] Guo L B, Li C M, Hu W, Zhou Y S, Zhang B Y, Cai Z X, Zeng X Y, Lu Y F 2011 Appl. Phys. Lett. 98 131501

Google Scholar

Google Scholar

[28] Yao S C, Lu J D, Li J Y, Chen K, Li J, Dong M R 2010 J. Anal. At. Spectrom. 25 1733

Google Scholar

Google Scholar

-

表 1 铝合金标样元素成分表(质量分数百分比)

Table 1. Element composition of standard aluminum alloy sample (weight percent)

样品 E311 E312a E313 E314 E315 E316 Cu 4.51 2.45 1.52 3.33 0.927 5.55 Mg 0.428 1.370 0.897 1.800 2.260 0.074 Fe 0.454 1.230 0.908 1.610 1.870 0.115 Ni 1.550 1.090 2.020 0.624 0.153 2.250 Mn 0.095 0.119 0.239 0.184 0.287 0.054 Si 0.094 0.724 1.220 0.371 1.530 0.090 Zn 0.140 0.220 0.334 0.166 0.367 0.084 Ti 0.02100 0.07800 0.12000 0.05500 0.16100 0.00095 表 2 定量分析参数对比, 含量为质量分数

Table 2. Comparison of the quantitive analysis parameters, the concentrations are the weight concentration.

内标法 梯度下降 无约束 约束 无约束 约束 R2 0.9066 0.9522 0.9712 0.9922 RMSEC/% 0.1903 0.1409 0.1467 0.0731 RMSEP/% 0.1910 0.1401 0.1124 0.0756 ARE/% 9.2220 6.8893 7.1373 3.5521 -

[1] 张新明, 邓运来, 张勇 2015 金属学报 51 257271

Google Scholar

Google Scholar

Zhang M X, Deng Y L, Zhang Y 2015 Acta Metall. Sin. 51 257271

Google Scholar

Google Scholar

[2] Su R M, Xiao J, Jia Y X, Wang K N, Qu Y D 2019 Mater. Res. Express 6 126561

Google Scholar

Google Scholar

[3] Ye M Z 2015 Metall. Anal. 1924

[4] Cheng A Y, Yu J, Gao C L, Zhang L S 2020 IOP Conf. Ser. : Mater. Sci. Eng. 780 062059

[5] Lahmar L, Benamar M E A, Melzi M A, Melkaou C H, Mabdoua Y 2020 X‐Ray Spectrom. 49 313

Google Scholar

Google Scholar

[6] Zhao S Y, Gao X, Chen A M, Lin J Q 2020 Appl. Phys. B 126 7

Google Scholar

Google Scholar

[7] Feng J, Wang Z, West L, Li Z, Lu J 2011 Anal. Bioanal. Chem. 400 3261

Google Scholar

Google Scholar

[8] Cai L, Wang Z, Li C, Huang X, Zhao D, Ding H 2019 Rev. Sci. Instrum. 90 053503

Google Scholar

Google Scholar

[9] Lin X M, Sun H R, Gao X, Xu Y T, Wang Z X, Wang Y 2021 Spectrochim. Acta, Part B 180 106200

Google Scholar

Google Scholar

[10] Zeng Q, Pan C, Li C, Fei T, Ding X, Du X, Wang Q 2018 Spectrochim. Acta, Part B 142 68

Google Scholar

Google Scholar

[11] Guo L B, Zhang D, Sun L X, Yao S C, Zhang L, Wang Z Z, Wang Q Q, Ding H B, Lu Y, Hou Z Y, Wang Z 2021 Front. Phys. 16 22500

Google Scholar

Google Scholar

[12] Fu Y T, Gu W L, Hou Z Y, Muhammed S A, Li T Q, Wang Y, Wang Z 2021 Front. Phys. 16 22502

Google Scholar

Google Scholar

[13] Guo L B, Hao Z Q, Shen M, Xiong W, He X N, Xie Z Q, Gao M, Li X Y, Zeng X Y, Lu Y F 2013 Opt. Express 21 1818818195

Google Scholar

Google Scholar

[14] Li X W, Yin H L, Wang Z, Fu Y T, Li Z, Ni W D 2015 Spectrochim. Acta, Part B 111 102107

Google Scholar

Google Scholar

[15] Ren L, Hao X J, Tang H J, Sun Y K 2019 Results Phys. 15 102798

Google Scholar

Google Scholar

[16] Tian Y, Chen Q, Lin Y Q, Lu Y 2021 Spectrochim. Acta, Part B 175 106027

Google Scholar

Google Scholar

[17] Hao Z Q, Li C M, Shen M, Yang X Y 2015 Opt. Express 23 77957801

Google Scholar

Google Scholar

[18] Rao A, Jenkins P R, Auxier J, Shattan M B 2021 J. Anal. At. Spectrom. 36 399406

Google Scholar

Google Scholar

[19] Ni B Z, Chen X L, Fu H B, Wang J G 2014 Front. Phys. 9 439445

Google Scholar

Google Scholar

[20] Zhang Y Q, Sun C, Yue Z Q, Shabbir S, Xu W J, Wu M T, Zou L, Tan Y Q, Chen F Y, Yu J 2020 Opt. Express 28 32019

Google Scholar

Google Scholar

[21] Li T Q, Hou Z Y, Fu Y T, Yu J L, Gu W L, Wang Z 2019 Anal. Chim. Acta. 1058 3947

Google Scholar

Google Scholar

[22] Hinton G E 1989 Artif. Intell. 40 185234

[23] Zhao J K, Zhang R F, Zhou Z, Chen S 2021 Neurocomputing 438 184194

[24] Hao W 2021 Appl. Math. Lett. 112 106739

Google Scholar

Google Scholar

[25] Gao X, Liu L, Song C, Lin J Q 2015 J. Phys. D: Appl. Phys. 48 175205

Google Scholar

Google Scholar

[26] Zhang D, Chen A M, Wang X W, Wang Y, Sui L Z, Ke D, Li S Y, Jiang Y F, Jin M X 2018 Spectrochim. Acta, Part B 143 7177

Google Scholar

Google Scholar

[27] Guo L B, Li C M, Hu W, Zhou Y S, Zhang B Y, Cai Z X, Zeng X Y, Lu Y F 2011 Appl. Phys. Lett. 98 131501

Google Scholar

Google Scholar

[28] Yao S C, Lu J D, Li J Y, Chen K, Li J, Dong M R 2010 J. Anal. At. Spectrom. 25 1733

Google Scholar

Google Scholar

计量

- 文章访问数: 6002

- PDF下载量: 80

- 被引次数: 0

下载:

下载: