-

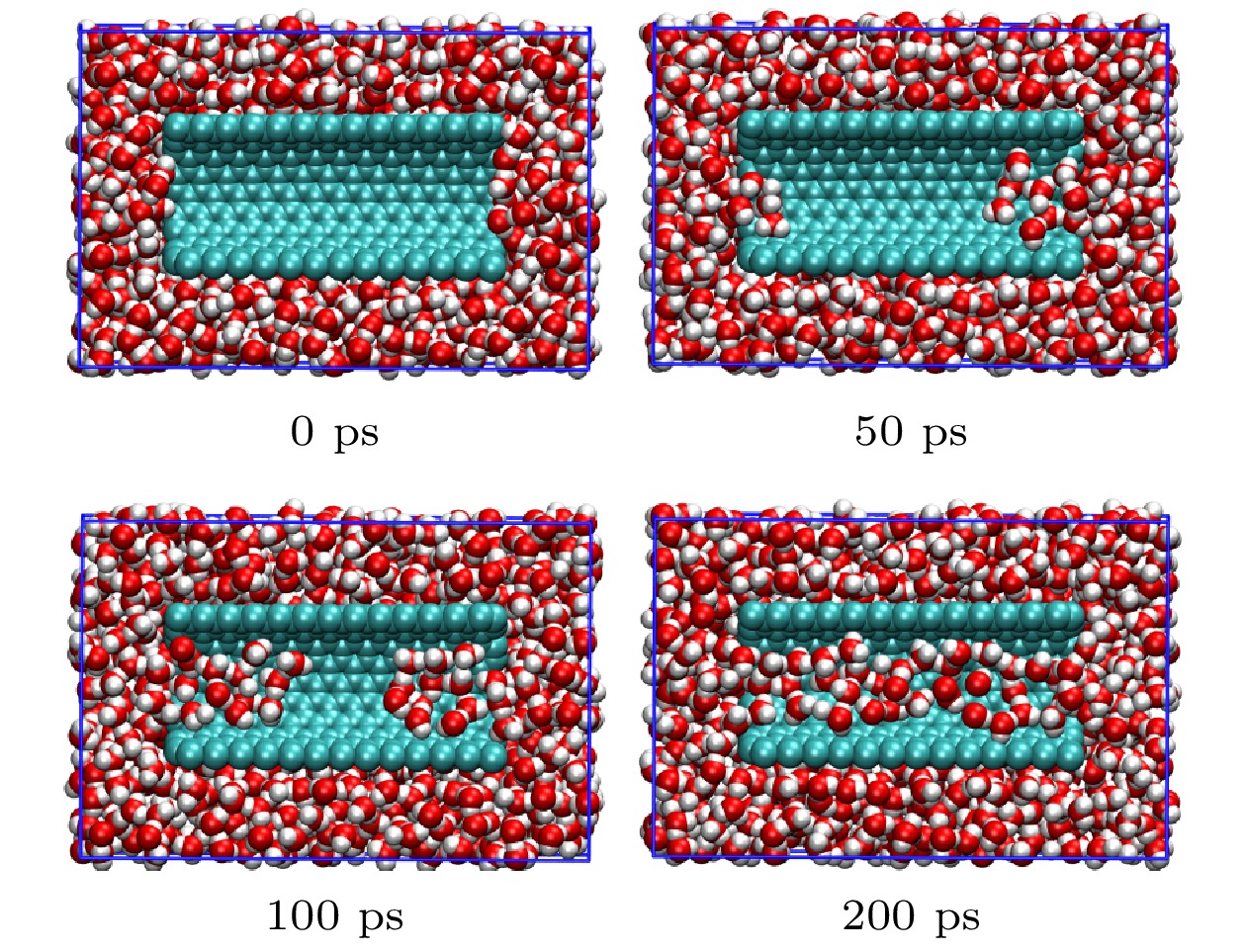

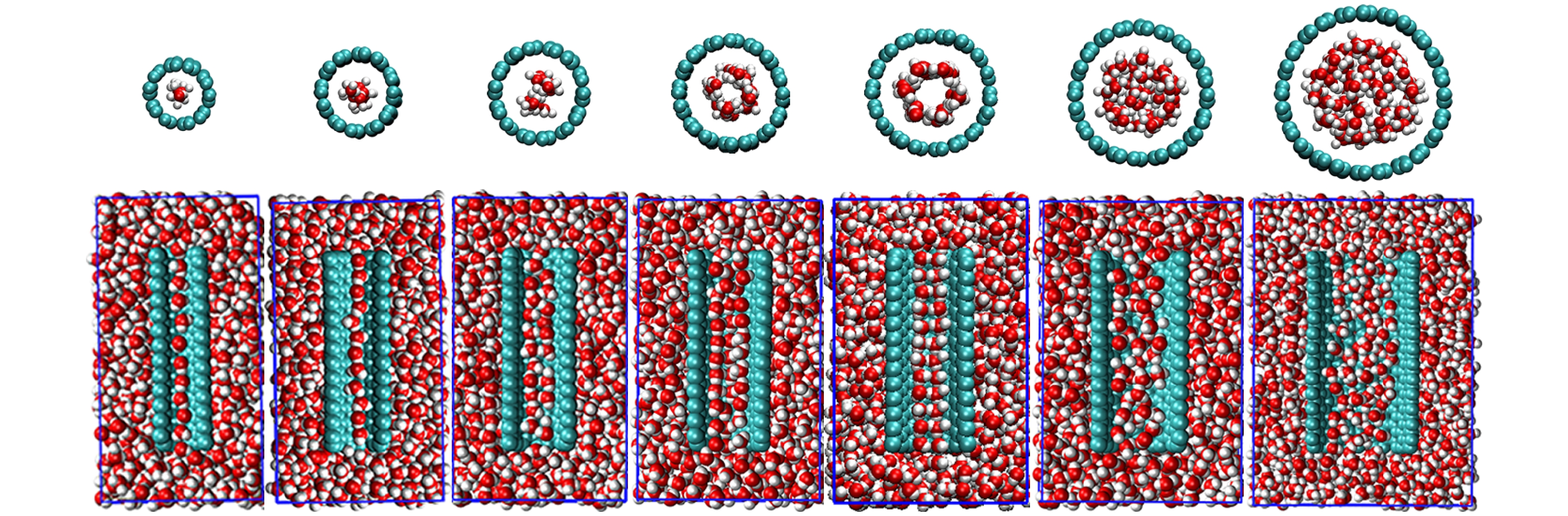

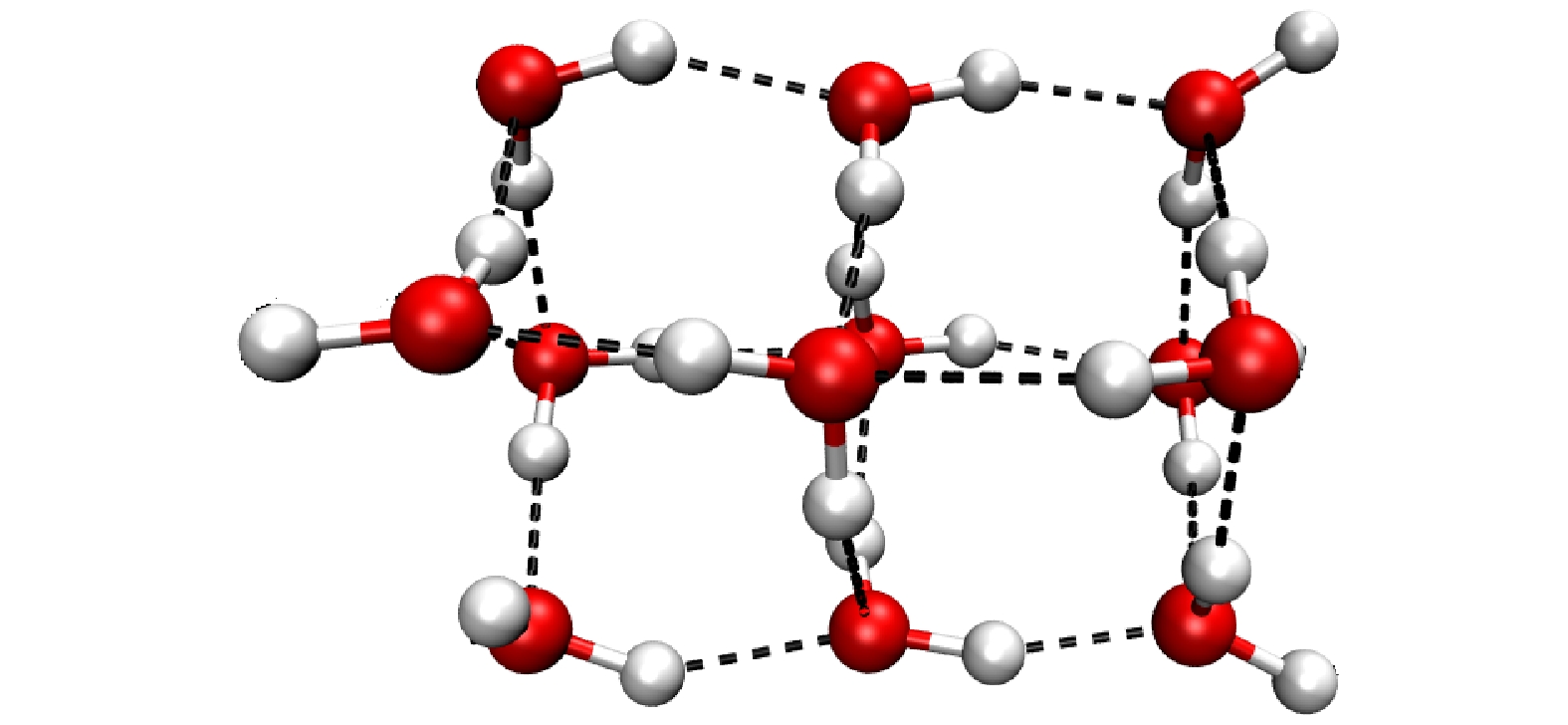

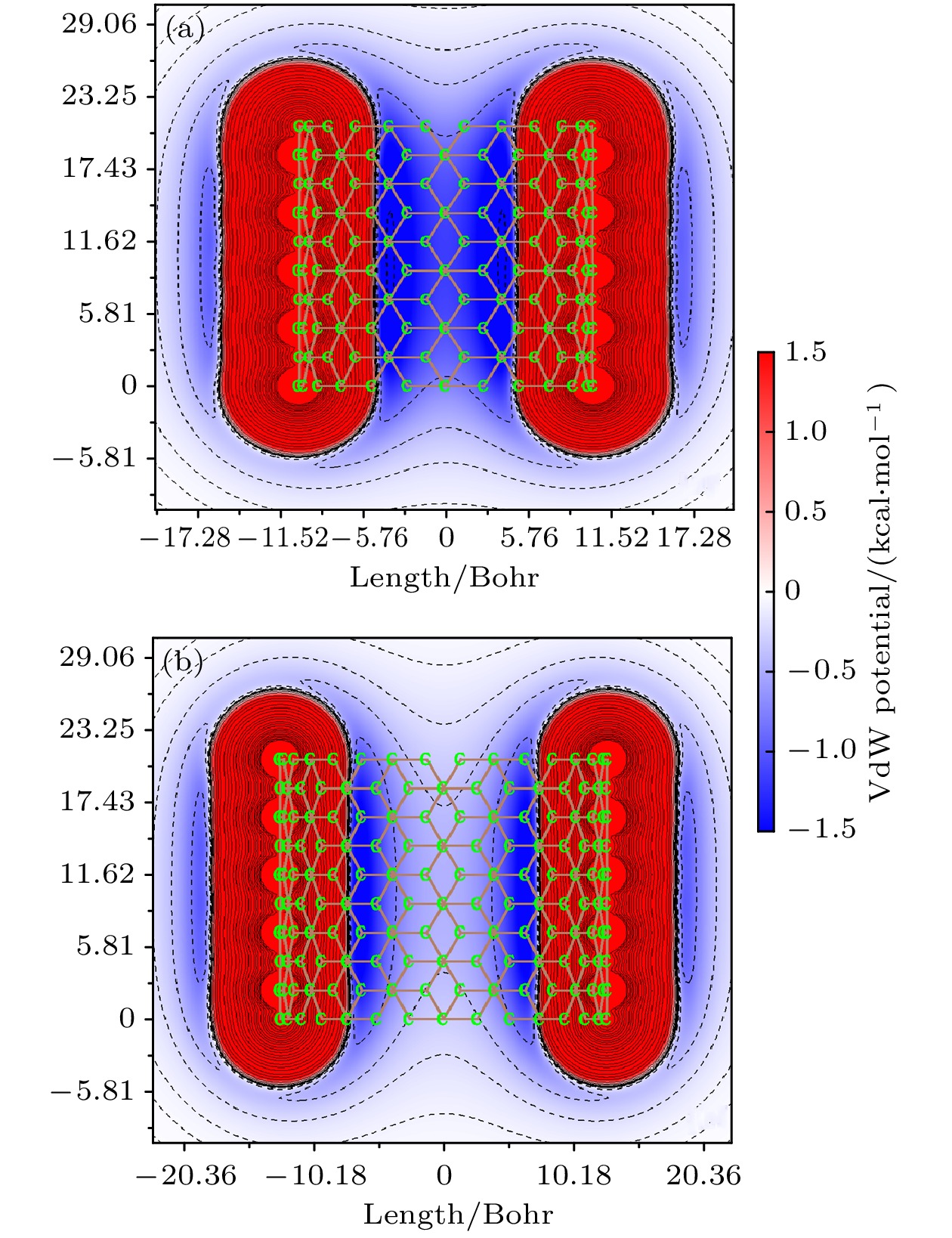

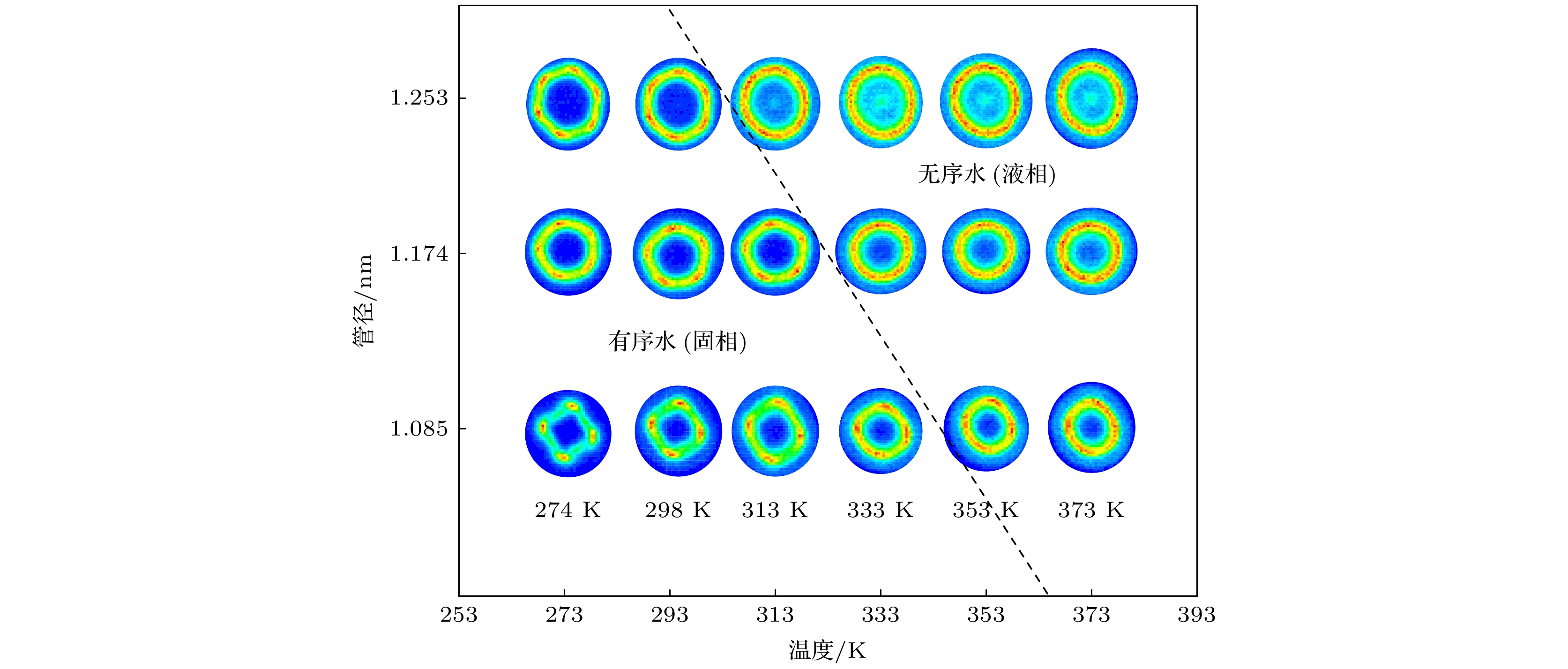

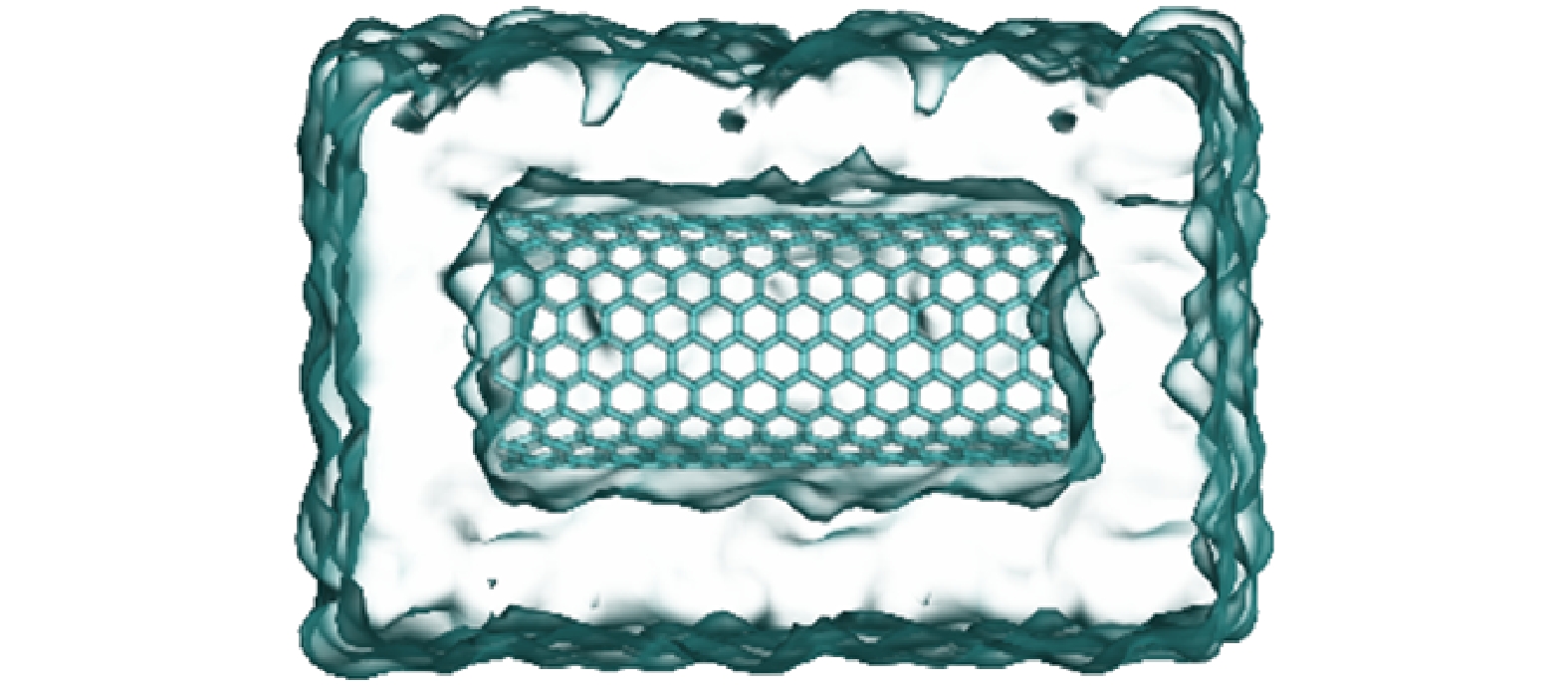

碳纳米管管腔作为分子物质的纳米通道, 其储存或输送水的能力具有重要研究价值. 为了研究碳纳米管管腔受限空间对水分子团簇结构和分布的影响, 本文采用分子动力学方法探究了管径、手性和温度对单壁碳纳米管管腔内水的结构和分布的影响. 结果表明: 在常温下, 管径尺寸范围为1.018—1.253 nm的单壁碳纳米管管内易形成有序的多元环水结构, 此范围以外碳纳米管管内难以形成水的有序结构; 且随着管径尺寸增大, 多元环水呈现由三元环至六元环的结构变化; 范德瓦耳斯势分布分析表明, 在上述管径范围内, 水分子趋向于贴近碳纳米管管壁分布而形成水的有序结构. 对比管径尺寸差别较小的碳纳米管, 其手性对多元环水结构影响不大. 多元环水结构的稳定性表现出温度依赖性, 管径较大的碳纳米管内的多元环水的有序结构更易随温度升高而消失.Since the discovery of carbon nanotubes (CNTs), they have attracted extensive attention from scholars in various fields because of their excellent properties. The hollow-structured CNTs are often regarded as conduits and containers, which can act as nano-channels for various molecular substances in the membrane structure. As a source of life, water is indispensable to any living organism. In the application of carbon nanotubes as nanochannels, the most important is the ability of carbon nanotubes to store and transport liquids, especially nanoscaled aqueous solutions. Water molecular clusters in confined spaces exhibit unusual structures and properties. The study of special water structures in carbon nanotubes is of great theoretical importance in chemistry, biology and materials science. There are great difficulties in making the experiment on a nanoscale, but molecular dynamic simulation enables us to better study and analyze the structure and properties of water in confined space of CNT on a nanoscale. One has also studied the influence of temperature on the structure of water, but there are few studies focusing on the effect of temperature on the structure of water in confined space. Therefore, molecular dynamics simulation is used to investigate the effects of CNT diameter, CNT chirality and temperature on the water structure and distribution in a confined space. The simulation calculation is completed by GROMACS, the SPE/C water model is used for water molecules, and GROMOS96 54a7 force field is used. Because of the presence of carbon nanotubes, water molecules tend to line up against the walls of the tubes, both inside and outside. In addition, water molecules tend to form highly ordered multi-ring structures in the carbon nanotubes with a size of 1.018–1.253 nm at a certain temperature. It is difficult to form the ordered structure of water in the outer carbon nanotubes. In the above range, with the increase of pipe diameter, the structure of multi-element ring water changes from three-element ring to six-element ring. On the one hand, the ordered structure depends on the diameter of the carbon nanotube, but the chirality of the carbon nanotube does not have a great influence on it. On the other hand, the stability of the ordered structure is temperature-dependent, and the ordered structure of multiple ring water in the carbon nanotube with a larger diameter is more likely to disappear with the increase of temperature. The van der Waals potential distribution is calculated by Multiwfn, and it is concluded that the van der Waals potential inside the tube is extremely low, resulting in a very large dispersion effect, and molecules can spontaneously move from the outer area to the tube. The van der Waals potential can also be negative outside the tube. This explains why water molecules tend to line up against the wall of the tube.

-

Keywords:

- confined space /

- single-wall carbon nanotube /

- water /

- van der Waals potential

[1] Iijima S 1991 Nature 354 56

Google Scholar

Google Scholar

[2] Gumhye J, Seung Y Y, Jin K K 2012 J. Mater. Chem. 22 14814

Google Scholar

Google Scholar

[3] Joshi R K, Carbone P, Wang F C, Kravets V G, Su Y, Grigorieva I V, Wu H A, Geim A K, Nair R R 2014 Science 343 752

Google Scholar

Google Scholar

[4] Marc G, Golovchenko J A 2007 Nat. Nanotechnol. 2 775

Google Scholar

Google Scholar

[5] David C T, Jeffrey C C 2012 Nano Lett. 12 3602

Google Scholar

Google Scholar

[6] Hansong C, Alan C C, Guido P P, Milen K K, Pamela P, Steve J S 2005 J. Phys. Chem. B 109 3780

Google Scholar

Google Scholar

[7] Eansom M S P, Kerr I D, Breed J, Sankararamakrishnan R 1996 Biophys. J. 70 693

Google Scholar

Google Scholar

[8] Koga K, Gao G T, Tanaka H, Zeng X C 2001 Nature 412 802

Google Scholar

Google Scholar

[9] Takaiwa D, Hatano I, Koga K, Tanaka H 2008 Proc. Natl. Acad. Sci. U.S.A. 105 39

Google Scholar

Google Scholar

[10] Boynton P, Di Ventra M 2013 Phys. Rev. Lett. 111 216804

Google Scholar

Google Scholar

[11] Ostmeyer J, Chakrapani S, Pan A C, Perozo E, Roux B 2013 Nature 501 121

Google Scholar

Google Scholar

[12] Dong H, Fiorin G, Carnevale V, Treptow W, Klein M L 2013 Proc. Natl. Acad. Sci. U.S.A. 110 17332

Google Scholar

Google Scholar

[13] Ohba T 2014 Angew Chem. 126 8170

Google Scholar

Google Scholar

[14] Barati Farimani A, Aluru N R 2011 J. Phys. Chem. B 115 12145

Google Scholar

Google Scholar

[15] Striolo A 2006 Nano Lett. 6 633

Google Scholar

Google Scholar

[16] Alexiadis A, Kassinos S 2008 Chem. Rev. 108 5014

Google Scholar

Google Scholar

[17] Spoel D V D, Lindahl E, Hess B, Groenhof G, Mark A E, Berendsen H J C 2005 J. Comput. Chem. 26 1701

Google Scholar

Google Scholar

[18] Berendsen H J C, Grigera J R, Straatsma T P 1987 J. Phys. Chem. 91 6269

Google Scholar

Google Scholar

[19] Mahoney M W, Jorgensen W L 2001 J. Chem. Phys. 114 363

Google Scholar

Google Scholar

[20] Mahoney M W, Jorgensen W L 2000 J. Chem. Phys. 112 8910

Google Scholar

Google Scholar

[21] Essmann U, Perera L, Berkowitz M L Darden T, Lee H, Pedersen L G 1995 J. Chem. Phys. 103 8577

Google Scholar

Google Scholar

[22] 韩典荣, 朱兴凤, 戴亚飞, 程承平, 罗成林 2015 64 230201

Google Scholar

Google Scholar

Han D R, Zhu X F, Dai Y F, Cheng C P, Luo C L 2015 Acta Phys. Sin. 64 230201

Google Scholar

Google Scholar

[23] Bussi G, Donadio D, Parrinello M 2007 J. Chem. Phys. 126 014101

Google Scholar

Google Scholar

[24] Lu T, Chen Q X 2020 ChemRxiv DOI: 10.26434/chemrxiv.12148572.v1

[25] Lu T, Chen F W 2012 J. Comput. Chem. 33 580

Google Scholar

Google Scholar

-

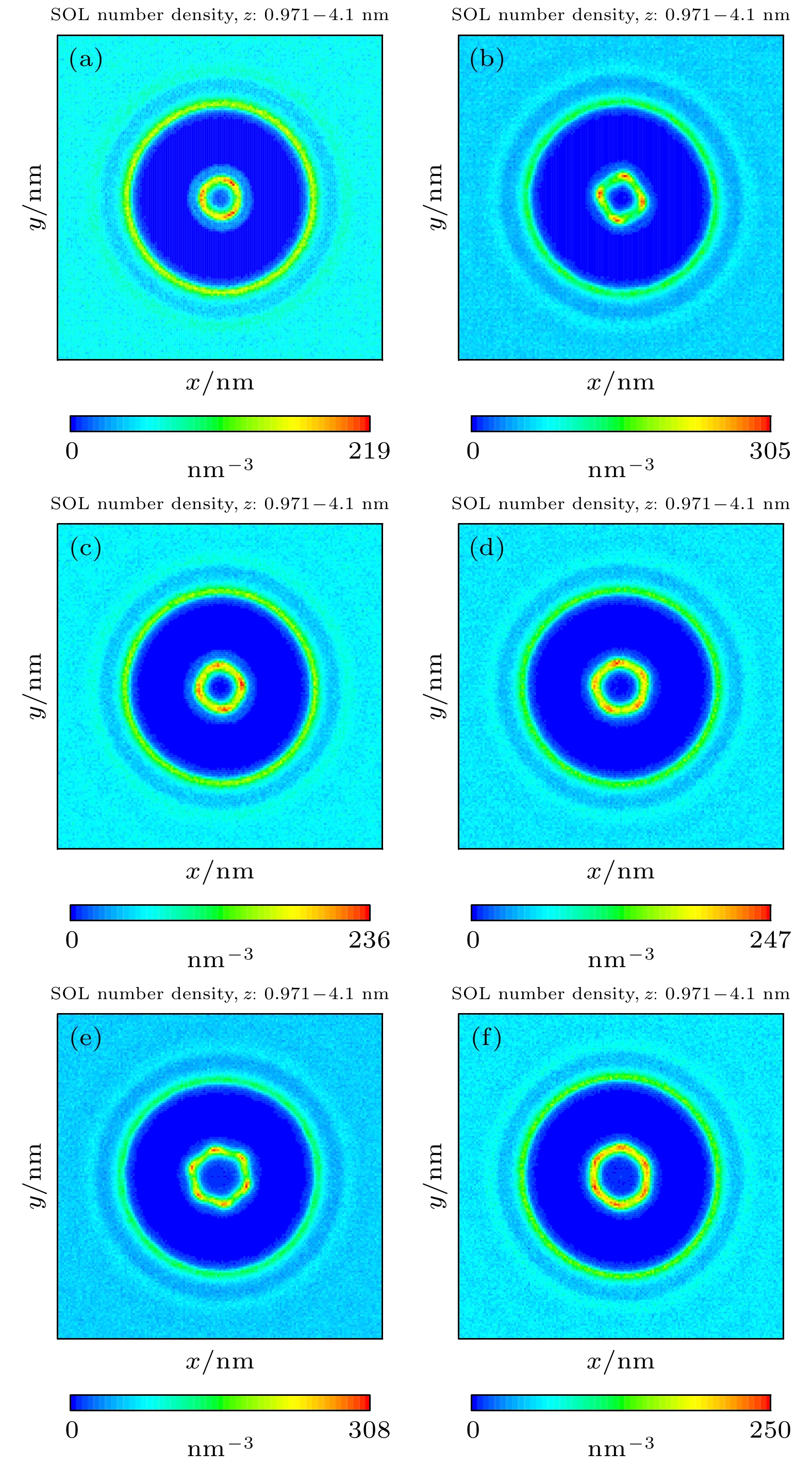

图 6 具有不同的手性参数和管径的碳纳米管内水的密度分布 (a) (13, 0), 1.018 nm; (b) (8, 8), 1.085 nm; (c) (14, 0), 1.096 nm; (d) (15, 0), 1.174 nm; (e) (9, 9), 1.220 nm; (f) (16, 0), 1.253 nm

Fig. 6. Density distributions of the water in CNTs with different diameters and chiralities: (a) (13, 0), 1.018 nm; (b) (8, 8), 1.085 nm; (c) (14, 0), 1.096 nm; (d) (15, 0), 1.174 nm; (e) (9, 9), 1.220 nm; (f) (16, 0), 1.253 nm.

图 10 不同温度下管内水分子的密度分布, 其中管径为1.085 nm的是(8, 8)管, 管径为1.174 nm的是(15, 0)管, 管径为1.253 nm的是(16, 0)管

Fig. 10. Density distribution of water molecules in CNTs at different temperatures. The diameter of (8, 8) CNT is 1.085 nm, the diameter of (15, 0) CNT is 1.174 nm, and the diameter of (16, 0) CNT is 1.253 nm.

表 1 碳纳米管类型

Table 1. Types of CNTs.

手性参数

(n, m)管径

D/nm手性参数

(n, m)管径

D/nm(5, 5) 0.678 (6, 6) 0.814 (7, 7) 0.949 (8, 8) 1.085 (9, 9) 1.220 (10, 10) 1.356 (12, 12) 1.627 (13, 0) 1.018 (14, 0) 1.096 (15, 0) 1.174 (16, 0) 1.253 表 2 不同水模型计算得到的物理性质

Table 2. Calculated physical properties of different water models.

-

[1] Iijima S 1991 Nature 354 56

Google Scholar

Google Scholar

[2] Gumhye J, Seung Y Y, Jin K K 2012 J. Mater. Chem. 22 14814

Google Scholar

Google Scholar

[3] Joshi R K, Carbone P, Wang F C, Kravets V G, Su Y, Grigorieva I V, Wu H A, Geim A K, Nair R R 2014 Science 343 752

Google Scholar

Google Scholar

[4] Marc G, Golovchenko J A 2007 Nat. Nanotechnol. 2 775

Google Scholar

Google Scholar

[5] David C T, Jeffrey C C 2012 Nano Lett. 12 3602

Google Scholar

Google Scholar

[6] Hansong C, Alan C C, Guido P P, Milen K K, Pamela P, Steve J S 2005 J. Phys. Chem. B 109 3780

Google Scholar

Google Scholar

[7] Eansom M S P, Kerr I D, Breed J, Sankararamakrishnan R 1996 Biophys. J. 70 693

Google Scholar

Google Scholar

[8] Koga K, Gao G T, Tanaka H, Zeng X C 2001 Nature 412 802

Google Scholar

Google Scholar

[9] Takaiwa D, Hatano I, Koga K, Tanaka H 2008 Proc. Natl. Acad. Sci. U.S.A. 105 39

Google Scholar

Google Scholar

[10] Boynton P, Di Ventra M 2013 Phys. Rev. Lett. 111 216804

Google Scholar

Google Scholar

[11] Ostmeyer J, Chakrapani S, Pan A C, Perozo E, Roux B 2013 Nature 501 121

Google Scholar

Google Scholar

[12] Dong H, Fiorin G, Carnevale V, Treptow W, Klein M L 2013 Proc. Natl. Acad. Sci. U.S.A. 110 17332

Google Scholar

Google Scholar

[13] Ohba T 2014 Angew Chem. 126 8170

Google Scholar

Google Scholar

[14] Barati Farimani A, Aluru N R 2011 J. Phys. Chem. B 115 12145

Google Scholar

Google Scholar

[15] Striolo A 2006 Nano Lett. 6 633

Google Scholar

Google Scholar

[16] Alexiadis A, Kassinos S 2008 Chem. Rev. 108 5014

Google Scholar

Google Scholar

[17] Spoel D V D, Lindahl E, Hess B, Groenhof G, Mark A E, Berendsen H J C 2005 J. Comput. Chem. 26 1701

Google Scholar

Google Scholar

[18] Berendsen H J C, Grigera J R, Straatsma T P 1987 J. Phys. Chem. 91 6269

Google Scholar

Google Scholar

[19] Mahoney M W, Jorgensen W L 2001 J. Chem. Phys. 114 363

Google Scholar

Google Scholar

[20] Mahoney M W, Jorgensen W L 2000 J. Chem. Phys. 112 8910

Google Scholar

Google Scholar

[21] Essmann U, Perera L, Berkowitz M L Darden T, Lee H, Pedersen L G 1995 J. Chem. Phys. 103 8577

Google Scholar

Google Scholar

[22] 韩典荣, 朱兴凤, 戴亚飞, 程承平, 罗成林 2015 64 230201

Google Scholar

Google Scholar

Han D R, Zhu X F, Dai Y F, Cheng C P, Luo C L 2015 Acta Phys. Sin. 64 230201

Google Scholar

Google Scholar

[23] Bussi G, Donadio D, Parrinello M 2007 J. Chem. Phys. 126 014101

Google Scholar

Google Scholar

[24] Lu T, Chen Q X 2020 ChemRxiv DOI: 10.26434/chemrxiv.12148572.v1

[25] Lu T, Chen F W 2012 J. Comput. Chem. 33 580

Google Scholar

Google Scholar

计量

- 文章访问数: 9420

- PDF下载量: 179

- 被引次数: 0

下载:

下载: