-

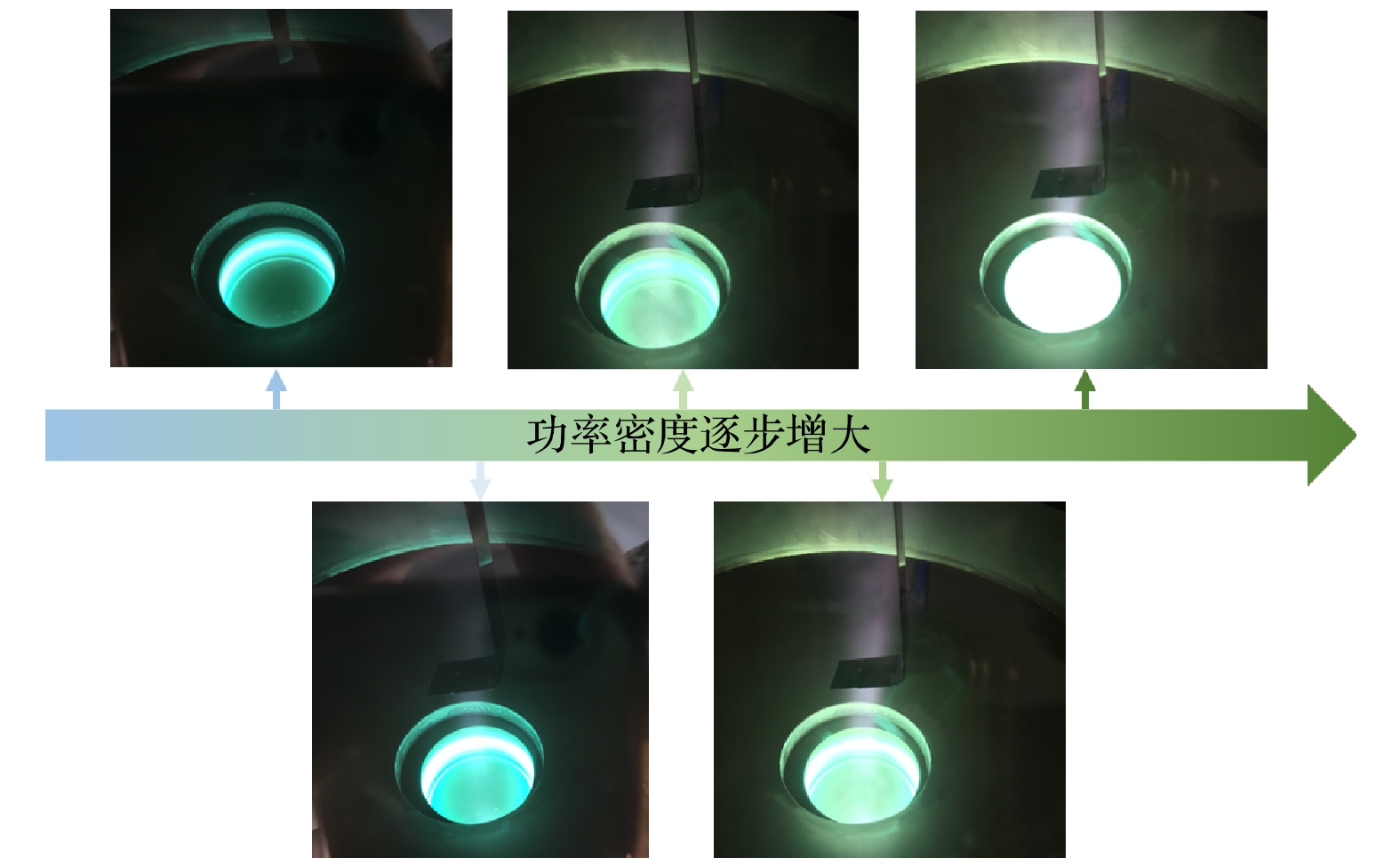

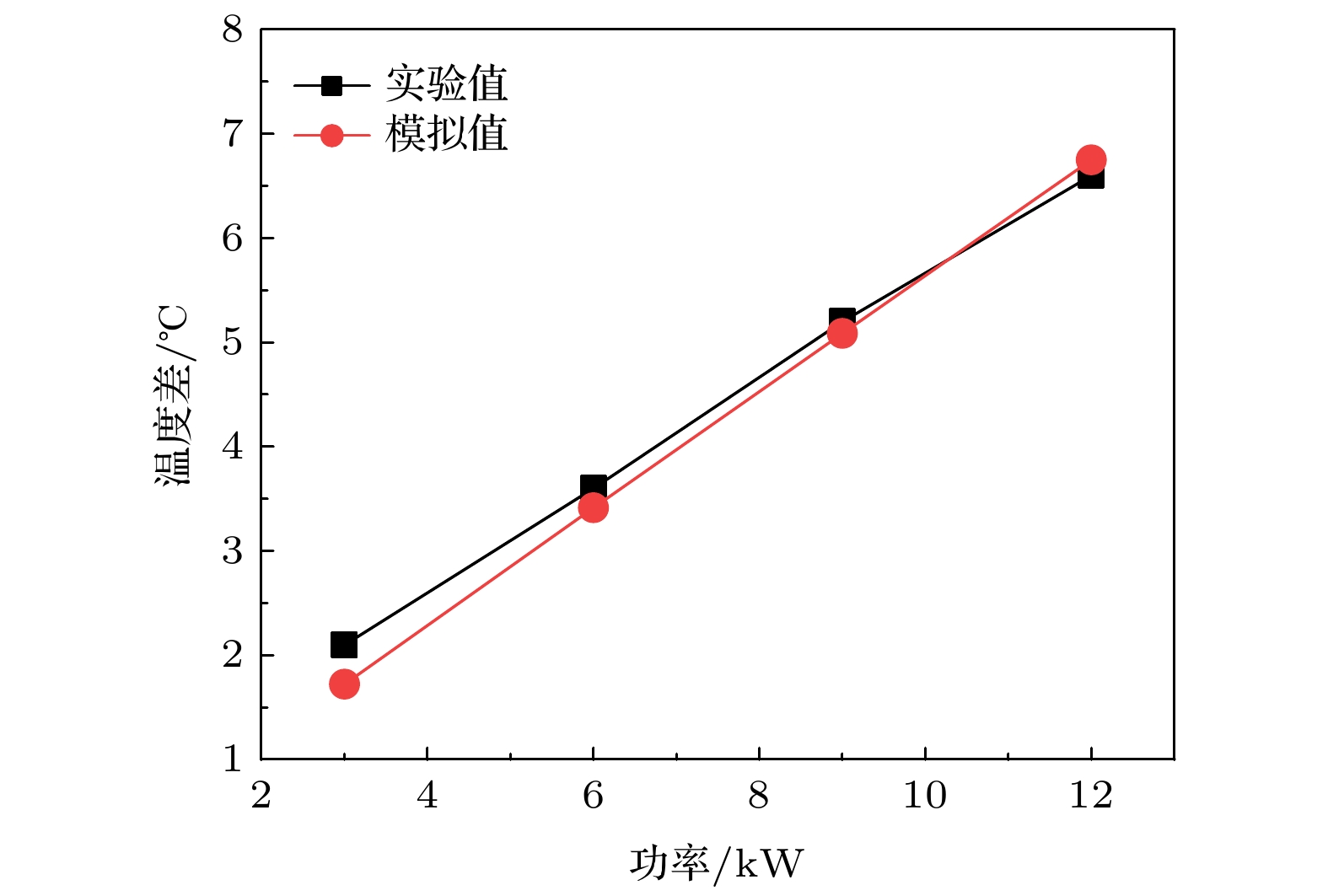

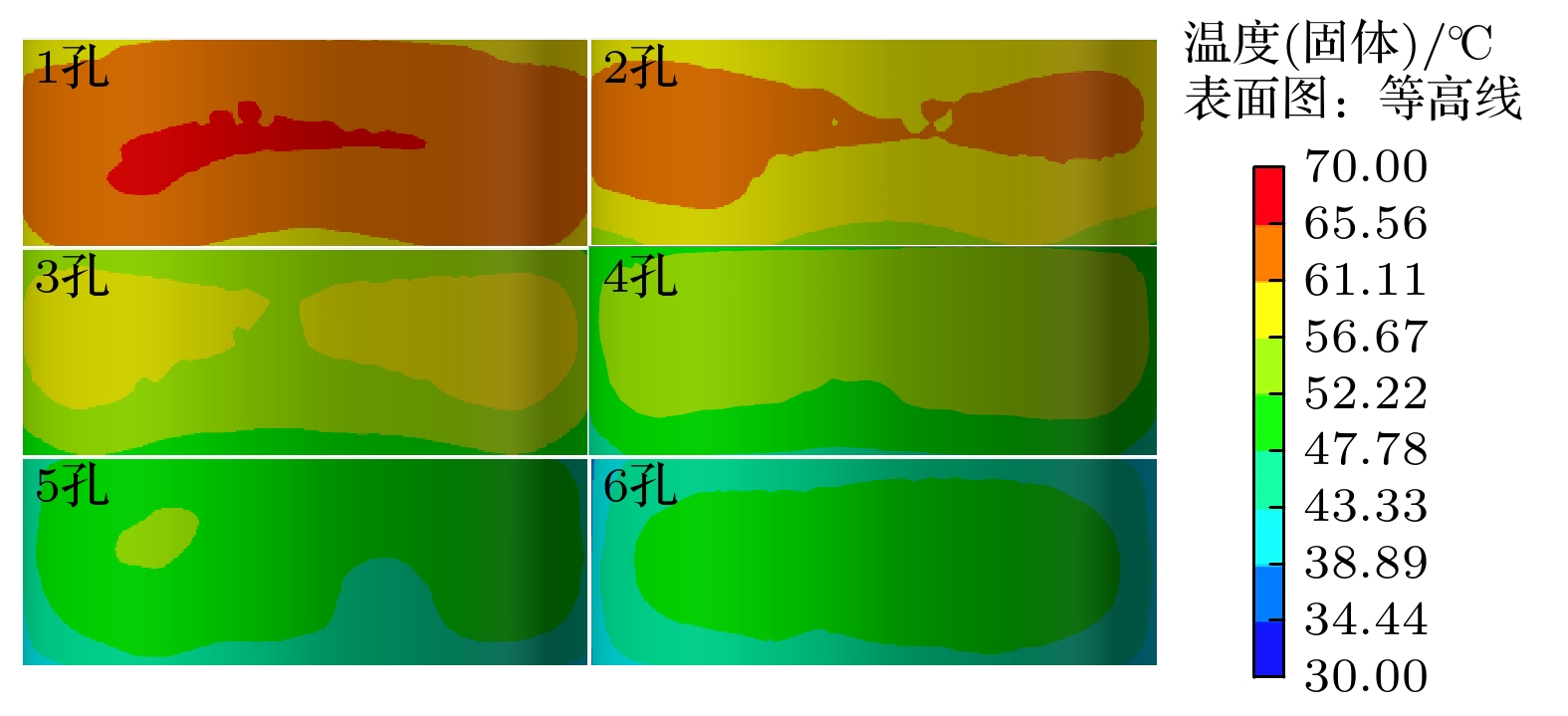

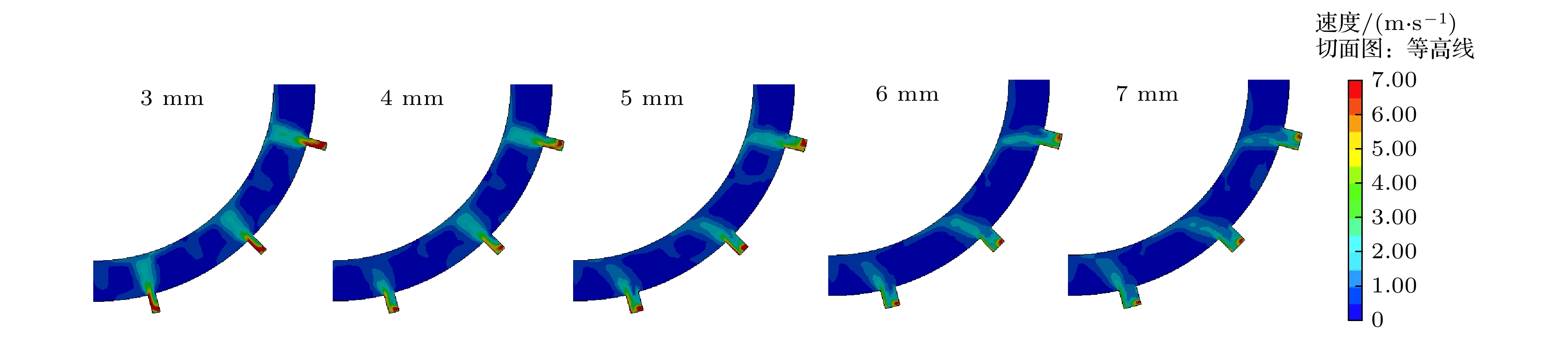

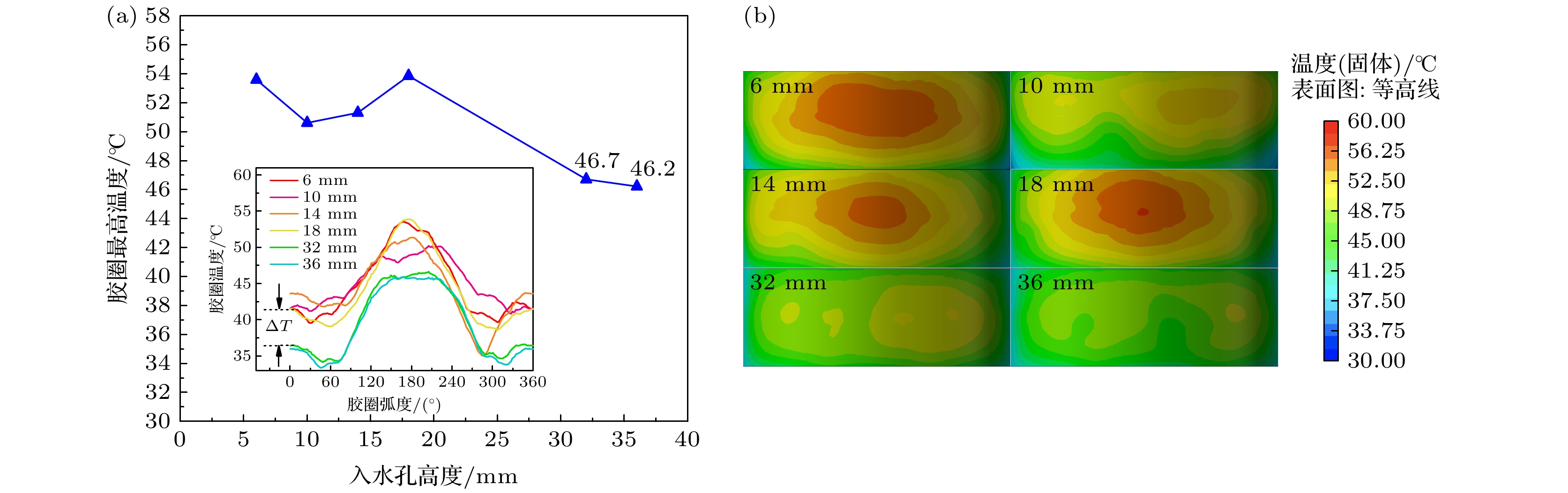

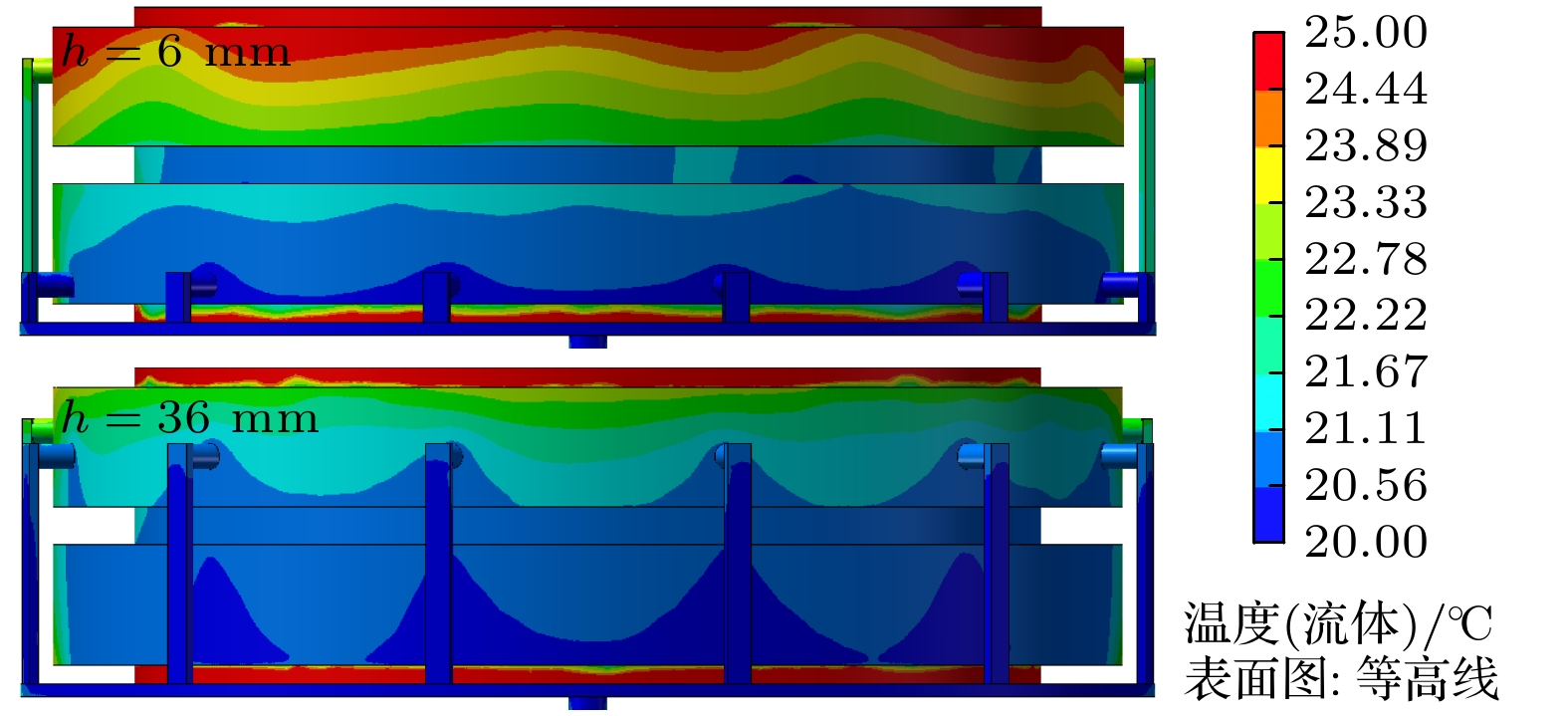

环形磁场金属等离子体源作为一种全新的等离子体源结构, 可用于产生高度离化、无大颗粒、高密度的离子束流, 但传统流道结构不能保证其高效、均匀散热, 大功率工作时可能引起密封胶圈的烧蚀失效, 需对其冷却流场进行优化设计. 利用Solidworks Flow Simulation软件对等离子体源冷却流道进行模拟, 分析出入水孔分布角度、孔数、孔径以及入水孔高度对冷却效果的影响规律, 并对流道结构参数进行优化. 结果表明, 增大水孔的周向分布范围, 有利于提高散热的均匀性; 入水孔设置在结构上层有利于减少冷却水的温度分层现象, 使铜套和密封胶圈都处于较好的冷却状态; 适当减小孔径有利于增大冷却水射流速度, 增大湍流程度强化传热, 提高换热效率. 优化后的流场结构可以提高冷却水的利用率, 在相同流量条件下获得更好的冷却效果, 改善等离子体源的放电稳定性, 为环形磁场金属等离子体源的冷却结构设计提供理论依据.

-

关键词:

- 环形磁场金属等离子体源 /

- 数值模拟 /

- 冷却 /

- 流场优化

In order to solve the problems of unstable discharge, low deposition rate and large difference in ionization rate between different targets in high power impulse magnetron sputtering, a novel cylindrical cathode with annular magnetic field based on hollow cathode effect is proposed, which can be used to produce ion beam with high ionization rate, high plasma density and no large particles. However, the traditional channel structure could not guarantee its high efficiency and uniform heat dissipation. The sealing ring may be damaged by ablation due to high power density, which restricts the further improvement of power density. Therefore, it is necessary to optimize the design of the channel structure. SolidWorks flow simulation software is used to simulate the cooling channel of plasma source. The influence of water hole structure parameters on cooling effect is analyzed, including distribution angle, hole number, diameter and inlet hole height. And the channel structure parameters are optimized. The results show that the increasing of the circumferential distribution range of the water hole is beneficial to the uniformity of heat dissipation, ensuring a large temperature difference between cooling water and copper sleeve, and strengthening heat exchange. The water inlet hole set in the upper layer of the structure is conducive to alleviating the temperature stratification phenomenon of the cooling water, so that the copper sleeve and sealing ring are in good cooling condition. Appropriately reducing the aperture is beneficial to increasing the cooling water jet velocity, enhancing the jet impact effect, and then increasing the turbulence degree, strengthening the heat transfer and improving the heat transfer efficiency. By systematically studying the influencing factors, the optimized cooling flow field structure of cylindrical cathode with an annular magnetic field is obtained. The distribution angle is 30°, the number of holes is 6, the aperture is 4 mm, and the height of water inlet hole is 36 mm. The optimized channel structure can improve the utilization rate of cooling water, obtaining better cooling effect at the same flow rate, and improving the discharge stability of the plasma source, which provides a basis for designing the cooling structure of the cylindrical cathode with annular magnetic field.-

Keywords:

- cylindrical cathode with annular magnetic field /

- numerical simulation /

- cooling /

- optimized design for the flow channel structure

[1] D'Avico L, Beltrami R, Lecis N, Trasatti S P 2019 Coatings 9 7

[2] Maksakova O, Simoẽs S, Pogrebnjak A, Bondar O, Kravchenko Y O, Koltunowicz T, Shaimardanov Z K 2019 J. Alloys Compd. 776 679

Google Scholar

Google Scholar

[3] Vu T D, Chen Z, Zeng X, Jiang M, Liu S, Gao Y, Long Y 2019 J. Alloys Compd. C 7 2121

[4] Kouznetsov V, Macak K, Schneider J M, Helmersson U, Petrov I 1999 Surf. Coat. Technol. 122 290

Google Scholar

Google Scholar

[5] 吴忠振, 田修波, 李春伟, Ricky K Y Fu, 潘锋, 朱剑豪 2014 63 175201

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Li C W, Fu R K Y, Pan F, Chu P K 2014 Acta Phys. Sin. 63 175201

Google Scholar

Google Scholar

[6] 吴忠振, 田修波, 潘锋, Ricky K Y Fu, 朱剑豪 2014 63 185207

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Phys. Sin. 63 185207

Google Scholar

Google Scholar

[7] Biswas B, Purandare Y, Sugumaran A, Khan I, Hovsepian P E 2018 Surf. Coat. Technol. 336 84

Google Scholar

Google Scholar

[8] Biswas B, Purandare Y, Khan I, Hovsepian P E 2018 Surf. Coat. Technol. 344 383

Google Scholar

Google Scholar

[9] Vitelaru C, Aijaz A, Parau A C, Kiss A E, Sobetkii A, Kubart T 2018 J. Phys. D: Appl. Phys. 51 165201

Google Scholar

Google Scholar

[10] Meier S M, Hecimovic A, Tsankov T V, Luggenhölscher D, Czarnetzki U 2018 Plasma Sources Sci. Technol. 27 035006

Google Scholar

Google Scholar

[11] Diyatmika W, Liang F K, Lou B S, Lu J H, Sun D E, Lee J W 2018 Surf. Coat. Technol. 352 680

Google Scholar

Google Scholar

[12] Ganesan R, Akhavan B, Dong X, McKenzie D, Bilek M 2018 Surf. Coat. Technol. 352 671

Google Scholar

Google Scholar

[13] Rudolph M, Brenning N, Raadu M A, Hajihoseini H, Gudmundsson J T, Anders A, Lundin D 2020 Plasma Sources Sci. Technol. 29 05LT01

Google Scholar

Google Scholar

[14] 吴忠振, 田修波, 潘锋, Ricky K Y Fu, 朱剑豪 2014 金属学报 10 1279

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Meta. Sin. 10 1279

Google Scholar

Google Scholar

[15] 肖舒, 吴忠振, 崔岁寒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 潘锋, 朱剑豪 2016 65 185202

Google Scholar

Google Scholar

Xiao S, Wu Z Z, Cui S H, Liu L L, Zheng B C, Lin H, Fu J Y, Tian X B, Pan F, Chu P K 2016 Acta Phys. Sin. 65 185202

Google Scholar

Google Scholar

[16] 崔岁寒, 吴忠振, , 肖舒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 朱剑豪, 谭文长, 潘锋 2017 66 095203

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Liu L L, Zheng B C, Lin H, Fu J Y, Tian X B, Chu P K, Tan W C, Pan F 2017 Acta Phys. Sin. 66 095203

Google Scholar

Google Scholar

[17] 崔岁寒, 吴忠振, , 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Chen L, Li T J, Liu L L, Fu R K Y, Tian X B, Chu P K, Tan W C 2019 Acta Phys. Sin. 68 195204

Google Scholar

Google Scholar

[18] Cui S H, Wu Z Z, Xiao S, Zheng B C, Chen L, Li T J, Fu R K Y, Chu P K, Tian X B, Tan W C Fang D N, Pan F 2020 J. Appl. Phys. 127 023301

Google Scholar

Google Scholar

[19] Marin F, de Miranda J R, de Souza A F 2018 Polym. Eng. Sci. 58 552

Google Scholar

Google Scholar

[20] Liu X, Xu X, Liu C, Bai W, Dang C 2018 Energy 147 1

Google Scholar

Google Scholar

[21] 曹珍恩, 巩春志, 田修波, 杨士勤 2008 真空 2 70

Google Scholar

Google Scholar

Cao Z E, Gong C Z, Tian X B, Yang S Q 2008 Vacuum 2 70

Google Scholar

Google Scholar

[22] Bräuer G, Szyszka B, Vergöhl M, Bandorf R 2010 Vacuum 84 1354

Google Scholar

Google Scholar

-

表 1 模型中各零部件材料物性参数

Table 1. Material property parameters of each component in the model.

材料 密度ρ/kg·m–3 比热J/kg·K 热导率W/m·K 部件 纯铁 7874 447 80 磁短路环 紫铜 8960 384 401 铜套、铜靶 软钢 7870 472 51.9 上板、上盖板、

周向套、底板钕铁硼 7400 502 32.2 环形磁铁 氟橡胶 1250 1790 0.2 胶圈 水 1000 4182 0.58 冷却水 表 2 不同出入水孔分布角度、孔数时的胶圈最高温度 (℃)

Table 2. Maximum temperature of aprons with different distribution angles and number of holes (℃).

角度/(°) 5 10 15 20 25 30 数量/个 1 60.48 60.48 60.48 60.48 60.48 60.48 2 59.83 59.51 59.93 59.20 58.27 59.63 3 57.42 58.79 57.75 57.04 57.62 55.84 4 57.40 57.18 55.52 53.95 53.40 53.24 5 57.15 56.13 53.40 49.75 51.26 50.47 6 55.93 54.82 53.07 52.75 49.87 46.50 -

[1] D'Avico L, Beltrami R, Lecis N, Trasatti S P 2019 Coatings 9 7

[2] Maksakova O, Simoẽs S, Pogrebnjak A, Bondar O, Kravchenko Y O, Koltunowicz T, Shaimardanov Z K 2019 J. Alloys Compd. 776 679

Google Scholar

Google Scholar

[3] Vu T D, Chen Z, Zeng X, Jiang M, Liu S, Gao Y, Long Y 2019 J. Alloys Compd. C 7 2121

[4] Kouznetsov V, Macak K, Schneider J M, Helmersson U, Petrov I 1999 Surf. Coat. Technol. 122 290

Google Scholar

Google Scholar

[5] 吴忠振, 田修波, 李春伟, Ricky K Y Fu, 潘锋, 朱剑豪 2014 63 175201

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Li C W, Fu R K Y, Pan F, Chu P K 2014 Acta Phys. Sin. 63 175201

Google Scholar

Google Scholar

[6] 吴忠振, 田修波, 潘锋, Ricky K Y Fu, 朱剑豪 2014 63 185207

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Phys. Sin. 63 185207

Google Scholar

Google Scholar

[7] Biswas B, Purandare Y, Sugumaran A, Khan I, Hovsepian P E 2018 Surf. Coat. Technol. 336 84

Google Scholar

Google Scholar

[8] Biswas B, Purandare Y, Khan I, Hovsepian P E 2018 Surf. Coat. Technol. 344 383

Google Scholar

Google Scholar

[9] Vitelaru C, Aijaz A, Parau A C, Kiss A E, Sobetkii A, Kubart T 2018 J. Phys. D: Appl. Phys. 51 165201

Google Scholar

Google Scholar

[10] Meier S M, Hecimovic A, Tsankov T V, Luggenhölscher D, Czarnetzki U 2018 Plasma Sources Sci. Technol. 27 035006

Google Scholar

Google Scholar

[11] Diyatmika W, Liang F K, Lou B S, Lu J H, Sun D E, Lee J W 2018 Surf. Coat. Technol. 352 680

Google Scholar

Google Scholar

[12] Ganesan R, Akhavan B, Dong X, McKenzie D, Bilek M 2018 Surf. Coat. Technol. 352 671

Google Scholar

Google Scholar

[13] Rudolph M, Brenning N, Raadu M A, Hajihoseini H, Gudmundsson J T, Anders A, Lundin D 2020 Plasma Sources Sci. Technol. 29 05LT01

Google Scholar

Google Scholar

[14] 吴忠振, 田修波, 潘锋, Ricky K Y Fu, 朱剑豪 2014 金属学报 10 1279

Google Scholar

Google Scholar

Wu Z Z, Tian X B, Pan F, Fu R K Y, Chu P K 2014 Acta Meta. Sin. 10 1279

Google Scholar

Google Scholar

[15] 肖舒, 吴忠振, 崔岁寒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 潘锋, 朱剑豪 2016 65 185202

Google Scholar

Google Scholar

Xiao S, Wu Z Z, Cui S H, Liu L L, Zheng B C, Lin H, Fu J Y, Tian X B, Pan F, Chu P K 2016 Acta Phys. Sin. 65 185202

Google Scholar

Google Scholar

[16] 崔岁寒, 吴忠振, , 肖舒, 刘亮亮, 郑博聪, 林海, 傅劲裕, 田修波, 朱剑豪, 谭文长, 潘锋 2017 66 095203

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Liu L L, Zheng B C, Lin H, Fu J Y, Tian X B, Chu P K, Tan W C, Pan F 2017 Acta Phys. Sin. 66 095203

Google Scholar

Google Scholar

[17] 崔岁寒, 吴忠振, , 肖舒, 陈磊, 李体军, 刘亮亮, 傅劲裕, 田修波, 朱剑豪, 谭文长 2019 68 195204

Google Scholar

Google Scholar

Cui S H, Wu Z Z, Xiao S, Chen L, Li T J, Liu L L, Fu R K Y, Tian X B, Chu P K, Tan W C 2019 Acta Phys. Sin. 68 195204

Google Scholar

Google Scholar

[18] Cui S H, Wu Z Z, Xiao S, Zheng B C, Chen L, Li T J, Fu R K Y, Chu P K, Tian X B, Tan W C Fang D N, Pan F 2020 J. Appl. Phys. 127 023301

Google Scholar

Google Scholar

[19] Marin F, de Miranda J R, de Souza A F 2018 Polym. Eng. Sci. 58 552

Google Scholar

Google Scholar

[20] Liu X, Xu X, Liu C, Bai W, Dang C 2018 Energy 147 1

Google Scholar

Google Scholar

[21] 曹珍恩, 巩春志, 田修波, 杨士勤 2008 真空 2 70

Google Scholar

Google Scholar

Cao Z E, Gong C Z, Tian X B, Yang S Q 2008 Vacuum 2 70

Google Scholar

Google Scholar

[22] Bräuer G, Szyszka B, Vergöhl M, Bandorf R 2010 Vacuum 84 1354

Google Scholar

Google Scholar

计量

- 文章访问数: 6287

- PDF下载量: 94

- 被引次数: 0

下载:

下载: