-

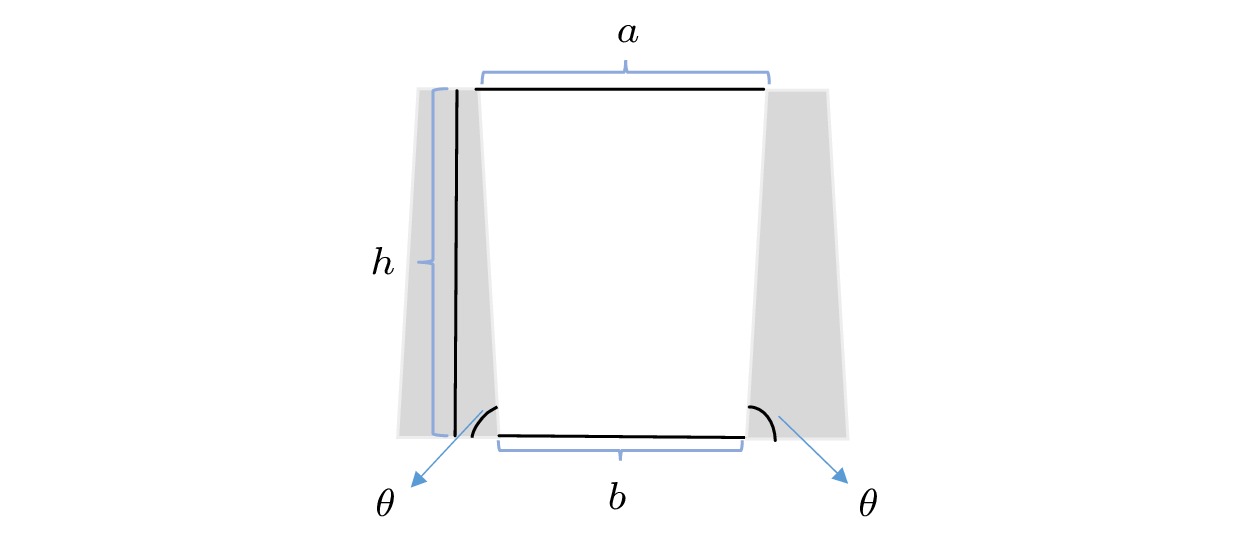

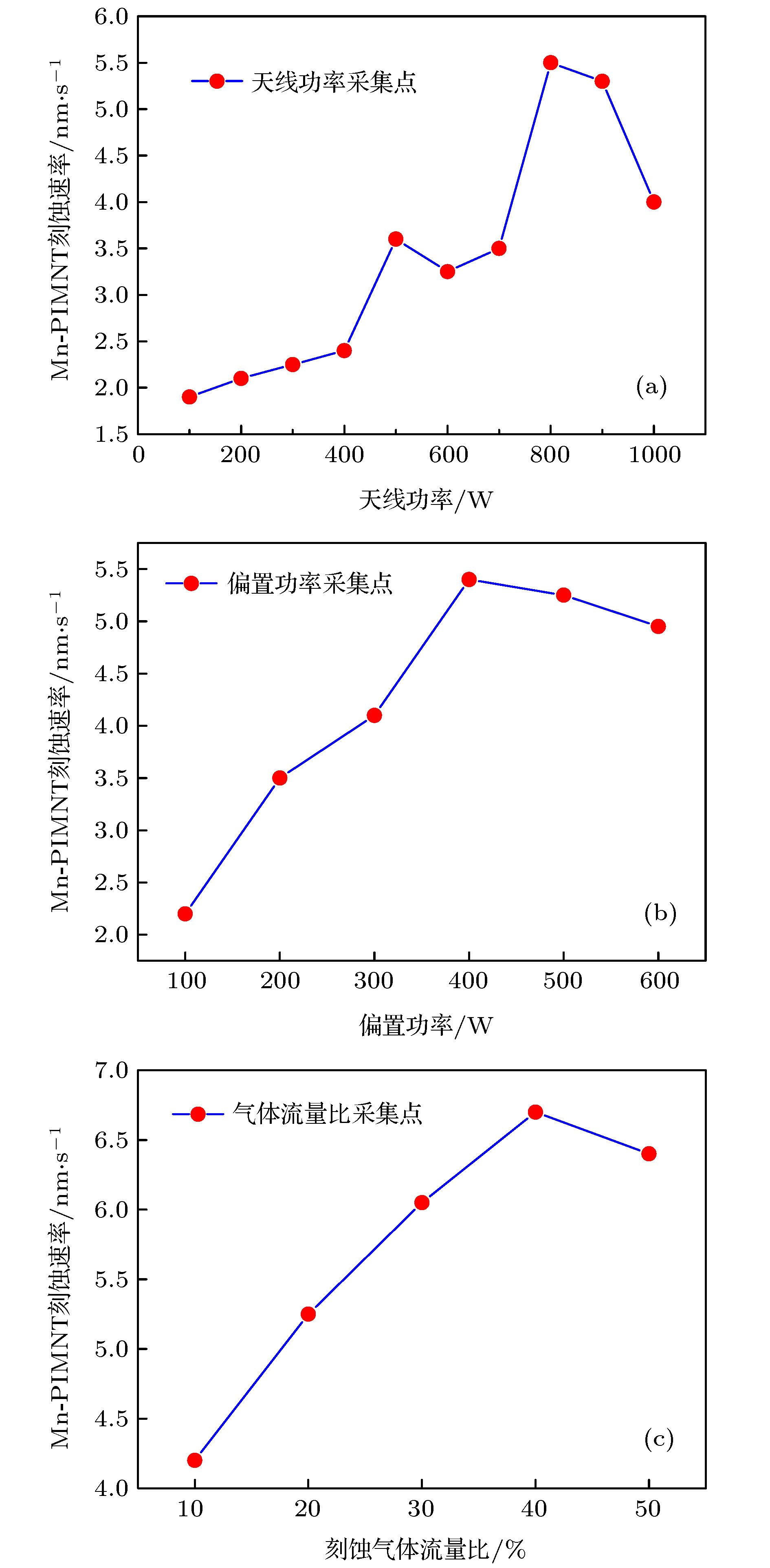

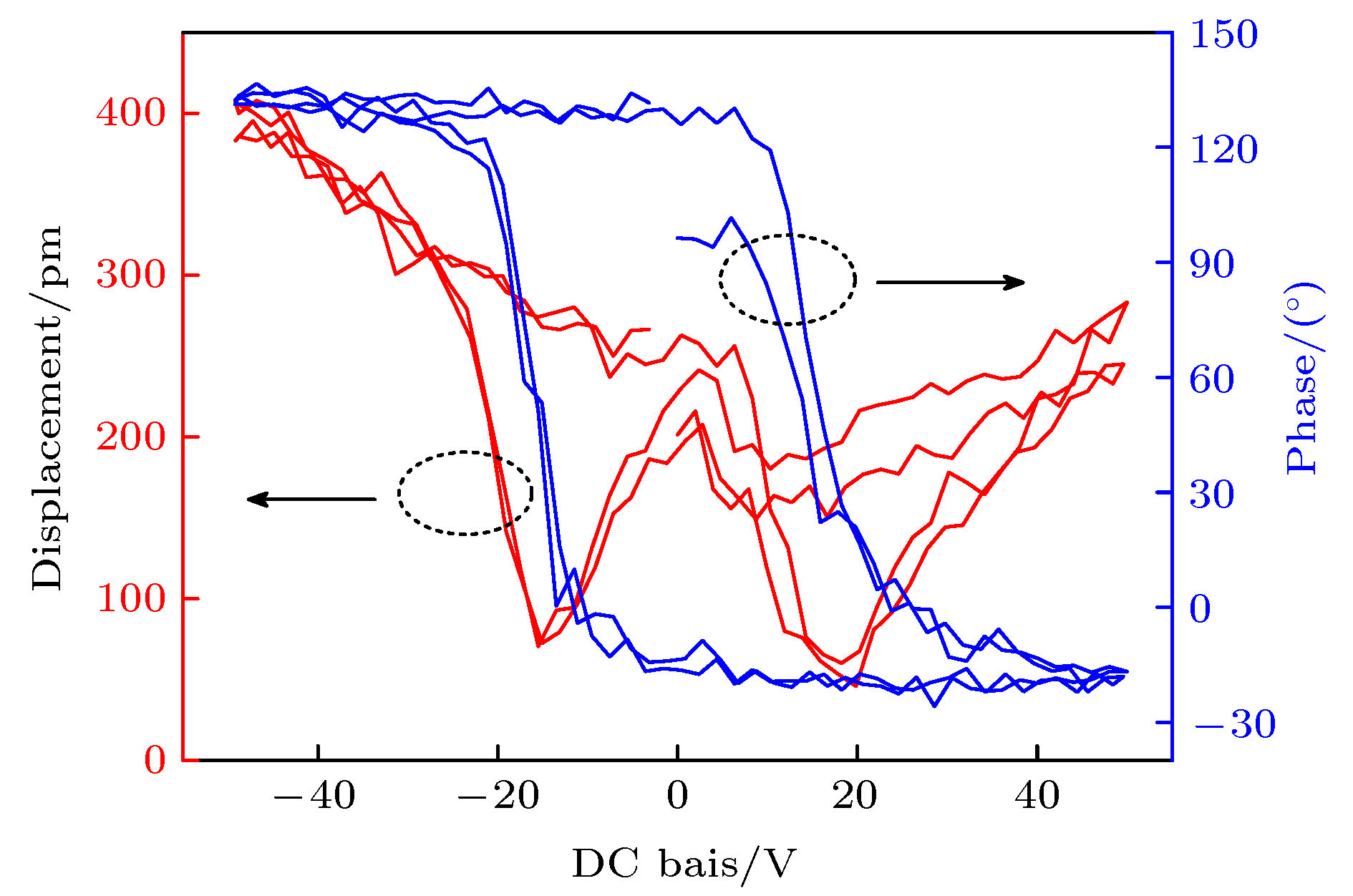

超声探头是高端医学超声诊疗设备的核心元件, 由弛豫型铁电单晶制备的新型压电器件可显著提高其性能. 由于高阵元密度阵列技术与微机电系统迅速发展, 传统切割填充法刀缝过宽, 难以降低阵元尺寸, 无法提高阵元密度, 更不利于高分辨率及高频率的应用需求. 采用紫外光刻-深反应离子刻蚀工艺的微机械制备方法, 可以降低缝宽、提升阵列密度. 制备了基于新型、高性能弛豫铁电单晶—Mn离子掺杂0.3Pb(In1/2Nb1/2)O3-0.4Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 (Mn-PIMNT)的微米尺度压电阵列. 研究了紫外光刻工艺参数、深反应离子刻蚀工艺参数对压电阵列形貌的影响规律, 得到了不同沟道深度与不同压电阵元形状的形成机制以及Mn-PIMNT单晶的刻蚀速率与天线功率、偏置功率及刻蚀气体比例之间的关系规律. 得到压电阵列阵元尺寸小于10 μm, 沟槽深度大于20 μm, 沟槽宽度小于5 μm, 侧壁角度高于87°. 通过压电力显微镜研究了微米尺度压电阵元的铁电畴结构及电场效应调控. 与传统切割填充法相比, 本文的加工方法不存在刀缝过宽, 可确保单晶晶向, 促进了高频率压电单晶复合材料、高密度超声换能器阵列以及新型压电微机械系统的发展.Relaxor ferroelectric single crystal piezoelectric materials have become the core components of new piezoelectric devices such as ultrasonic transducers used in high-end medical ultrasound diagnostic and therapeutic equipment. High-element density array technology and micro-electro-mechanical systems have developed rapidly. For the new generation of 20–80 MHz medical high-frequency ultrasound transducers, the thickness of high-frequency piezoelectric composite material is usually 20–60 μm, and the width of each piezoelectric column is about 5–15 μm. However, the kerf of traditional cutting-and-filling method is too wide, and it is difficult to reduce the size of the array element, which is not conducive to the density of the array element and the demand for higher frequency applications with higher resolution. In this work, a micromechanical fabrication method based on deep reactive ion etching is used to reduce the slit width and increase the array density. We study the fabrication technology of novel and high-performance relaxor ferroelectric single crystal Mn doped Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 (Mn-PIMNT) micro scale piezoelectric array. The influence of the parameters of lithography and deep reactive ion etching on the morphology of piezoelectric array are studied. We obtain the formation mechanisms of different kerfs, different shapes of piezoelectric array element and the relationship among etching rate of Mn-PIMNT single crystal with antenna power, bias power and etching gas ratio. Finally, the size of piezoelectric array element is less than 10 μm, the etching depth is more than 20 μm, the kerf width is less than 5 μm, the angle is controllable, and the maximum is more than 87°. The ferroelectric domain structure and the regulation of electric field effect of micro scale piezoelectric elements are studied by means of piezoelectric force microscope. The variation rules of piezoelectric properties and micro scale are obtained. This method can effectively bypass the shortcomings of the wide kerf and the destruction of the crystal orientation by the traditional cutting-and-filling method. It provides a new preparation technology for the development of high-frequency piezoelectric composites, high-density ultrasonic transducer arrays and new piezoelectric micro mechanical systems. This project presents the guidance and reference for the new micromachining technology of ferroelectric materials, and also lays the foundation for the high-frequency piezoelectric composite and high-frequency ultrasonic transducer.

[1] Wang D W, Cao M S, Zhang S J 2012 J. Am. Ceram. Soc. 95 3220

Google Scholar

Google Scholar

[2] Wang D W, Cao M S, Zhang S J 2012 Phys. Status Solidi RRL 6 135

Google Scholar

Google Scholar

[3] Wang D W, Cao M S, Zhao Q L, Cui Y, Zhang S J 2013 Phys. Status Solidi RRL 7 221

Google Scholar

Google Scholar

[4] Lee J S, Park E C, Lee S H, Lee D S 2005 Mater. Chem. Phys. 90 381

Google Scholar

Google Scholar

[5] 罗豪甦, 沈关顺, 齐振一, 许桂生, 王评初, 乐秀宏, 李金龙, 仲维卓, 殷之文 1997 人工晶体学报 26 191

Luo H S, Shen G S, Qi Z Y, Xu G S, Wang P C, Le X H, Li J L, Zhong W Z, Yin Z W 1997 J. Synthetic Crystals 26 191

[6] Luo H S, Xu G S, Wang P C, Yin Z W 1999 Ferroelectrics 231 97

Google Scholar

Google Scholar

[7] Xu G S, Luo H S, Xu H Q, Qi Z Y, Wang P C, Zhong W Z, Yin Z W 2001 J. Cryst. Growth. 222 202

Google Scholar

Google Scholar

[8] Feng Z Y, He T H, Xu H Q, Luo H S, Yin Z W 2004 Solid. State. Commun. 130 557

Google Scholar

Google Scholar

[9] Wu X, Liu L H, Li X B, Zhang Q H, Ren B, Lin D, Zhao X Y, Luo H S, Huang Y L 2011 J. Cryst. Growth. 318 865

Google Scholar

Google Scholar

[10] Deng C G, He C J, Chen Z Y, Chen H B, Mao R, Liu Y W, Zhu K J, Gao H F, Ding Y 2019 J. Appl. Phys. 126 085702

Google Scholar

Google Scholar

[11] He C J, Chen Z Y, Chen H B, Wu T, Wang J M, Gu X R, Liu Y W, Zhu K J 2018 J. Nanophotonics 12 046019

Google Scholar

Google Scholar

[12] He C J, Chen H B, Bai F, Fan Z B, Sun L, Xu F, Wang J M, Liu Y W, Zhu K J 2012 J. Appl. Phys. 112 126102

Google Scholar

Google Scholar

[13] Jia Y M, Luo H S, Zhao X Y, Wang F F 2008 Adv. Mater. 20 4776

Google Scholar

Google Scholar

[14] He C J, Chen H B, Wang J M, Gu X R, Wu T, Liu Y W 2015 J. Appl. Phys. 117 164104

Google Scholar

Google Scholar

[15] Yang Y, Jung J H, Yun B K, Zhang F, Pradel K C, Guo W, Wang Z L 2012 Adv. Mater. 24 5357

Google Scholar

Google Scholar

[16] 岳晴雯 2016 博士学位论文 (上海: 中国科学院大学)

Yue Q W 2016 Ph. D. Dissertation (Shanghai: University of Chinese Academy of Sciences) (in Chinese)

[17] Sun E W, Cao W W 2014 Prog. Mater. Sci. 65 124

Google Scholar

Google Scholar

[18] Zhu R F, Zhao J, Liu F, Zhang Z, Fang B J, Chen J W, Xu H Q, Wang X A, Luo H S 2020 J. Am. Ceram. Soc. 103 2575

Google Scholar

Google Scholar

[19] Xie Q X, Hu Y Q, Xue S D, Ma J P, Zhao X Y, Tang Y X, Wang F F, Chew K H, Lin D, Luo H S 2019 Mater. Chem. Phys. 238 121890

Google Scholar

Google Scholar

[20] Zhang J S, Ren W, Jing X P, Shi P, Wu X Q 2015 Ceram. Int. 41 S656

Google Scholar

Google Scholar

[21] Jian X H, Li S B, Huang W B, Cui Y Y, Jiang X N 2015 J. Intell. Mater. Syst. Struct. 26 2011

Google Scholar

Google Scholar

[22] 周丹, 罗来慧, 王飞飞, 贾艳敏, 赵祥永, 罗豪甦 2008 57 4552

Google Scholar

Google Scholar

Zhou D, Luo L H, Wang F F, Jia Y M, Zhao X Y, Luo H S 2008 Acta Phys. Sin. 57 4552

Google Scholar

Google Scholar

[23] 乔学光, 邵志华, 包维佳, 荣强周 2017 66 074205

Google Scholar

Google Scholar

Qiao X G, Shao Z H, Bao W J, Rong Q Z 2017 Acta Phys. Sin. 66 074205

Google Scholar

Google Scholar

[24] 徐萌, 晏建民, 徐志学, 郭磊, 郑仁奎, 李晓光 2018 67 157506

Google Scholar

Google Scholar

Xu M, Yan J M, Xu Z X, Guo L, Zheng R K, Li X G 2018 Acta Phys. Sin. 67 157506

Google Scholar

Google Scholar

[25] 赵章风, 张文俊, 牛丽丽, 孟龙, 郑海荣 2018 67 194302

Google Scholar

Google Scholar

Zhao Z F, Zhang W J, Niu L L, Meng L, Zheng H R 2018 Acta Phys. Sin. 67 194302

Google Scholar

Google Scholar

[26] Wang J S, Xiao J J, Zhao X Y, Wang F F, Tang Y X, Zhang Q Z, Fang B J, Zhu R F, Yue Q W, Liu D X, Deng J 2020 Ceram. Int. 46 11913

Google Scholar

Google Scholar

[27] Nakano N, Petrovic Z L, Makabe T 1994 Jpn. J. Appl. Phys. 33 2223

Google Scholar

Google Scholar

[28] Crintea D L, Czarnetzki U, Iordanova S, Koleva I, Luggenholscher D 2009 J. Phys. D: Appl. Phys. 42 045208

Google Scholar

Google Scholar

[29] Sakoda T, Okraku-Yirenkyi Y, Youl-Moon S, Otsubo M, Chikahisa H 2001 Jpn. J. Appl. Phys. 40 6607

Google Scholar

Google Scholar

[30] Uchida T, Hamaguchi S 2008 J. Phys. D: Appl. Phys. 41 083001

Google Scholar

Google Scholar

[31] Wang Y J, Luo C T, Wang S H, Chen C, Yuan G L, Luo H S, Viehland D 2020 Adv. Electron. Mater. 6 1900949

Google Scholar

Google Scholar

[32] Li Y, Lu G X, Chen J J, Jing J C, Huo T C, Chen R M, Jiang L M, Zhou Q F, Chen Z P 2019 Photoacoustics 15 100138

Google Scholar

Google Scholar

[33] Jiang L M, Chen R M, Xing J, Lu G X, Li R Z, Jiang Y, Shung K K, Zhu J G, Zhou Q F 2019 J. Appl. Phys. 125 214501

Google Scholar

Google Scholar

[34] Zhou Q F, Lam K H, Zheng H R, Qiu W B, Shung K K 2014 Prog. Mater. Sci. 66 87

Google Scholar

Google Scholar

[35] Zhang J S, Ren W, Liu Y T, Wu X Q, Fei C L, Quan Y, Zhou Q F 2018 Sensors 18 1

Google Scholar

Google Scholar

-

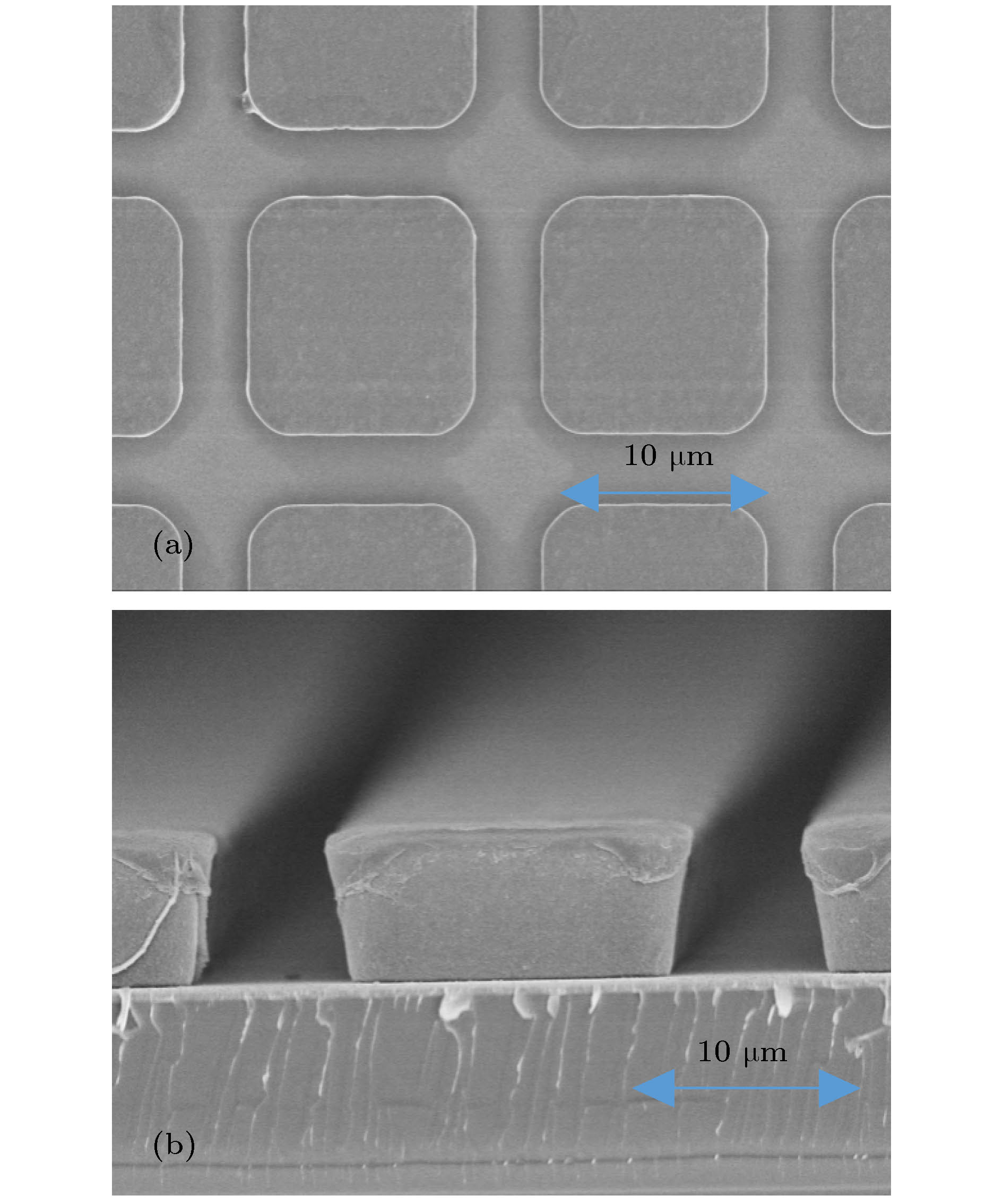

图 2 紫外光刻实验结果 (a), (b) 阵元尺寸为12.94 μm时, 光学显微镜下的表面形貌和扫描电子显微镜下的截面图; (c), (d) 阵元尺寸为13.97 μm时, 光学显微镜下的表面形貌和扫描电子显微镜下的截面图

Fig. 2. Results of lithography: (a), (b) Surface morphology under optical microscope and cross section under scanning electron microscope when the element size is 12.94 μm; (c), (d) surface morphology under optical microscope and cross section under scanning electron microscope when the element size is 13.97 μm.

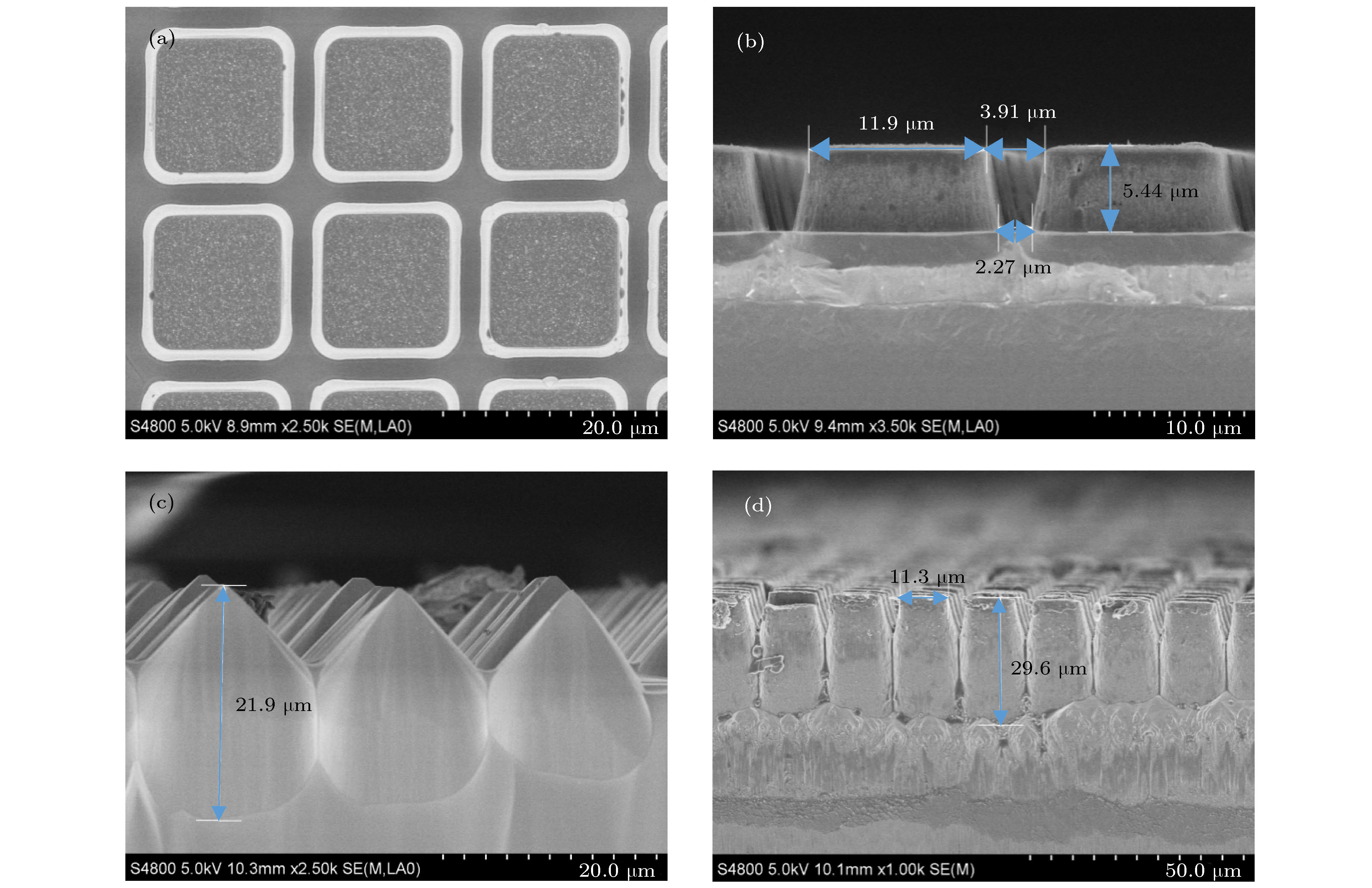

图 6 刻蚀结果 (a) 高密度面阵表面形貌; (b) 高密度面阵截面形貌; (c) 锥形阵列截面形貌; (d) 深刻蚀高密度面阵截面形貌

Fig. 6. Etching results: (a) Surface morphology of high density array; (b) cross section morphology of high density array; (c) cross section morphology of conical array; (d) the surface morphology of deep etching of high density surface array.

图 7 压电力显微镜下的不同尺度区域结构 (a) 30 μm × 30 μm区域的表面形貌; (b) 30 μm × 30 μm区域的面外振幅; (c) 30 μm × 30 μm区域的相位; (d) 5 μm × 5 μm区域的表面形貌; (e) 5 μm × 5 μm区域的面外振幅; (f) 5 μm × 5 μm区域的相位; (g) 1 μm × 1 μm区域的表面形貌; (h) 1 μm × 1 μm区域的面外振幅; (i) 1 μm × 1 μm区域的相位

Fig. 7. Structure of different scale areas under the piezoelectric microscope: (a) Surface morphology of 30 μm × 30 μm area; (b) out of plane amplitude of 30 μm × 30 μm area; (c) phase of 30 μm × 30 μm area; (d) surface morphology of 5 μm × 5 μm area; (e) out of plane amplitude of 5 μm × 5 μm area; (f) phase of 5 μm × 5 μm area; (g) surface morphology of 1 μm × 1 μm area; (h) out of plane amplitude of 1 μm × 1 μm area; (i) phase of 1 μm × 1 μm area.

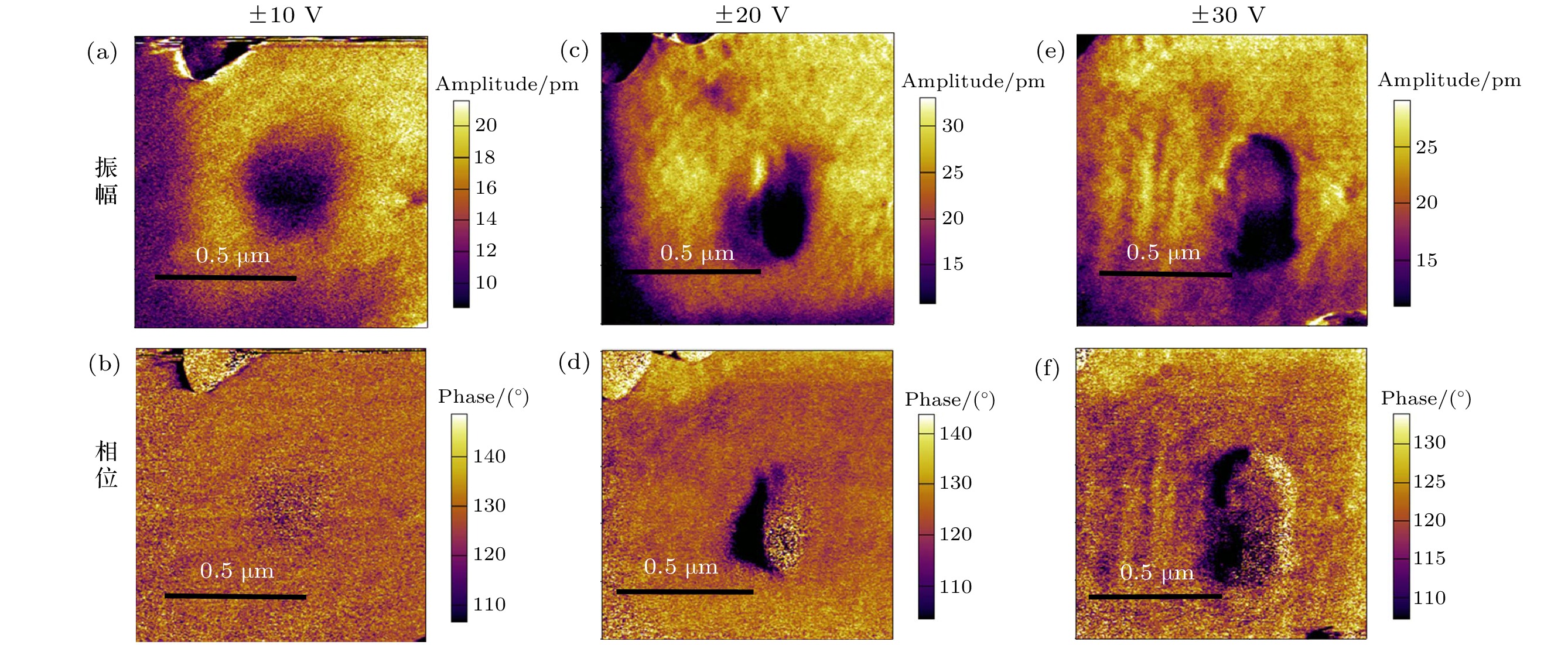

图 8 压电力显微镜下1 μm × 1 μm区域的结果 (a) ± 10 V电压下的面外振幅; (b) ± 10 V电压下的相位; (c) ± 20 V电压下的面外振幅; (d) ± 20 V电压下的相位; (e) ± 30 V电压下的面外振幅; (f) ± 30 V电压下的相位

Fig. 8. Results of 1 μm × 1 μm area under the piezoelectric force microscope: (a) Out of plane amplitude at ± 10 V; (b) phase at ± 10 V; (c) out of plane amplitude at ± 20 V; (d) phase at ± 20 V; (e) out of plane amplitude at ± 30 V; (f) phase at ± 30 V.

表 1 电镀液配料成分及含量

Table 1. Composition and content of electroplate bath ingredients.

成分 含量 氨基磺酸镍/g·L–1 280—400 硼酸/g·L–1 40—50 阳极活化剂/g·L–1 60—100 润湿剂/mL·L–1 1—5 去应力剂 适量 -

[1] Wang D W, Cao M S, Zhang S J 2012 J. Am. Ceram. Soc. 95 3220

Google Scholar

Google Scholar

[2] Wang D W, Cao M S, Zhang S J 2012 Phys. Status Solidi RRL 6 135

Google Scholar

Google Scholar

[3] Wang D W, Cao M S, Zhao Q L, Cui Y, Zhang S J 2013 Phys. Status Solidi RRL 7 221

Google Scholar

Google Scholar

[4] Lee J S, Park E C, Lee S H, Lee D S 2005 Mater. Chem. Phys. 90 381

Google Scholar

Google Scholar

[5] 罗豪甦, 沈关顺, 齐振一, 许桂生, 王评初, 乐秀宏, 李金龙, 仲维卓, 殷之文 1997 人工晶体学报 26 191

Luo H S, Shen G S, Qi Z Y, Xu G S, Wang P C, Le X H, Li J L, Zhong W Z, Yin Z W 1997 J. Synthetic Crystals 26 191

[6] Luo H S, Xu G S, Wang P C, Yin Z W 1999 Ferroelectrics 231 97

Google Scholar

Google Scholar

[7] Xu G S, Luo H S, Xu H Q, Qi Z Y, Wang P C, Zhong W Z, Yin Z W 2001 J. Cryst. Growth. 222 202

Google Scholar

Google Scholar

[8] Feng Z Y, He T H, Xu H Q, Luo H S, Yin Z W 2004 Solid. State. Commun. 130 557

Google Scholar

Google Scholar

[9] Wu X, Liu L H, Li X B, Zhang Q H, Ren B, Lin D, Zhao X Y, Luo H S, Huang Y L 2011 J. Cryst. Growth. 318 865

Google Scholar

Google Scholar

[10] Deng C G, He C J, Chen Z Y, Chen H B, Mao R, Liu Y W, Zhu K J, Gao H F, Ding Y 2019 J. Appl. Phys. 126 085702

Google Scholar

Google Scholar

[11] He C J, Chen Z Y, Chen H B, Wu T, Wang J M, Gu X R, Liu Y W, Zhu K J 2018 J. Nanophotonics 12 046019

Google Scholar

Google Scholar

[12] He C J, Chen H B, Bai F, Fan Z B, Sun L, Xu F, Wang J M, Liu Y W, Zhu K J 2012 J. Appl. Phys. 112 126102

Google Scholar

Google Scholar

[13] Jia Y M, Luo H S, Zhao X Y, Wang F F 2008 Adv. Mater. 20 4776

Google Scholar

Google Scholar

[14] He C J, Chen H B, Wang J M, Gu X R, Wu T, Liu Y W 2015 J. Appl. Phys. 117 164104

Google Scholar

Google Scholar

[15] Yang Y, Jung J H, Yun B K, Zhang F, Pradel K C, Guo W, Wang Z L 2012 Adv. Mater. 24 5357

Google Scholar

Google Scholar

[16] 岳晴雯 2016 博士学位论文 (上海: 中国科学院大学)

Yue Q W 2016 Ph. D. Dissertation (Shanghai: University of Chinese Academy of Sciences) (in Chinese)

[17] Sun E W, Cao W W 2014 Prog. Mater. Sci. 65 124

Google Scholar

Google Scholar

[18] Zhu R F, Zhao J, Liu F, Zhang Z, Fang B J, Chen J W, Xu H Q, Wang X A, Luo H S 2020 J. Am. Ceram. Soc. 103 2575

Google Scholar

Google Scholar

[19] Xie Q X, Hu Y Q, Xue S D, Ma J P, Zhao X Y, Tang Y X, Wang F F, Chew K H, Lin D, Luo H S 2019 Mater. Chem. Phys. 238 121890

Google Scholar

Google Scholar

[20] Zhang J S, Ren W, Jing X P, Shi P, Wu X Q 2015 Ceram. Int. 41 S656

Google Scholar

Google Scholar

[21] Jian X H, Li S B, Huang W B, Cui Y Y, Jiang X N 2015 J. Intell. Mater. Syst. Struct. 26 2011

Google Scholar

Google Scholar

[22] 周丹, 罗来慧, 王飞飞, 贾艳敏, 赵祥永, 罗豪甦 2008 57 4552

Google Scholar

Google Scholar

Zhou D, Luo L H, Wang F F, Jia Y M, Zhao X Y, Luo H S 2008 Acta Phys. Sin. 57 4552

Google Scholar

Google Scholar

[23] 乔学光, 邵志华, 包维佳, 荣强周 2017 66 074205

Google Scholar

Google Scholar

Qiao X G, Shao Z H, Bao W J, Rong Q Z 2017 Acta Phys. Sin. 66 074205

Google Scholar

Google Scholar

[24] 徐萌, 晏建民, 徐志学, 郭磊, 郑仁奎, 李晓光 2018 67 157506

Google Scholar

Google Scholar

Xu M, Yan J M, Xu Z X, Guo L, Zheng R K, Li X G 2018 Acta Phys. Sin. 67 157506

Google Scholar

Google Scholar

[25] 赵章风, 张文俊, 牛丽丽, 孟龙, 郑海荣 2018 67 194302

Google Scholar

Google Scholar

Zhao Z F, Zhang W J, Niu L L, Meng L, Zheng H R 2018 Acta Phys. Sin. 67 194302

Google Scholar

Google Scholar

[26] Wang J S, Xiao J J, Zhao X Y, Wang F F, Tang Y X, Zhang Q Z, Fang B J, Zhu R F, Yue Q W, Liu D X, Deng J 2020 Ceram. Int. 46 11913

Google Scholar

Google Scholar

[27] Nakano N, Petrovic Z L, Makabe T 1994 Jpn. J. Appl. Phys. 33 2223

Google Scholar

Google Scholar

[28] Crintea D L, Czarnetzki U, Iordanova S, Koleva I, Luggenholscher D 2009 J. Phys. D: Appl. Phys. 42 045208

Google Scholar

Google Scholar

[29] Sakoda T, Okraku-Yirenkyi Y, Youl-Moon S, Otsubo M, Chikahisa H 2001 Jpn. J. Appl. Phys. 40 6607

Google Scholar

Google Scholar

[30] Uchida T, Hamaguchi S 2008 J. Phys. D: Appl. Phys. 41 083001

Google Scholar

Google Scholar

[31] Wang Y J, Luo C T, Wang S H, Chen C, Yuan G L, Luo H S, Viehland D 2020 Adv. Electron. Mater. 6 1900949

Google Scholar

Google Scholar

[32] Li Y, Lu G X, Chen J J, Jing J C, Huo T C, Chen R M, Jiang L M, Zhou Q F, Chen Z P 2019 Photoacoustics 15 100138

Google Scholar

Google Scholar

[33] Jiang L M, Chen R M, Xing J, Lu G X, Li R Z, Jiang Y, Shung K K, Zhu J G, Zhou Q F 2019 J. Appl. Phys. 125 214501

Google Scholar

Google Scholar

[34] Zhou Q F, Lam K H, Zheng H R, Qiu W B, Shung K K 2014 Prog. Mater. Sci. 66 87

Google Scholar

Google Scholar

[35] Zhang J S, Ren W, Liu Y T, Wu X Q, Fei C L, Quan Y, Zhou Q F 2018 Sensors 18 1

Google Scholar

Google Scholar

计量

- 文章访问数: 9903

- PDF下载量: 128

- 被引次数: 0

下载:

下载: