-

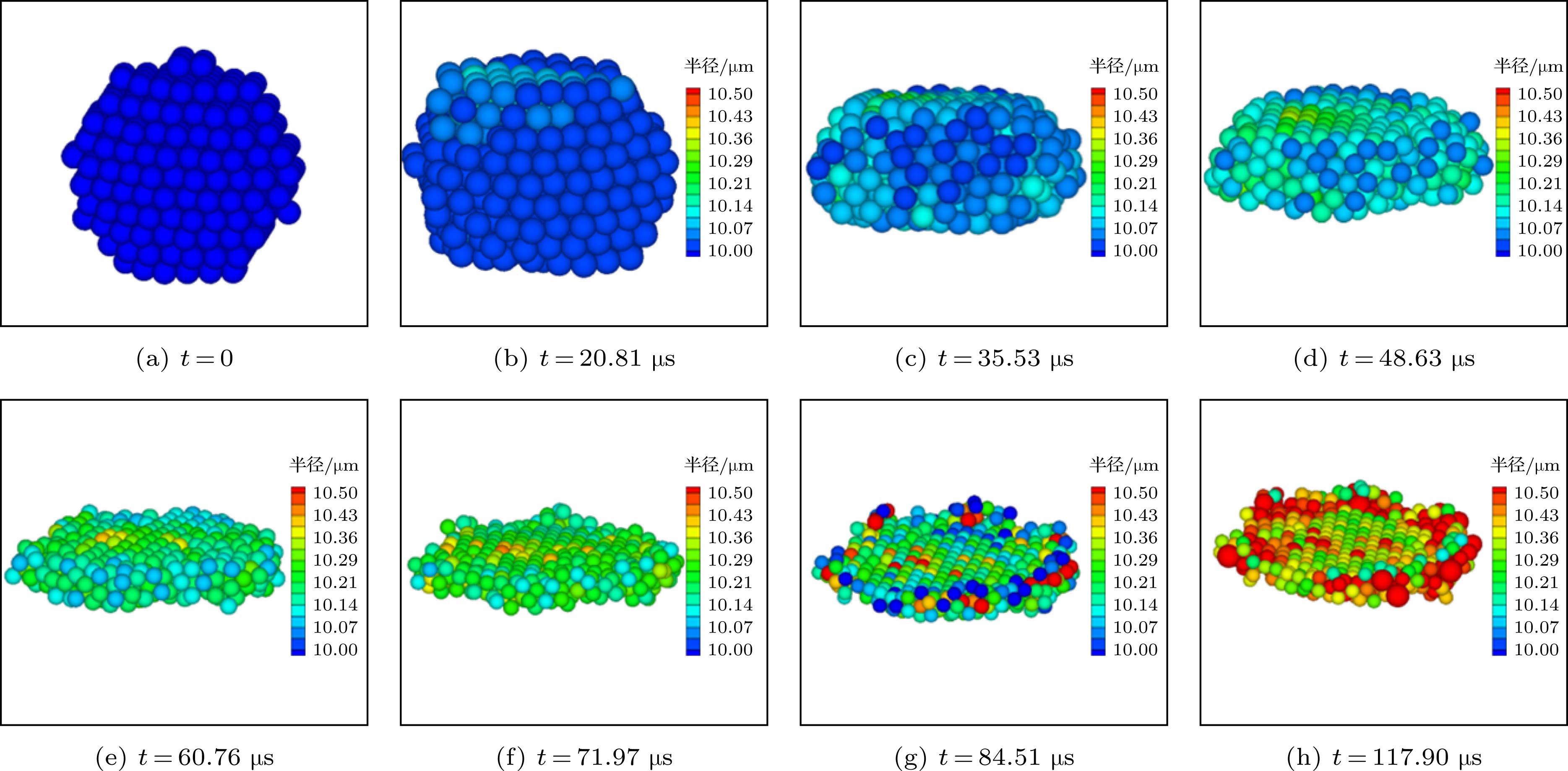

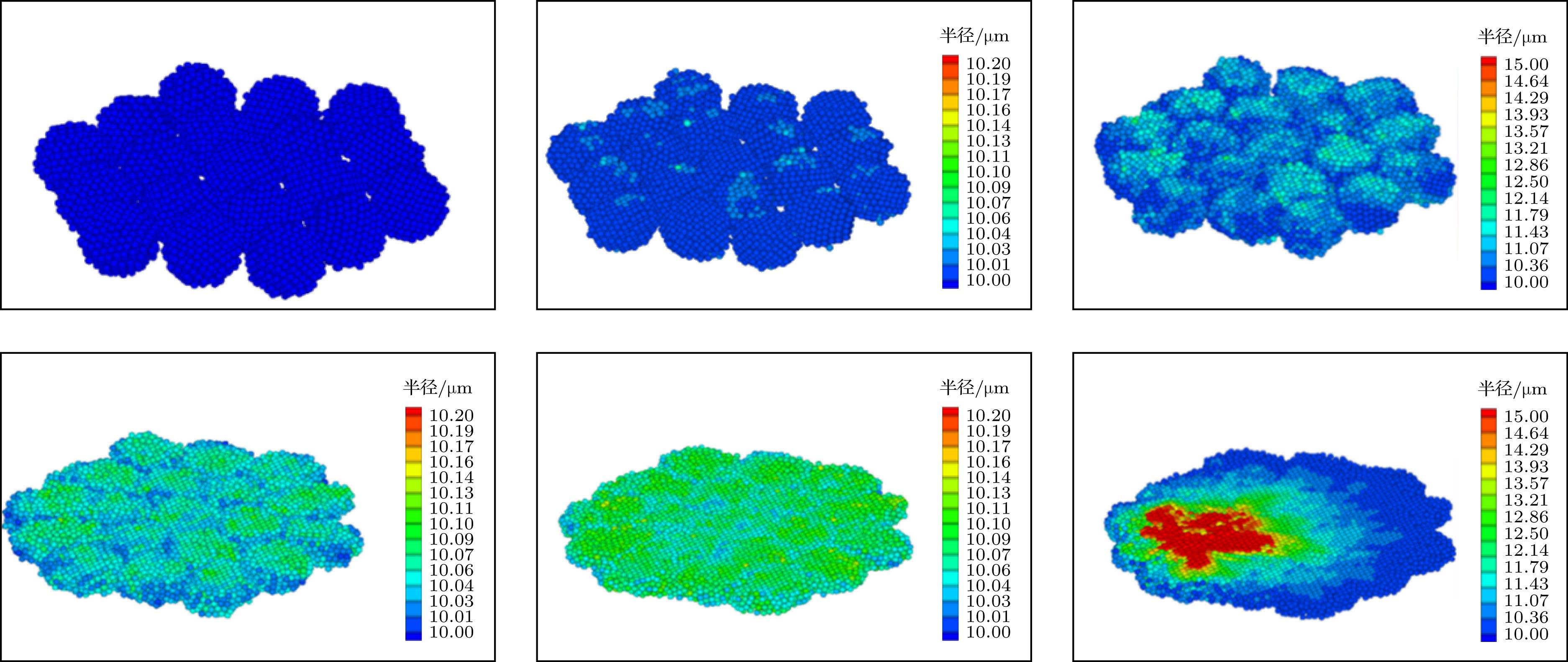

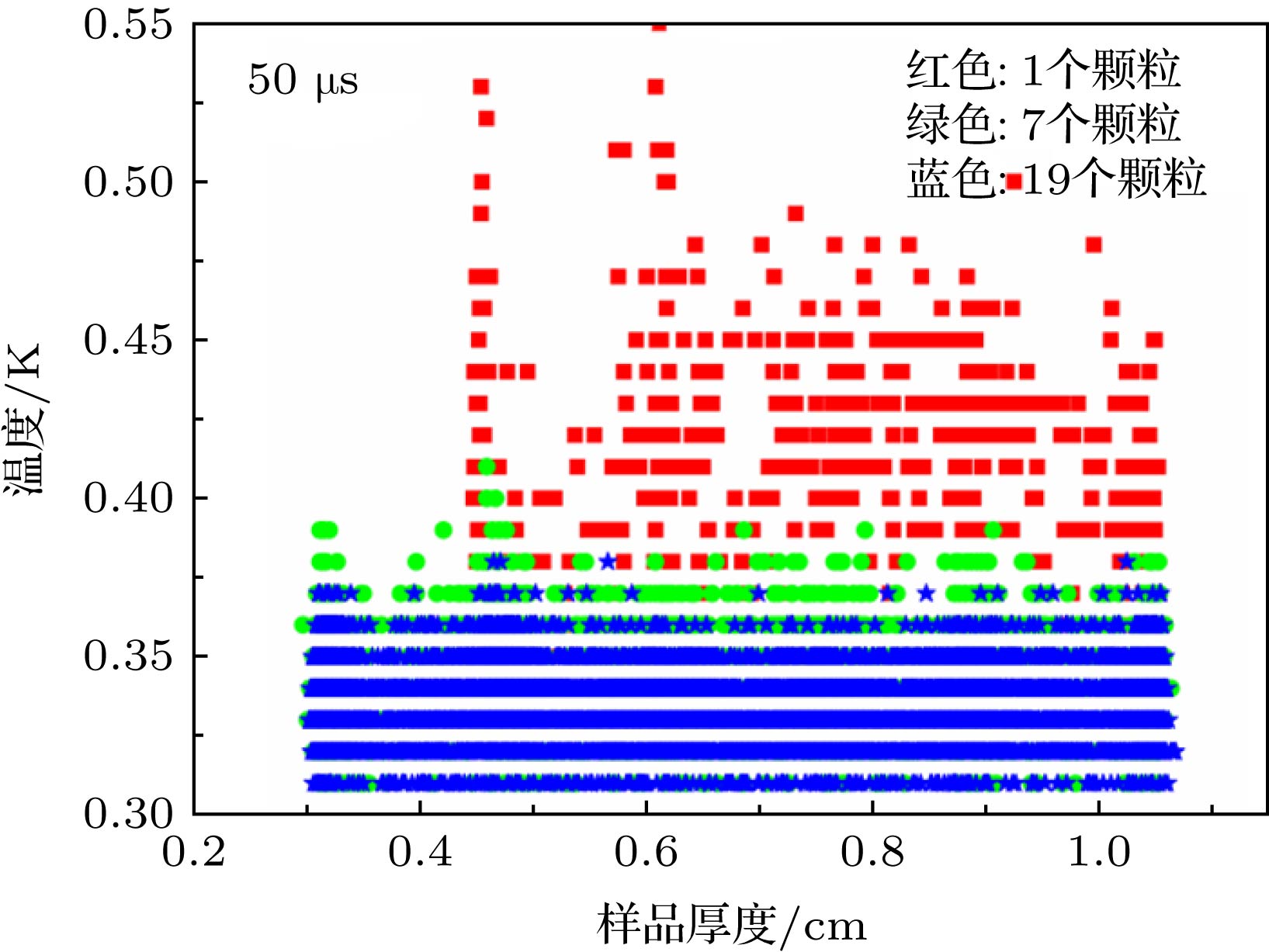

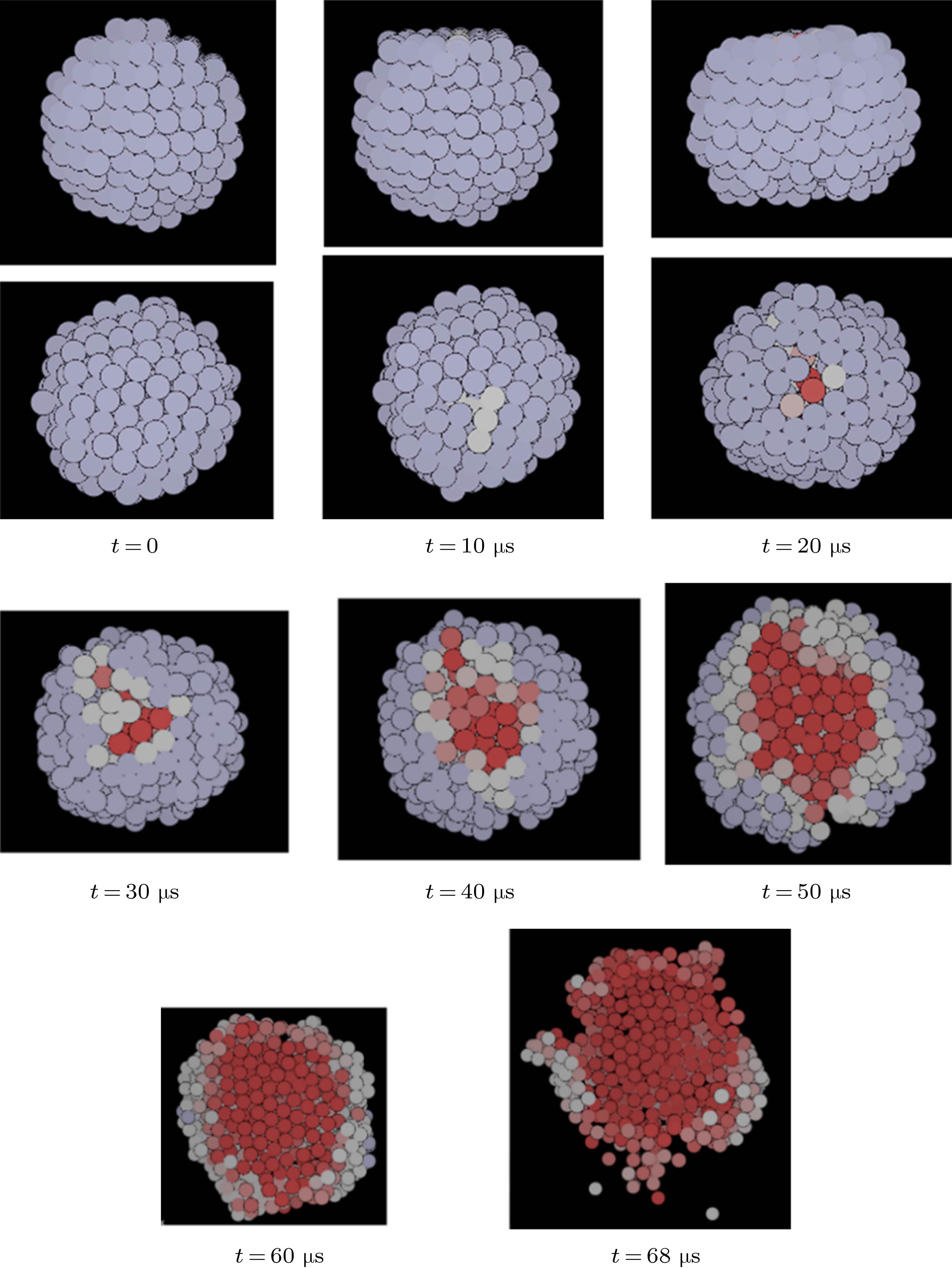

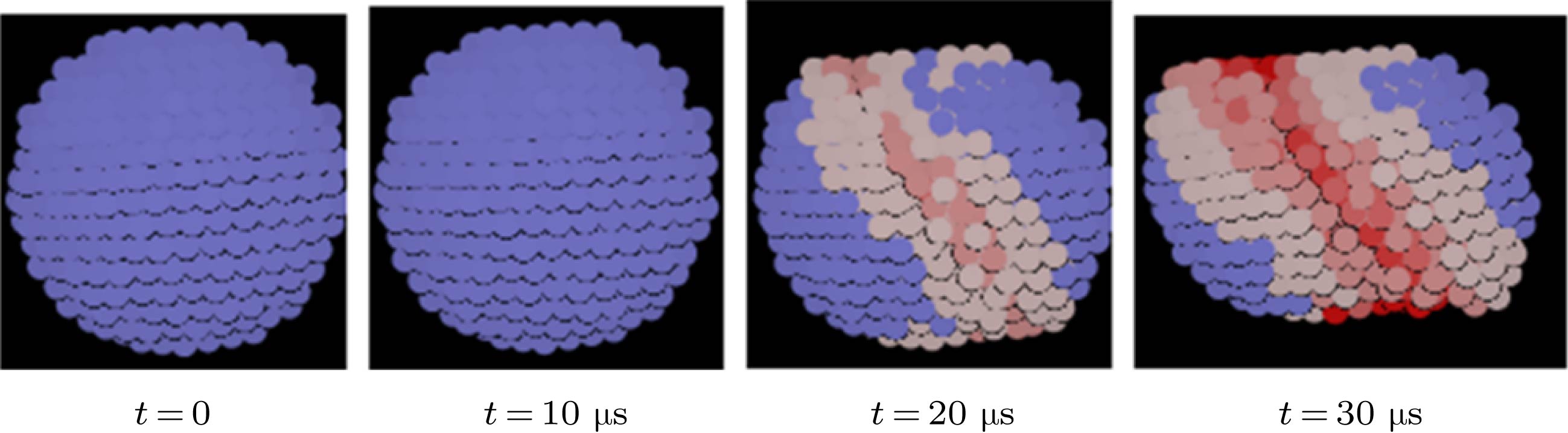

炸药颗粒的冲击点火机理一直是人们关注并不断研究的课题, 但是迄今为止进展缓慢. 随着计算技术的高速发展, 三维离散元方法(three-dimensional discrete meso-element method, DM3)被认为是一种高效且直观的研究炸药冲击点火的有效手段. 本文基于三维离散元方法对奥克托今(HMX)颗粒在落锤撞击条件下的撞击变形和升温点火进行了研究, 模拟计算表明, 炸药的颗粒尺寸、堆积程度、内部缺陷以及落锤的冲击力大小都将影响HMX颗粒的升温点火和燃烧蔓延. 同时, 基于以上结果, 本文提出了尖顶变形加热点火机制以及平顶颗粒剪切加热机制. 特别地, 含内部缺陷的HMX颗粒在冲击条件下将出现两种情况: 尺寸较大的颗粒在孔洞处出现温度优势, 颗粒尺寸较小的温度优势出现在尖顶位置.The ignition mechanism of the explosive particles under impact has been a hot topic, but the research progress is slow. With the rapid development of computer science, the three-dimensional discrete element technique (DM3) is regarded as an efficient and intuitive method to study the explosive ignition under impact. As is well known, octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine (HMX) is one of the most effective explosive particles in performance, which has high density and energy and thus possesses a significant application. In this paper, the deformation and ignition of HMX particles under impact of drop hammer are investigated based on the three-dimensional discrete element technique. Specifically, the computational process for shock loading as well as chemical reaction is employed in DM3 model through using the state equation of Hugoniot, the reactive model of Arrhenius, the state equation of JWL. The results show that the size, degree of accumulation, defect and the force of drop hammer can definitely influence the ignition and propagation of HMX particles. Under the same shock loading, the particles on a small scale would produce less power. On the same scale of particle, the less the number of particles, the shorter the deformation time is, so the temperature increases more easily. As for the different shapes of single particles, the deformation and ignition first appear from the ‘top’ for the spire particles, and then the deformation and ignition of flat particles happens from ‘shear’. Specifically, there are two results of the internal defect HMX particles under impact: the particles with bigger size (discrete elements 256 × 34 = 8704) have a temperature advantage near the ‘hole’, while the temperature advantage of the particles with the smaller size (discrete elements 93 × 35 = 3814) appears on the ‘top’.

-

Keywords:

- three-dimensional discrete element /

- octogen particles /

- ignition

[1] Alder B J, Wainwright T E 1957 J. Chem. Phys. 27 1208

Google Scholar

Google Scholar

[2] Cundall P A, Strack O D L 1979 Géotechnique 29 47

Google Scholar

Google Scholar

[3] 赵永志, 江茂强, 徐平, 郑津洋 2009 58 1819

Google Scholar

Google Scholar

Zhao Y Z, Jiang M Q, Xu P, Zheng J Y 2009 Acta Phys. Sin. 58 1819

Google Scholar

Google Scholar

[4] Cundall P A 1971 Proceedings of the Symposium of the International Society of Rock Mechanics 2 2

[5] 徐泳, 孙其诚, 张凌, 黄文彬 2003 力学进展 33 251

Google Scholar

Google Scholar

Xu Y, Sun Q C, Zhang L, Huang W B 2003 Advances in Mechanics 33 251

Google Scholar

Google Scholar

[6] Ahlinhan M F, Houehanou E, Koube M B, Doko V, Alaye Q, Sungura N E 2018 Adjovi Geomaterials 8 39

Google Scholar

Google Scholar

[7] Cundall P A, Hart R D 1979 Numerical Methods in Geomechanics 1 289

[8] Cundall P A, Hart R D 1992 International Journal for Computer-Aided Engineering and Software 9 101

Google Scholar

Google Scholar

[9] Cundall P A 2001 Proceedings of the Institution of Civil Engineers-Geotechnical Engineering 149 41

[10] 王泳嘉 1986第一届全国岩石力学数值计算及模型试验讨论会论文集 江西吉安 1986年6月20−27日 第3237页

Wang Y J 1986 Proceedings of the First National Symposium on Numerical Computation and Model Testing of Rock Mechanics Ji’an, Jiangxi, June 20-27 1986 pp32−37 (in Chinese)

[11] 刘凯欣, 高凌天 2003 力学进展 33 483

Google Scholar

Google Scholar

Liu K X, Gao L T 2003 Advances in Mechanics 33 483

Google Scholar

Google Scholar

[12] Tang Z P, Horie Y, Psakhie S G 1997 High-Pressure Compression of Solids IV (New York: Springer) pp143−175

[13] Tang Z P, Horie Y, Psakhie S G 1996 AIP Conference Proceedings 370 657

Google Scholar

Google Scholar

[14] 于继东, 王文强, 刘仓理, 赵峰, 孙承维 2008 爆炸与冲击 28 488

Google Scholar

Google Scholar

Yu J D, Wang W Q, Liu C L, Zhao F, Sun C W 2008 Explosion and Shock Waves 28 488

Google Scholar

Google Scholar

[15] 刘超, 石艺娜, 秦承森, 梁仙红 2014 计算物理 31 51

Google Scholar

Google Scholar

Liu C, Shi Y N, Qin C S, Liang X H 2014 Chinese Journal of Computational Physics 31 51

Google Scholar

Google Scholar

[16] 刘超, 石艺娜, 秦承森, 梁仙红 2014 兵工学报 35 1009

Google Scholar

Google Scholar

Liu C, Shi Y N, Qin C S, Liang X H 2014 Acta Armamentarii 35 1009

Google Scholar

Google Scholar

[17] 孟凡净, 刘焜 2014 63 262

Meng F J, Liu K 2014 Acta Phys. Sin. 63 262

[18] 赵啦啦, 刘初升, 闫俊霞, 徐志鹏 2010 59 187007

Zhao L L, Liu C S, Yan J X, Xu Z P 2010 Acta Phys. Sin. 59 187007

[19] 程琦, 冉宪文, 刘苹, 汤文辉, Raphael Blumenfeld 2018 67 0147028

Cheng Q, Ran X W, Liu P, Tang W H, Raphael B 2018 Acta Phys. Sin. 67 0147028

[20] Su Y, Fan J Y, Zheng Z Y, Zhao J J, Song H J 2019 Chin. Phys. B 27 056404

[21] 范航, 何冠松, 杨志剑, 聂福德, 陈鹏万 2019 68 106201

Google Scholar

Google Scholar

Fan H, He G S, Yang Z J, Nie F D, Chen P W 2019 Acta Phys. Sin. 68 106201

Google Scholar

Google Scholar

[22] Tian Y, Wang H, Zhang C S, Tian Q, Zhang W B, Li H J, Li J, Liu B D, Sun G A, Peng T P, Xu Y, Gong J 2017 Chin. Phys. Lett. 34 066101

Google Scholar

Google Scholar

[23] 尚海林, 赵锋, 王文强, 傅华 2010 爆炸与冲击 30 131

Google Scholar

Google Scholar

Shsng H L, Zhao F, Wang W Q, Fu H 2010 Explosion and Shock Waves 30 131

Google Scholar

Google Scholar

[24] 章冠人, 陈大年 1991 凝聚炸药起爆动力学 (北京: 国防工业出版社) 第89−128页

Zhang G R, Chen D N 1991 Initiation Kinetics of Condensed Explosive (Beijing: National Defense Industry Press) pp89−128 (in Chinese)

[25] 尚海林 2009 硕士学位论文 (绵阳: 中国工程物理研究院)

Shang H L 2009 M. S. Thesis (Mianyang: China Academy of Engineering Physics) (in Chinese)

[26] Campbell A W, Davis W C, Travis J R 1961 Phys. Fluids 4 498

Google Scholar

Google Scholar

[27] Walker F E, Wasley R J 1970 Combust. Flame 3 233

[28] 傅华, 赵峰, 谭多望, 王文强, 尚海林 2011 高压 25 8

Google Scholar

Google Scholar

Fu H, Zhao F, Tan D W, Wang W Q, Shang H L 2011 Chinese Journal of High Pressure Physics 25 8

Google Scholar

Google Scholar

[29] 葛妮娜, 姬广富, 陈向荣, 魏永凯 2013 爆炸与冲击 S1 34

Ge N N, Ji G F, Chen X R, Wei Y K 2013 Explosion and Shock Waves S S1 34

[30] Millett J C F, Taylor P, Roberts A, Appleby-Thomas G 2017 J. Dynamic Behavior Mater. 3 100

Google Scholar

Google Scholar

[31] 唐志平 2003 中国科学E辑: 技术科学 11 989

Tang Z P 2003 Sci. China Technol. Sci. 11 989

[32] 尚海林 2018 博士学位论文 (绵阳: 中国工程物理研究院)

Shang H L 2018 Ph. D. Dissertation (Mianyang: China Academy of Engineering Physics) (in Chinese)

-

表 1 HMX的计算参数

Table 1. The calculating parameters of HMX.

密度/

g·cm–3摩擦

系数元的半径/

μm元的能量${Q_r}$/

MJ·kg–1比热$C_v^i$/

J·g–1K1.83 0.35 10 6.19 1.1 -

[1] Alder B J, Wainwright T E 1957 J. Chem. Phys. 27 1208

Google Scholar

Google Scholar

[2] Cundall P A, Strack O D L 1979 Géotechnique 29 47

Google Scholar

Google Scholar

[3] 赵永志, 江茂强, 徐平, 郑津洋 2009 58 1819

Google Scholar

Google Scholar

Zhao Y Z, Jiang M Q, Xu P, Zheng J Y 2009 Acta Phys. Sin. 58 1819

Google Scholar

Google Scholar

[4] Cundall P A 1971 Proceedings of the Symposium of the International Society of Rock Mechanics 2 2

[5] 徐泳, 孙其诚, 张凌, 黄文彬 2003 力学进展 33 251

Google Scholar

Google Scholar

Xu Y, Sun Q C, Zhang L, Huang W B 2003 Advances in Mechanics 33 251

Google Scholar

Google Scholar

[6] Ahlinhan M F, Houehanou E, Koube M B, Doko V, Alaye Q, Sungura N E 2018 Adjovi Geomaterials 8 39

Google Scholar

Google Scholar

[7] Cundall P A, Hart R D 1979 Numerical Methods in Geomechanics 1 289

[8] Cundall P A, Hart R D 1992 International Journal for Computer-Aided Engineering and Software 9 101

Google Scholar

Google Scholar

[9] Cundall P A 2001 Proceedings of the Institution of Civil Engineers-Geotechnical Engineering 149 41

[10] 王泳嘉 1986第一届全国岩石力学数值计算及模型试验讨论会论文集 江西吉安 1986年6月20−27日 第3237页

Wang Y J 1986 Proceedings of the First National Symposium on Numerical Computation and Model Testing of Rock Mechanics Ji’an, Jiangxi, June 20-27 1986 pp32−37 (in Chinese)

[11] 刘凯欣, 高凌天 2003 力学进展 33 483

Google Scholar

Google Scholar

Liu K X, Gao L T 2003 Advances in Mechanics 33 483

Google Scholar

Google Scholar

[12] Tang Z P, Horie Y, Psakhie S G 1997 High-Pressure Compression of Solids IV (New York: Springer) pp143−175

[13] Tang Z P, Horie Y, Psakhie S G 1996 AIP Conference Proceedings 370 657

Google Scholar

Google Scholar

[14] 于继东, 王文强, 刘仓理, 赵峰, 孙承维 2008 爆炸与冲击 28 488

Google Scholar

Google Scholar

Yu J D, Wang W Q, Liu C L, Zhao F, Sun C W 2008 Explosion and Shock Waves 28 488

Google Scholar

Google Scholar

[15] 刘超, 石艺娜, 秦承森, 梁仙红 2014 计算物理 31 51

Google Scholar

Google Scholar

Liu C, Shi Y N, Qin C S, Liang X H 2014 Chinese Journal of Computational Physics 31 51

Google Scholar

Google Scholar

[16] 刘超, 石艺娜, 秦承森, 梁仙红 2014 兵工学报 35 1009

Google Scholar

Google Scholar

Liu C, Shi Y N, Qin C S, Liang X H 2014 Acta Armamentarii 35 1009

Google Scholar

Google Scholar

[17] 孟凡净, 刘焜 2014 63 262

Meng F J, Liu K 2014 Acta Phys. Sin. 63 262

[18] 赵啦啦, 刘初升, 闫俊霞, 徐志鹏 2010 59 187007

Zhao L L, Liu C S, Yan J X, Xu Z P 2010 Acta Phys. Sin. 59 187007

[19] 程琦, 冉宪文, 刘苹, 汤文辉, Raphael Blumenfeld 2018 67 0147028

Cheng Q, Ran X W, Liu P, Tang W H, Raphael B 2018 Acta Phys. Sin. 67 0147028

[20] Su Y, Fan J Y, Zheng Z Y, Zhao J J, Song H J 2019 Chin. Phys. B 27 056404

[21] 范航, 何冠松, 杨志剑, 聂福德, 陈鹏万 2019 68 106201

Google Scholar

Google Scholar

Fan H, He G S, Yang Z J, Nie F D, Chen P W 2019 Acta Phys. Sin. 68 106201

Google Scholar

Google Scholar

[22] Tian Y, Wang H, Zhang C S, Tian Q, Zhang W B, Li H J, Li J, Liu B D, Sun G A, Peng T P, Xu Y, Gong J 2017 Chin. Phys. Lett. 34 066101

Google Scholar

Google Scholar

[23] 尚海林, 赵锋, 王文强, 傅华 2010 爆炸与冲击 30 131

Google Scholar

Google Scholar

Shsng H L, Zhao F, Wang W Q, Fu H 2010 Explosion and Shock Waves 30 131

Google Scholar

Google Scholar

[24] 章冠人, 陈大年 1991 凝聚炸药起爆动力学 (北京: 国防工业出版社) 第89−128页

Zhang G R, Chen D N 1991 Initiation Kinetics of Condensed Explosive (Beijing: National Defense Industry Press) pp89−128 (in Chinese)

[25] 尚海林 2009 硕士学位论文 (绵阳: 中国工程物理研究院)

Shang H L 2009 M. S. Thesis (Mianyang: China Academy of Engineering Physics) (in Chinese)

[26] Campbell A W, Davis W C, Travis J R 1961 Phys. Fluids 4 498

Google Scholar

Google Scholar

[27] Walker F E, Wasley R J 1970 Combust. Flame 3 233

[28] 傅华, 赵峰, 谭多望, 王文强, 尚海林 2011 高压 25 8

Google Scholar

Google Scholar

Fu H, Zhao F, Tan D W, Wang W Q, Shang H L 2011 Chinese Journal of High Pressure Physics 25 8

Google Scholar

Google Scholar

[29] 葛妮娜, 姬广富, 陈向荣, 魏永凯 2013 爆炸与冲击 S1 34

Ge N N, Ji G F, Chen X R, Wei Y K 2013 Explosion and Shock Waves S S1 34

[30] Millett J C F, Taylor P, Roberts A, Appleby-Thomas G 2017 J. Dynamic Behavior Mater. 3 100

Google Scholar

Google Scholar

[31] 唐志平 2003 中国科学E辑: 技术科学 11 989

Tang Z P 2003 Sci. China Technol. Sci. 11 989

[32] 尚海林 2018 博士学位论文 (绵阳: 中国工程物理研究院)

Shang H L 2018 Ph. D. Dissertation (Mianyang: China Academy of Engineering Physics) (in Chinese)

计量

- 文章访问数: 13127

- PDF下载量: 106

- 被引次数: 0

下载:

下载: