-

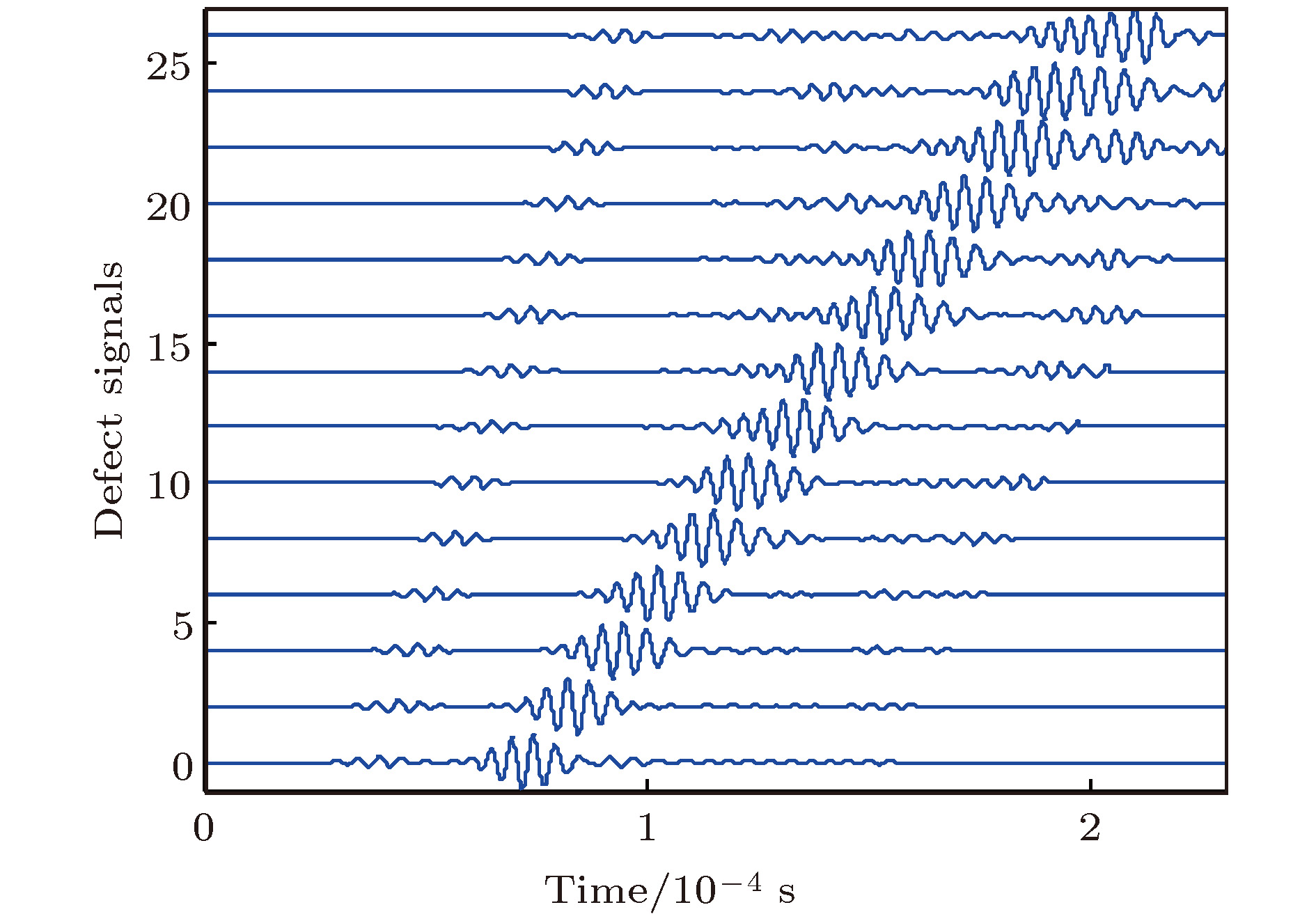

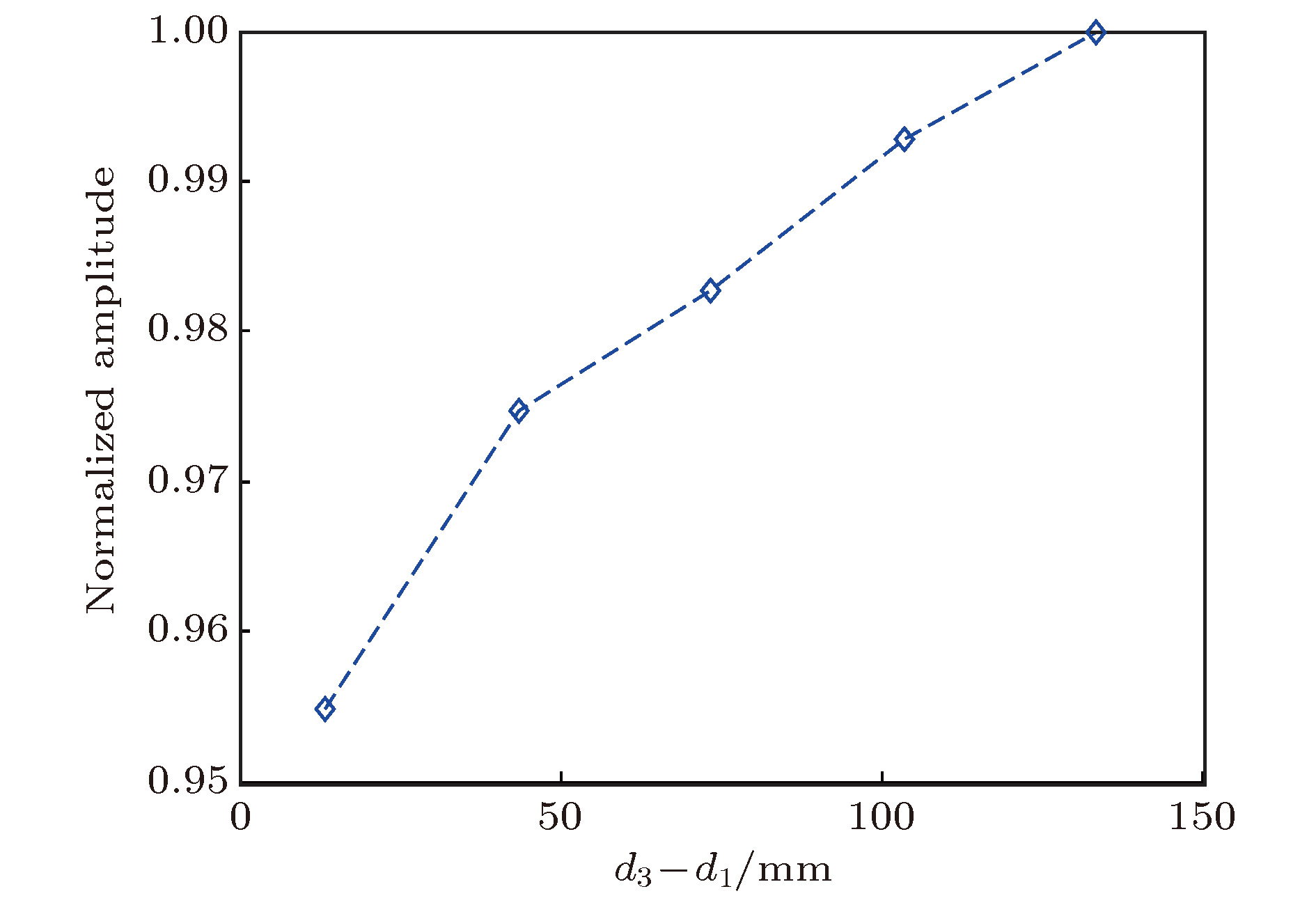

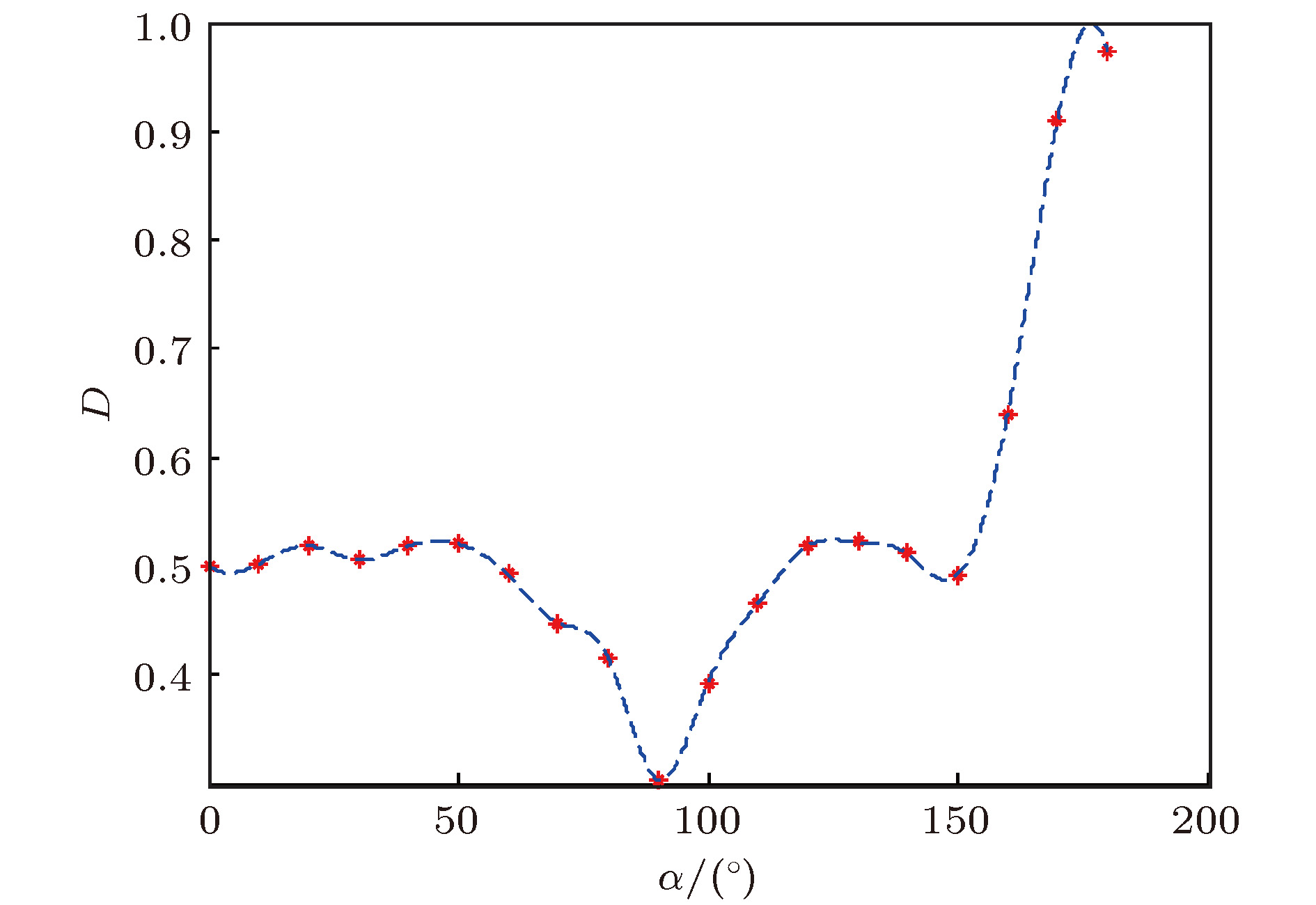

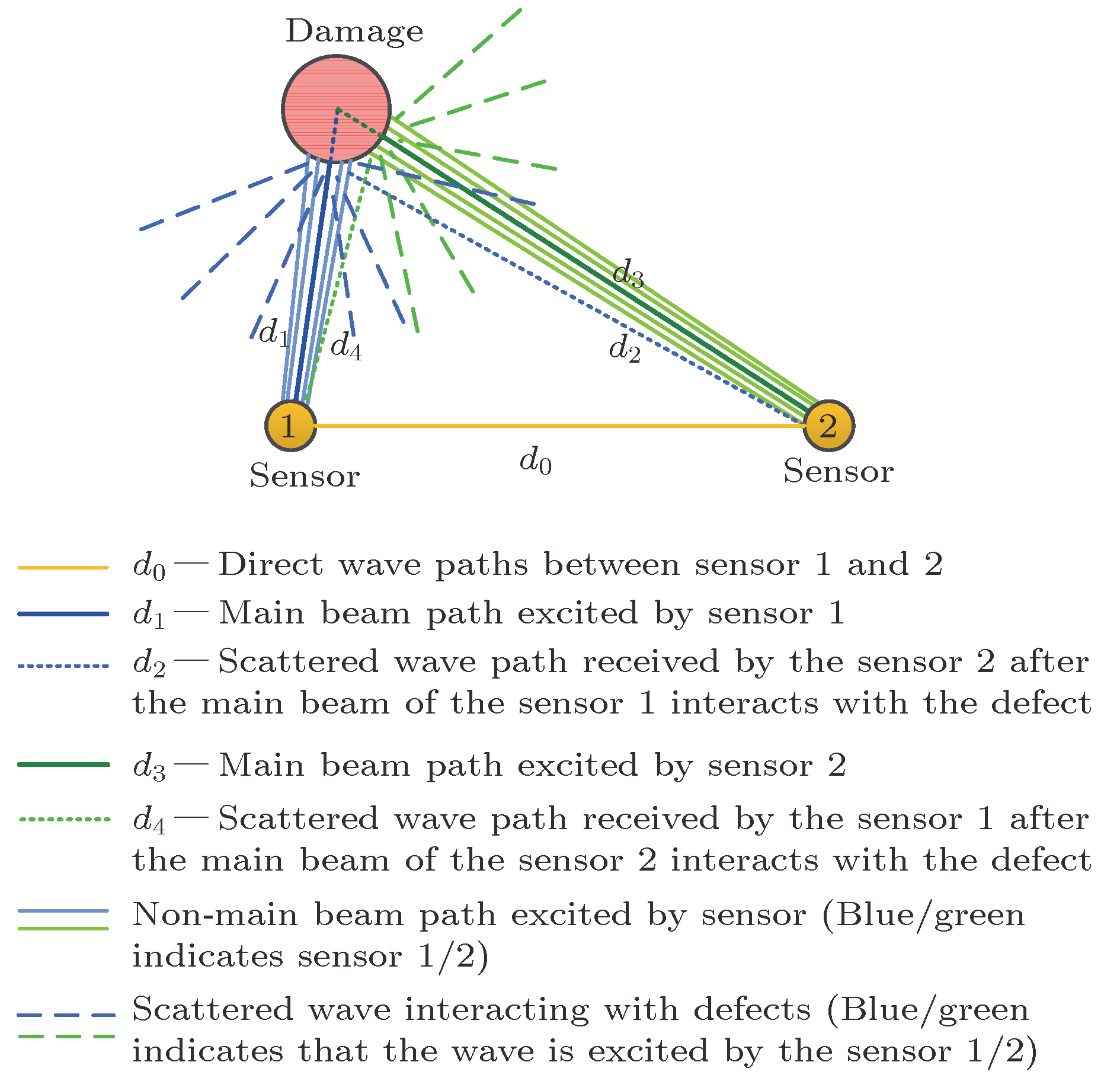

针对传统基线相减成像方法受环境温度影响的问题, 考虑到反转路径下超声波在缺陷处散射场的差异性, 提出了一种基于反转路径差信号的兰姆波稀疏阵列成像方法. 通过数值仿真, 对反转路径差信号的来源进行了分析, 并研究了缺陷与两个传感器的夹角及路径差对反转路径差信号幅值的影响规律. 在此基础上, 通过数值仿真及检测实验, 研究了基于反转路径差信号的兰姆波成像方法对板中缺陷检测的有效性. 结果表明, 基于反转路径差信号的兰姆波成像方法可以很好地消除直达波对缺陷成像的影响, 实现板中不同位置的圆孔和矩形缺陷成像, 且成像分辨率较高, 定位较准确. 本文为板结构大范围健康监测提供了一种可行的新方案.The traditional Lamb wave structure health monitoring imaging method based on reference signal is affected by environmental factors such as temperature change. To solve this problem, considering the difference in the scattered fields generated by the interaction between ultrasonic waves and defects in the reverse path, a Lamb wave imaging method is proposed in this paper based on the difference signal of sparse array in inverse path. Numerical simulations are carried out to determine the generation conditions of difference signal in inversion path, and the influences of the angles and distances between the defect and the two sensors on the amplitude of difference signal in inversion path. It is found that the difference signal in reverse path is much more obvious when the defect appears as asymmetric distribution towards the excitation sensor and receiving sensors; the amplitude of difference signal in inverse path is affected by distance difference of the Lamb wave propagating in reverse path and the scattering coefficient of the defect. On this basis, the effectiveness of the Lamb wave imaging method based on the difference signal in inverse path is studied numerically and experimentally. The results show that the Lamb wave imaging method based on the difference signal in inversion path can perfectly eliminate the interference between direct wave and the boundary reflection wave, and the imaging method can detect the defect at different positions in the plate. Moreover, the imaging resolution is higher and the defect location is accurate. The research work provides a new feasible scheme for the extensive health monitoring of plate structure.

-

Keywords:

- Lamb waves /

- plate structure /

- difference signal in reverse paths /

- sparse array

[1] Abbas M, Shafiee M 2018 Sensors 18 3958

Google Scholar

Google Scholar

[2] 高广健, 邓明晰, 李明亮, 刘畅 2015 64 224301

Google Scholar

Google Scholar

Gao G J, Deng M X, Li M L, Liu C 2015 Acta Phys. Sin. 64 224301

Google Scholar

Google Scholar

[3] Kudela P, Radzienski M, Ostachowicz W, Yang Z 2018 Mech. Syst. Signal Proc. 108 21

Google Scholar

Google Scholar

[4] Chen S J, Zhou S P, Li Y, Xiang Y X, Qi M X 2017 Chin. Phys. Lett. 34 044301

Google Scholar

Google Scholar

[5] Petrone G 2018 Aerosp. Sci. Technol. 82 304

[6] Munian R K, Mahapatra D R, Gopalakrishnan S 2018 Compos. Struct. 206 484

Google Scholar

Google Scholar

[7] Mohammadi M, Pouyan A A, Khan N A, Abolghasemi V 2018 Signal Process. 150 85

Google Scholar

Google Scholar

[8] Kim C Y, Park K J 2015 NDT&E Int. 74 15

[9] Wilcox P D, Lowe M, Cawley P 2003 IEEE Trans. Ultrason. Ferroelectr. 50 419

Google Scholar

Google Scholar

[10] Xu K, Ta D, Moilanen P, Wang W Q 2012 J. Acoust. Soc. Am. 131 2714

Google Scholar

Google Scholar

[11] Agrahari J K, Kapuria S 2018 Struct. Control HLTH. 25 e2064

Google Scholar

Google Scholar

[12] Salmanpour M S, Sharif K Z, Mhf A 2017 Sensors 17 1178

Google Scholar

Google Scholar

[13] Muller A, Robertson-Welsh B, Gaydecki P, Gresil M, Soutis C 2017 Appl. Compos. Mater. 24 553

Google Scholar

Google Scholar

[14] Zhao X L, Gao H D, Zhang G F, Ayhan B, Yan F, Kwan C, Rose J L 2007 Smart Mater. Struct. 16 1208

Google Scholar

Google Scholar

[15] Chen F, Wilcox P D 2007 Ultrasonics 47 111

Google Scholar

Google Scholar

[16] Douglass A C S, Harley J B 2018 IEEE Trans. Ultrason. Ferroelectr. 65 851

Google Scholar

Google Scholar

[17] Lu Y, Michaels J E 2009 IEEE Sens. J. 9 1462

Google Scholar

Google Scholar

[18] Sohn H 2007 Philos. Trans. R. Soc. A:-Math. Phys. 365 539

Google Scholar

Google Scholar

[19] Clarke T, Cawley P, Wilcox P, Croxford A 2009 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 56 2666

Google Scholar

Google Scholar

[20] Konstantinidis G, Wilcox P D, Drinkwater B W 2007 IEEE Sens. J. 7 905

Google Scholar

Google Scholar

[21] Park H W, Sohn H, Law K H, Farrar C R 2007 J. Sound Vibr. 302 50

Google Scholar

Google Scholar

[22] Jan H, Morteza T, Steven D, van Koen D A 2016 Material 9 901

Google Scholar

Google Scholar

[23] Tabatabaeipour M, Hettler J, Delrue S, van Den Abeele K 2016 NDT&E Int. 80 23

[24] Ciampa F, Pickering S G, Scarselli G, Meo M 2017 Struct. Control HLTH. 24 e1911

Google Scholar

Google Scholar

[25] Demetgul M, Senyurek V Y, Uyandik R, Tansel I N, Yazicioglu O 2015 Measurement 69 42

Google Scholar

Google Scholar

[26] Nguyen L T, Kocur G K, Saenger E H 2018 Ultrasonics 90 153

Google Scholar

Google Scholar

[27] Hongye L, Xin C, Michaels J E, Michaels T E, Cunfu H 2019 Ultrasonics 91 220

Google Scholar

Google Scholar

[28] Zhang J, Drinkwater B W, Wilcox P D 2008 IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 55 2254

Google Scholar

Google Scholar

[29] 郑阳, 何存富, 周进节, 张也弛 2013 工程力学 30 236

Zheng Y, He C F, Zhou J J, Zhang Y C 2013 Eng. Mech. 30 236

[30] Harley J B, Moura J M 2013 J. Acoust. Soc. Am. 133 2732

Google Scholar

Google Scholar

[31] Harley J B, José M F 2014 J. Acoust. Soc. Am. 135 1231

Google Scholar

Google Scholar

[32] Soleimanpour R, Ng C T 2016 J. Civil Struct. Health Monit. 6 447

Google Scholar

Google Scholar

-

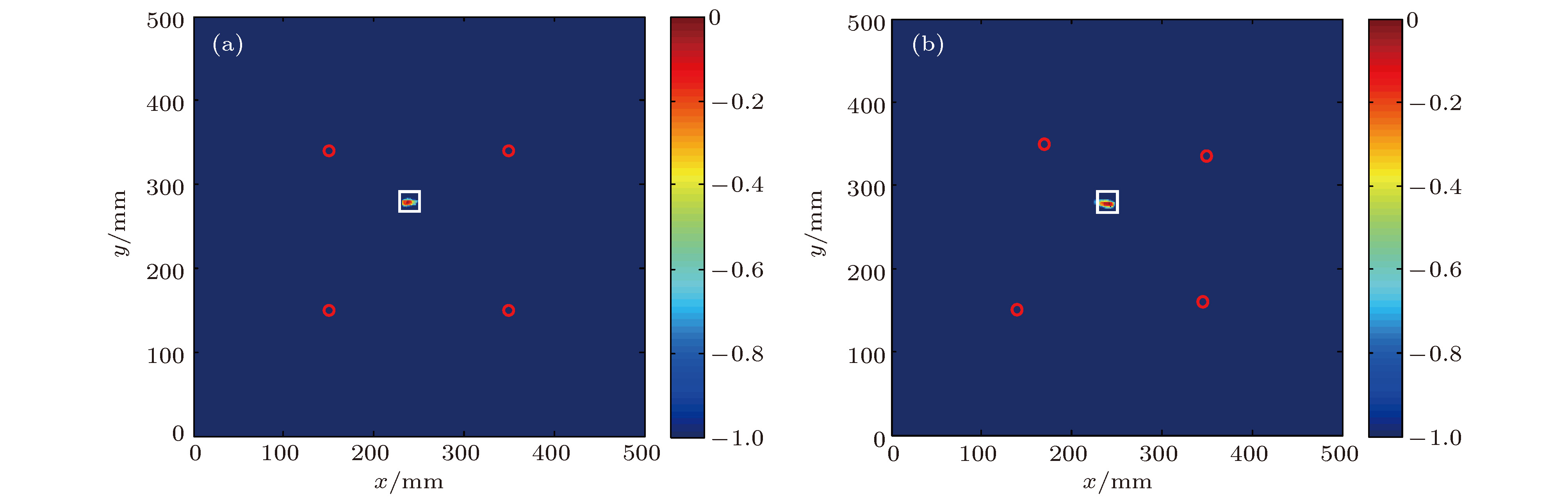

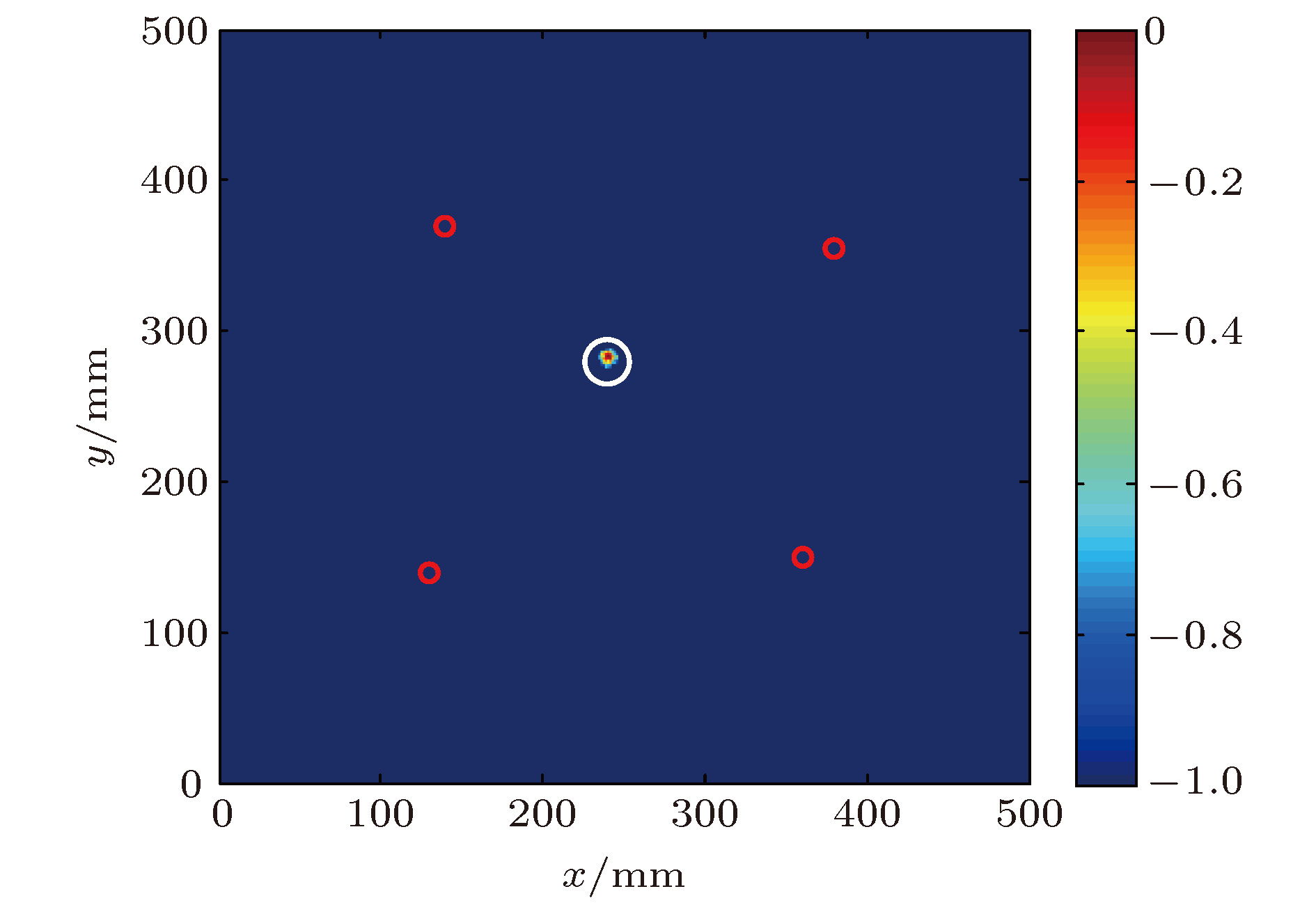

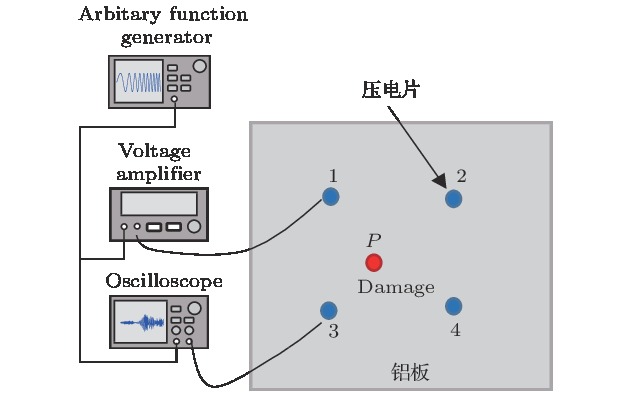

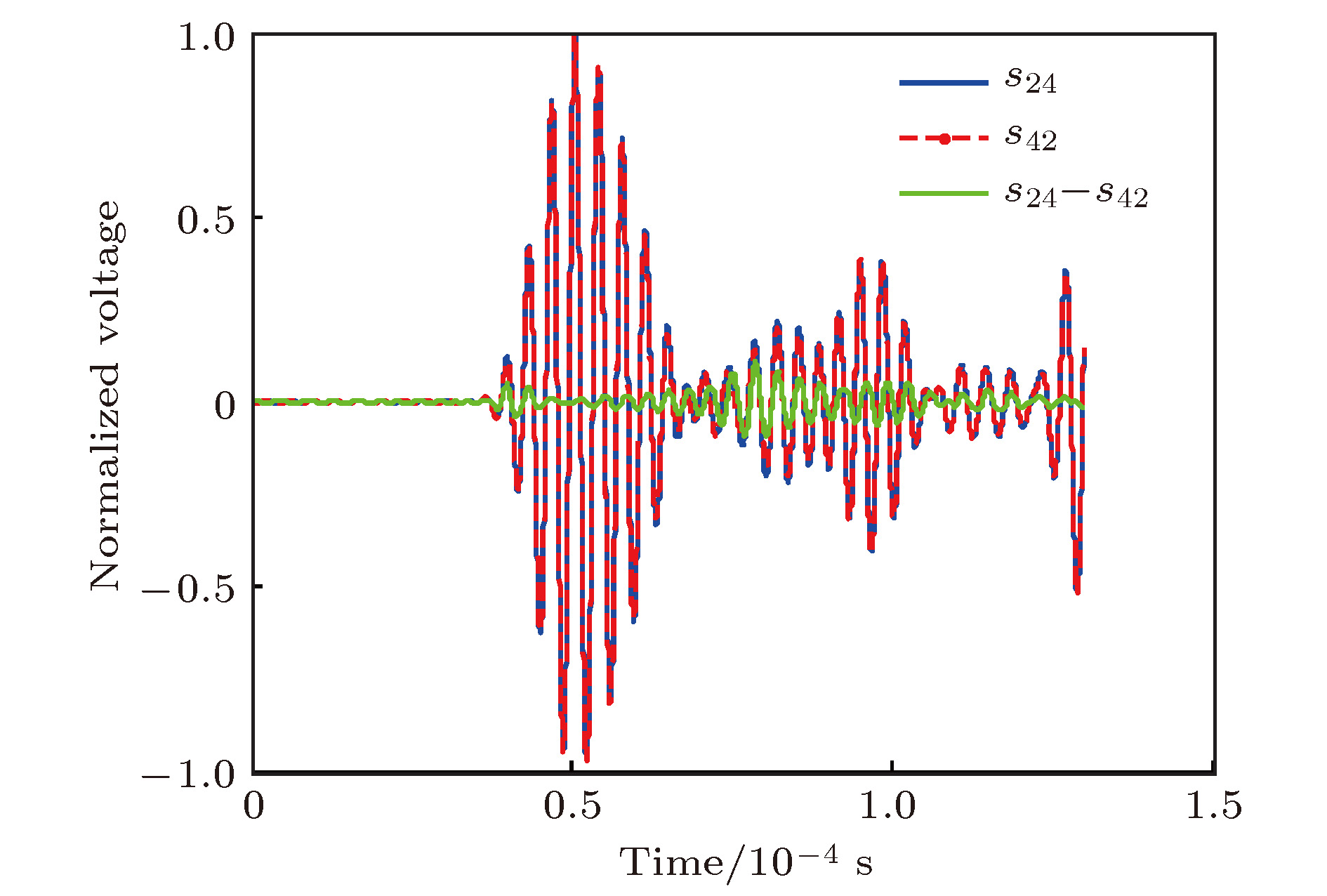

图 19 典型传感器对的反转路径差信号及其对成像的贡献 (a) 1号和3号传感器对的反转路径差信号; (b) 1号和3号传感器对的反转路径差信号对成像的贡献; (c) 2号和4号传感器对的反转路径差信号; (d) 2号和4号传感器对的反转路径差信号对成像的贡献

Fig. 19. Inverted path delta signal of a typical sensor pairs and its contribution to imaging: (a) Inverted path delta signal of sensor pairs of number1 and number 3; (b) contribution to imaging of inverted path delta signal of sensor pairs of number1 and number 3; (c) inverted path delta signal of sensor pairs of number 2 and number 4; (d)contribution to imaging of inverted path delta signal of sensor pairs of number 2 and number 4.

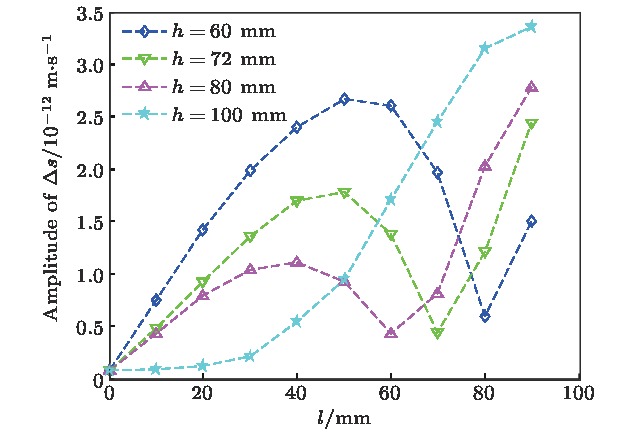

表 1 不同位置缺陷的坐标(单位mm)以及相应的夹角α (单位(°))

Table 1. Coordinates (unit: mm) of defects at different locations and corresponding angles α (unit: (°))

h l 0 10 20 30 40 50 60 70 80 90 60 118.1 117.7 116.6 114.62 111.8 108.0 103.1 97.1 90.0 81.93 72 102.7 102.3 101.3 99.6 97.1 93.9 90.0 85.35 80.1 74.3 80 108.5 108.1 107.0 105.2 102.6 99.1 94.8 89.6 83.7 77.2 100 90.0 89.7 88.8 87.4 85.4 82.8 79.8 76.2 72.2 68.0 表 2 圆形缺陷检测时仿真参数及定位结果(单位: mm)

Table 2. Simulation parameters and positioning results for circular defect detection (unit: mm).

序号 传感器1 传感器2 传感器3 传感器4 缺陷P位置 定位结果 定位误差 1 (基于参考信号) (150, 350) (350, 350) (150, 150) (350, 150) (280, 280) (284, 281) 4.1 2 (150, 350) (350, 350) (150, 150) (350, 150) (280, 280) (285, 285) 7.1 3 (150, 340) (350, 340) (150, 150) (350, 150) (240, 280) (239, 282) 2.2 4 (170, 350) (350, 335) (140, 150) (345, 160) (240, 280) (239, 281) 1.4 表 3 矩形缺陷检测时仿真参数及定位结果(单位: mm)

Table 3. Simulation parameters and positioning results for rectangular defect detection (unit: mm).

序号 传感器1 传感器2 传感器3 传感器4 缺陷P位置 定位结果 定位误差 1 (150, 340) (350, 340) (150, 150) (350, 150) (240, 280) (239, 279) 1.4 2 (170, 350) (350, 335) (140, 150) (345, 160) (240, 280) (241, 279) 1.4 表 4 考虑边界影响时仿真参数及定位结果(单位: mm)

Table 4. Simulation parameters and positioning results when considering boundary effects (unit: mm).

序号 传感器1 传感器2 传感器3 传感器4 缺陷位置 定位结果 定位误差 1 (140, 370) (380, 3355) (130, 140) (360, 150) (240, 280) (240, 284) 4 -

[1] Abbas M, Shafiee M 2018 Sensors 18 3958

Google Scholar

Google Scholar

[2] 高广健, 邓明晰, 李明亮, 刘畅 2015 64 224301

Google Scholar

Google Scholar

Gao G J, Deng M X, Li M L, Liu C 2015 Acta Phys. Sin. 64 224301

Google Scholar

Google Scholar

[3] Kudela P, Radzienski M, Ostachowicz W, Yang Z 2018 Mech. Syst. Signal Proc. 108 21

Google Scholar

Google Scholar

[4] Chen S J, Zhou S P, Li Y, Xiang Y X, Qi M X 2017 Chin. Phys. Lett. 34 044301

Google Scholar

Google Scholar

[5] Petrone G 2018 Aerosp. Sci. Technol. 82 304

[6] Munian R K, Mahapatra D R, Gopalakrishnan S 2018 Compos. Struct. 206 484

Google Scholar

Google Scholar

[7] Mohammadi M, Pouyan A A, Khan N A, Abolghasemi V 2018 Signal Process. 150 85

Google Scholar

Google Scholar

[8] Kim C Y, Park K J 2015 NDT&E Int. 74 15

[9] Wilcox P D, Lowe M, Cawley P 2003 IEEE Trans. Ultrason. Ferroelectr. 50 419

Google Scholar

Google Scholar

[10] Xu K, Ta D, Moilanen P, Wang W Q 2012 J. Acoust. Soc. Am. 131 2714

Google Scholar

Google Scholar

[11] Agrahari J K, Kapuria S 2018 Struct. Control HLTH. 25 e2064

Google Scholar

Google Scholar

[12] Salmanpour M S, Sharif K Z, Mhf A 2017 Sensors 17 1178

Google Scholar

Google Scholar

[13] Muller A, Robertson-Welsh B, Gaydecki P, Gresil M, Soutis C 2017 Appl. Compos. Mater. 24 553

Google Scholar

Google Scholar

[14] Zhao X L, Gao H D, Zhang G F, Ayhan B, Yan F, Kwan C, Rose J L 2007 Smart Mater. Struct. 16 1208

Google Scholar

Google Scholar

[15] Chen F, Wilcox P D 2007 Ultrasonics 47 111

Google Scholar

Google Scholar

[16] Douglass A C S, Harley J B 2018 IEEE Trans. Ultrason. Ferroelectr. 65 851

Google Scholar

Google Scholar

[17] Lu Y, Michaels J E 2009 IEEE Sens. J. 9 1462

Google Scholar

Google Scholar

[18] Sohn H 2007 Philos. Trans. R. Soc. A:-Math. Phys. 365 539

Google Scholar

Google Scholar

[19] Clarke T, Cawley P, Wilcox P, Croxford A 2009 IEEE Trans. Ultrason. Ferroelectr. Freq. Control 56 2666

Google Scholar

Google Scholar

[20] Konstantinidis G, Wilcox P D, Drinkwater B W 2007 IEEE Sens. J. 7 905

Google Scholar

Google Scholar

[21] Park H W, Sohn H, Law K H, Farrar C R 2007 J. Sound Vibr. 302 50

Google Scholar

Google Scholar

[22] Jan H, Morteza T, Steven D, van Koen D A 2016 Material 9 901

Google Scholar

Google Scholar

[23] Tabatabaeipour M, Hettler J, Delrue S, van Den Abeele K 2016 NDT&E Int. 80 23

[24] Ciampa F, Pickering S G, Scarselli G, Meo M 2017 Struct. Control HLTH. 24 e1911

Google Scholar

Google Scholar

[25] Demetgul M, Senyurek V Y, Uyandik R, Tansel I N, Yazicioglu O 2015 Measurement 69 42

Google Scholar

Google Scholar

[26] Nguyen L T, Kocur G K, Saenger E H 2018 Ultrasonics 90 153

Google Scholar

Google Scholar

[27] Hongye L, Xin C, Michaels J E, Michaels T E, Cunfu H 2019 Ultrasonics 91 220

Google Scholar

Google Scholar

[28] Zhang J, Drinkwater B W, Wilcox P D 2008 IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 55 2254

Google Scholar

Google Scholar

[29] 郑阳, 何存富, 周进节, 张也弛 2013 工程力学 30 236

Zheng Y, He C F, Zhou J J, Zhang Y C 2013 Eng. Mech. 30 236

[30] Harley J B, Moura J M 2013 J. Acoust. Soc. Am. 133 2732

Google Scholar

Google Scholar

[31] Harley J B, José M F 2014 J. Acoust. Soc. Am. 135 1231

Google Scholar

Google Scholar

[32] Soleimanpour R, Ng C T 2016 J. Civil Struct. Health Monit. 6 447

Google Scholar

Google Scholar

计量

- 文章访问数: 9884

- PDF下载量: 68

- 被引次数: 0

下载:

下载: