-

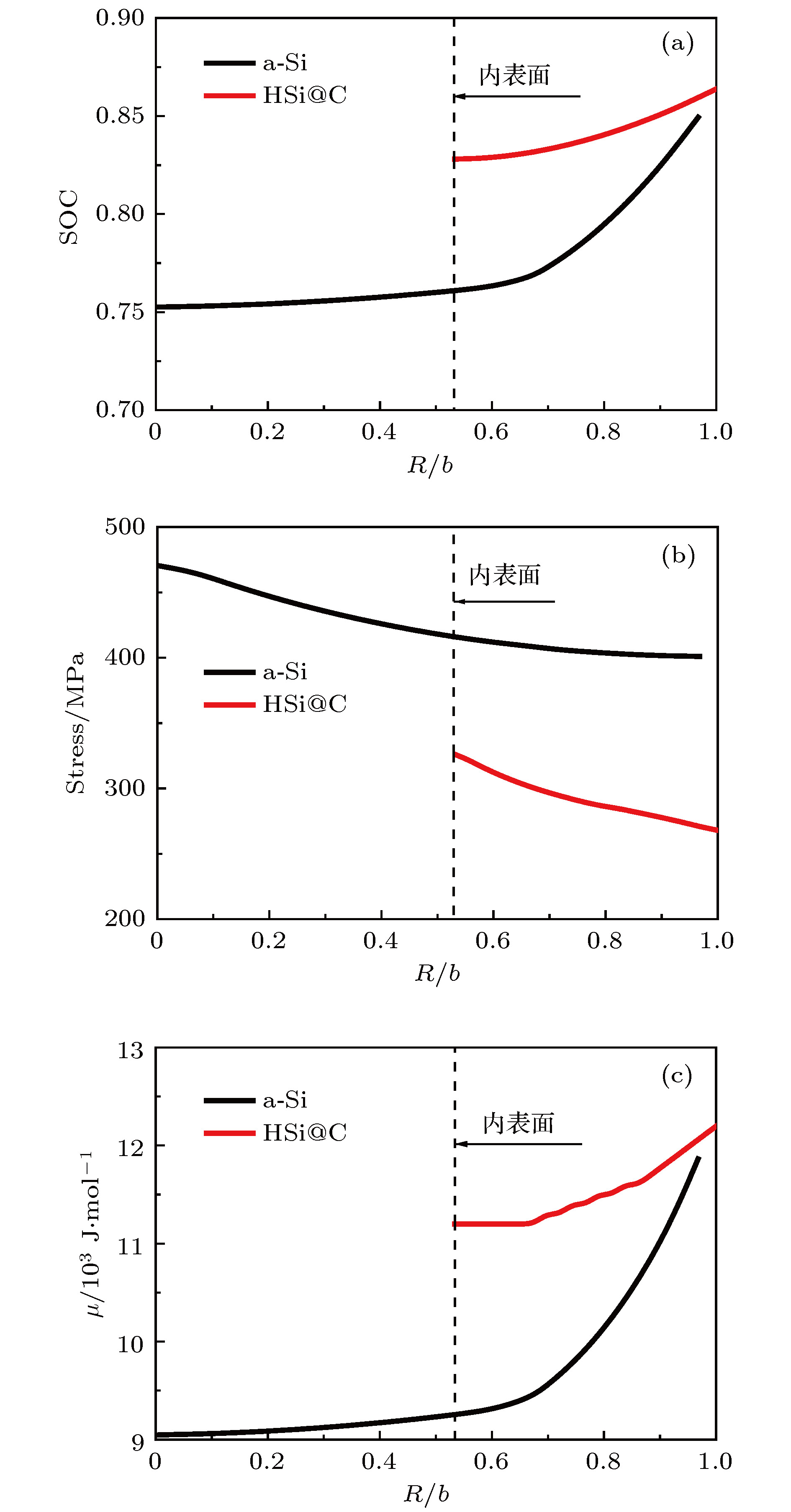

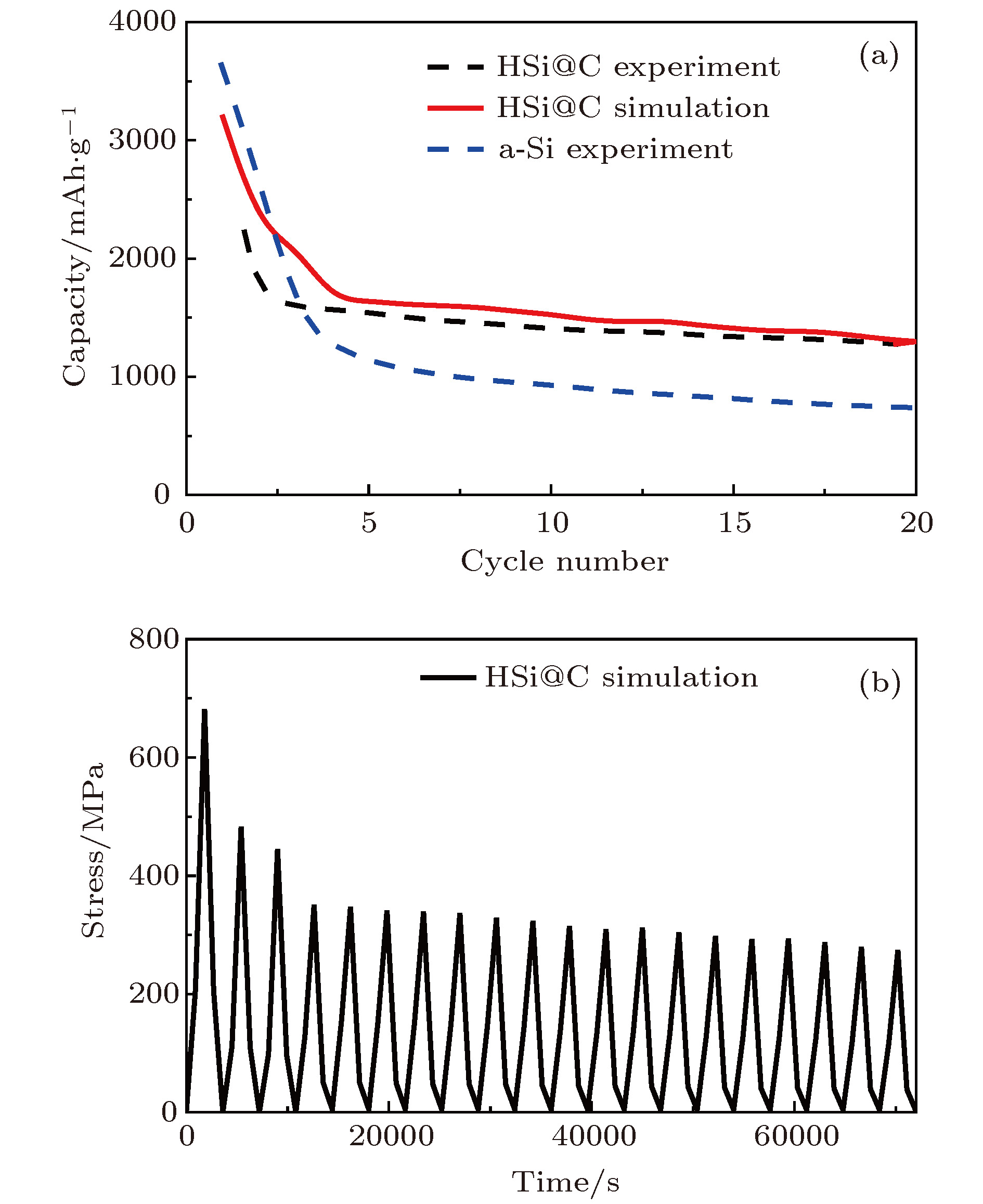

针对锂离子电池硅及其复合电极材料, 采用Cahn-Hilliard型扩散方程与有限变形理论全耦合的电化学-力模型来描述其在循环锂化过程中的扩散和力学相关性问题, 构造高效的数值算法, 在商用有限元软件平台上实现对该理论的数值求解. 在此基础上, 研究了硅电极恒流锂化和脱锂过程, 基于界面反应动力学, 得到电压响应曲线, 计算结果整体趋势与实验结果吻合较好, 同时预测的应力响应也与实验结果一致, 验证了本方法的有效性. 其次, 研究了中空碳包覆硅负极锂化过程中的电化学与力学行为, 计算结果表明, 锂化期间中空碳包覆硅负极应力水平明显低于实心硅负极, 随锂化的进行, 应力差值越来越大, 锂化结束时应力值降低约27%, 这种应力的缓解提高了整个电极内化学势水平, 使得锂离子浓度水平显著提高, 更易达到完全锂化状态. 同时, 数值研究表明应力水平的缓解延缓了中空碳包覆硅负极的容量衰减(容量提升74%), 充分显示出该电极良好的电化学性能. 本研究揭示了应力对硅复合电极容量影响的作用机制, 为将连续介质电化学-力耦合理论应用于实验预测提供了途径并为电极材料设计提供了理论依据.Electrochemical-mechanical coupling mechanism plays an important role in stress relaxation and cycle stability during charging and discharging of lithium ion batteries. The hollow core-shell structure has become a research hotspot in recent years due to the dual effects of its carbon layer and internal voids on volume expansion. However, the theory of diffusion induced stress has not been used to determine how the elastoplastic deformation of amorphous silicon affects the electrochemical performance of silicon anodes with more complex geometries. Based on the Cahn-Hilliard type of material diffusion and finite deformation, a fully coupled diffusion-deformation theory is developed to describe the electrochemical-mechanical coupling mechanism of silicon-polar particles. According to the interface reaction kinetics, the voltage response curve is obtained. The overall trend of the calculated results accords well with the experimental results, and the predicted stress response is also consistent with the experimental result, and thus verifying the effectiveness of the method. Taking the hollow carbon-coated silicon structure that has received much attention in recent years as an example, we study the electrochemical and mechanical behavior during lithiation of hollow carbon-coated silicon anodes and the capacity decay and stress evolution after charge and discharge cycles. The numerical simulation results show that the stress level of the hollow carbon-coated silicon electrode is significantly lower than that of the solid silicon electrode during the whole lithiation. With the lithiation, the stress difference becomes larger and the stress value at the end of lithiation is reduced by about 27%. It fully shows the dual effects of carbon layer and internal pores on stress relaxation and release. In addition, the concentration gradient in the solid silicon negative electrode is too large, which will result in greater stress. In contrast, the lithium ion concentration inside the hollow carbon-coated silicon particles during lithiation is significantly higher than that of the solid silicon particles, and tends to be evenly distributed, which conduces to alleviating the mechanical degradation of the electrode. At the same time, the hollow carbon coated silicon electrode reaches the fully lithiated state earlier, which fully shows the excellent electrochemical performance of the hollow core-shell structure. Finally, the numerical calculation shows that the capacity attenuation is quite consistent with the experimental measurements. Mitigation of stress levels under structural control delays the attenuation of the capacity of hollow carbon-coated silicon anodes. The excellent cycle stability can be attributed to the dual effect of carbon coating and internal pores on volume expansion and stress relief.

-

Keywords:

- electrochemical-mechanical coupling /

- hollow carbon coated silicon particles /

- finite element numerical method /

- cyclic stability

[1] 程昀, 李劼, 贾明, 汤依伟, 杜双龙, 艾立华, 殷宝华, 艾亮 2015 64 210202

Google Scholar

Google Scholar

Cheng Y, Li J, Jia M, Tang Y W, Du S L, Ai L H, Yin B H, Ai L 2015 Acta Phys. Sin. 64 210202

Google Scholar

Google Scholar

[2] 蒋跃辉, 艾亮, 贾明, 程昀, 杜双龙, 李书国 2017 66 118202

Google Scholar

Google Scholar

Jiang Y H, Ai L, Jia M, Cheng Y, Du S L, Li S G 2017 Acta Phys. Sin. 66 118202

Google Scholar

Google Scholar

[3] 张俊乾, 吕浡, 宋亦诚 2017 力学季刊 38 14

Zhang J Q, Lü B, Song Y C 2017 Chin. Quart. Mech. 38 14

[4] DeLuca C M, Maute K, Dunn M L 2011 J. Power Sources 196 9672

Google Scholar

Google Scholar

[5] Liu N, Lu Z, Zhao J, Mcdowell M T, Lee H W, Zhao W, Cui Y 2014 Nat. Nanotechnol. 9 187

Google Scholar

Google Scholar

[6] Sun Y, Liu N, Cui Y 2016 Nat. Energy 1 16071

Google Scholar

Google Scholar

[7] Jia Z, Li T 2015 J. Power Sources 275 866

Google Scholar

Google Scholar

[8] Yao Y, McDowell M T, Ryu I, Wu H, Liu N, Hu L, Nix W D, Cui Y 2011 Nano Lett. 11 2949

Google Scholar

Google Scholar

[9] Hu B, Ma Z S, Lei W, Zou Y, Lu C 2017 Theor. Appl. Mech. Lett. 7 199

Google Scholar

Google Scholar

[10] Ma Z S, Xie Z C, Wang Y, Zhang P P, Pan Y, Zhou Y C, Lu C 2015 J. Power Sources 290 114

Google Scholar

Google Scholar

[11] Zhang X Y, Song W L, Liu Z L, Chen H S, Li T, Wei Y J, Fang D N 2017 J. Mater. Chem. A 51 2793

[12] Cho J 2010 J. Mater. Chem. 20 4009

Google Scholar

Google Scholar

[13] Luo F, Liu B, Zheng J, Chu G, Zhong K, Li H, Huang X, Chen L 2015 J. Electrochem. Soc. 162 A2509

Google Scholar

Google Scholar

[14] Terranova M L, Orlanducci S, Tamburri E, Guglielmotti V, Rossi M 2014 J. Power Sources 246 167

Google Scholar

Google Scholar

[15] Hao F, Fang D 2013 J. Electrochem. Soc. 160 A595

Google Scholar

Google Scholar

[16] Su L W, Zhou Z, Ren M M 2010 Chem. Commun. 46 2590

Google Scholar

Google Scholar

[17] Hwa Y, Kim W S, Hong S H, Sohn H J 2012 Electrochim. Acta 71 201

Google Scholar

Google Scholar

[18] Yan D, Bai Y, Yu C, Li X, Zhang W 2014 J. Alloys Compd. 609 86

Google Scholar

Google Scholar

[19] Xu Y, Zhu Y, Wang C 2014 J. Mater. Chem. A 2 9751

Google Scholar

Google Scholar

[20] Shao D, Tang D, Mai Y, Zhang L 2013 J. Mater. Chem. A 1 15068

Google Scholar

Google Scholar

[21] Ma X, Liu M, Gan L, Tripathi P K, Zhao Y, Zhu D, Xu Z, Chen L 2014 Phys. Chem. Chem. Phys. 16 4135

Google Scholar

Google Scholar

[22] Liu N, Wu H, McDowell M T, Yao Y, Wang C, Cui Y 2012 Nano Lett. 12 3315

Google Scholar

Google Scholar

[23] Ashuri M, He Q, Liu Y, Zhang K, Emani S, Sawicki M S, Shamie J S, Shaw L L 2016 Electrochim. Acta 215 126

Google Scholar

Google Scholar

[24] Ashuri M, He Q, Zhang K, Emani S, Shaw L L 2016 J. Sol-Gel. Sci. Technol. 82 201

Google Scholar

Google Scholar

[25] Guo Z, Ji L, Chen L 2017 J. Mater. Sci. 52 13606

Google Scholar

Google Scholar

[26] Zhang J, Lu B, Song Y, Ji X 2012 J. Power Sources 209 220

Google Scholar

Google Scholar

[27] Song Y, Shao X, Guo Z, Zhang J 2013 J. Phys. D: Appl. Phys. 46 105307

Google Scholar

Google Scholar

[28] 宋旭, 陆勇俊, 石明亮, 赵翔, 王峰会 2018 67 140201

Google Scholar

Google Scholar

Song X, Lu Y J, Shi M L, Zhao X, Wang F H 2018 Acta Phys. Sin. 67 140201

Google Scholar

Google Scholar

[29] Zhao Y, Stein P, Xu B X 2015 Comput. Meth. Appl. Mech. Eng. 297 325

Google Scholar

Google Scholar

[30] Anand L 2012 J. Mech. Phys. Solids 60 1983

Google Scholar

Google Scholar

[31] Sethuraman V A, Chon M J, Shimshak M, van Winkle N, Guduru P R 2010 Electrochem. Commun. 12 1614

Google Scholar

Google Scholar

[32] Lu Y, Zhang P, Wang F, Zhang K, Zhao X 2018 Electrochim. Acta 274 359

Google Scholar

Google Scholar

[33] Ding N, Xu J, Yao Y X, Wegner G, Fang X, Chen C H, Lieberwirth I 2009 Solid State Ionics 180 222

Google Scholar

Google Scholar

[34] Pharr M, Suo Z, Vlassak J J 2014 J. Power Sources 270 569

Google Scholar

Google Scholar

[35] Bucci G, Nadimpalli S P V, Sethuraman V A, Bower A F, Guduru P R 2014 J. Mech. Phys. Solids 62 276

Google Scholar

Google Scholar

-

图 2 中空碳包覆硅结构的建模 (a) Ashuri等[24]实验制备的中空碳包覆硅颗粒TEM图像; (b)中空核-壳结构有限元模型示意图; (c)中空核-壳结构有限元网格划分示意图

Fig. 2. Modeling of hollow carbon coated silicon structure: (a) TEM image of hollow carbon coated silicon particles reproduced by Ashuri et al.[24]; (b) finite element model of hollow core-shell structure; (c) schematic diagram of finite element meshing of hollow core-shell structure.

表 1 材料参数

Table 1. Material parameters.

-

[1] 程昀, 李劼, 贾明, 汤依伟, 杜双龙, 艾立华, 殷宝华, 艾亮 2015 64 210202

Google Scholar

Google Scholar

Cheng Y, Li J, Jia M, Tang Y W, Du S L, Ai L H, Yin B H, Ai L 2015 Acta Phys. Sin. 64 210202

Google Scholar

Google Scholar

[2] 蒋跃辉, 艾亮, 贾明, 程昀, 杜双龙, 李书国 2017 66 118202

Google Scholar

Google Scholar

Jiang Y H, Ai L, Jia M, Cheng Y, Du S L, Li S G 2017 Acta Phys. Sin. 66 118202

Google Scholar

Google Scholar

[3] 张俊乾, 吕浡, 宋亦诚 2017 力学季刊 38 14

Zhang J Q, Lü B, Song Y C 2017 Chin. Quart. Mech. 38 14

[4] DeLuca C M, Maute K, Dunn M L 2011 J. Power Sources 196 9672

Google Scholar

Google Scholar

[5] Liu N, Lu Z, Zhao J, Mcdowell M T, Lee H W, Zhao W, Cui Y 2014 Nat. Nanotechnol. 9 187

Google Scholar

Google Scholar

[6] Sun Y, Liu N, Cui Y 2016 Nat. Energy 1 16071

Google Scholar

Google Scholar

[7] Jia Z, Li T 2015 J. Power Sources 275 866

Google Scholar

Google Scholar

[8] Yao Y, McDowell M T, Ryu I, Wu H, Liu N, Hu L, Nix W D, Cui Y 2011 Nano Lett. 11 2949

Google Scholar

Google Scholar

[9] Hu B, Ma Z S, Lei W, Zou Y, Lu C 2017 Theor. Appl. Mech. Lett. 7 199

Google Scholar

Google Scholar

[10] Ma Z S, Xie Z C, Wang Y, Zhang P P, Pan Y, Zhou Y C, Lu C 2015 J. Power Sources 290 114

Google Scholar

Google Scholar

[11] Zhang X Y, Song W L, Liu Z L, Chen H S, Li T, Wei Y J, Fang D N 2017 J. Mater. Chem. A 51 2793

[12] Cho J 2010 J. Mater. Chem. 20 4009

Google Scholar

Google Scholar

[13] Luo F, Liu B, Zheng J, Chu G, Zhong K, Li H, Huang X, Chen L 2015 J. Electrochem. Soc. 162 A2509

Google Scholar

Google Scholar

[14] Terranova M L, Orlanducci S, Tamburri E, Guglielmotti V, Rossi M 2014 J. Power Sources 246 167

Google Scholar

Google Scholar

[15] Hao F, Fang D 2013 J. Electrochem. Soc. 160 A595

Google Scholar

Google Scholar

[16] Su L W, Zhou Z, Ren M M 2010 Chem. Commun. 46 2590

Google Scholar

Google Scholar

[17] Hwa Y, Kim W S, Hong S H, Sohn H J 2012 Electrochim. Acta 71 201

Google Scholar

Google Scholar

[18] Yan D, Bai Y, Yu C, Li X, Zhang W 2014 J. Alloys Compd. 609 86

Google Scholar

Google Scholar

[19] Xu Y, Zhu Y, Wang C 2014 J. Mater. Chem. A 2 9751

Google Scholar

Google Scholar

[20] Shao D, Tang D, Mai Y, Zhang L 2013 J. Mater. Chem. A 1 15068

Google Scholar

Google Scholar

[21] Ma X, Liu M, Gan L, Tripathi P K, Zhao Y, Zhu D, Xu Z, Chen L 2014 Phys. Chem. Chem. Phys. 16 4135

Google Scholar

Google Scholar

[22] Liu N, Wu H, McDowell M T, Yao Y, Wang C, Cui Y 2012 Nano Lett. 12 3315

Google Scholar

Google Scholar

[23] Ashuri M, He Q, Liu Y, Zhang K, Emani S, Sawicki M S, Shamie J S, Shaw L L 2016 Electrochim. Acta 215 126

Google Scholar

Google Scholar

[24] Ashuri M, He Q, Zhang K, Emani S, Shaw L L 2016 J. Sol-Gel. Sci. Technol. 82 201

Google Scholar

Google Scholar

[25] Guo Z, Ji L, Chen L 2017 J. Mater. Sci. 52 13606

Google Scholar

Google Scholar

[26] Zhang J, Lu B, Song Y, Ji X 2012 J. Power Sources 209 220

Google Scholar

Google Scholar

[27] Song Y, Shao X, Guo Z, Zhang J 2013 J. Phys. D: Appl. Phys. 46 105307

Google Scholar

Google Scholar

[28] 宋旭, 陆勇俊, 石明亮, 赵翔, 王峰会 2018 67 140201

Google Scholar

Google Scholar

Song X, Lu Y J, Shi M L, Zhao X, Wang F H 2018 Acta Phys. Sin. 67 140201

Google Scholar

Google Scholar

[29] Zhao Y, Stein P, Xu B X 2015 Comput. Meth. Appl. Mech. Eng. 297 325

Google Scholar

Google Scholar

[30] Anand L 2012 J. Mech. Phys. Solids 60 1983

Google Scholar

Google Scholar

[31] Sethuraman V A, Chon M J, Shimshak M, van Winkle N, Guduru P R 2010 Electrochem. Commun. 12 1614

Google Scholar

Google Scholar

[32] Lu Y, Zhang P, Wang F, Zhang K, Zhao X 2018 Electrochim. Acta 274 359

Google Scholar

Google Scholar

[33] Ding N, Xu J, Yao Y X, Wegner G, Fang X, Chen C H, Lieberwirth I 2009 Solid State Ionics 180 222

Google Scholar

Google Scholar

[34] Pharr M, Suo Z, Vlassak J J 2014 J. Power Sources 270 569

Google Scholar

Google Scholar

[35] Bucci G, Nadimpalli S P V, Sethuraman V A, Bower A F, Guduru P R 2014 J. Mech. Phys. Solids 62 276

Google Scholar

Google Scholar

计量

- 文章访问数: 11989

- PDF下载量: 240

- 被引次数: 0

下载:

下载: