-

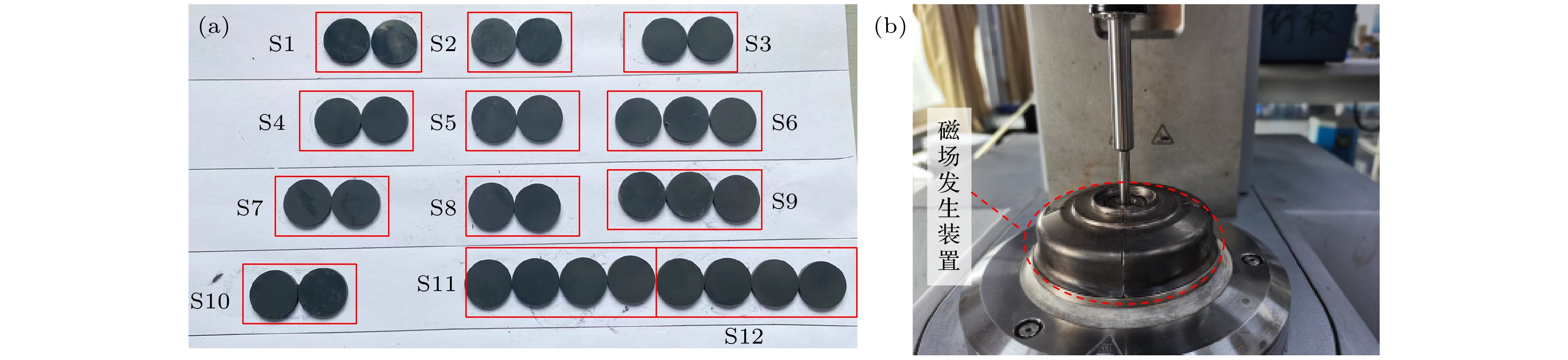

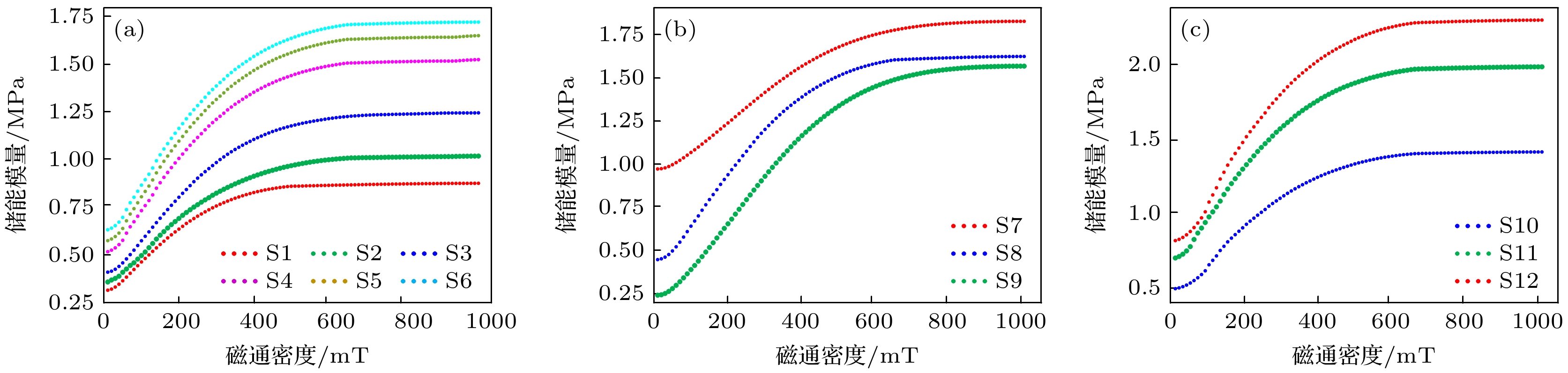

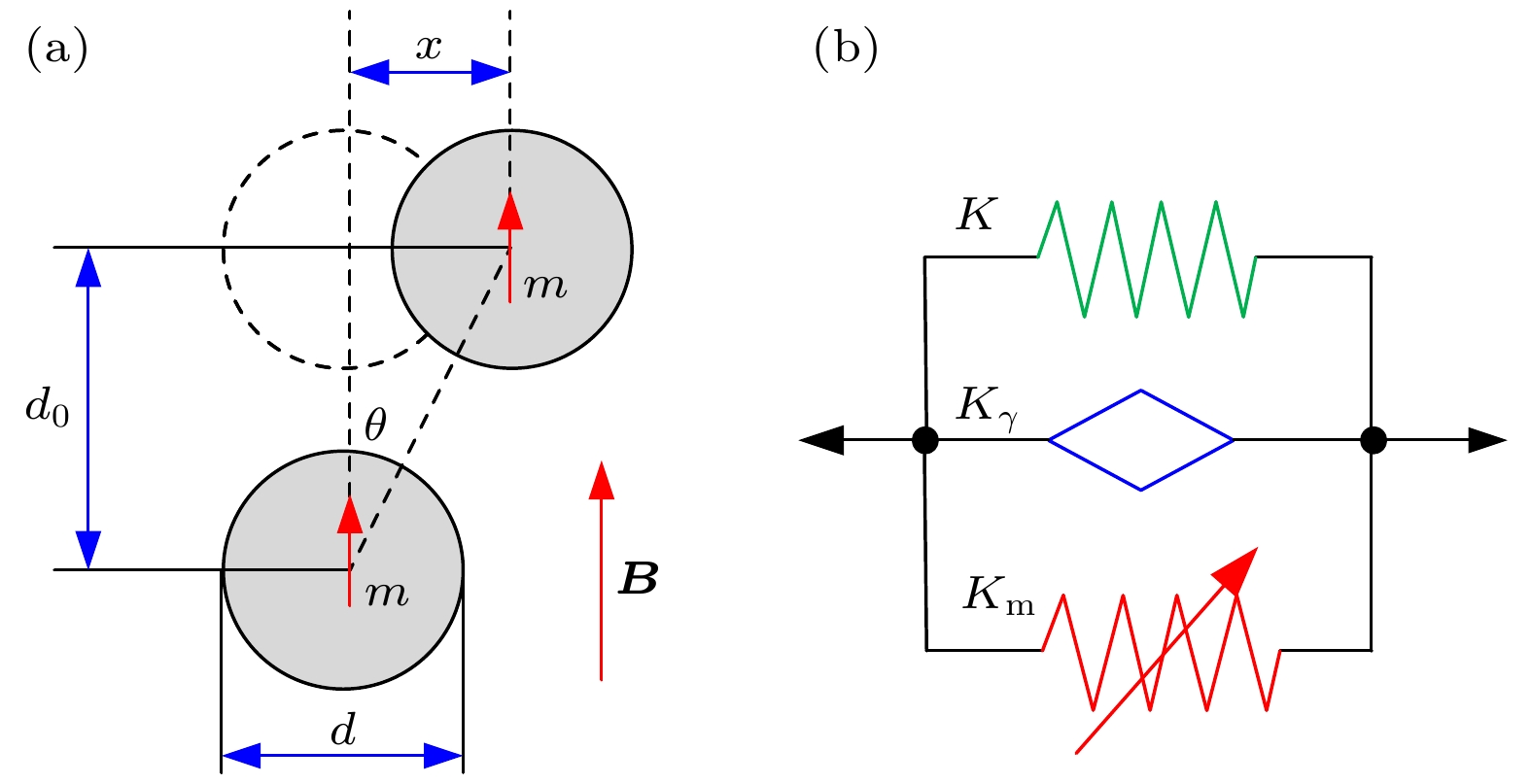

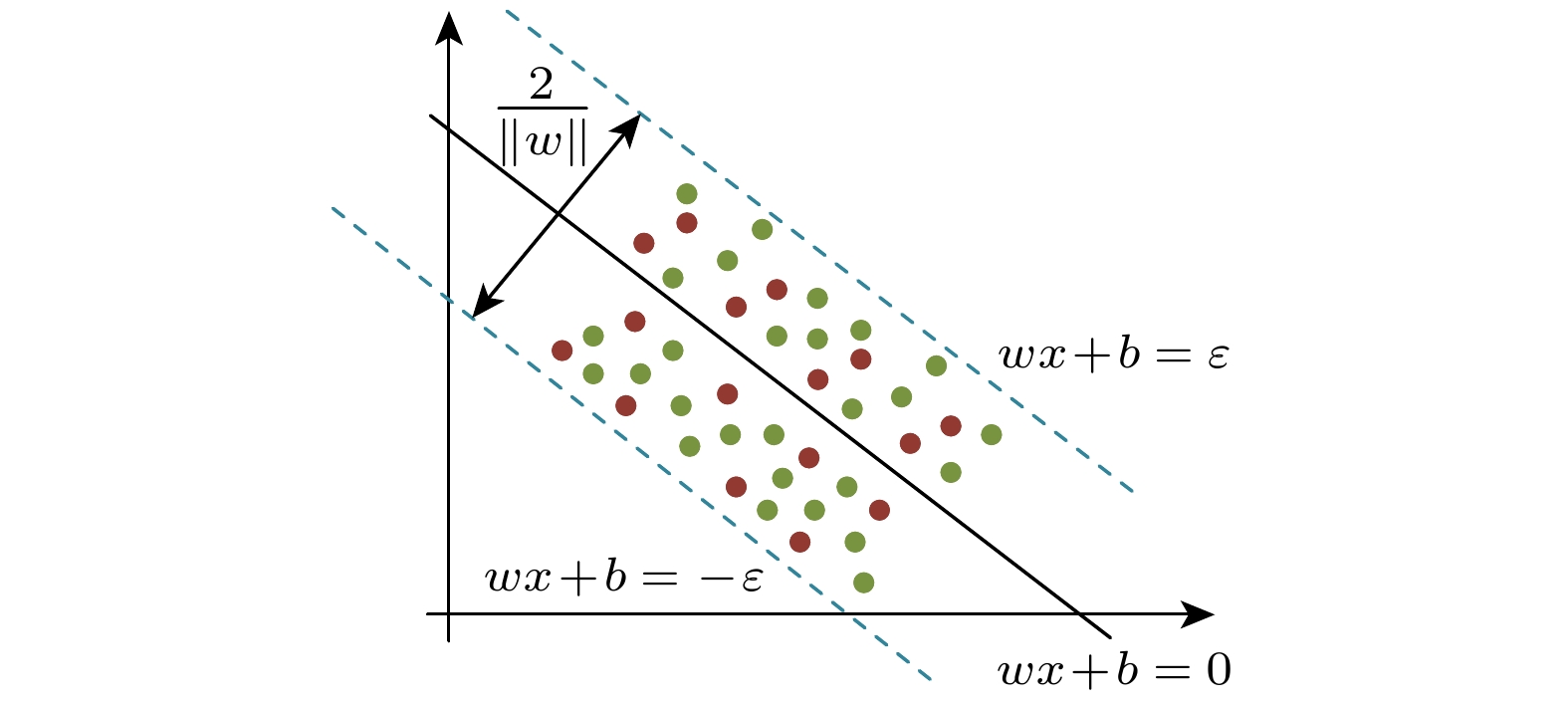

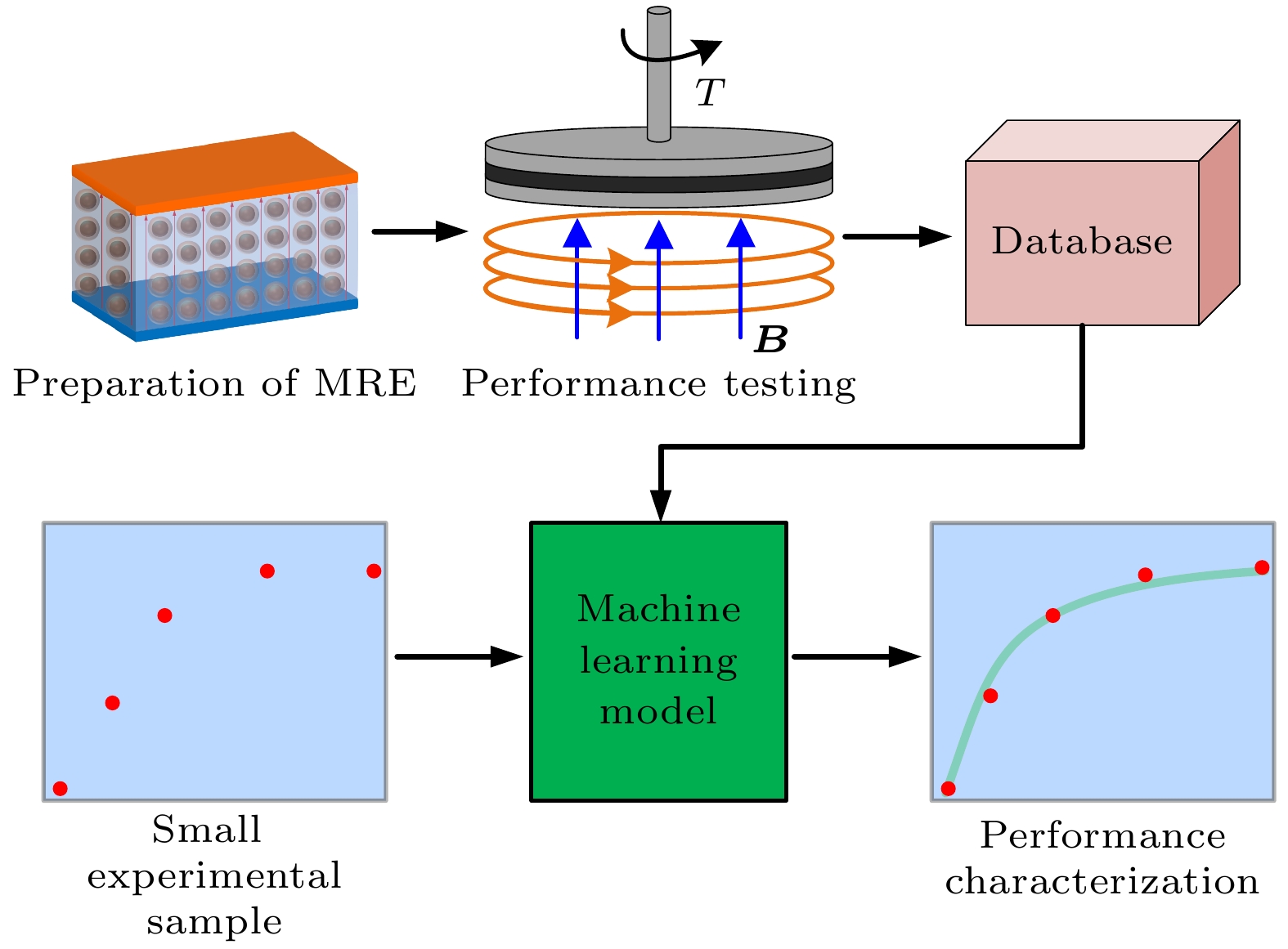

Magnetorheological elastomers (MREs) are smart materials with a wide range of applications, particularly in reducing vibrations and noise. Traditional methods of testing their magnetically-induced properties, although thorough, are labor-intensive and time-consuming. In this work, we introduce an innovative method that harnesses machine learning to rapidly characterize MREs by using a smallest dataset, thus simplifying the characterization process. Initially, 12 types of MREs are prepared and tested on a shear rheometer with a controllable magnetic field. From these data, we strategically select five representative data points from each sample to form a training dataset. Using this dataset, we develop a support vector regression (SVR) model to characterize the magnetically-induced storage modulus of the MRE. The SVR model exhibits remarkable accuracy, with a correlation coefficient (R2) of 0.998 or higher, exceeding the precision of traditional models. The training time of this model is very brief, only 0.02 seconds, thus greatly accelerating the characterization speed of MRE. Moreover, the SVR model demonstrates strong generalization ability, maintaining a high correlation coefficient of 0.998 or greater even when silicone oil is added to the MREs or tested under various loading frequencies. In a word, the machine learning model not only accelerates the evaluation process but also provides a valuable reference for developing innovative MREs, marking a significant advancement in the field of smart materials research.

[1] Vatandoost H, Hemmatian M, Sedaghati R, Rakheja S 2020 Compos. Part B Eng. 182 107648

Google Scholar

Google Scholar

[2] Nam T H, Petríková I, Marvalová B 2020 Polym. Test. 81 106272

Google Scholar

Google Scholar

[3] Kukla M, Warguła Ł, Talaśka K, Wojtkowiak D 2020 Materials 13 4795

Google Scholar

Google Scholar

[4] Agirre-Olabide I, Elejabarrieta M J 2018 Polym. Test. 66 114

Google Scholar

Google Scholar

[5] Zainudin A A, Yunus N A, Mazlan S A, Shabdin M K, Abdul Aziz S A, Nordin N A, Nazmi N, Abdul Rahman M A 2020 Appl. Sci. 10 1638

Google Scholar

Google Scholar

[6] Jaafar M F, Mustapha F, Mustapha M 2021 J. Mater. Res. Technol. 15 5010

Google Scholar

Google Scholar

[7] Leng D X, Zhu Z H, Liu G J, Li Y C 2022 Ocean Eng. 253 111293

Google Scholar

Google Scholar

[8] Jin T H, Liu Z M, Sun S S, Ren Z S, Deng L, Yang B, Christie M D, Li W H 2020 Mech. Syst. Signal Process. 135 106338

Google Scholar

Google Scholar

[9] 刘少刚, 赵跃超, 赵丹 2019 68 234301

Google Scholar

Google Scholar

Liu S G, Zhao Y C, Zhao D 2019 Acta Phys. Sin. 68 234301

Google Scholar

Google Scholar

[10] Wang Q, Chen Z X, Wang Y H, Gong N, Yang J, Li W H, Sun S S 2024 Mech. Syst. Signal Process. 208 111029

Google Scholar

Google Scholar

[11] 胡红生, 王炅, 钱苏翔, 李延成, 沈娜, 严拱标 2011 机械工程学报 47 84

Hu H S, Wang J, Qian S X, Li Y C, Shen N, Yan G B 2011 Chin. J. Mech. Eng. 47 84

[12] 文永蓬, 孙倩, 周伟浩, 尚慧琳, 郭林生 2018 机械工程学报 54 114

Wen Y P, Sun Q, Zhou W H, Shang H L, Guo L S 2018 Chin. J. Mech. Eng. 54 114

[13] Jolly M R, Carlson J D, Muñoz B C 1996 Smart Mater. Struct. 5 607

Google Scholar

Google Scholar

[14] Zhu Y S, Gong X L, Dang H, Zhang X Z, Zhang P Q 2006 Chin. J. Chem. Phys. 19 126

Google Scholar

Google Scholar

[15] Li W H, Zhang X Z 2010 Smart Mater. Struct. 19 035002

Google Scholar

Google Scholar

[16] Ivaneyko D, Toshchevikov V, Saphiannikova M, Heinrich G 2011 Macromol. Theory Simul. 20 411

Google Scholar

Google Scholar

[17] Ivaneyko D, Toshchevikov V, Borin D, Saphiannikova M, Heinrich G 2014 Macromol. Symp. 338 96

Google Scholar

Google Scholar

[18] Li W H, Zhou Y, Tian T F 2010 Rheol. Acta 49 733

Google Scholar

Google Scholar

[19] Gu Z R, Luo Y P, Su Z B, Zhang L Y, Ren H J, Wang Y, Luo J 2023 J. Magn. Magn. Mater. 580 170795

Google Scholar

Google Scholar

[20] Feng Y Y, Yang X J, Liu J G, Chen Z Q 2023 Phys. Stat. Mech. Its Appl. 621 128789

Google Scholar

Google Scholar

[21] Chen L, Gong X L, Li W H 2008 Polym. Test. 27 340

Google Scholar

Google Scholar

[22] Li Y C, Li J C, Li W H, Samali B 2013 Smart Mater. Struct. 22 035005

Google Scholar

Google Scholar

[23] Ahmad Khairi M H, Abd Fatah A Y, Mazlan S A, Ubaidillah U, Nordin N A, Nik Ismail N I, Choi S B, Abdul Aziz S A 2019 Int. J. Mol. Sci. 20 4085

Google Scholar

Google Scholar

[24] Gowda D K, Odenbach S 2023 J. Magn. Magn. Mater. 579 170856

Google Scholar

Google Scholar

[25] 刘浩, 须颖, 罗杨泉, 肖海善 2022 机械工程学报 58 328

Google Scholar

Google Scholar

Liu H, Xu Y, Luo Y Q, Xiao S H 2022 Chin. J. Mech. Eng. 58 328

Google Scholar

Google Scholar

[26] 孙涛, 袁健美 2023 72 218901

Google Scholar

Google Scholar

Sun T, Yuan J M 2023 Acta Phys. Sin. 72 218901

Google Scholar

Google Scholar

[27] 寇雯博, 董灏, 邹岷强, 韩均言, 贾西西 2021 70 030701

Google Scholar

Google Scholar

Kou W B, Dong H, Zou M Q, Han J Y, Jia X X 2021 Acta Phys. Sin. 70 030701

Google Scholar

Google Scholar

[28] Goodall R E A, Lee A A 2020 Nat. Commun. 11 6280

Google Scholar

Google Scholar

[29] Goodall R E A, Parackal A S, Faber F A, Armiento R, Lee A A 2022 Sci. Adv. 8 eabn4117

Google Scholar

Google Scholar

[30] Bessa M A, Bostanabad R, Liu Z, Hu A, Apley D W, Brinson C, Chen W, Liu W K 2017 Comput. Methods Appl. Mech. Eng. 320 633

Google Scholar

Google Scholar

[31] Clément A, Soize C, Yvonnet J 2012 Int. J. Numer. Methods Eng. 91 799

Google Scholar

Google Scholar

[32] Le B A, Yvonnet J, He Q C 2015 Int. J. Numer. Methods Eng. 104 1061

Google Scholar

Google Scholar

[33] Shen L, Qian Q 2022 Comput. Mater. Sci. 211 111475

Google Scholar

Google Scholar

[34] Jung J, Kim Y, Park J, Ryu S 2022 Compos. Struct. 285 115210

Google Scholar

Google Scholar

[35] Huang D Z, Xu K, Farhat C, Darve E 2020 J. Comput. Phys. 416 109491

Google Scholar

Google Scholar

[36] Li X, Liu Z, Cui S, Luo C, Li C, Zhuang Z 2019 Comput. Methods Appl. Mech. Eng. 347 735

Google Scholar

Google Scholar

[37] Liu X, Yan Z, Zhong Z 2021 Int. J. Hydrog. Energy 46 22079

Google Scholar

Google Scholar

[38] El Said B 2023 Int. J. Solids Struct. 276 112334

Google Scholar

Google Scholar

[39] Li Z Q, Li X, Chen Y, Zhang C 2023 Compos. Struct. 323 117473

Google Scholar

Google Scholar

[40] Nguyen X B, Komatsuzaki T, Iwata Y, Asanuma H 2018 Mech. Syst. Signal Process. 101 449

Google Scholar

Google Scholar

[41] Wang L Z, Chen Z B, Jiang L K, Cheng L 2023 J. Magn. Magn. Mater. 570 170441

Google Scholar

Google Scholar

[42] Kumbhar S B, Chavan S P, Gawade S S 2018 Mech. Syst. Signal Process. 100 208

Google Scholar

Google Scholar

[43] Eem S H, Jung H J, Koo J H 2012 IEEE Trans. Magn. 48 3080

Google Scholar

Google Scholar

[44] Norouzi M, Sajjadi Alehashem S M, Vatandoost H, Ni Y Q, Shahmardan M M 2016 J. Intell. Mater. Syst. Struct. 27 1121

Google Scholar

Google Scholar

[45] Nguyen X B, Komatsuzaki T, Zhang N 2020 Mech. Syst. Signal Process. 141 106438

Google Scholar

Google Scholar

[46] Yang S, Wang P, Liu Y, Dong X, Tong Y, Zhao Y 2021 Front. Mater. 8 743716

Google Scholar

Google Scholar

[47] Wang Q, Dong X F, Li L Y, Ou J P 2017 Smart Mater. Struct. 26 065010

Google Scholar

Google Scholar

-

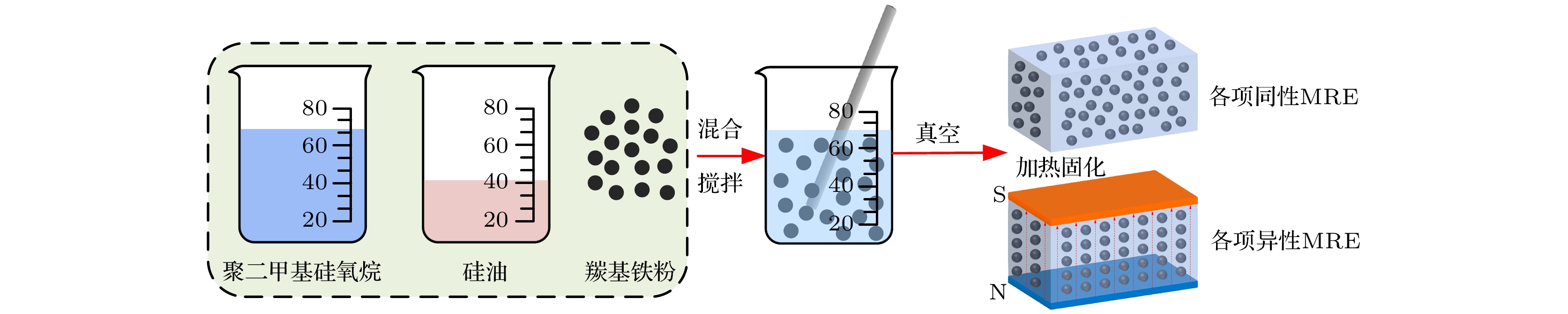

表 1 MER样品配比及测试工况

Table 1. Ratio and testing conditions of MRE.

S1 S2 S3 S4 S5 S6 S7 S8 S9 S10 S11 S12 铁磁颗粒/% 12 15 18 21 24 27 27 27 27 27 27 27 硅油/% 5 5 5 5 5 5 0 10 15 5 5 5 加载频率/Hz 75 75 75 75 75 75 75 75 75 30 60 90 表 2 不同模型对S6样品的预测结果

Table 2. Prediction results of different models on S6 sample.

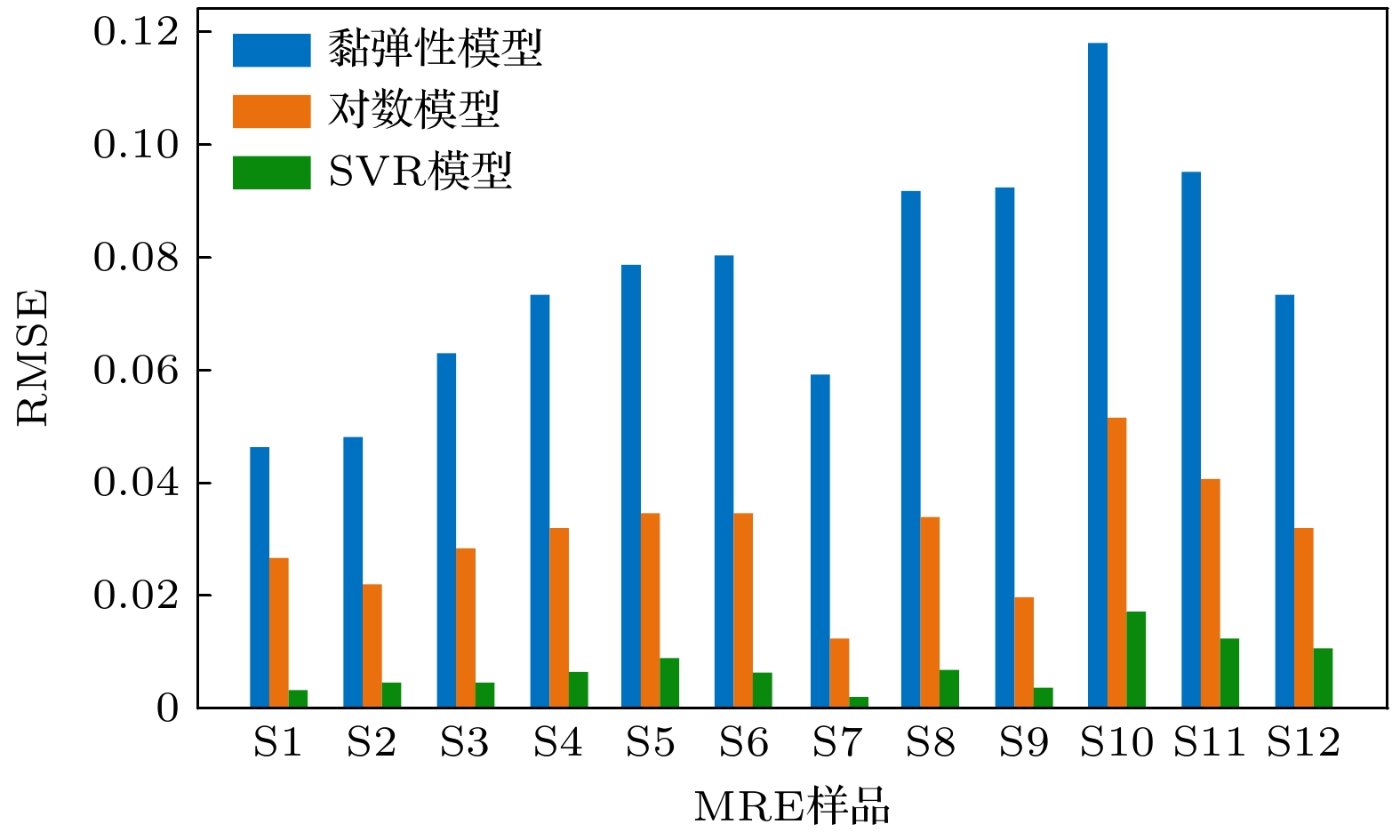

训练样本数量 4 5 10 20 train R2 0.999 0.999 0.999 0.999 test R2 0.878 0.998 0.998 0.998 RSME 0.112 0.0125 0.0133 0.0111 表 3 基于SVR模型预测不同MRE样品的RMSE与R2

Table 3. Prediction of RMSE and R2 for different MRE samples based on SVR model.

样品 RMSE R2 S1 3378 0.999 S2 5006 0.999 S3 4246 0.999 S4 6671 0.998 S5 8579 0.999 S6 8669 0.998 S7 2275 0.999 S8 6547 0.999 S9 3630 0.999 S10 17122 0.998 S11 12642 0.998 S12 10409 0.998 表 4 不同模型对S6样品的预测结果

Table 4. Prediction results of different models on S6 samples.

模型 磁场范围/mT R2 磁偶极子模型 0—1000 0.836 动态黏弹性模型 0—326 0.93 四参数分数阶导数黏弹性模型 0—150 0.97 动态磁力学模型 90—178 0.99 三参数本构模型(Maxwell形式) 125—540 0.958 渗透模型 0—375 0.9 Ramberg-Osgood模型 0—500 0.9 修正Kelvin–Voigt黏弹模型 0—272 0.93 自适应光滑库仑摩擦模型 — 0.92 修正Bouc-Wen模型 0—545 0.9 非线性流变模型 0—330 0.98 SVR模型 0—1000 0.998 -

[1] Vatandoost H, Hemmatian M, Sedaghati R, Rakheja S 2020 Compos. Part B Eng. 182 107648

Google Scholar

Google Scholar

[2] Nam T H, Petríková I, Marvalová B 2020 Polym. Test. 81 106272

Google Scholar

Google Scholar

[3] Kukla M, Warguła Ł, Talaśka K, Wojtkowiak D 2020 Materials 13 4795

Google Scholar

Google Scholar

[4] Agirre-Olabide I, Elejabarrieta M J 2018 Polym. Test. 66 114

Google Scholar

Google Scholar

[5] Zainudin A A, Yunus N A, Mazlan S A, Shabdin M K, Abdul Aziz S A, Nordin N A, Nazmi N, Abdul Rahman M A 2020 Appl. Sci. 10 1638

Google Scholar

Google Scholar

[6] Jaafar M F, Mustapha F, Mustapha M 2021 J. Mater. Res. Technol. 15 5010

Google Scholar

Google Scholar

[7] Leng D X, Zhu Z H, Liu G J, Li Y C 2022 Ocean Eng. 253 111293

Google Scholar

Google Scholar

[8] Jin T H, Liu Z M, Sun S S, Ren Z S, Deng L, Yang B, Christie M D, Li W H 2020 Mech. Syst. Signal Process. 135 106338

Google Scholar

Google Scholar

[9] 刘少刚, 赵跃超, 赵丹 2019 68 234301

Google Scholar

Google Scholar

Liu S G, Zhao Y C, Zhao D 2019 Acta Phys. Sin. 68 234301

Google Scholar

Google Scholar

[10] Wang Q, Chen Z X, Wang Y H, Gong N, Yang J, Li W H, Sun S S 2024 Mech. Syst. Signal Process. 208 111029

Google Scholar

Google Scholar

[11] 胡红生, 王炅, 钱苏翔, 李延成, 沈娜, 严拱标 2011 机械工程学报 47 84

Hu H S, Wang J, Qian S X, Li Y C, Shen N, Yan G B 2011 Chin. J. Mech. Eng. 47 84

[12] 文永蓬, 孙倩, 周伟浩, 尚慧琳, 郭林生 2018 机械工程学报 54 114

Wen Y P, Sun Q, Zhou W H, Shang H L, Guo L S 2018 Chin. J. Mech. Eng. 54 114

[13] Jolly M R, Carlson J D, Muñoz B C 1996 Smart Mater. Struct. 5 607

Google Scholar

Google Scholar

[14] Zhu Y S, Gong X L, Dang H, Zhang X Z, Zhang P Q 2006 Chin. J. Chem. Phys. 19 126

Google Scholar

Google Scholar

[15] Li W H, Zhang X Z 2010 Smart Mater. Struct. 19 035002

Google Scholar

Google Scholar

[16] Ivaneyko D, Toshchevikov V, Saphiannikova M, Heinrich G 2011 Macromol. Theory Simul. 20 411

Google Scholar

Google Scholar

[17] Ivaneyko D, Toshchevikov V, Borin D, Saphiannikova M, Heinrich G 2014 Macromol. Symp. 338 96

Google Scholar

Google Scholar

[18] Li W H, Zhou Y, Tian T F 2010 Rheol. Acta 49 733

Google Scholar

Google Scholar

[19] Gu Z R, Luo Y P, Su Z B, Zhang L Y, Ren H J, Wang Y, Luo J 2023 J. Magn. Magn. Mater. 580 170795

Google Scholar

Google Scholar

[20] Feng Y Y, Yang X J, Liu J G, Chen Z Q 2023 Phys. Stat. Mech. Its Appl. 621 128789

Google Scholar

Google Scholar

[21] Chen L, Gong X L, Li W H 2008 Polym. Test. 27 340

Google Scholar

Google Scholar

[22] Li Y C, Li J C, Li W H, Samali B 2013 Smart Mater. Struct. 22 035005

Google Scholar

Google Scholar

[23] Ahmad Khairi M H, Abd Fatah A Y, Mazlan S A, Ubaidillah U, Nordin N A, Nik Ismail N I, Choi S B, Abdul Aziz S A 2019 Int. J. Mol. Sci. 20 4085

Google Scholar

Google Scholar

[24] Gowda D K, Odenbach S 2023 J. Magn. Magn. Mater. 579 170856

Google Scholar

Google Scholar

[25] 刘浩, 须颖, 罗杨泉, 肖海善 2022 机械工程学报 58 328

Google Scholar

Google Scholar

Liu H, Xu Y, Luo Y Q, Xiao S H 2022 Chin. J. Mech. Eng. 58 328

Google Scholar

Google Scholar

[26] 孙涛, 袁健美 2023 72 218901

Google Scholar

Google Scholar

Sun T, Yuan J M 2023 Acta Phys. Sin. 72 218901

Google Scholar

Google Scholar

[27] 寇雯博, 董灏, 邹岷强, 韩均言, 贾西西 2021 70 030701

Google Scholar

Google Scholar

Kou W B, Dong H, Zou M Q, Han J Y, Jia X X 2021 Acta Phys. Sin. 70 030701

Google Scholar

Google Scholar

[28] Goodall R E A, Lee A A 2020 Nat. Commun. 11 6280

Google Scholar

Google Scholar

[29] Goodall R E A, Parackal A S, Faber F A, Armiento R, Lee A A 2022 Sci. Adv. 8 eabn4117

Google Scholar

Google Scholar

[30] Bessa M A, Bostanabad R, Liu Z, Hu A, Apley D W, Brinson C, Chen W, Liu W K 2017 Comput. Methods Appl. Mech. Eng. 320 633

Google Scholar

Google Scholar

[31] Clément A, Soize C, Yvonnet J 2012 Int. J. Numer. Methods Eng. 91 799

Google Scholar

Google Scholar

[32] Le B A, Yvonnet J, He Q C 2015 Int. J. Numer. Methods Eng. 104 1061

Google Scholar

Google Scholar

[33] Shen L, Qian Q 2022 Comput. Mater. Sci. 211 111475

Google Scholar

Google Scholar

[34] Jung J, Kim Y, Park J, Ryu S 2022 Compos. Struct. 285 115210

Google Scholar

Google Scholar

[35] Huang D Z, Xu K, Farhat C, Darve E 2020 J. Comput. Phys. 416 109491

Google Scholar

Google Scholar

[36] Li X, Liu Z, Cui S, Luo C, Li C, Zhuang Z 2019 Comput. Methods Appl. Mech. Eng. 347 735

Google Scholar

Google Scholar

[37] Liu X, Yan Z, Zhong Z 2021 Int. J. Hydrog. Energy 46 22079

Google Scholar

Google Scholar

[38] El Said B 2023 Int. J. Solids Struct. 276 112334

Google Scholar

Google Scholar

[39] Li Z Q, Li X, Chen Y, Zhang C 2023 Compos. Struct. 323 117473

Google Scholar

Google Scholar

[40] Nguyen X B, Komatsuzaki T, Iwata Y, Asanuma H 2018 Mech. Syst. Signal Process. 101 449

Google Scholar

Google Scholar

[41] Wang L Z, Chen Z B, Jiang L K, Cheng L 2023 J. Magn. Magn. Mater. 570 170441

Google Scholar

Google Scholar

[42] Kumbhar S B, Chavan S P, Gawade S S 2018 Mech. Syst. Signal Process. 100 208

Google Scholar

Google Scholar

[43] Eem S H, Jung H J, Koo J H 2012 IEEE Trans. Magn. 48 3080

Google Scholar

Google Scholar

[44] Norouzi M, Sajjadi Alehashem S M, Vatandoost H, Ni Y Q, Shahmardan M M 2016 J. Intell. Mater. Syst. Struct. 27 1121

Google Scholar

Google Scholar

[45] Nguyen X B, Komatsuzaki T, Zhang N 2020 Mech. Syst. Signal Process. 141 106438

Google Scholar

Google Scholar

[46] Yang S, Wang P, Liu Y, Dong X, Tong Y, Zhao Y 2021 Front. Mater. 8 743716

Google Scholar

Google Scholar

[47] Wang Q, Dong X F, Li L Y, Ou J P 2017 Smart Mater. Struct. 26 065010

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4336

- PDF Downloads: 67

- Cited By: 0

DownLoad:

DownLoad: