-

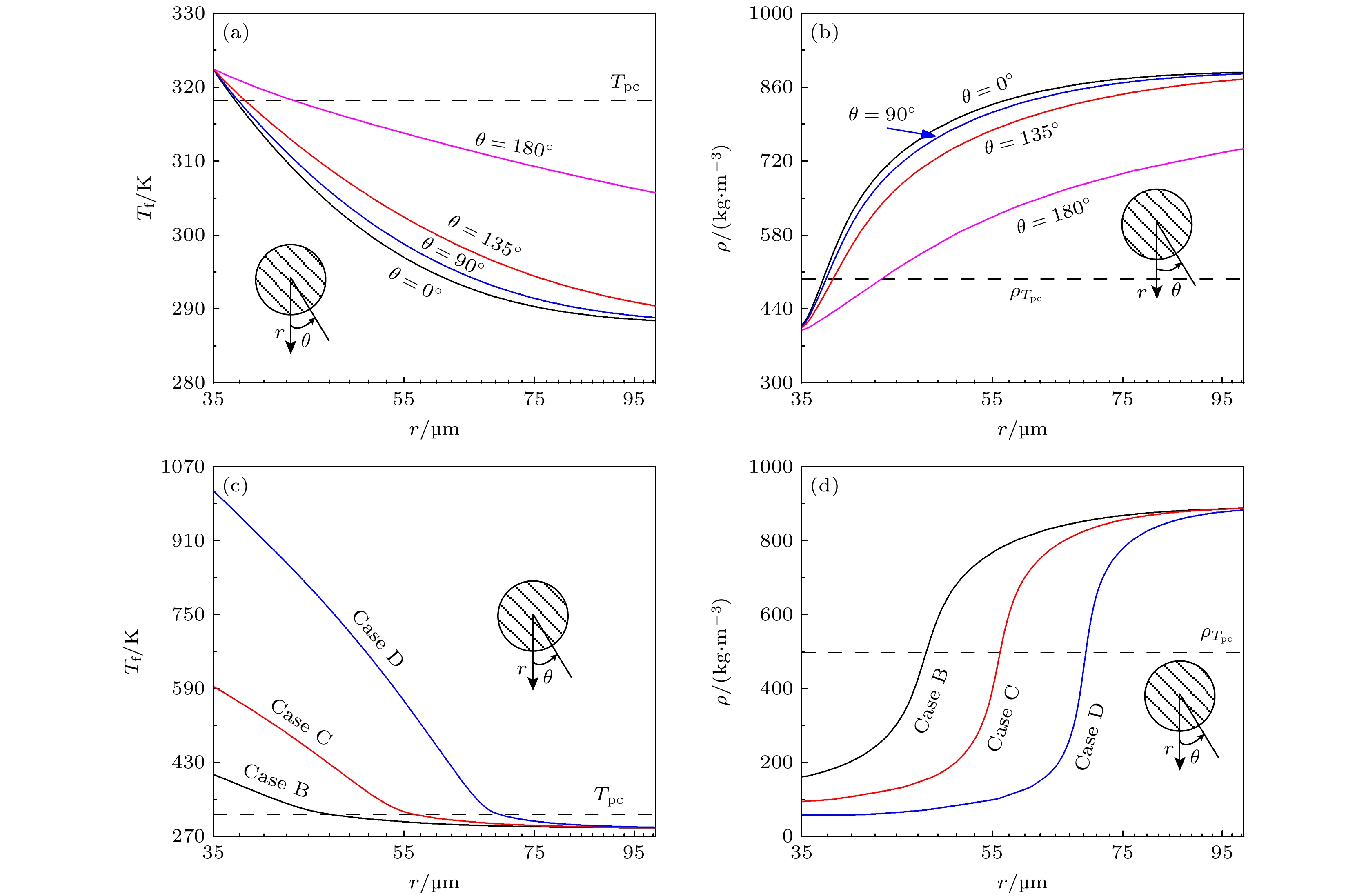

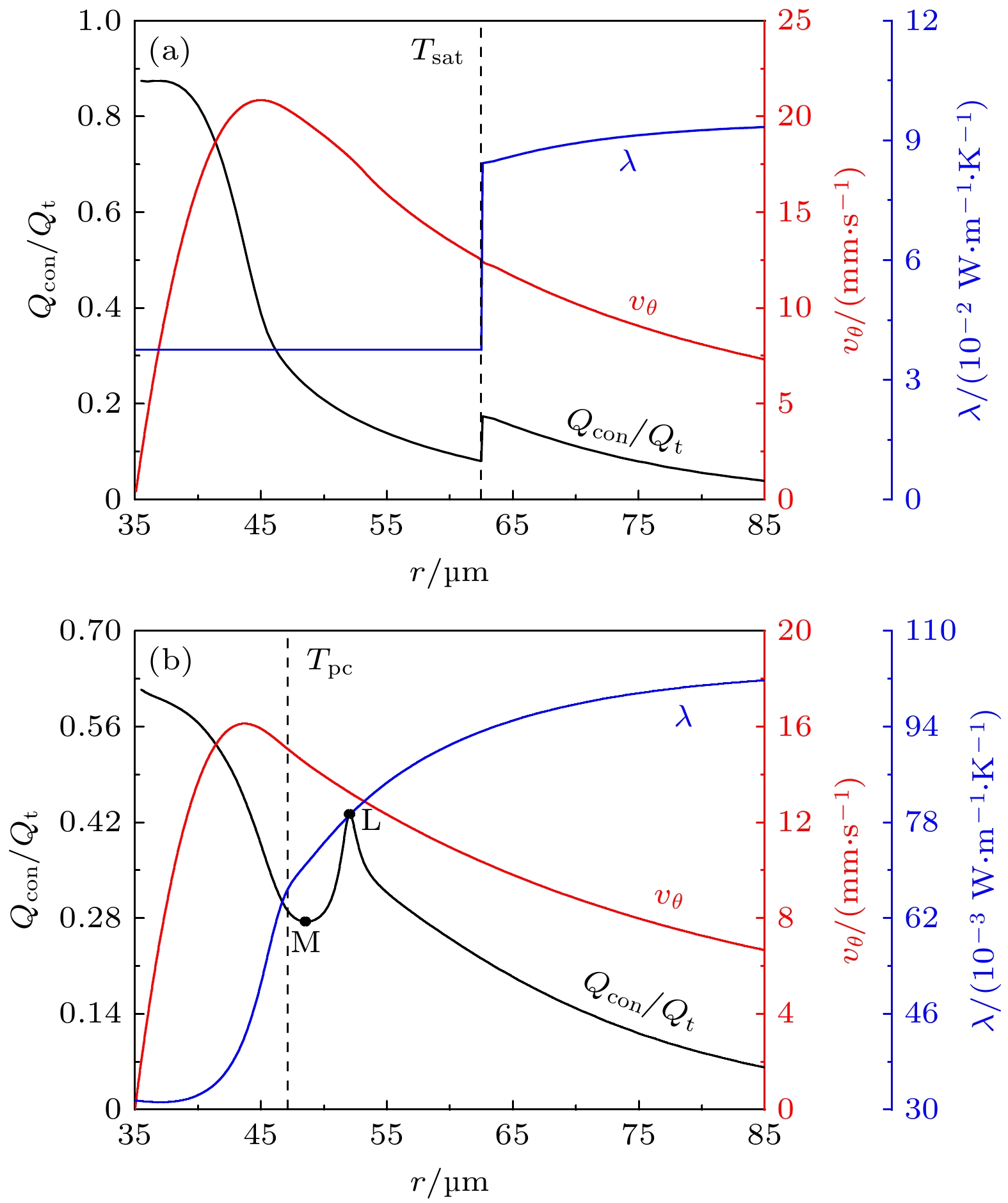

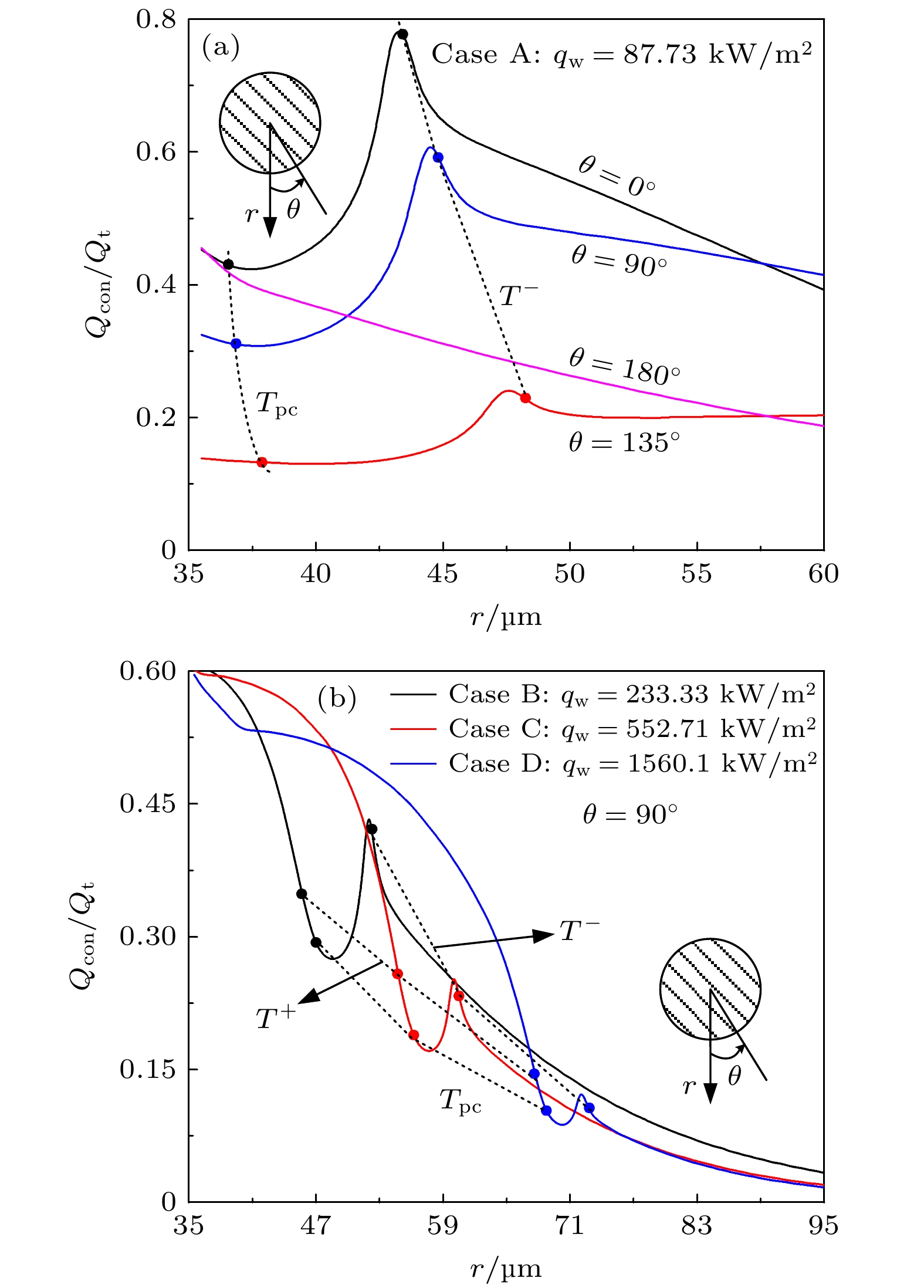

The heat transfer of supercritical pseudo-boiling has been preliminarily studied, but the definition of gas-liquid interface is still not unified. The fluid-structure coupling numerical simulation of heat transfer characteristics in supercritical CO2 pool is carried out by using laminar flow model. Platinum wire is the heating element, with diameter d = 70 μm. The heat flux density qw is in a range of 0–2000 kW/m2, and the pressure P is in a range of 8–10 MPa. Multi-scale mesh is used to model the heating wire, and simulation values accord well with the experimental data. The results show that due to the increase of the circumferential average Rayleigh number Raave of the heating filament with qw, the characteristic of the natural convection zone is that h increases with qw. The temperatures of the four characteristic working conditions in the evaporation-like zone show a downward trend along the r direction. Through analogy with subcritical heat transfer and by calculating the thermal conductivity ratio Qcon/Qt, the supercritical is divided into three regions, T < TL is liquid-like region (LL), TL < T < TM is two-phase-like region (TPL), T > TM is vapor-like region (VL). The rule is the same as that of x partition according to supercritical pseudo-boiling dryness. According to the curves of average thermal conductivity λave and thermal resistance RG versus heat flux qw, determined by calculating thermal conductivity ratio, the variation law of heat transfer coefficient h with qw in evaporation-like region can be well explained, as qw increases, the thermal conductivity thermal resistance RG increases, and the heat from the heating filament is difficult to transfer to the fluid outside the vapor-like membrane, leading the heat transfer coefficient h to decrease when qA < qw < qC, and a significant increase in λave when qw > qC, and the recovery of heat transfer when h rises again. In this paper, a new method of determining the gas-liquid interface of supercritical pool heat transfer is proposed. This method can effectively explain the heat transfer mechanism in the evaporation-like zone, and provide a theoretical basis for developing supercritical pool heat transfer in the future.

-

Keywords:

- supercritical /

- pool heat transfer /

- fluid-structure coupling /

- numerical simulation

[1] Tsai W C, Wang Y D 2019 Prog. Polym. Sci. 98 101161

Google Scholar

Google Scholar

[2] Knez Z, Markocic E, Leitgeb M, Primozic M, Hrncic M K, Skerget M 2014 Energy 77 235

Google Scholar

Google Scholar

[3] Sarkar J 2015 Renew Sust. Energ Rev. 48 434

Google Scholar

Google Scholar

[4] Liu Y P, Wang Y, Huang D G 2019 Energy 189 115900

Google Scholar

Google Scholar

[5] Kafengauz N L, Fedorov M I 1966 J. Eng. Phys. 11 99

Google Scholar

Google Scholar

[6] Ackerman J W 1970 J. Heat Trans. 92 490

Google Scholar

Google Scholar

[7] Knapp K K, Sabersky R H 1965 Int. J. Heat Mass Transfer 9 41

Google Scholar

Google Scholar

[8] Abadzic E, Goldstein R J 1970 Int. J. Heat Mass Transfer 13 1163

Google Scholar

Google Scholar

[9] Tamba J, Takahashi T, Ohara T, Aihara T 1998 Exp. Therm. Fluid Sci. 17 248

Google Scholar

Google Scholar

[10] Zhu B G, Xu J L, Yan C S, Xie J 2020 Int. J. Heat Mass Transfer 148 119080

Google Scholar

Google Scholar

[11] Xu J L, Zhang H S, Zhu B G, Xie J 2020 Sol. Energy 195 27

Google Scholar

Google Scholar

[12] Zhua B G, Xu J L, Wua X M, Xie J, Li M J 2019 Int. J. Therm. Sci. 136 254

Google Scholar

Google Scholar

[13] Huang D, Wu Z, Sunden B, Li W 2016 Appl. Energ. 162 494

Google Scholar

Google Scholar

[14] Rousselet Y, Warrier G 2012 J. Heat Transfer 135 022501

Google Scholar

Google Scholar

[15] Warrier G, Rousselet Y 2012 J. Heat Transfer 135 022502

Google Scholar

Google Scholar

[16] 张海松, 徐进良, 朱鑫杰 2021 70 044401

Google Scholar

Google Scholar

Zhang H S, Xu J L, Zhu X J 2021 Acta Phys. Sin. 70 044401

Google Scholar

Google Scholar

[17] Cheng L Y, Wang Q Y, Xu J L, 2024 Int. J. Heat Mass Transfer 220 124953

Google Scholar

Google Scholar

[18] He X T, Xu J L, Yu X J, Xie J 2023 Int. J. Heat Mass Transfer 214 124417

Google Scholar

Google Scholar

[19] 何孝天, 徐进良, 程怡玮 2023 72 057801

Google Scholar

Google Scholar

He X T, Xu J L, Cheng Y W 2023 Acta Phys. Sin. 72 057801

Google Scholar

Google Scholar

[20] Simeoni G G, Bryk T, Gorelli F A, Krisch M, Ruocco G, Santoro M, Scopigno T 2010 Nat. Phys. 6 503

Google Scholar

Google Scholar

[21] Maxi F, Contescu C, Boillat P, Niceno B, Karalis K, Testino A, Ludwig C H 2019 Nat. Commun. 19 12117

Google Scholar

Google Scholar

[22] Banuti D T 2015 J. Supercrit. Fluid 98 12

Google Scholar

Google Scholar

[23] Xu J L, Wang Y, Ma X J 2021 Phys. Rev. 104 014142

Google Scholar

Google Scholar

[24] Wang Q Y, Ma X J, Xu J L, Li M J, Wang Y 2021 Int. J. Heat Mass Transfer 181 121875

Google Scholar

Google Scholar

[25] 闫晨帅, 徐进良 2020 4 044401

Google Scholar

Google Scholar

Yan C S, Xu J L 2020 Acta Phys. Sin. 4 044401

Google Scholar

Google Scholar

[26] Tripathi P M, Basu S 2021 Phys. Fluids 33 043304

Google Scholar

Google Scholar

[27] Li X L, Yu X Y, Liu P T, Fan Y H, Yang D L, Tang G H 2023 Int. J. Heat Mass Transfer 216 124563

Google Scholar

Google Scholar

[28] Wang J T, Li Z L, Zhai Y L, Wang H 2023 Int. J. Heat Mass Transfer 201 123571

Google Scholar

Google Scholar

[29] 于博文, 何孝天, 徐进良 2023 中国科学: 技术科学 3 25

Google Scholar

Google Scholar

Yu B W, He X T, Xu J L 2023 Sci. Sin. Tech. 3 25

Google Scholar

Google Scholar

[30] 杨世铭, 陶文铨 2011 传热学 (北京: 高等教育出版社)

Yang S M, Tao W Q 2011 Heat Transfer Science (Beijing: Higher Education Press

[31] He X T, Xu J L, Xie J 2024 Phys. Fluids 36 013343

Google Scholar

Google Scholar

[32] Liu M, Liu S H, Xi D P, Huang S F, Huang Y P 2023 Nucl. Energy 104 2391

Google Scholar

Google Scholar

-

表 1 网格独立性验证

Table 1. Grid independence verification.

Grid No. 径向节点数 周向节点数 Tw/K 网格数 误差/% 1 100 21 310.2 407.7×104 –3.71 2 100 41 316.0 82.6×104 –1.88 3 100 81 321.3 169.8×104 –0.26/0.23 4 100 121 322.1 261.4×104 0 5 40 81 328.7 156.3×104 2.08 6 70 81 326.1 163.1×104 1.29 7 130 81 322.0 176.5×104 0 -

[1] Tsai W C, Wang Y D 2019 Prog. Polym. Sci. 98 101161

Google Scholar

Google Scholar

[2] Knez Z, Markocic E, Leitgeb M, Primozic M, Hrncic M K, Skerget M 2014 Energy 77 235

Google Scholar

Google Scholar

[3] Sarkar J 2015 Renew Sust. Energ Rev. 48 434

Google Scholar

Google Scholar

[4] Liu Y P, Wang Y, Huang D G 2019 Energy 189 115900

Google Scholar

Google Scholar

[5] Kafengauz N L, Fedorov M I 1966 J. Eng. Phys. 11 99

Google Scholar

Google Scholar

[6] Ackerman J W 1970 J. Heat Trans. 92 490

Google Scholar

Google Scholar

[7] Knapp K K, Sabersky R H 1965 Int. J. Heat Mass Transfer 9 41

Google Scholar

Google Scholar

[8] Abadzic E, Goldstein R J 1970 Int. J. Heat Mass Transfer 13 1163

Google Scholar

Google Scholar

[9] Tamba J, Takahashi T, Ohara T, Aihara T 1998 Exp. Therm. Fluid Sci. 17 248

Google Scholar

Google Scholar

[10] Zhu B G, Xu J L, Yan C S, Xie J 2020 Int. J. Heat Mass Transfer 148 119080

Google Scholar

Google Scholar

[11] Xu J L, Zhang H S, Zhu B G, Xie J 2020 Sol. Energy 195 27

Google Scholar

Google Scholar

[12] Zhua B G, Xu J L, Wua X M, Xie J, Li M J 2019 Int. J. Therm. Sci. 136 254

Google Scholar

Google Scholar

[13] Huang D, Wu Z, Sunden B, Li W 2016 Appl. Energ. 162 494

Google Scholar

Google Scholar

[14] Rousselet Y, Warrier G 2012 J. Heat Transfer 135 022501

Google Scholar

Google Scholar

[15] Warrier G, Rousselet Y 2012 J. Heat Transfer 135 022502

Google Scholar

Google Scholar

[16] 张海松, 徐进良, 朱鑫杰 2021 70 044401

Google Scholar

Google Scholar

Zhang H S, Xu J L, Zhu X J 2021 Acta Phys. Sin. 70 044401

Google Scholar

Google Scholar

[17] Cheng L Y, Wang Q Y, Xu J L, 2024 Int. J. Heat Mass Transfer 220 124953

Google Scholar

Google Scholar

[18] He X T, Xu J L, Yu X J, Xie J 2023 Int. J. Heat Mass Transfer 214 124417

Google Scholar

Google Scholar

[19] 何孝天, 徐进良, 程怡玮 2023 72 057801

Google Scholar

Google Scholar

He X T, Xu J L, Cheng Y W 2023 Acta Phys. Sin. 72 057801

Google Scholar

Google Scholar

[20] Simeoni G G, Bryk T, Gorelli F A, Krisch M, Ruocco G, Santoro M, Scopigno T 2010 Nat. Phys. 6 503

Google Scholar

Google Scholar

[21] Maxi F, Contescu C, Boillat P, Niceno B, Karalis K, Testino A, Ludwig C H 2019 Nat. Commun. 19 12117

Google Scholar

Google Scholar

[22] Banuti D T 2015 J. Supercrit. Fluid 98 12

Google Scholar

Google Scholar

[23] Xu J L, Wang Y, Ma X J 2021 Phys. Rev. 104 014142

Google Scholar

Google Scholar

[24] Wang Q Y, Ma X J, Xu J L, Li M J, Wang Y 2021 Int. J. Heat Mass Transfer 181 121875

Google Scholar

Google Scholar

[25] 闫晨帅, 徐进良 2020 4 044401

Google Scholar

Google Scholar

Yan C S, Xu J L 2020 Acta Phys. Sin. 4 044401

Google Scholar

Google Scholar

[26] Tripathi P M, Basu S 2021 Phys. Fluids 33 043304

Google Scholar

Google Scholar

[27] Li X L, Yu X Y, Liu P T, Fan Y H, Yang D L, Tang G H 2023 Int. J. Heat Mass Transfer 216 124563

Google Scholar

Google Scholar

[28] Wang J T, Li Z L, Zhai Y L, Wang H 2023 Int. J. Heat Mass Transfer 201 123571

Google Scholar

Google Scholar

[29] 于博文, 何孝天, 徐进良 2023 中国科学: 技术科学 3 25

Google Scholar

Google Scholar

Yu B W, He X T, Xu J L 2023 Sci. Sin. Tech. 3 25

Google Scholar

Google Scholar

[30] 杨世铭, 陶文铨 2011 传热学 (北京: 高等教育出版社)

Yang S M, Tao W Q 2011 Heat Transfer Science (Beijing: Higher Education Press

[31] He X T, Xu J L, Xie J 2024 Phys. Fluids 36 013343

Google Scholar

Google Scholar

[32] Liu M, Liu S H, Xi D P, Huang S F, Huang Y P 2023 Nucl. Energy 104 2391

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 4483

- PDF Downloads: 273

- Cited By: 0

DownLoad:

DownLoad: