-

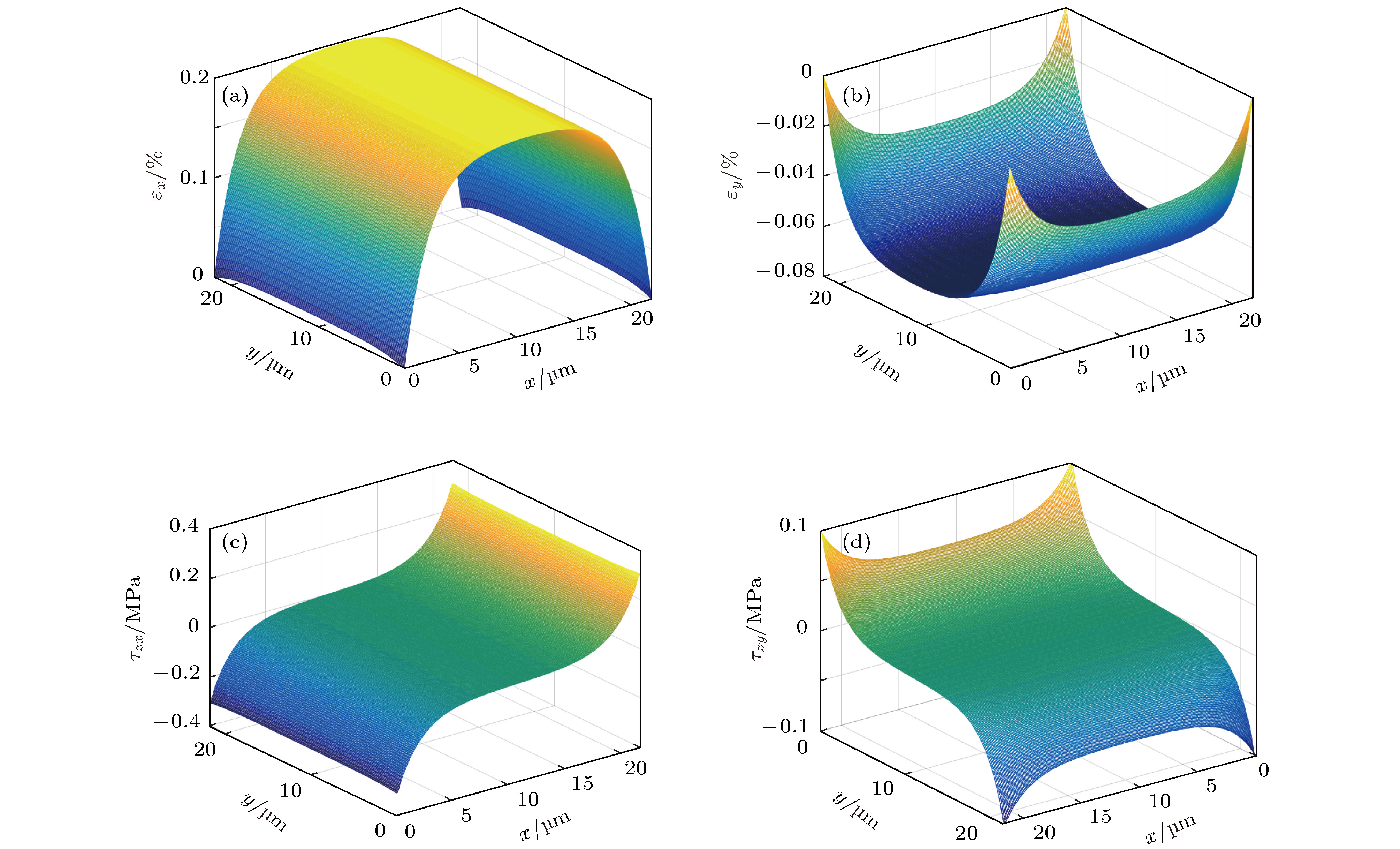

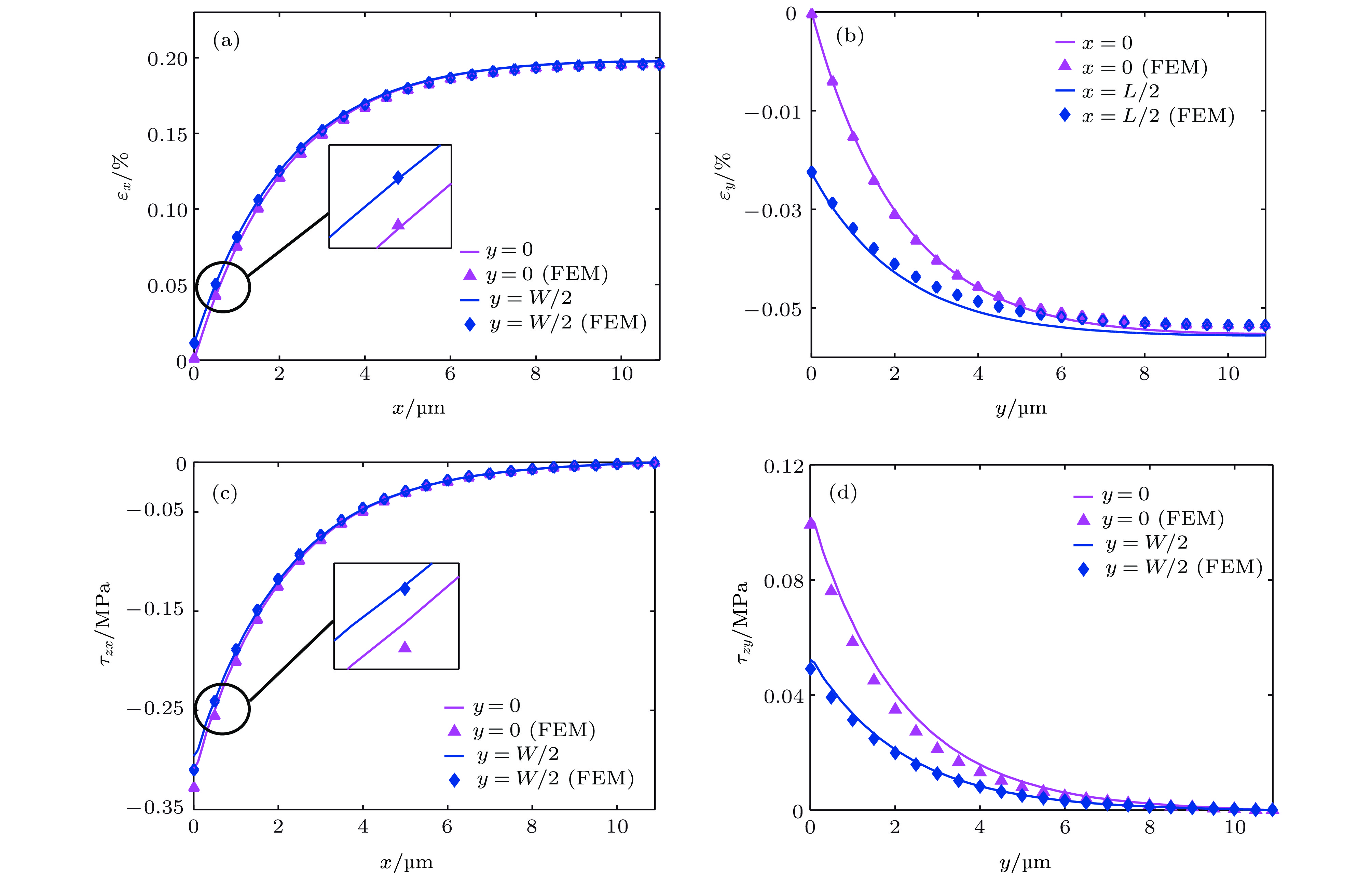

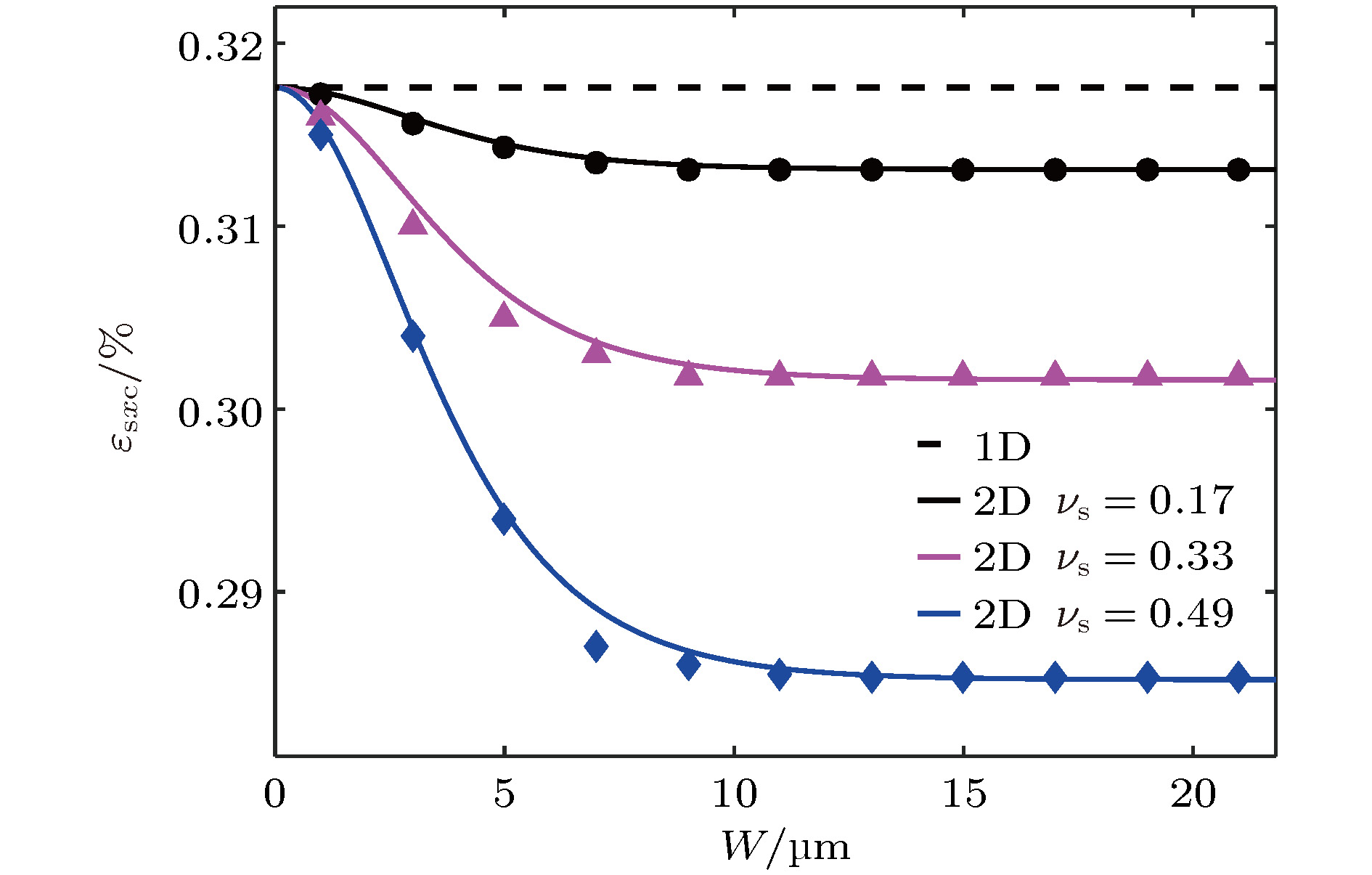

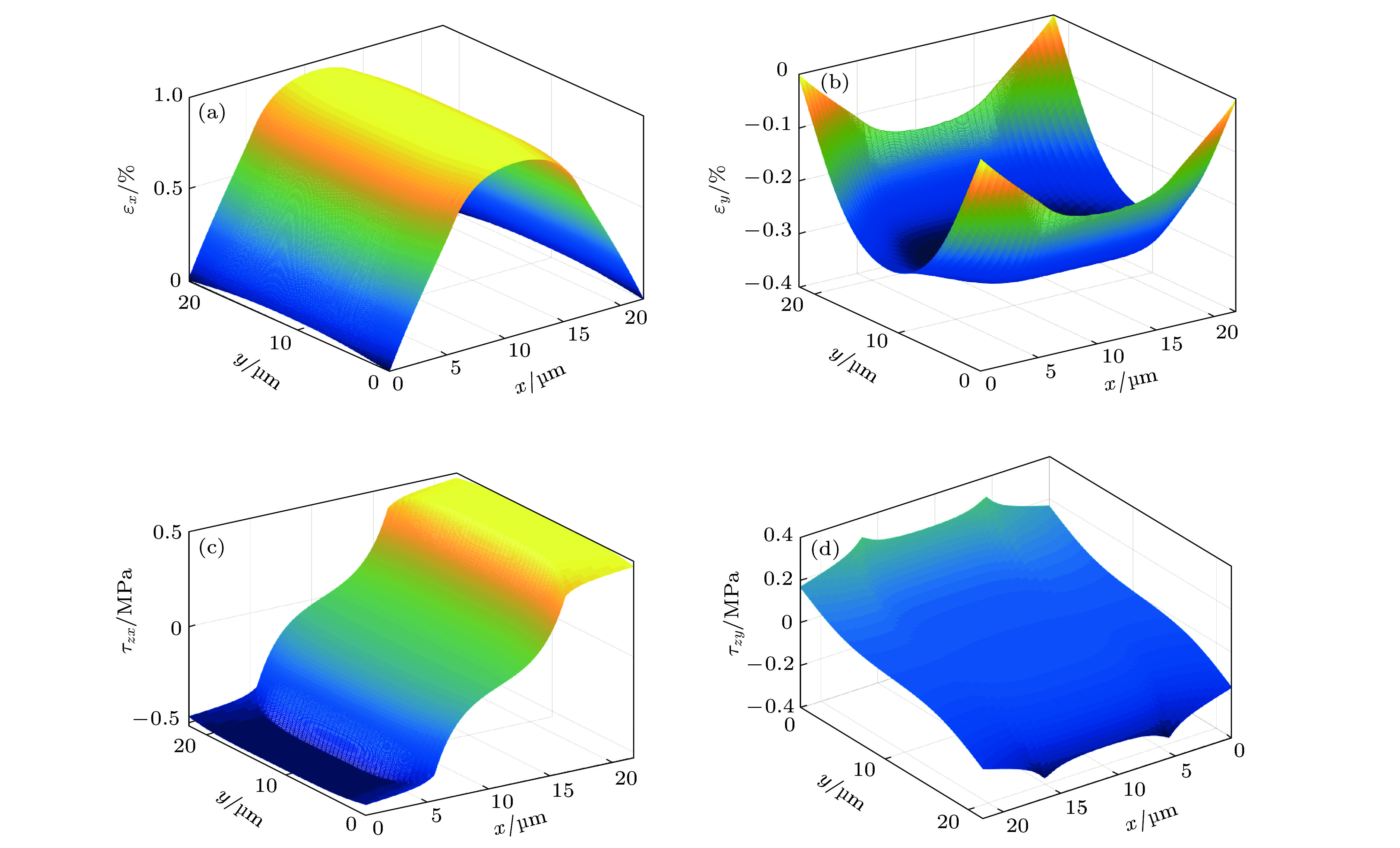

Interfacial mechanical properties have a great influence on the overall mechanical performance of graphene/flexible substrate composite structure. Therefore, it is necessary to study interfacial shear stress transfer between graphene and flexible substrate. In this paper, a two-dimensional nonlinear shear-lag model (2D model) is presented. Taking the effects of Poisson’s ratio of the graphene and substrate into consideration, the bidirectional interfacial shear stress transfer between graphene and flexible substrate subjected to uniaxial tension is investigated by the 2D model when the Poisson’s ratio of substrate is larger than that of graphene. In the elastic bonding stage, the semi-analytical solutions of the bidirectional normal strains of the graphene and bidirectional interfacial shear stresses are derived, respectively, and their distributions at different positions are illustrated. The critical strain for interfacial sliding is derived by the 2D model, and the results show that the critical strain has a micron-scaled characteristic width. The width size of graphene has a significant influence on the critical strain when it is less than the characteristic width, but the size effect can be ignored when the width of graphene is larger than the characteristic width. In addition, the Poisson’s ratio of substrate can also affect the critical strain. Based on the 2D model, the finite element simulations are made to investigate the distribution of graphene's normal strains and interfacial shear stresses in the interfacial sliding stage. Furthermore, compared with the results obtained via one-dimensional nonlinear shear-lag model (1D model), the distributions of graphene’s normal strains and interfacial shear stresses calculated by 2D model show obvious bidimensional effects both in the elastic bonding stage and in the interfacial sliding stage when the width of graphene is large. There exists a compression strain in the graphene and a transverse (perpendicular to the tensile direction) shear stress in the interface, which are neglected in the 1D model. And the distributions of graphene’s tensile strain and longitudinal (along the tensile direction) interfacial shear stress are not uniform along the width, which are also significantly different from the results of 1D model. Moreover, the critical strain for interfacial sliding derived by the 2D model is lower than that obtained by the 1D model. However, when the width of graphene is small enough, the 2D model can be approximately replaced by the 1D model. Finally, by fitting the Raman experimental results, the reliability of the 2D model is verified, and the interfacial stiffness (100 TPa/m) and shear strength (0.295 MPa) between graphene and polyethylene terephthalate (PET) substrate are calculated.

-

Keywords:

- graphene/flexible substrate structure /

- Poisson’s ratio /

- interfacial shear stress transfer /

- two-dimensional nonlinear shear-lag model

[1] Geim A K 2009 Science 324 1530

Google Scholar

Google Scholar

[2] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer H L 2008 Solid State Commun. 146 351

Google Scholar

Google Scholar

[3] Lee C G, Wei X D, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[4] Li X, Zhang R J, Yu W J, Wang K L, Wei J Q, Wu D H, Cao A Y, Li Z H, Cheng Y, Zheng Q S, Ruoff R S, Zhu H W 2012 Sci. Rep. 2 870

Google Scholar

Google Scholar

[5] Young R J, Kinloch I A, Gong L, Novoselov K S 2012 Compos. Sci. Technol. 72 1459

Google Scholar

Google Scholar

[6] Gong L, Kinloch I A, Young R J, Riaz I, Jalil R, Novoselov K S 2010 Adv. Mater. 22 2694

Google Scholar

Google Scholar

[7] Jiang T, Huang R, Zhu Y 2014 Adv. Funct. Mater. 24 396

Google Scholar

Google Scholar

[8] Xu C C, Xue T, Guo J G, Qin Q H, Wu S, Song H B, Xie H M 2015 J. Appl. Phys. 117 164301

Google Scholar

Google Scholar

[9] Xu C C, Xue T, Guo J G, Kang Y L, Qiu W, Song H B, Xie H M 2015 Mater. Lett. 161 755

Google Scholar

Google Scholar

[10] 仇巍, 张启鹏, 李秋, 许超宸, 郭建刚 2017 66 166801

Google Scholar

Google Scholar

Qiu W, Zhang Q P, Li Q, Xu C C, Guo J G 2017 Acta Phys. Sin. 66 166801

Google Scholar

Google Scholar

[11] Cox H L 1952 Br. J. Appl. Phys. 3 72

Google Scholar

Google Scholar

[12] Guo G D, Zhu Y 2015 J. Appl. Mech. 82 031005

Google Scholar

Google Scholar

[13] Cui Z, Guo J G 2016 AIP Adv. 6 125110

Google Scholar

Google Scholar

[14] Zhang S L, Li J C M 2004 J. Polym. Sci., Part B: Polym. Phys. 42 260

Google Scholar

Google Scholar

[15] Kurennov S S 2014 Mech. Compos. Mater. 50 105

Google Scholar

Google Scholar

[16] Mathias J D, Grédiac M, Balandraud X 2006 Int. J. Solids Struct. 43 6921

Google Scholar

Google Scholar

[17] Randrianalisoa J, Dendievel R, Bréchet Y 2011 Compos. Part B: Eng. 42 2055

Google Scholar

Google Scholar

[18] Park K, Paulino G H 2011 Appl. Mech. Rev. 64 060802

Google Scholar

Google Scholar

[19] Dourado N, Silva F G A, de Moura M F S F 2018 Constr. Build. Mater. 176 14

Google Scholar

Google Scholar

[20] Högberg J L 2006 Int. J. Fract. 141 549

Google Scholar

Google Scholar

[21] Camanho P P, Davila C G, de Moura M F 2003 J. Compos. Mater. 37 1415

Google Scholar

Google Scholar

[22] Faccio R, Denis P A, Pardo H, Goyenola C, Mombrú A W 2009 J. Phys. Condens. Matter 21 285304

Google Scholar

Google Scholar

[23] 许超宸 2019 博士学位论文 (天津: 天津大学)

Xu C C 2019 Ph. D. Dissertation (Tianjin: Tianjin University) (in Chinese)

[24] Mohiuddin T M G, Lombardo A, Nair R R, Bonetti A, Savini G, Jalil R, Bonini N, Basko D M, Galiotis C, Marzari N, Novoselov K S, Geim A K, Ferrari A C 2009 Phys. Rev. B 79 205433

Google Scholar

Google Scholar

[25] Sakata H, Dresselhaus G, Dresselhaus M S, Endo M 1988 J. Appl. Phys. 63 2769

Google Scholar

Google Scholar

[26] Ni Z H, Yu T, Lu Y H, Wang Y Y, Feng Y P, Shen Z X 2008 ACS Nano 2 2301

Google Scholar

Google Scholar

[27] Yu T, Ni Z H, Du C L, You Y M, Wang Y Y, Shen Z X 2008 J. Phys. Chem. C 112 12602

[28] Koukaras E N, Androulidakis C, Anagnostopoulos G, Papagelis K, Galiotis C 2016 Extreme Mech. Lett. 8 191

Google Scholar

Google Scholar

-

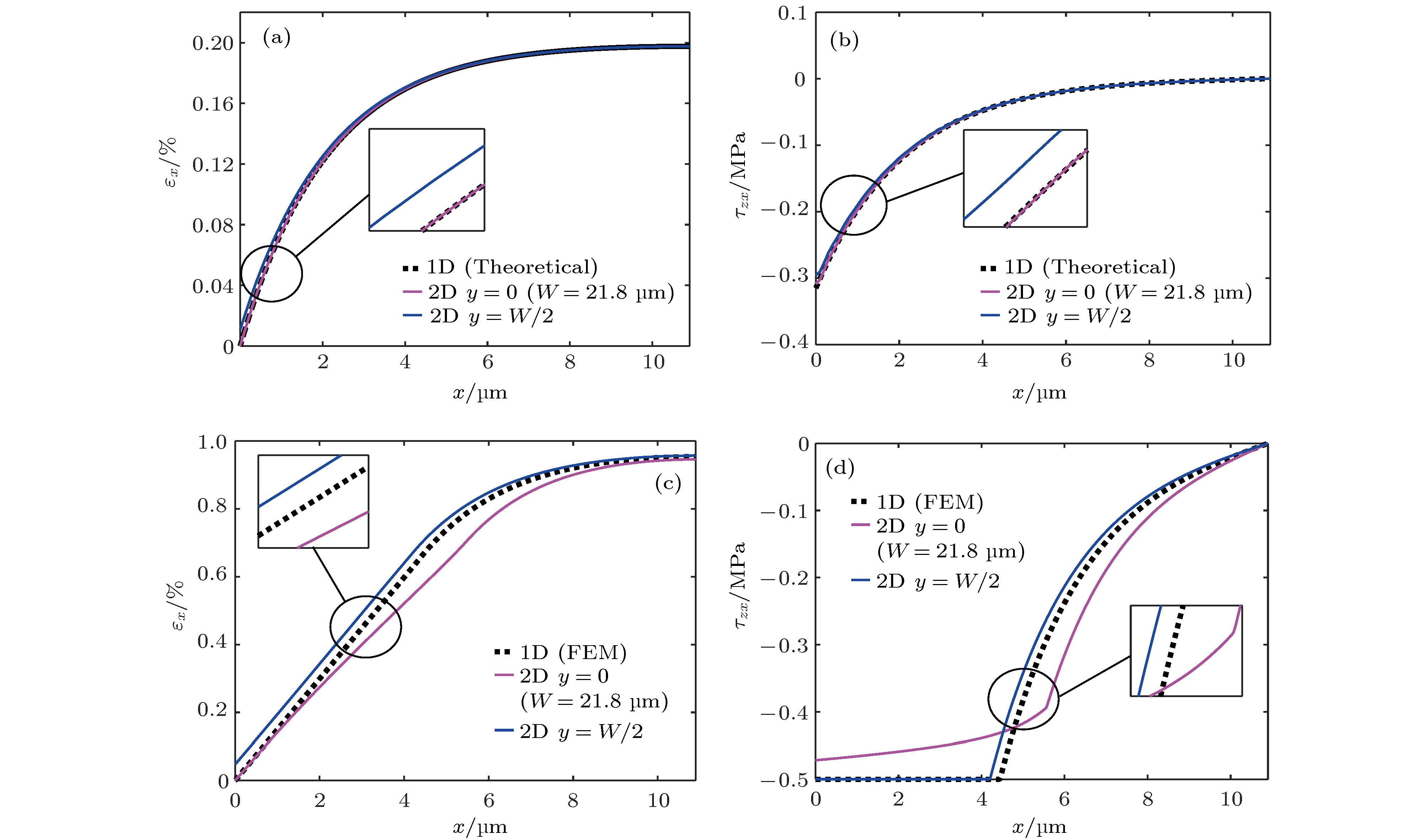

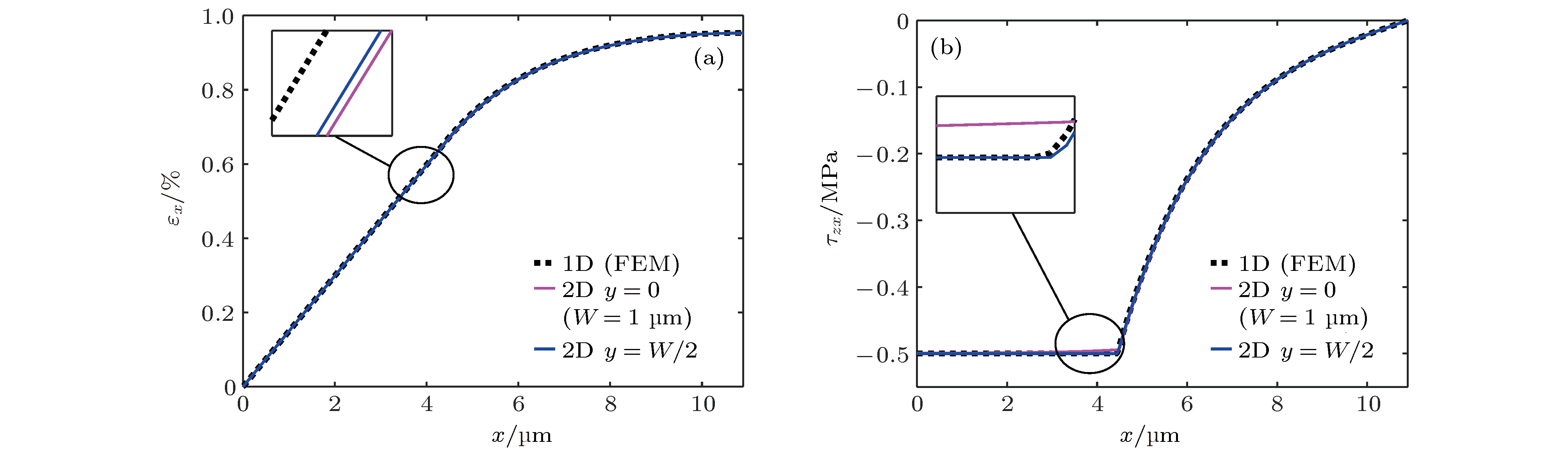

图 11 二维模型与一维模型结果的比较 (W = 21.8 μm) (a) εx和(b) τzx在弹性粘结阶段(εsx = 0.2%); (c) εx和(d) τzx在界面滑移阶段 (εsx = 1%)

Figure 11. Comparisons of the results obtained via one-dimensional and two-dimensional models (W = 21.8 μm): (a) εx and (b) τzx at the elastic bonding stage (εsx = 0.2%); (c) εx and (d) τzx at the interfacial sliding stage (εsx = 1%).

图 13 利用二维模型与实验数据拟合 (a) 基底拉伸应变εsx = 0.25%时εm沿石墨烯中心线(y = W/2)的分布; (b) 不同基底载荷作用下石墨烯中心C点处

$ \varepsilon_{\rm m}^{C} $ 的大小Figure 13. Fitting results of experimental data by using 2D model: (a) εm along the centerline (y = W/2) when the tensile strain εsx = 0.25%; (b)

$ \varepsilon_{\rm m}^{C} $ at the center point C under different tensile loads. -

[1] Geim A K 2009 Science 324 1530

Google Scholar

Google Scholar

[2] Bolotin K I, Sikes K J, Jiang Z, Klima M, Fudenberg G, Hone J, Kim P, Stormer H L 2008 Solid State Commun. 146 351

Google Scholar

Google Scholar

[3] Lee C G, Wei X D, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[4] Li X, Zhang R J, Yu W J, Wang K L, Wei J Q, Wu D H, Cao A Y, Li Z H, Cheng Y, Zheng Q S, Ruoff R S, Zhu H W 2012 Sci. Rep. 2 870

Google Scholar

Google Scholar

[5] Young R J, Kinloch I A, Gong L, Novoselov K S 2012 Compos. Sci. Technol. 72 1459

Google Scholar

Google Scholar

[6] Gong L, Kinloch I A, Young R J, Riaz I, Jalil R, Novoselov K S 2010 Adv. Mater. 22 2694

Google Scholar

Google Scholar

[7] Jiang T, Huang R, Zhu Y 2014 Adv. Funct. Mater. 24 396

Google Scholar

Google Scholar

[8] Xu C C, Xue T, Guo J G, Qin Q H, Wu S, Song H B, Xie H M 2015 J. Appl. Phys. 117 164301

Google Scholar

Google Scholar

[9] Xu C C, Xue T, Guo J G, Kang Y L, Qiu W, Song H B, Xie H M 2015 Mater. Lett. 161 755

Google Scholar

Google Scholar

[10] 仇巍, 张启鹏, 李秋, 许超宸, 郭建刚 2017 66 166801

Google Scholar

Google Scholar

Qiu W, Zhang Q P, Li Q, Xu C C, Guo J G 2017 Acta Phys. Sin. 66 166801

Google Scholar

Google Scholar

[11] Cox H L 1952 Br. J. Appl. Phys. 3 72

Google Scholar

Google Scholar

[12] Guo G D, Zhu Y 2015 J. Appl. Mech. 82 031005

Google Scholar

Google Scholar

[13] Cui Z, Guo J G 2016 AIP Adv. 6 125110

Google Scholar

Google Scholar

[14] Zhang S L, Li J C M 2004 J. Polym. Sci., Part B: Polym. Phys. 42 260

Google Scholar

Google Scholar

[15] Kurennov S S 2014 Mech. Compos. Mater. 50 105

Google Scholar

Google Scholar

[16] Mathias J D, Grédiac M, Balandraud X 2006 Int. J. Solids Struct. 43 6921

Google Scholar

Google Scholar

[17] Randrianalisoa J, Dendievel R, Bréchet Y 2011 Compos. Part B: Eng. 42 2055

Google Scholar

Google Scholar

[18] Park K, Paulino G H 2011 Appl. Mech. Rev. 64 060802

Google Scholar

Google Scholar

[19] Dourado N, Silva F G A, de Moura M F S F 2018 Constr. Build. Mater. 176 14

Google Scholar

Google Scholar

[20] Högberg J L 2006 Int. J. Fract. 141 549

Google Scholar

Google Scholar

[21] Camanho P P, Davila C G, de Moura M F 2003 J. Compos. Mater. 37 1415

Google Scholar

Google Scholar

[22] Faccio R, Denis P A, Pardo H, Goyenola C, Mombrú A W 2009 J. Phys. Condens. Matter 21 285304

Google Scholar

Google Scholar

[23] 许超宸 2019 博士学位论文 (天津: 天津大学)

Xu C C 2019 Ph. D. Dissertation (Tianjin: Tianjin University) (in Chinese)

[24] Mohiuddin T M G, Lombardo A, Nair R R, Bonetti A, Savini G, Jalil R, Bonini N, Basko D M, Galiotis C, Marzari N, Novoselov K S, Geim A K, Ferrari A C 2009 Phys. Rev. B 79 205433

Google Scholar

Google Scholar

[25] Sakata H, Dresselhaus G, Dresselhaus M S, Endo M 1988 J. Appl. Phys. 63 2769

Google Scholar

Google Scholar

[26] Ni Z H, Yu T, Lu Y H, Wang Y Y, Feng Y P, Shen Z X 2008 ACS Nano 2 2301

Google Scholar

Google Scholar

[27] Yu T, Ni Z H, Du C L, You Y M, Wang Y Y, Shen Z X 2008 J. Phys. Chem. C 112 12602

[28] Koukaras E N, Androulidakis C, Anagnostopoulos G, Papagelis K, Galiotis C 2016 Extreme Mech. Lett. 8 191

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 21933

- PDF Downloads: 296

- Cited By: 0

DownLoad:

DownLoad: