-

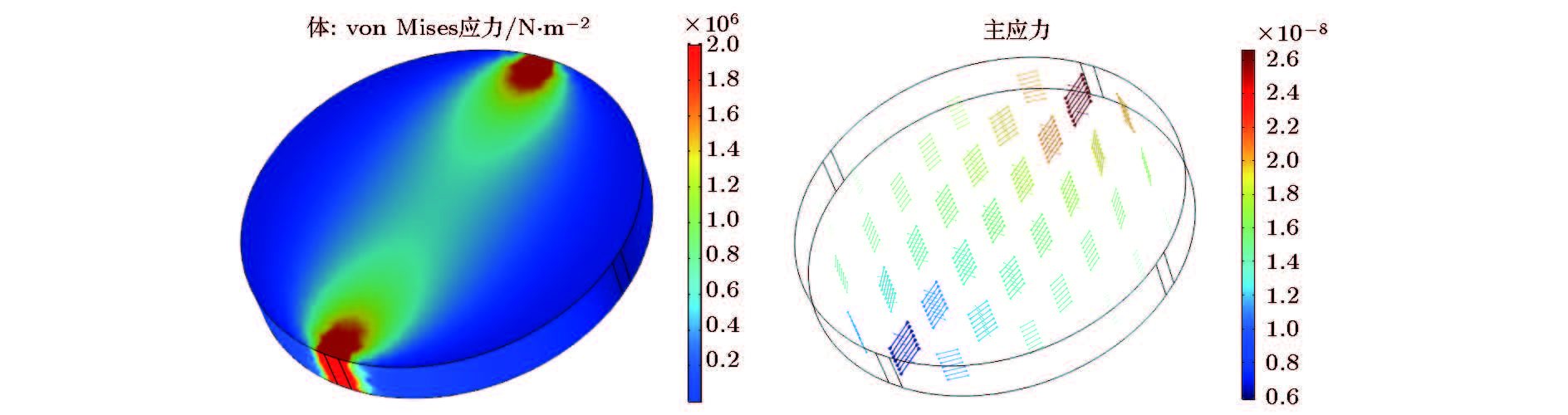

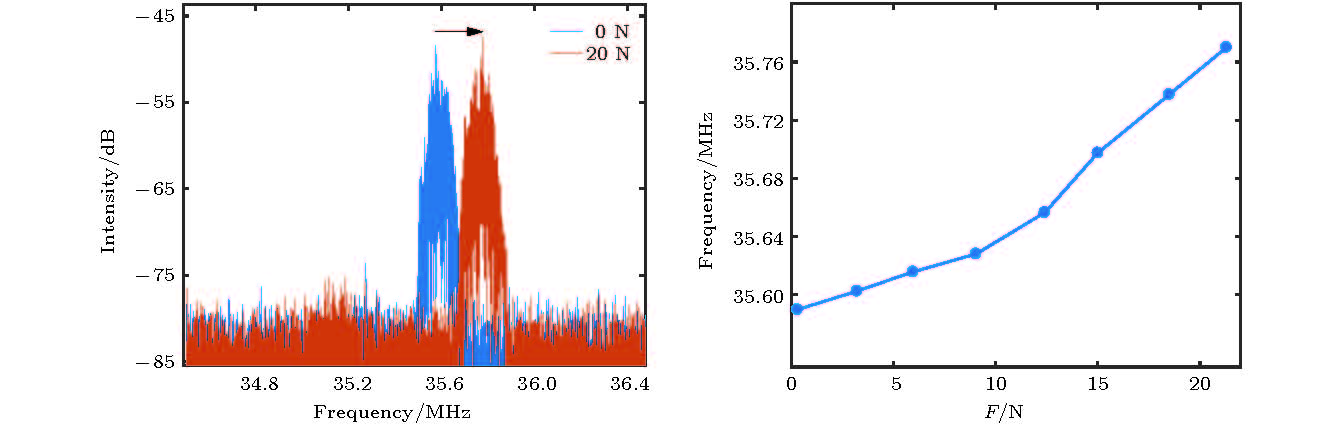

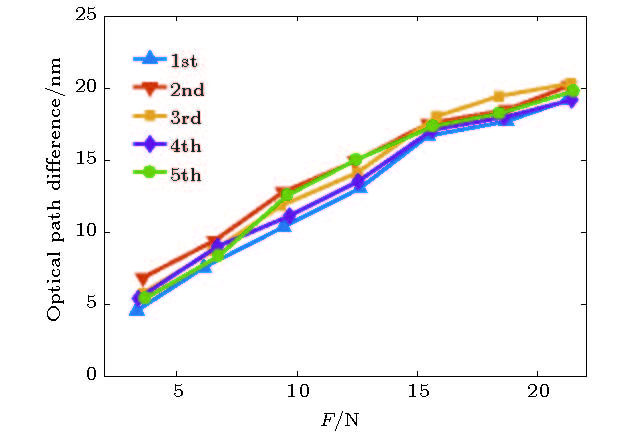

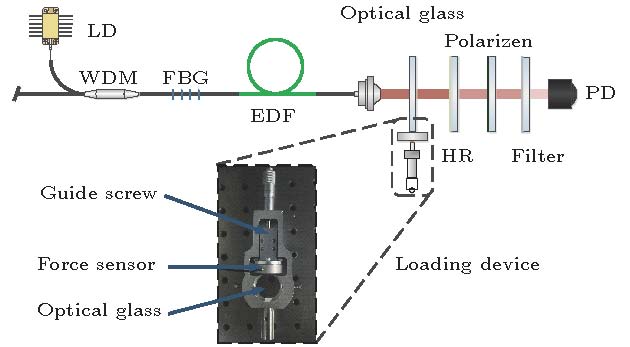

光学元件在红外波段的应力-光学常数是众多光学系统关心的问题之一. 本文提出一种基于1556.16 nm掺铒光纤激光频率分裂效应的光学玻璃内应力致双折射测量方法. 选择平面介质膜腔镜和光纤光栅(FBG)构成线形半开放式谐振腔, 并分析了光纤自身弯曲引入谐振腔内的双折射. 将待测光学玻璃附带力传感结构放置在谐振腔内, 结合Jones矩阵传递方程得到了外载荷所致双折射与空腔双折射的叠加模型. 对光学玻璃的载荷从0逐级递加到20 N, 内腔的频率分裂量增加, 根据双折射叠加模型和频率分裂原理解出应力与频率分裂量的对应关系, 且该结果可溯源到基本物理量—波长. 实验结果表明, 系统灵敏度为22060 Pa/nm, 线性度为99.44%, 可广泛应用于红外波段的光学元件双折射精确测量.When the optical component works in a complicated working environment such as a large temperature difference or a multi-modal state, internal stress accumulation is likely to occur, which affects the overall performance of the optical system. The stress-optical constant of optical component in the infrared range is one of the concerns of many optical systems. In this paper, a method of measuring the internal stress-induced birefringence of optical glass based on the frequency splitting effect of 1556.16 nm erbium-doped fiber laser is proposed. The planar dielectric lenticular and fiber Bragg grating (FBG) are selected to form a linear semi-open resonator by using an erbium-doped fiber as a gain medium, and a 976 nm semiconductor laser (LD) with a single-mode pigtail output for pumping. At the pump power of 200 mW, a laser output with a spectral center wavelength of 1556.16 nm, a spectral 3-dB bandwidth of 0.018 nm, and a longitudinal mode spacing of 40.77 MHz is obtained. The birefringence and its fast axis introduced into the cavity by the fiber itself are analyzed. The force sensing structure of the optical glass to be tested is placed in the cavity, and the frequency splitting of the laser after the stress loading on the optical glass in the cavity is compared with the scenario in the empty cavity, and the bifurcation and cavity birefringence caused by the external load are obtained by combining the Jones matrix transfer equation. The load on the optical glass is gradually increased from 0 to 20 N. In the stress loading process, the direction of the stress birefringence in the optical glass is parallel to the direction of the applied force. The frequency splitting of the inner cavity increases from 35.59 MHz to 35.77 MHz, which corresponds to a 679.18 nm—682.62 nm optical path difference of the cavity. The correspondence between stress and frequency splitting is understood according to the birefringence superposition model and frequency splitting, and the result can be traced back to the basic physical quantity-wavelength. Continuous loading of the optical glass results in a system with measurement repeatability better than 0.0459 MHz. The experiment is designed to avoid the uncorrected systematic error of the system induced by the sub-cavity effect. The non-aligned error equation is obtained, and the error is calibrated. The experimental results show that the sensitivity of the instrument for K9 glass is 22060 Pa/nm and the linearity is 99.44%. The method has no damage to the surface of the optical structure, nor occlusion nor influence of its normal in-service work. It is of significance for optical lens, structural measurement and error correction, and can be widely used for accurately measuring the birefringence of optical components in the infrared band.

-

Keywords:

- fiber laser /

- frequency splitting /

- stress measurement

[1] Findlay S J, Harrison N D 2002 Mater. Today 5 18

[2] Tomozawa M, Lezzi P J, Hepburn R W J 2012 J. Non-Cryst. Solids 358 2650

[3] Guo P, Gao Q, Jia H U 2000 Opt. Pre. Eng. 1

[4] Zhu K Y, Guo B, Lu Y T, Zhang S, Tan Y D 2017 Optica 4 729

Google Scholar

Google Scholar

[5] Jeong B H, Park J H 2018 U.S. Patent US10006982B2

[6] Norrby S J 2006 J. Cataract Refract Surg 32 545

[7] Montalto L, Paone N, Rinaldi D 2015 Opt. Eng. 54 081210−1/9

Google Scholar

Google Scholar

[8] Vourna P, Hervoches C, Vrana M 2015 IEEE Trans. Magn. 51 1

[9] Okoro C, Levine L E, Xu R 2014 IEEE Trans. Electron. Dev. 61 2473

[10] Reul A, Lauhoff C, Krooß P 2018 Shape Memory & Superelasticity 1

[11] Yang X, Cheng Y, Zhu Z 2018 Electric Welding Machine 323

[12] Nagib N N, Bahrawi M S, Ismail L Z 2015 Opt. Laser Technol. 69 77

Google Scholar

Google Scholar

[13] Mori A, Tomita R 2015 Instrum Sci. Technol. 43 379

Google Scholar

Google Scholar

[14] Liu W, Liu M, Zhang S 2008 Appl. Opt. 47 5562

Google Scholar

Google Scholar

[15] Xu Z, Luo Y, Sun Q 2019 IEEE Photonics Technol. Lett. PP 1

[16] 吕志国, 杨直, 李峰, 李强龙, 王屹山, 杨小君 2018 67 184205

Google Scholar

Google Scholar

Lü Z G, Yang Z, Li F, Li Q L, Wang Y S, Yang X J 2018 Acta Phys. Sin. 67 184205

Google Scholar

Google Scholar

[17] 王雪娇, 肖起榕, 闫平, 陈霄, 李丹, 杜成, 莫琦, 衣永青, 潘蓉, 巩马理 2015 64 164204

Google Scholar

Google Scholar

Wang X J, Xiao Q R, Yan P, Chen X, Li D, Du C, Mo Q, Yi Y Q, Pan R, Gong M L 2015 Acta Phys. Sin. 64 164204

Google Scholar

Google Scholar

[18] Wang J J, Zhang L, Zhou J, Si L, Chen J B, Feng Y C 2012 Opt. Lett. 10

[19] Hang Y S, Xiao Q R, Li D, Wang Z H, Wang X J, Yan P, Gong M L 2018 Chin. Phys. B 27 044201

-

-

[1] Findlay S J, Harrison N D 2002 Mater. Today 5 18

[2] Tomozawa M, Lezzi P J, Hepburn R W J 2012 J. Non-Cryst. Solids 358 2650

[3] Guo P, Gao Q, Jia H U 2000 Opt. Pre. Eng. 1

[4] Zhu K Y, Guo B, Lu Y T, Zhang S, Tan Y D 2017 Optica 4 729

Google Scholar

Google Scholar

[5] Jeong B H, Park J H 2018 U.S. Patent US10006982B2

[6] Norrby S J 2006 J. Cataract Refract Surg 32 545

[7] Montalto L, Paone N, Rinaldi D 2015 Opt. Eng. 54 081210−1/9

Google Scholar

Google Scholar

[8] Vourna P, Hervoches C, Vrana M 2015 IEEE Trans. Magn. 51 1

[9] Okoro C, Levine L E, Xu R 2014 IEEE Trans. Electron. Dev. 61 2473

[10] Reul A, Lauhoff C, Krooß P 2018 Shape Memory & Superelasticity 1

[11] Yang X, Cheng Y, Zhu Z 2018 Electric Welding Machine 323

[12] Nagib N N, Bahrawi M S, Ismail L Z 2015 Opt. Laser Technol. 69 77

Google Scholar

Google Scholar

[13] Mori A, Tomita R 2015 Instrum Sci. Technol. 43 379

Google Scholar

Google Scholar

[14] Liu W, Liu M, Zhang S 2008 Appl. Opt. 47 5562

Google Scholar

Google Scholar

[15] Xu Z, Luo Y, Sun Q 2019 IEEE Photonics Technol. Lett. PP 1

[16] 吕志国, 杨直, 李峰, 李强龙, 王屹山, 杨小君 2018 67 184205

Google Scholar

Google Scholar

Lü Z G, Yang Z, Li F, Li Q L, Wang Y S, Yang X J 2018 Acta Phys. Sin. 67 184205

Google Scholar

Google Scholar

[17] 王雪娇, 肖起榕, 闫平, 陈霄, 李丹, 杜成, 莫琦, 衣永青, 潘蓉, 巩马理 2015 64 164204

Google Scholar

Google Scholar

Wang X J, Xiao Q R, Yan P, Chen X, Li D, Du C, Mo Q, Yi Y Q, Pan R, Gong M L 2015 Acta Phys. Sin. 64 164204

Google Scholar

Google Scholar

[18] Wang J J, Zhang L, Zhou J, Si L, Chen J B, Feng Y C 2012 Opt. Lett. 10

[19] Hang Y S, Xiao Q R, Li D, Wang Z H, Wang X J, Yan P, Gong M L 2018 Chin. Phys. B 27 044201

计量

- 文章访问数: 10900

- PDF下载量: 88

- 被引次数: 0

下载:

下载: