-

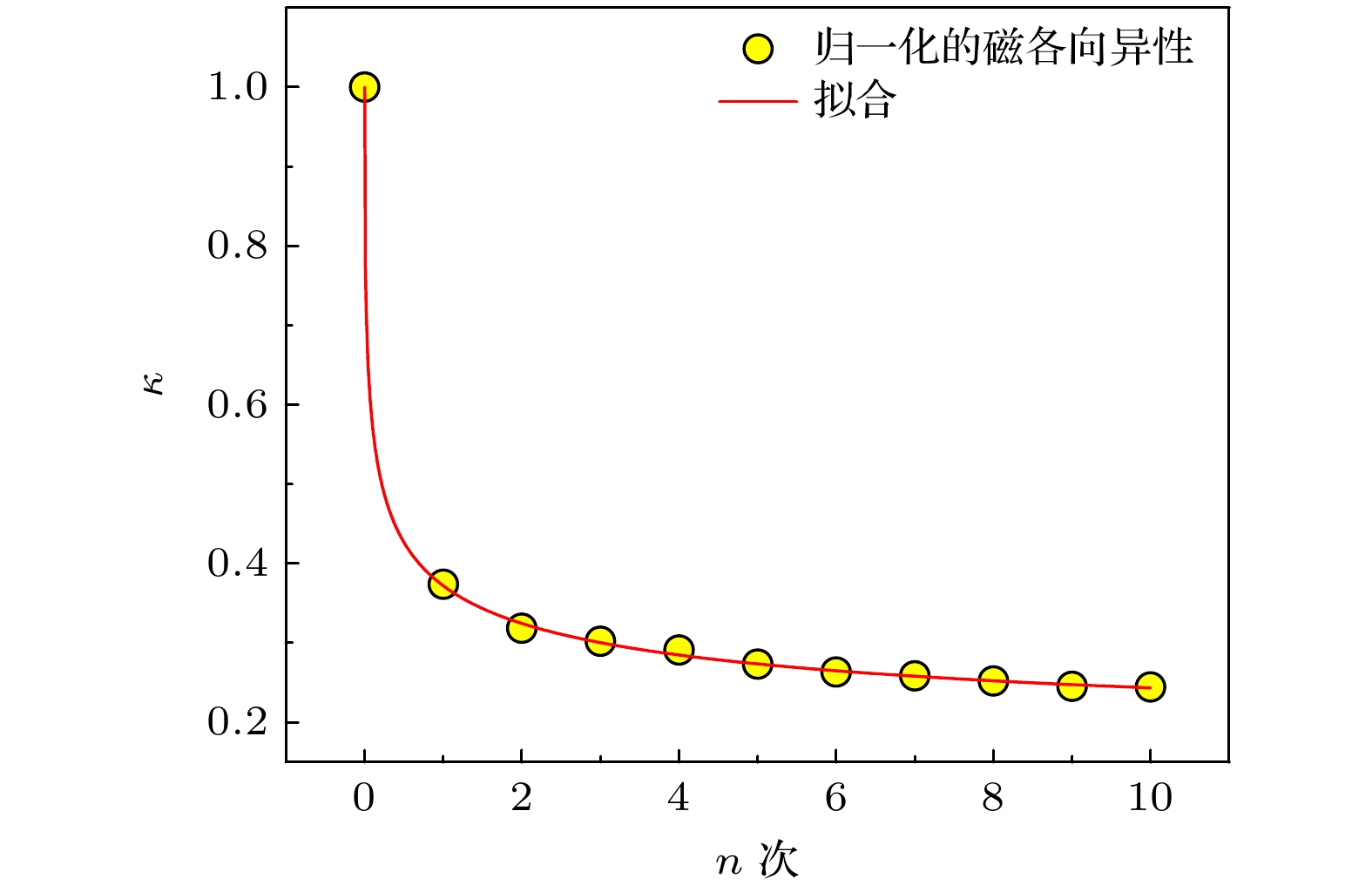

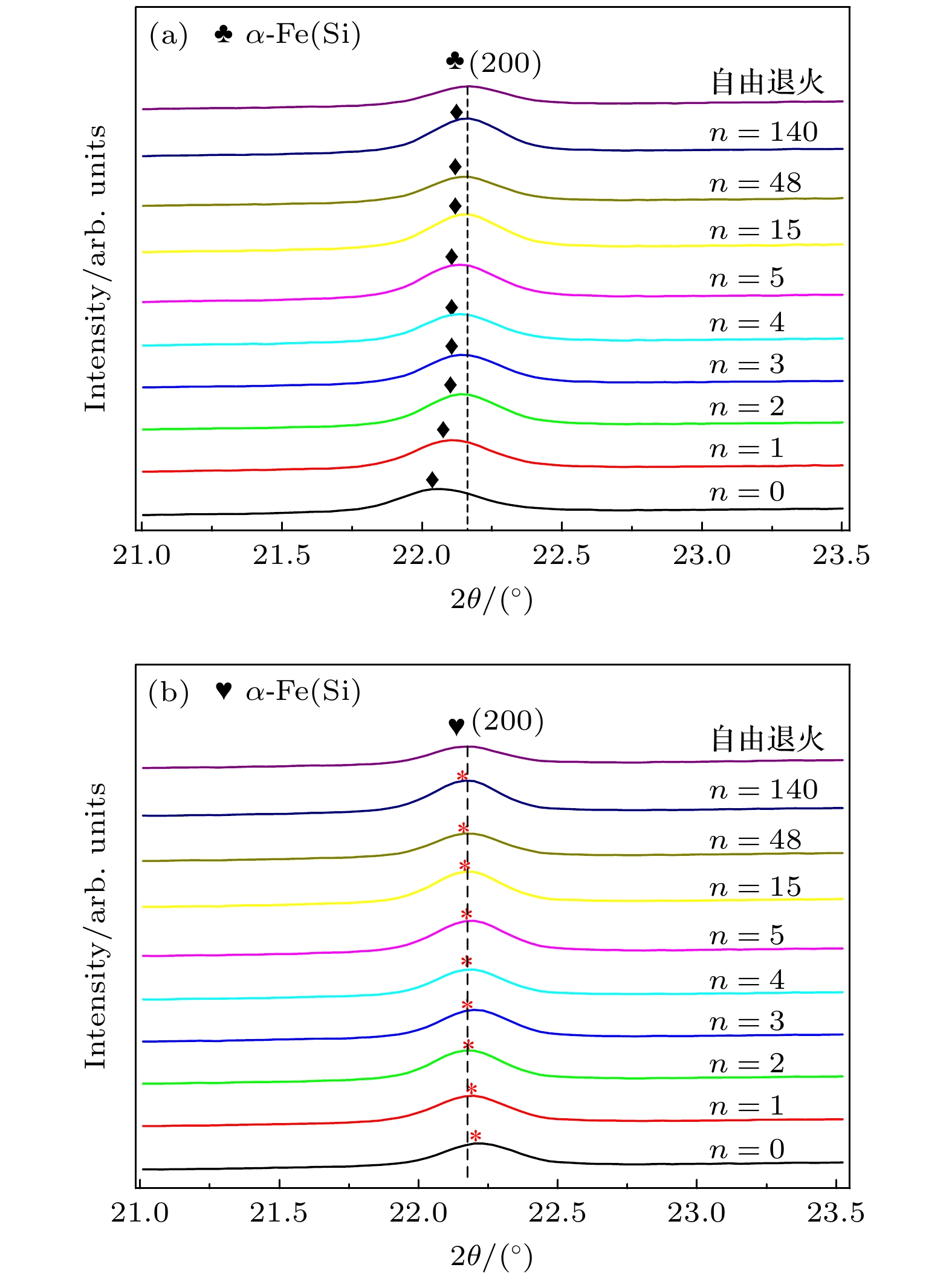

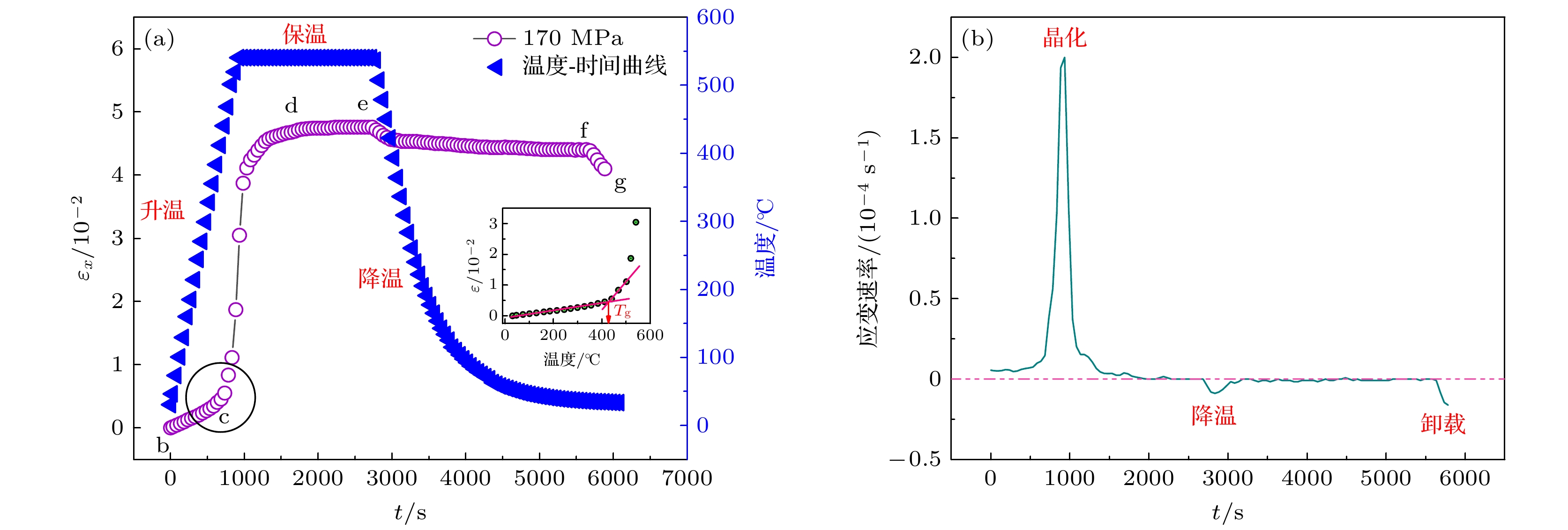

Fe-based amorphous and nanocrystalline soft magnetic alloys are regarded as the significant dual-green energy-saving materials because of their superior magnetic properties and straightforward fabrication procedure. As such, they have attracted much attention in the fields of the electronic information and electrical power. In this work, Fe73.5Cu1Nb3Si13.5B9 (%) amorphous alloy ribbon is subjected to various physical ageing treatments in nitrogen atmosphere. These treatments include annealing at 540 ℃ for 30 min under different tensile stresses and isothermal tempering without tensile stress for several cycles. The origin of stress-induced magnetic anisotropy is investigated through using dynamic strain analysis, the longitudinally driven giant magento-impedance effect, and synchrotron radiation X-ray diffraction. In the process of tensile stress annealing, it is found that the axial strain of ribbon is elastic strain when annealing temperature is below the glass transition point, and plastic strain when annealing temperature is above the glass transition point; the precipitation of nanocrystalline phase has a pinning effect on amorphous matrix, which slows down the strain rates and makes the tend stable. Additionally, isothermal tempering studies show that the stress-induced magnetic anisotropy and lattice plane anisotropy have different relaxation patterns. It is found through numerical fitting that the stress-induced magnetic anisotropy can reach a stable value of 0.144 by infinite tempering, whereas the lattice plane anisotropy can only relax to zero by finite tempering. A model of nanocrystalline grain distribution anisotropy is developed to re-examine the origin of stress-induced magnetic anisotropy. It supports a viewpoint that the nanocrystalline grain distribution anisotropy

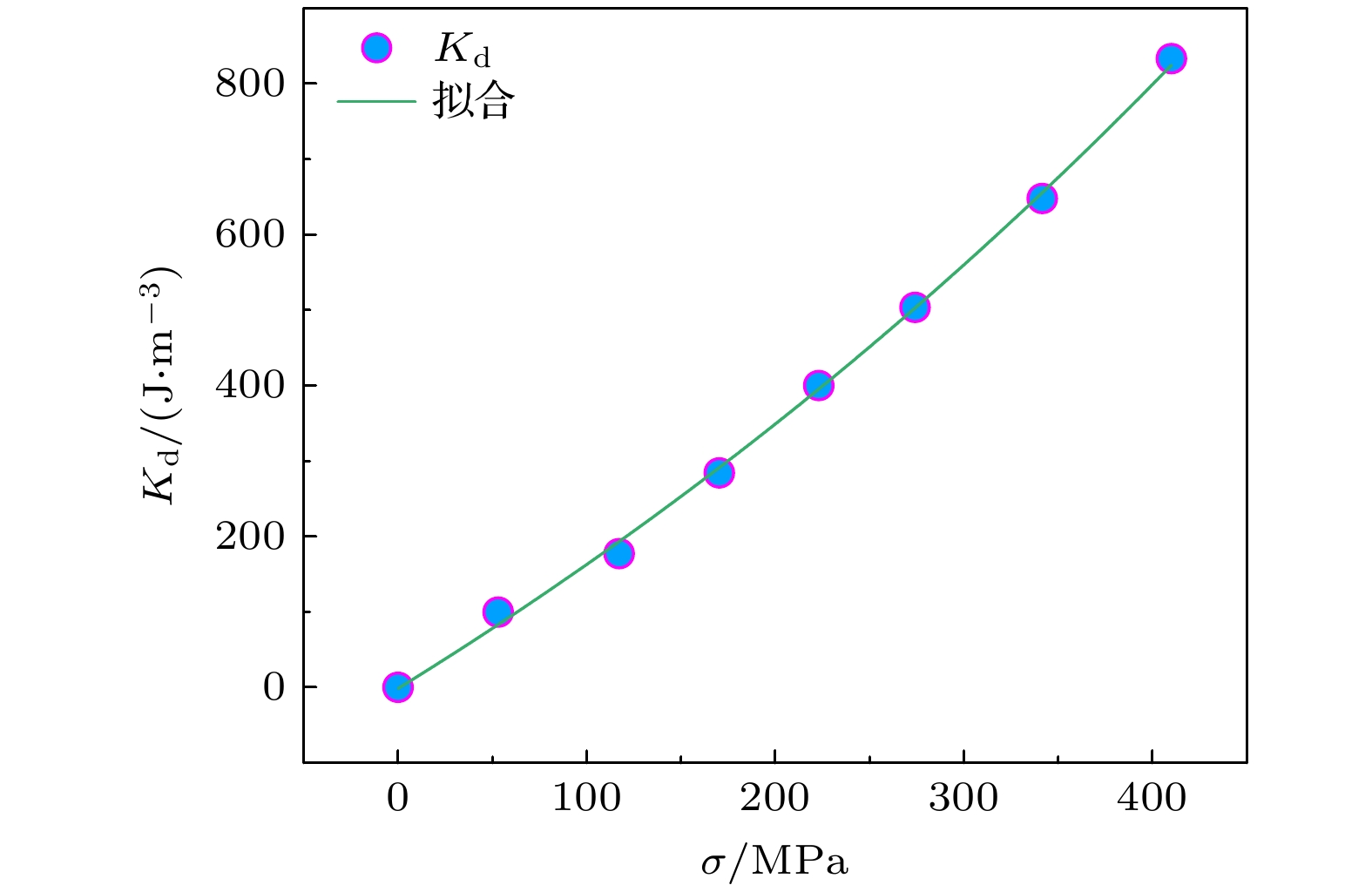

$\Delta \delta $ is responsible for the stress-induced irreversible magnetic anisotropy${K_{\text{d}}}$ , and that their relationship can be described as a following function:${K_{\text{d}}} = k\Delta \delta $ . Therefore, it is proposed that the stress-induced anisotropy originates from a synergistic interaction between the lattice plane anisotropy and the nanocrystalline grain distribution anisotropy in Fe-based alloy ribbon. This work has important implications for understanding the mechanism of the stress-induced magnetic anisotropy.-

Keywords:

- irreversible magnetic anisotropy /

- lattice plane anisotropy /

- nanocrystalline grain distribution anisotropy /

- synchrotron radiation

[1] 姚可夫, 施凌翔, 陈双琴, 邵洋, 陈娜, 贾蓟丽 2018 67 016101

Google Scholar

Google Scholar

Yao K F, Shi L X, Chen S Q, Shao Y, Chen N, Jia J L 2018 Acta Phys. Sin. 67 016101

Google Scholar

Google Scholar

[2] Li Y M, Jia X J, Zhang W, Zhang Y, Xie G Q, Qiu Z Y, Luan J H, Jiao Z B 2021 J. Mater. Sci. Technol. 65 171

Google Scholar

Google Scholar

[3] Corte-Leon P, Zhukova V, Blanco J M, González-Legarreta L, Ipatov M, Zhukov A 2020 J. Magn. Magn. Mater. 510 166939

Google Scholar

Google Scholar

[4] Sai Ram B, Paul A K, Kulkarni S V 2021 J. Magn. Magn. Mater. 537 16820

[5] Li F C, Liu T, Zhang J Y, Shuang S, Wang Q, Wang A D, Wang J G, Yang Y 2019 Mater. Today Adv. 4 100027

Google Scholar

Google Scholar

[6] 马海健, 魏文庆, 鲍文科, 神祥博, 王长春, 王伟民 2020 稀有金属材料与工程 49 2904

Ma H J, Wei W Q, Bao W K, Shen X B, Wang C C, Wang W M 2020 Rare Metal Mat. Eng. 49 2904

[7] Liu T, Wang A D, Zhao C L, Yue S Q, Wang X M, Liu C T 2019 Mater. Res. Bull. 112 323

Google Scholar

Google Scholar

[8] Lukshina V A, Dmitrieva N V, Cerdeira M A, Potapov A P 2012 J. Alloys Compd. 536 374

Google Scholar

Google Scholar

[9] Correa A M, Bohn F 2018 J. Magn. Magn. Mater. 453 30

Google Scholar

Google Scholar

[10] Varga L K 2020 J. Magn. Magn. Mater. 500 166327

Google Scholar

Google Scholar

[11] Fang Y Z, Zheng J J, Wu F M, Xu Q M, Zhang J Q, Ye H Q, Zheng J L, Li T Y 2010 Appl. Phys. Lett. 96 092508

Google Scholar

Google Scholar

[12] Néel L 1954 J. Phys. 4 225

[13] Hofmann B, Kronmüller H 1996 J. Magn. Magn. Mater. 152 91

Google Scholar

Google Scholar

[14] Herzer G 1996 J. Magn. Magn. Mater. 157-158 133

Google Scholar

Google Scholar

[15] Nielsen O V, Nielsen H J V 1980 Solid State Commun. 35 281

Google Scholar

Google Scholar

[16] Ohnuma M, Hono K, Yanai T, Fukunaga H, Yoshizawa Y 2003 Appl. Phys. Lett. 83 2859

Google Scholar

Google Scholar

[17] Ohnuma M, Hono K, Yanai T, Nakano H, Fukunaga H, Yoshizawa Y 2005 Appl. Phys. Lett. 86 152513

Google Scholar

Google Scholar

[18] Ohnuma M, Yanai T, Hono K, Nakano M, Fukunaga H, Yoshizawa Y, Herzer G 2010 J. Appl. Phys. 108 093927

Google Scholar

Google Scholar

[19] Nutor R K, Xu X J, Fan X Z, He X W, Fang Y Z 2018 Chinese J. Phys. 56 180

Google Scholar

Google Scholar

[20] Nutor R K, Xu X J, Fan X Z, He X W, Lu X A, Fang Y Z 2019 J. Magn. Magn. Mater. 471 544

[21] Nutor R K, Fan X Z, He X W, Xu X J, Lu X A, Jiang J Z, Fang Y Z 2019 J. Alloys Compd. 774 1243

Google Scholar

Google Scholar

[22] Kurlyandskaya G V, Lukshina V A, Larrañaga A, Orue I, Zaharova A A, Shishkin D A 2013 J. Alloys Compd. 566 31

Google Scholar

Google Scholar

[23] Ohnuma M, Herzer G, Kozikowski P, Polak C, Budinsky V, Koppoju S 2012 Acta. Mater. 60 1278

Google Scholar

Google Scholar

[24] Leary A M, Keylin V, Ohodnicki P R, McHenry M E 2015 J. Appl. Phys. 117 17A338

Google Scholar

Google Scholar

[25] Herzer G, Schulz R US Patent 6 254 695 B1 [2001-06-03]

[26] Hilzinger H R 1981 Proceedings of the 4th International Conference on Rapidly Quenched Metals Sendai, Japan, August 24–28, 1981 p701

[27] 许校嘉, 方峥, 陆轩昂, 叶慧群, 范晓珍, 郑金菊, 何兴伟, 郭春羽, 李文忠, 方允樟 2019 68 137501

Google Scholar

Google Scholar

Xu X J, Fang Z, Lu X A, Ye H Q, Fan X Z, Zheng J J, He X W, Guo C Y, Li W Z, Fang Y Z 2019 Acta Phys. Sin. 68 137501

Google Scholar

Google Scholar

[28] Wu C, Chen H P, Lv H P, Yan M 2016 J. Alloys Compd. 673 278

Google Scholar

Google Scholar

[29] Allia P, Baricco M, Tiberto P, Vinai F 1993 J. Appl. Phys. 74 3137

Google Scholar

Google Scholar

[30] Fan X Z, He X W, Nutor R K, Pan R M, Zheng J J, Ye H Q, Wu F M, Jiang J Z, Fang Y Z 2019 J. Magn. Magn. Mater. 469 349

Google Scholar

Google Scholar

[31] 汪卫华 2013 物理学进展 33 177

Wang W H 2013 Prog. Phys. 33 177

-

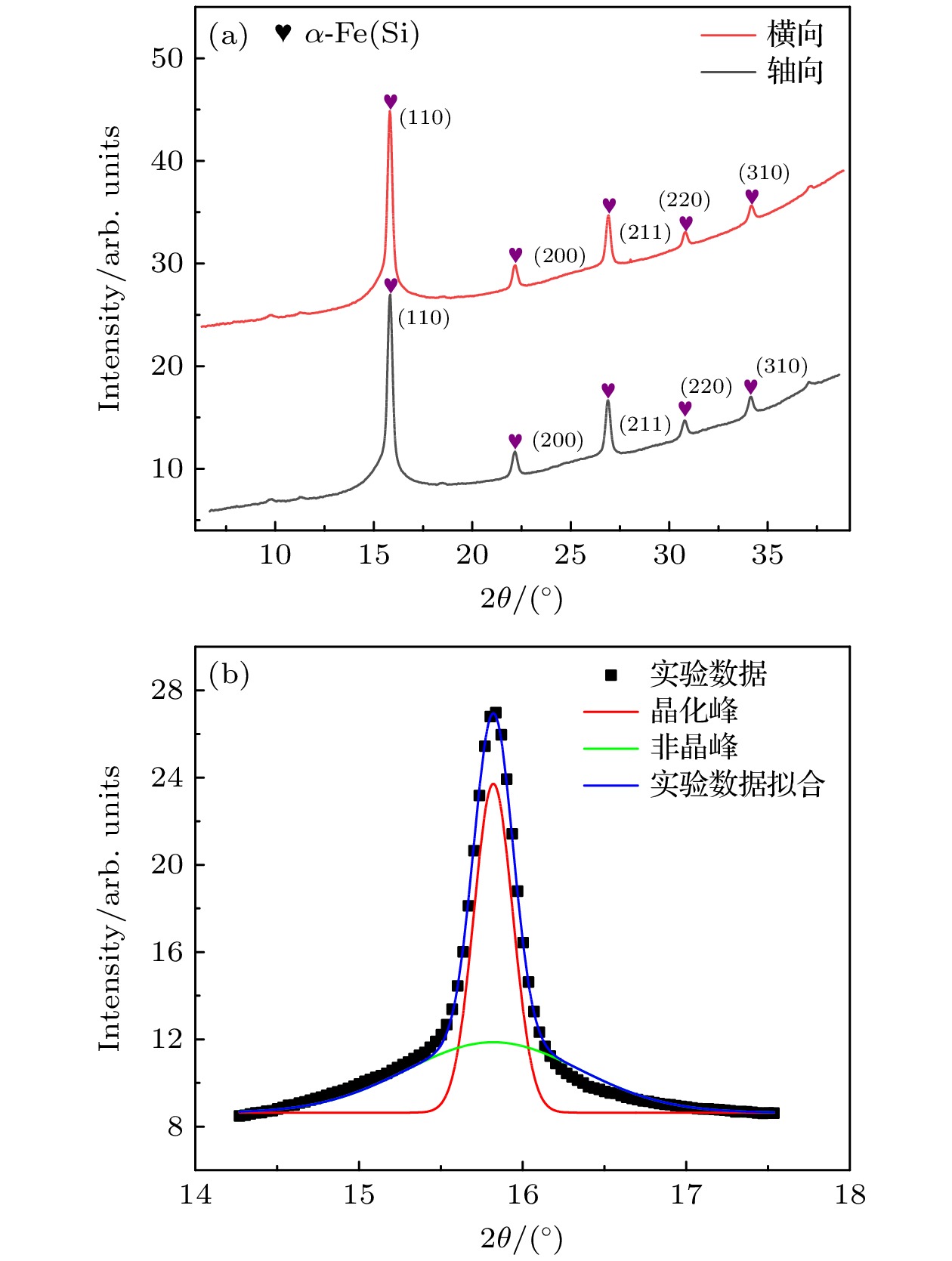

表 1 自由退火Fe基合金薄带的结构参数

Table 1. Structural parameters of Fe-based alloy ribbons annealed without tensile stress.

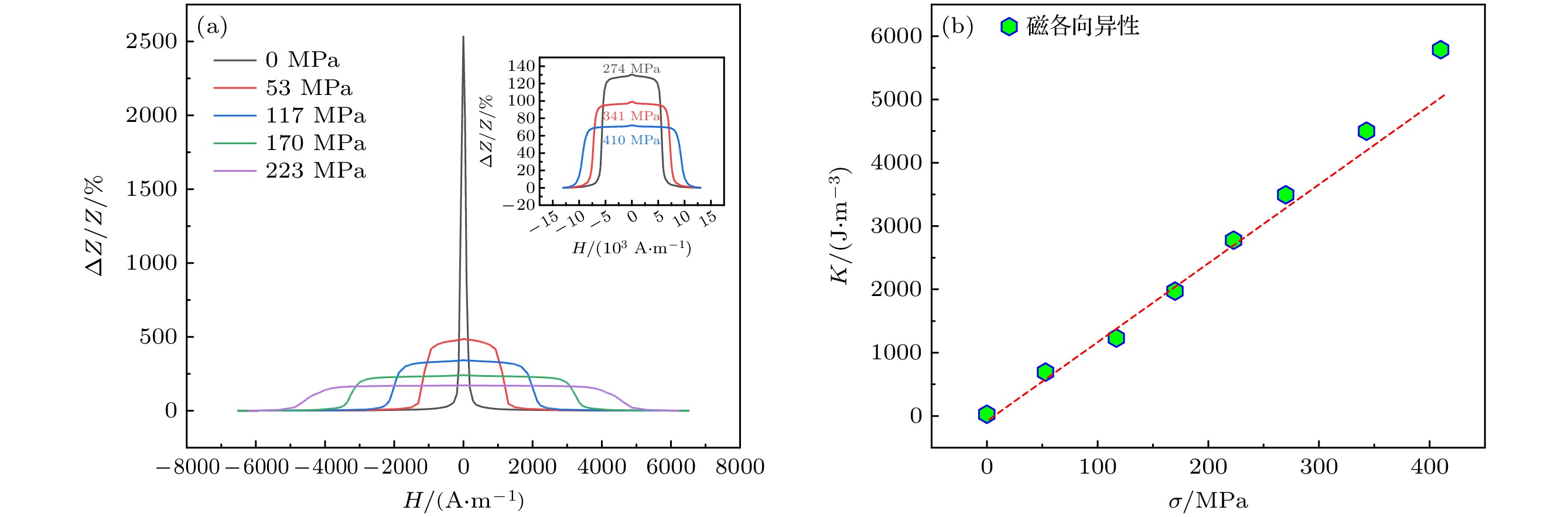

衍射矢量 晶粒尺寸/nm 晶化分数 晶粒间隙 D(110) D(200) D(211) D(220) D(310) Vcr/% δ0/nm 轴向 9.38 10.87 11.27 9.45 12.94 51.04 2.76 横向 9.30 11.77 12.03 10.40 12.66 51.27 2.74 平均值 11.00 51.16 2.75 表 2 张应力退火Fe基合金薄带结构和磁学参数

Table 2. Structural and magnetic parameters of Fe-based alloy ribbons annealed with different tensile stress.

张应力

σ/MPa分布各向异性

∆δ/nm磁各向异性 Hk/(A·m–1) K/(J·m–3) Kd/(J·m–3) Ke/(J·m–3) 0 0 47.51 27.25 0 — 53 0.05 1181.73 692.14 99.67 592.47 117 0.14 2001.46 1229.06 176.98 1052.08 170 0.20 3194.23 1972.59 284.05 1688.54 223 0.28 4540.54 2777.20 399.92 2377.28 270 0.38 5645.52 3495.28 503.32 2991.96 343 0.51 7335.80 4498.91 647.84 3851.07 410 0.65 9380.54 5786.89 833.31 4953.58 -

[1] 姚可夫, 施凌翔, 陈双琴, 邵洋, 陈娜, 贾蓟丽 2018 67 016101

Google Scholar

Google Scholar

Yao K F, Shi L X, Chen S Q, Shao Y, Chen N, Jia J L 2018 Acta Phys. Sin. 67 016101

Google Scholar

Google Scholar

[2] Li Y M, Jia X J, Zhang W, Zhang Y, Xie G Q, Qiu Z Y, Luan J H, Jiao Z B 2021 J. Mater. Sci. Technol. 65 171

Google Scholar

Google Scholar

[3] Corte-Leon P, Zhukova V, Blanco J M, González-Legarreta L, Ipatov M, Zhukov A 2020 J. Magn. Magn. Mater. 510 166939

Google Scholar

Google Scholar

[4] Sai Ram B, Paul A K, Kulkarni S V 2021 J. Magn. Magn. Mater. 537 16820

[5] Li F C, Liu T, Zhang J Y, Shuang S, Wang Q, Wang A D, Wang J G, Yang Y 2019 Mater. Today Adv. 4 100027

Google Scholar

Google Scholar

[6] 马海健, 魏文庆, 鲍文科, 神祥博, 王长春, 王伟民 2020 稀有金属材料与工程 49 2904

Ma H J, Wei W Q, Bao W K, Shen X B, Wang C C, Wang W M 2020 Rare Metal Mat. Eng. 49 2904

[7] Liu T, Wang A D, Zhao C L, Yue S Q, Wang X M, Liu C T 2019 Mater. Res. Bull. 112 323

Google Scholar

Google Scholar

[8] Lukshina V A, Dmitrieva N V, Cerdeira M A, Potapov A P 2012 J. Alloys Compd. 536 374

Google Scholar

Google Scholar

[9] Correa A M, Bohn F 2018 J. Magn. Magn. Mater. 453 30

Google Scholar

Google Scholar

[10] Varga L K 2020 J. Magn. Magn. Mater. 500 166327

Google Scholar

Google Scholar

[11] Fang Y Z, Zheng J J, Wu F M, Xu Q M, Zhang J Q, Ye H Q, Zheng J L, Li T Y 2010 Appl. Phys. Lett. 96 092508

Google Scholar

Google Scholar

[12] Néel L 1954 J. Phys. 4 225

[13] Hofmann B, Kronmüller H 1996 J. Magn. Magn. Mater. 152 91

Google Scholar

Google Scholar

[14] Herzer G 1996 J. Magn. Magn. Mater. 157-158 133

Google Scholar

Google Scholar

[15] Nielsen O V, Nielsen H J V 1980 Solid State Commun. 35 281

Google Scholar

Google Scholar

[16] Ohnuma M, Hono K, Yanai T, Fukunaga H, Yoshizawa Y 2003 Appl. Phys. Lett. 83 2859

Google Scholar

Google Scholar

[17] Ohnuma M, Hono K, Yanai T, Nakano H, Fukunaga H, Yoshizawa Y 2005 Appl. Phys. Lett. 86 152513

Google Scholar

Google Scholar

[18] Ohnuma M, Yanai T, Hono K, Nakano M, Fukunaga H, Yoshizawa Y, Herzer G 2010 J. Appl. Phys. 108 093927

Google Scholar

Google Scholar

[19] Nutor R K, Xu X J, Fan X Z, He X W, Fang Y Z 2018 Chinese J. Phys. 56 180

Google Scholar

Google Scholar

[20] Nutor R K, Xu X J, Fan X Z, He X W, Lu X A, Fang Y Z 2019 J. Magn. Magn. Mater. 471 544

[21] Nutor R K, Fan X Z, He X W, Xu X J, Lu X A, Jiang J Z, Fang Y Z 2019 J. Alloys Compd. 774 1243

Google Scholar

Google Scholar

[22] Kurlyandskaya G V, Lukshina V A, Larrañaga A, Orue I, Zaharova A A, Shishkin D A 2013 J. Alloys Compd. 566 31

Google Scholar

Google Scholar

[23] Ohnuma M, Herzer G, Kozikowski P, Polak C, Budinsky V, Koppoju S 2012 Acta. Mater. 60 1278

Google Scholar

Google Scholar

[24] Leary A M, Keylin V, Ohodnicki P R, McHenry M E 2015 J. Appl. Phys. 117 17A338

Google Scholar

Google Scholar

[25] Herzer G, Schulz R US Patent 6 254 695 B1 [2001-06-03]

[26] Hilzinger H R 1981 Proceedings of the 4th International Conference on Rapidly Quenched Metals Sendai, Japan, August 24–28, 1981 p701

[27] 许校嘉, 方峥, 陆轩昂, 叶慧群, 范晓珍, 郑金菊, 何兴伟, 郭春羽, 李文忠, 方允樟 2019 68 137501

Google Scholar

Google Scholar

Xu X J, Fang Z, Lu X A, Ye H Q, Fan X Z, Zheng J J, He X W, Guo C Y, Li W Z, Fang Y Z 2019 Acta Phys. Sin. 68 137501

Google Scholar

Google Scholar

[28] Wu C, Chen H P, Lv H P, Yan M 2016 J. Alloys Compd. 673 278

Google Scholar

Google Scholar

[29] Allia P, Baricco M, Tiberto P, Vinai F 1993 J. Appl. Phys. 74 3137

Google Scholar

Google Scholar

[30] Fan X Z, He X W, Nutor R K, Pan R M, Zheng J J, Ye H Q, Wu F M, Jiang J Z, Fang Y Z 2019 J. Magn. Magn. Mater. 469 349

Google Scholar

Google Scholar

[31] 汪卫华 2013 物理学进展 33 177

Wang W H 2013 Prog. Phys. 33 177

Catalog

Metrics

- Abstract views: 6898

- PDF Downloads: 74

- Cited By: 0

DownLoad:

DownLoad: