-

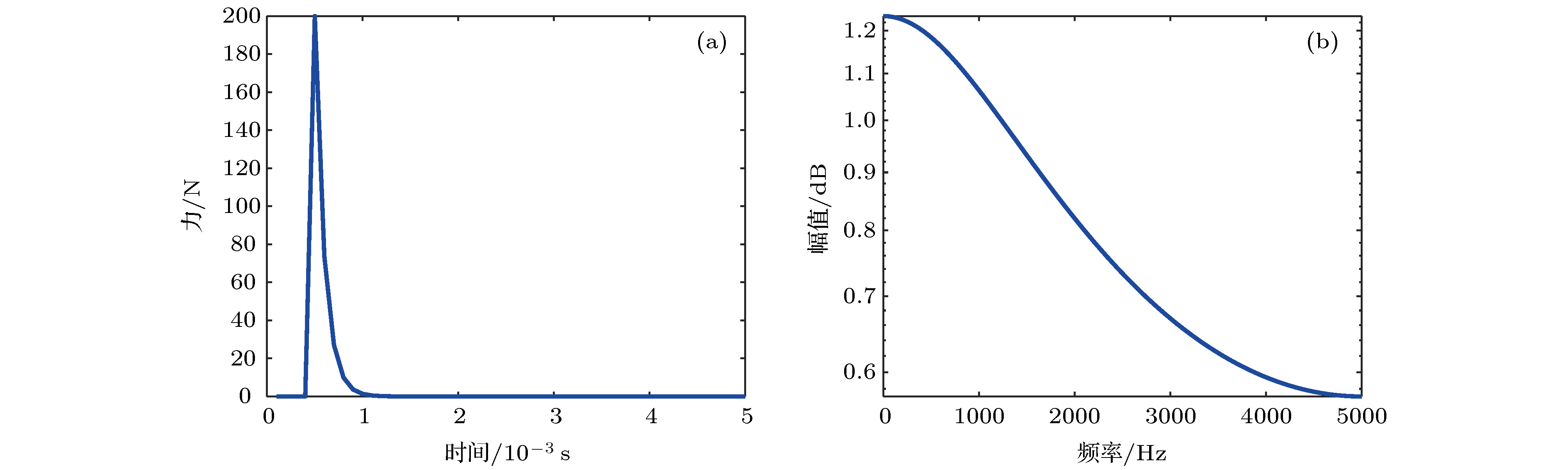

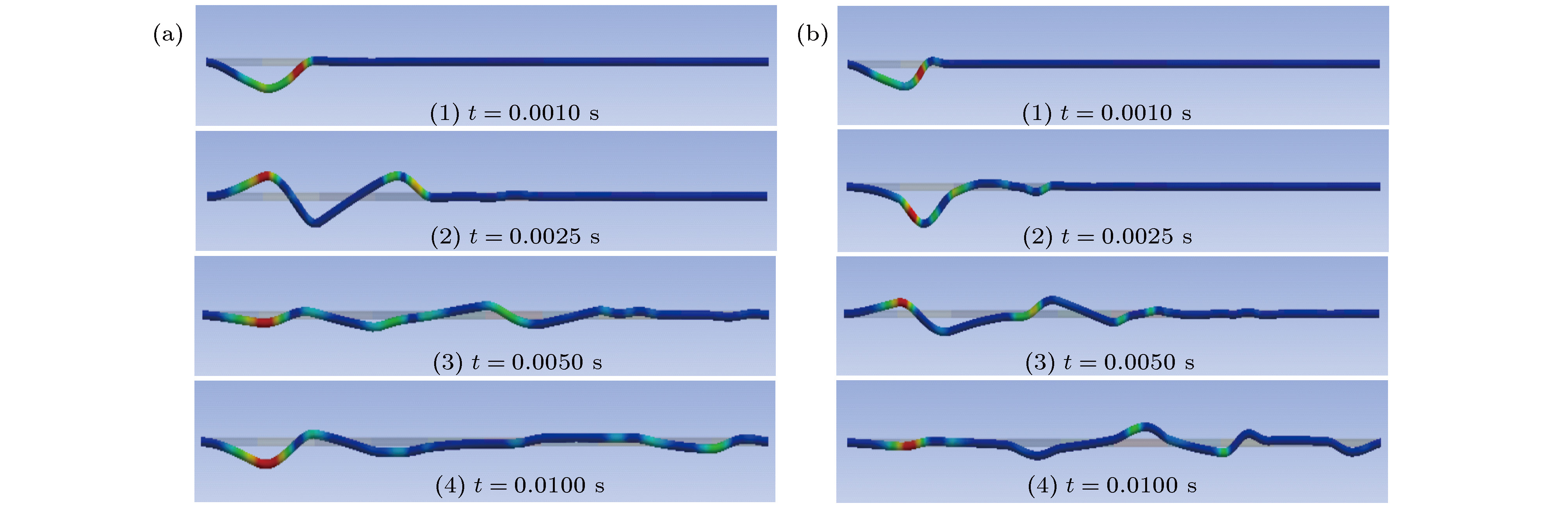

Fluid-structure interaction pipeline systems are extensively adopted to transfer matter, energy and momentum, which are widely used in various fields. Due to the fluid-structure interaction effect, the pipe wall proves to produce strong vibration and noise under fluid action, which has a serious influence on the safety and concealment of the equipment, even leading to serious damages. Therefore, it is of great significance to study the vibration characteristics of fluid-structure interaction pipeline and methods to reduce the vibration of pipeline both in theory and in practice. Phononic crystal can suppress the propagation of elastic waves in a specific frequency range by their special band-gap characteristics, which have wide application prospects in the field of vibration and noise reduction. Especially, the band gap characteristics of phononic crystal pipeline used to design fluid-structure interaction pipeline system have been widely studied, thus providing a new technical approach to reducing the vibration and noise of the pipeline. In this paper, based on the theory of phononic crystal, the vibration transfer characteristics of the Bragg phononic crystal pipeline under fluid-structure interaction are studied. Combining the transfer matrix method and the finite element method, the band structure and band gap characteristics are calculated. Using the finite element method, the vibration characteristics of the phononic crystal pipeline under fluid-structure interaction effect, the shock excitation of pipe wall and the shock excitation of the fluid are considered. The influence of the fluid-structure interaction on the vibration transmission characteristics of the phononic crystal pipeline is also analyzed. The research results indicate that when the fluid velocity in the fluid-structure interaction pipeline system is small the Bragg phononic crystal pipeline has a good attenuation effect on the shock excitation of pipe wall in the band gap range, and that when the fluid velocity increases the fluid-structure interaction effect becomes significant, the attenuation effect becoming weaker. Bragg phononic crystal pipeline has a certain attenuation effect on the pipe wall vibration caused by the fluid shock excitation near the band gap. The research results are expected to be able to provide a technical reference for the vibration control of pipeline systems under fluid-structure interaction conditions. -

Keywords:

- fluid-structure interaction /

- phononic crystal /

- vibration band gap /

- shock vibration

[1] 邵沛泽 2015 硕士学位论文 (北京: 北京工业大学)

Shao P Z 2015 M. S. Thesis (Beijing: Beijing Institute of Technology) (in Chinese)

[2] 张阿漫, 戴绍仕 2011 流固耦合动力学 (北京: 国防工业出版社) 第3页

Zhang A M, Dai S S 2011 Dynamics of Solid-fluid Interaction (Beijing: National Defense Industry Press) p3 (in Chinese)

[3] 马璐 2015 硕士学位论文 (兰州: 兰州理工大学)

Ma L 2015 M.S. Thesis (Lanzhou: Lanzhou University of Technology) (in Chinese)

[4] 宋学官, 蔡林, 张华 2012 ANSYS流固耦合分析与工程实例 (北京: 中国水利水电出版社)第1页

Song X G, Cai L, Zhang H 2012 ANSYS Fluid-structure Coupling Analysis and Engineering Example (Beijing: China Water & Power Press) p1 (in Chinese)

[5] 王海彦, 刘永刚 2015 ANSYS Fluent 流体数值计算方法与实例 (北京: 中国铁道出版社) 第2页

Wang H Y, Liu Y G 2015 ANSYS Numerical Calculation Method and Example of ANSYS Fluent Fluid (Beijing: China Railway Press) p2 (in Chinese)

[6] Chimakurthi S K, Reuss S, Tooley M, Scampoli S 2018 Eng. Comput.-Germany 34 385

Google Scholar

Google Scholar

[7] Díaz-de-Anda A, Pimentel A, Flores J, Morales A, Gutiérrez L, Méndez-Sánchez R A 2005 J. Acoust. Soc. Am. 117 2814

Google Scholar

Google Scholar

[8] Yang X D, Cui Q D, Qian Y J, Zhang W, Lim C W 2018 J. Appl. Mech. T ASME 85 0610121

Google Scholar

Google Scholar

[9] Peiró-Torres M P, Castiñeira-Ibáñez S, Redondo J, Sánchez-Pérez J V 2019 Appl. Phys. Lett. 114 171901

Google Scholar

Google Scholar

[10] Iqbal M, Jaya M M, Bursi O S, Kumar A, Ceravolo R 2020 Sci. Rep. 10 85

Google Scholar

Google Scholar

[11] Sharma B, Sun C T 2016 J. Sandw. Struct. Mater. 18 50

Google Scholar

Google Scholar

[12] Chen J S, Sharma B, Sun C T 2011 Compos. Struct. 93 2120

Google Scholar

Google Scholar

[13] Chen J S, Sun C T 2011 J. Sandw. Struct. Mater. 13 391

Google Scholar

Google Scholar

[14] Chen J S, Huang Y J 2016 J. Vib. Acoust. 138 0410091

Google Scholar

Google Scholar

[15] Pai P F, Peng H, Jiang S 2014 Int. J. Mech. Sci. 79 195

Google Scholar

Google Scholar

[16] Chen Y Y, Barnhart M V, Chen J K, Hu G K, Sun C T, Huang G L 2016 Compos. Struct. 136 358

Google Scholar

Google Scholar

[17] Alamri S, Li B, Tan K T 2018 J. Appl. Phys. 123 95111

Google Scholar

Google Scholar

[18] Li B, Liu Y, Tan K 2019 J. Sandw. Struct. Mater. 21 1880

Google Scholar

Google Scholar

[19] Li Q Q, He Z C, Li E, Cheng A G 2018 Smart. Mater. Struct. 27 95015

Google Scholar

Google Scholar

[20] Li Q Q, He Z C, Li E, Cheng A G 2019 J. Appl. Phys. 125 35104

Google Scholar

Google Scholar

[21] Yu D L, Wang G, Liu Y Z, Wen J H, Qiu J 2006 Chin. Phys. 15 266

Google Scholar

Google Scholar

[22] 沈惠杰, 温激鸿, 郁殿龙, 温熙森 2009 58 8357

Google Scholar

Google Scholar

Shen H J, Wen J H, Yu D L, Wen X S 2009 Acta Phys. Sin. 58 8357

Google Scholar

Google Scholar

[23] Shen H, Wen J, Yu D, Wen X 2009 J. Sound Vib. 328 57

Google Scholar

Google Scholar

[24] Koo G K, Park Y S 1998 J. Sound Vib. 210 53

Google Scholar

Google Scholar

[25] Sorokina S V, Ershova O A 2004 J. Sound Vib. 278 501

Google Scholar

Google Scholar

[26] Sorokina S V, Ershova O A 2006 J. Sound Vib. 291 81

Google Scholar

Google Scholar

[27] Sorokin S, Holst-Jensen O 2012 J. Vib. Acoust 134 41001

Google Scholar

Google Scholar

[28] Yu D L, Wen J H, Zhao H G, Liu Y Z, Wen X S 2008 J. Sound Vib. 318 193

Google Scholar

Google Scholar

[29] Yu D L, Wen J H, Zhao H G, Liu Y Z, Wen X S 2011 J. Vib. Acoust 133 14501

Google Scholar

Google Scholar

[30] Yu D L, Wen J H, Shen H J, Wen X S 2012 Phys. Lett. A 376 3417

Google Scholar

Google Scholar

[31] Yu D L, Du C Y, Shen H J, Liu J W, Wen J H 2017 Chin. Phys. Lett. 34 190

Google Scholar

Google Scholar

[32] Yu D L, Shen H J, Liu J W, Yin J F, Zhang Z F, Wen J H 2018 Chin. Phys. B 27 285

Google Scholar

Google Scholar

[33] Yu D L, Paidoussis M P, Shen H J, Wang L 2014 J. Appl. Mech.-T ASME 81 11001

Google Scholar

Google Scholar

[34] Wen J H, Shen H J, Yu D L, Wen X S 2010 Chin. Phys. Lett. 27 133

Google Scholar

Google Scholar

[35] Wei Z D, Li B R, Du J M, Yang G 2016 Chin. Phys. Lett. 33 68

Google Scholar

Google Scholar

[36] 刘东彦, 李发, 张建兴, 李宝仁 2016 机床与液压 44 74

Google Scholar

Google Scholar

Liu D Y, Li F, Zhang J X, Li B R 2016 Mach. Tool & Hydr. 44 74

Google Scholar

Google Scholar

[37] Shen H J, Wen J H, Yu D L, Asgari M, Wen X S 2013 J. Sound Vib. 332 4193

Google Scholar

Google Scholar

[38] Shen H J, Wen J H, Yu D L, Yuan B, Wen X S 2014 J. Fluid. Struct. 46 134

Google Scholar

Google Scholar

[39] Shen H J, Wen J H, Païdoussis M P, Yu D L, Asgari M, Wen X S 2012 Phys. Lett. A 376 3351

Google Scholar

Google Scholar

[40] Shen H J, Païdoussis M P, Wen J H, Yu D L, Wen X S 2014 J. Sound Vib. 333 2735

Google Scholar

Google Scholar

[41] Shen H J, Wen J H, Yu D L, Wen X S 2014 J. Vib. Control 21 3034

Google Scholar

Google Scholar

[42] Liang F, Yang X D 2020 Appl. Math. Model. 77 522

Google Scholar

Google Scholar

[43] 尹志勇, 钟荣, 刘忠族 2006 舰船科学技术 28 23

Yin Z Y, Zhong R, Liu Z Z 2006 Ship Sci. Tech. 28 23

[44] Khudayarov B A, Komilova K M, Turaev F Z 2019 Int. J. Appl. Mech. 11 1950090

Google Scholar

Google Scholar

[45] Khudayarov B A, Komilova K M, Turaev F Z, Aliyarov J A 2020 Int. J. Pres. Ves. Pip. 179 104034

Google Scholar

Google Scholar

[46] 林磊 2005 硕士学位论文 (西安: 西北工业大学)

Lin L 2005 M. S. Thesis (Xi'an: Northwestern Polytechnical University) (in Chinese)

[47] Khudayarov B A, Komilova K M, Turaev F Z 2020 J. Nat. Gas. Sci. Eng. 75 103148

Google Scholar

Google Scholar

[48] 张亚峰 2014 硕士学位论文 (长沙: 国防科技大学)

Zhang Y F 2014 M. S. Thesis (Changsha: National University of Defense Technology) (in Chinese)

[49] 温熙森, 温激鸿, 郁殿龙, 王刚, 刘耀宗, 韩小云 2018 声子晶体 (北京: 国防工业出版社) 第207页

Wen X S, Wen J H, Yu D L, Wang G, Liu Y Z, Han X Y, 2009 Phononic Crystals (Beijing: National Defence Industry Press) p207 (in Chinese)

[50] Liu J W, Yu D L, Zhang Z F, Shen H J, Wen J H 2019 Acta. Mech. Solida Sin. 32 173

Google Scholar

Google Scholar

[51] Budenkov G A and Nedzvetskaya O V 2004 Russ. J. Nondestruct T-Engl. Tr. 40 99

Google Scholar

Google Scholar

[52] 胡兵, 郁殿龙 2019 第十三届全国振动理论及应用学术会议 中国西安, 11月9−12 第7页

Hu B, Yu D L 2019 The 13th National Conference on Vibration Theory and Application Xi'an, China, November 9−12 p7 (in Chinese)

[53] Ferràs D, Manso P A, Schleiss A J, Covas D I C 2016 Compos. Struct. 175 74

Google Scholar

Google Scholar

-

表 1 管路材料参数

Table 1. Pipeline material parameters.

材料名称 杨氏模量/GPa 密度/kg·m–3 泊松比 结构钢 200 7850 0.3 环氧树脂 4.35 1180 0.3672 -

[1] 邵沛泽 2015 硕士学位论文 (北京: 北京工业大学)

Shao P Z 2015 M. S. Thesis (Beijing: Beijing Institute of Technology) (in Chinese)

[2] 张阿漫, 戴绍仕 2011 流固耦合动力学 (北京: 国防工业出版社) 第3页

Zhang A M, Dai S S 2011 Dynamics of Solid-fluid Interaction (Beijing: National Defense Industry Press) p3 (in Chinese)

[3] 马璐 2015 硕士学位论文 (兰州: 兰州理工大学)

Ma L 2015 M.S. Thesis (Lanzhou: Lanzhou University of Technology) (in Chinese)

[4] 宋学官, 蔡林, 张华 2012 ANSYS流固耦合分析与工程实例 (北京: 中国水利水电出版社)第1页

Song X G, Cai L, Zhang H 2012 ANSYS Fluid-structure Coupling Analysis and Engineering Example (Beijing: China Water & Power Press) p1 (in Chinese)

[5] 王海彦, 刘永刚 2015 ANSYS Fluent 流体数值计算方法与实例 (北京: 中国铁道出版社) 第2页

Wang H Y, Liu Y G 2015 ANSYS Numerical Calculation Method and Example of ANSYS Fluent Fluid (Beijing: China Railway Press) p2 (in Chinese)

[6] Chimakurthi S K, Reuss S, Tooley M, Scampoli S 2018 Eng. Comput.-Germany 34 385

Google Scholar

Google Scholar

[7] Díaz-de-Anda A, Pimentel A, Flores J, Morales A, Gutiérrez L, Méndez-Sánchez R A 2005 J. Acoust. Soc. Am. 117 2814

Google Scholar

Google Scholar

[8] Yang X D, Cui Q D, Qian Y J, Zhang W, Lim C W 2018 J. Appl. Mech. T ASME 85 0610121

Google Scholar

Google Scholar

[9] Peiró-Torres M P, Castiñeira-Ibáñez S, Redondo J, Sánchez-Pérez J V 2019 Appl. Phys. Lett. 114 171901

Google Scholar

Google Scholar

[10] Iqbal M, Jaya M M, Bursi O S, Kumar A, Ceravolo R 2020 Sci. Rep. 10 85

Google Scholar

Google Scholar

[11] Sharma B, Sun C T 2016 J. Sandw. Struct. Mater. 18 50

Google Scholar

Google Scholar

[12] Chen J S, Sharma B, Sun C T 2011 Compos. Struct. 93 2120

Google Scholar

Google Scholar

[13] Chen J S, Sun C T 2011 J. Sandw. Struct. Mater. 13 391

Google Scholar

Google Scholar

[14] Chen J S, Huang Y J 2016 J. Vib. Acoust. 138 0410091

Google Scholar

Google Scholar

[15] Pai P F, Peng H, Jiang S 2014 Int. J. Mech. Sci. 79 195

Google Scholar

Google Scholar

[16] Chen Y Y, Barnhart M V, Chen J K, Hu G K, Sun C T, Huang G L 2016 Compos. Struct. 136 358

Google Scholar

Google Scholar

[17] Alamri S, Li B, Tan K T 2018 J. Appl. Phys. 123 95111

Google Scholar

Google Scholar

[18] Li B, Liu Y, Tan K 2019 J. Sandw. Struct. Mater. 21 1880

Google Scholar

Google Scholar

[19] Li Q Q, He Z C, Li E, Cheng A G 2018 Smart. Mater. Struct. 27 95015

Google Scholar

Google Scholar

[20] Li Q Q, He Z C, Li E, Cheng A G 2019 J. Appl. Phys. 125 35104

Google Scholar

Google Scholar

[21] Yu D L, Wang G, Liu Y Z, Wen J H, Qiu J 2006 Chin. Phys. 15 266

Google Scholar

Google Scholar

[22] 沈惠杰, 温激鸿, 郁殿龙, 温熙森 2009 58 8357

Google Scholar

Google Scholar

Shen H J, Wen J H, Yu D L, Wen X S 2009 Acta Phys. Sin. 58 8357

Google Scholar

Google Scholar

[23] Shen H, Wen J, Yu D, Wen X 2009 J. Sound Vib. 328 57

Google Scholar

Google Scholar

[24] Koo G K, Park Y S 1998 J. Sound Vib. 210 53

Google Scholar

Google Scholar

[25] Sorokina S V, Ershova O A 2004 J. Sound Vib. 278 501

Google Scholar

Google Scholar

[26] Sorokina S V, Ershova O A 2006 J. Sound Vib. 291 81

Google Scholar

Google Scholar

[27] Sorokin S, Holst-Jensen O 2012 J. Vib. Acoust 134 41001

Google Scholar

Google Scholar

[28] Yu D L, Wen J H, Zhao H G, Liu Y Z, Wen X S 2008 J. Sound Vib. 318 193

Google Scholar

Google Scholar

[29] Yu D L, Wen J H, Zhao H G, Liu Y Z, Wen X S 2011 J. Vib. Acoust 133 14501

Google Scholar

Google Scholar

[30] Yu D L, Wen J H, Shen H J, Wen X S 2012 Phys. Lett. A 376 3417

Google Scholar

Google Scholar

[31] Yu D L, Du C Y, Shen H J, Liu J W, Wen J H 2017 Chin. Phys. Lett. 34 190

Google Scholar

Google Scholar

[32] Yu D L, Shen H J, Liu J W, Yin J F, Zhang Z F, Wen J H 2018 Chin. Phys. B 27 285

Google Scholar

Google Scholar

[33] Yu D L, Paidoussis M P, Shen H J, Wang L 2014 J. Appl. Mech.-T ASME 81 11001

Google Scholar

Google Scholar

[34] Wen J H, Shen H J, Yu D L, Wen X S 2010 Chin. Phys. Lett. 27 133

Google Scholar

Google Scholar

[35] Wei Z D, Li B R, Du J M, Yang G 2016 Chin. Phys. Lett. 33 68

Google Scholar

Google Scholar

[36] 刘东彦, 李发, 张建兴, 李宝仁 2016 机床与液压 44 74

Google Scholar

Google Scholar

Liu D Y, Li F, Zhang J X, Li B R 2016 Mach. Tool & Hydr. 44 74

Google Scholar

Google Scholar

[37] Shen H J, Wen J H, Yu D L, Asgari M, Wen X S 2013 J. Sound Vib. 332 4193

Google Scholar

Google Scholar

[38] Shen H J, Wen J H, Yu D L, Yuan B, Wen X S 2014 J. Fluid. Struct. 46 134

Google Scholar

Google Scholar

[39] Shen H J, Wen J H, Païdoussis M P, Yu D L, Asgari M, Wen X S 2012 Phys. Lett. A 376 3351

Google Scholar

Google Scholar

[40] Shen H J, Païdoussis M P, Wen J H, Yu D L, Wen X S 2014 J. Sound Vib. 333 2735

Google Scholar

Google Scholar

[41] Shen H J, Wen J H, Yu D L, Wen X S 2014 J. Vib. Control 21 3034

Google Scholar

Google Scholar

[42] Liang F, Yang X D 2020 Appl. Math. Model. 77 522

Google Scholar

Google Scholar

[43] 尹志勇, 钟荣, 刘忠族 2006 舰船科学技术 28 23

Yin Z Y, Zhong R, Liu Z Z 2006 Ship Sci. Tech. 28 23

[44] Khudayarov B A, Komilova K M, Turaev F Z 2019 Int. J. Appl. Mech. 11 1950090

Google Scholar

Google Scholar

[45] Khudayarov B A, Komilova K M, Turaev F Z, Aliyarov J A 2020 Int. J. Pres. Ves. Pip. 179 104034

Google Scholar

Google Scholar

[46] 林磊 2005 硕士学位论文 (西安: 西北工业大学)

Lin L 2005 M. S. Thesis (Xi'an: Northwestern Polytechnical University) (in Chinese)

[47] Khudayarov B A, Komilova K M, Turaev F Z 2020 J. Nat. Gas. Sci. Eng. 75 103148

Google Scholar

Google Scholar

[48] 张亚峰 2014 硕士学位论文 (长沙: 国防科技大学)

Zhang Y F 2014 M. S. Thesis (Changsha: National University of Defense Technology) (in Chinese)

[49] 温熙森, 温激鸿, 郁殿龙, 王刚, 刘耀宗, 韩小云 2018 声子晶体 (北京: 国防工业出版社) 第207页

Wen X S, Wen J H, Yu D L, Wang G, Liu Y Z, Han X Y, 2009 Phononic Crystals (Beijing: National Defence Industry Press) p207 (in Chinese)

[50] Liu J W, Yu D L, Zhang Z F, Shen H J, Wen J H 2019 Acta. Mech. Solida Sin. 32 173

Google Scholar

Google Scholar

[51] Budenkov G A and Nedzvetskaya O V 2004 Russ. J. Nondestruct T-Engl. Tr. 40 99

Google Scholar

Google Scholar

[52] 胡兵, 郁殿龙 2019 第十三届全国振动理论及应用学术会议 中国西安, 11月9−12 第7页

Hu B, Yu D L 2019 The 13th National Conference on Vibration Theory and Application Xi'an, China, November 9−12 p7 (in Chinese)

[53] Ferràs D, Manso P A, Schleiss A J, Covas D I C 2016 Compos. Struct. 175 74

Google Scholar

Google Scholar

Catalog

Metrics

- Abstract views: 11096

- PDF Downloads: 189

- Cited By: 0

DownLoad:

DownLoad: