-

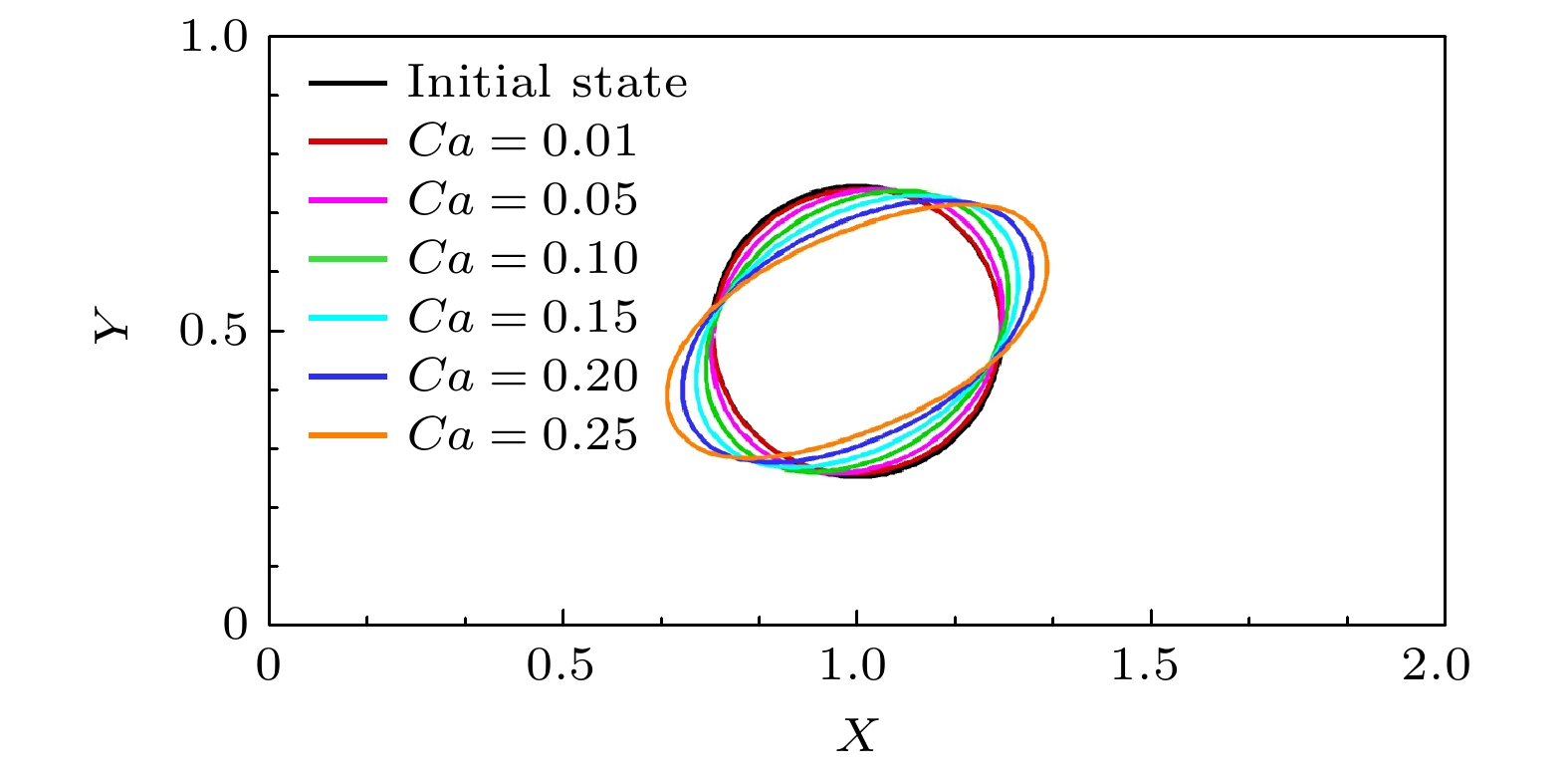

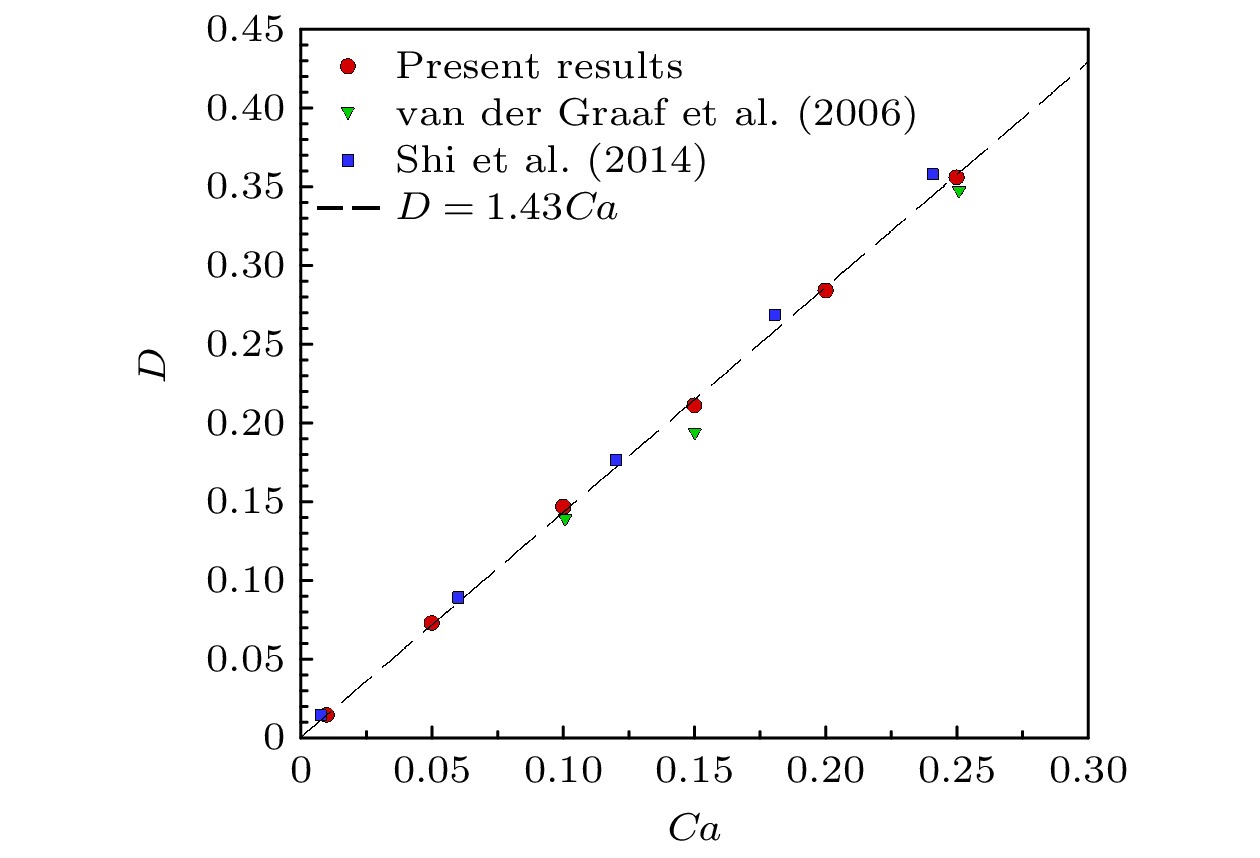

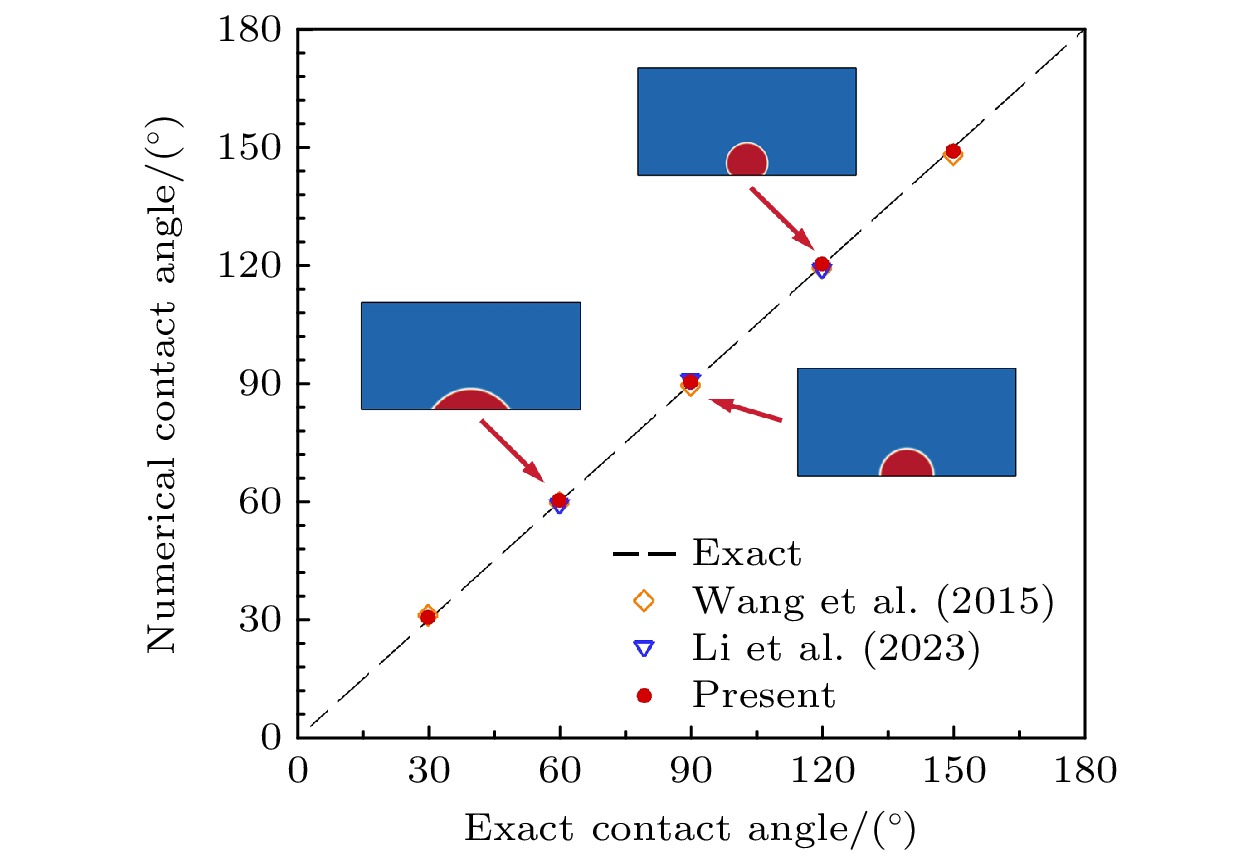

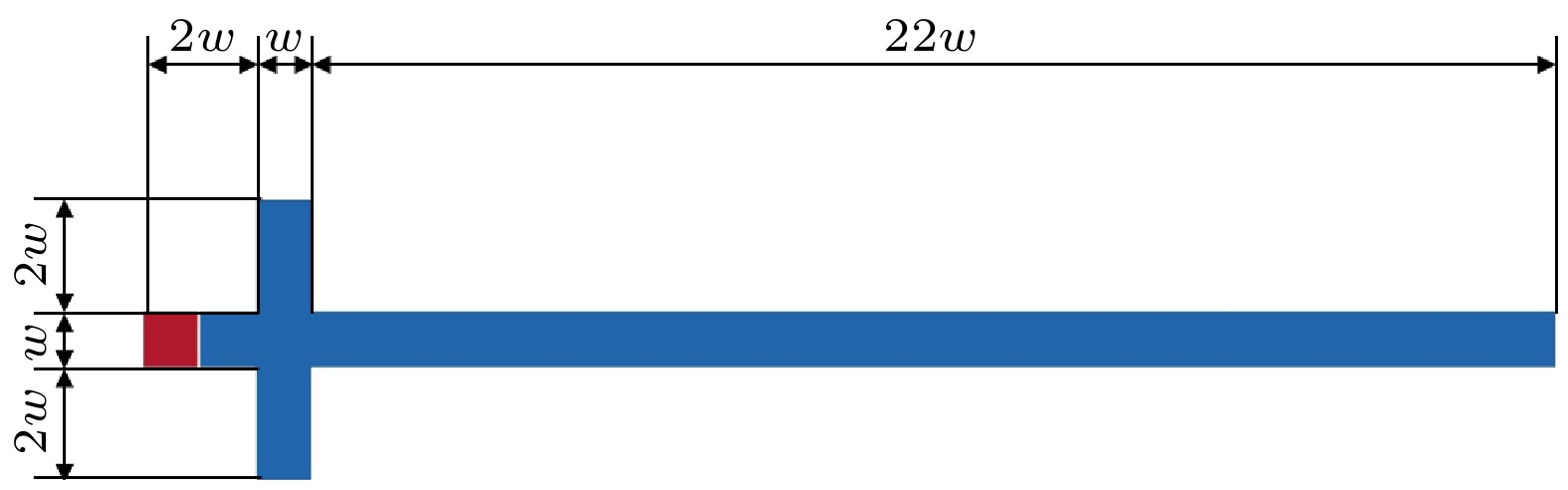

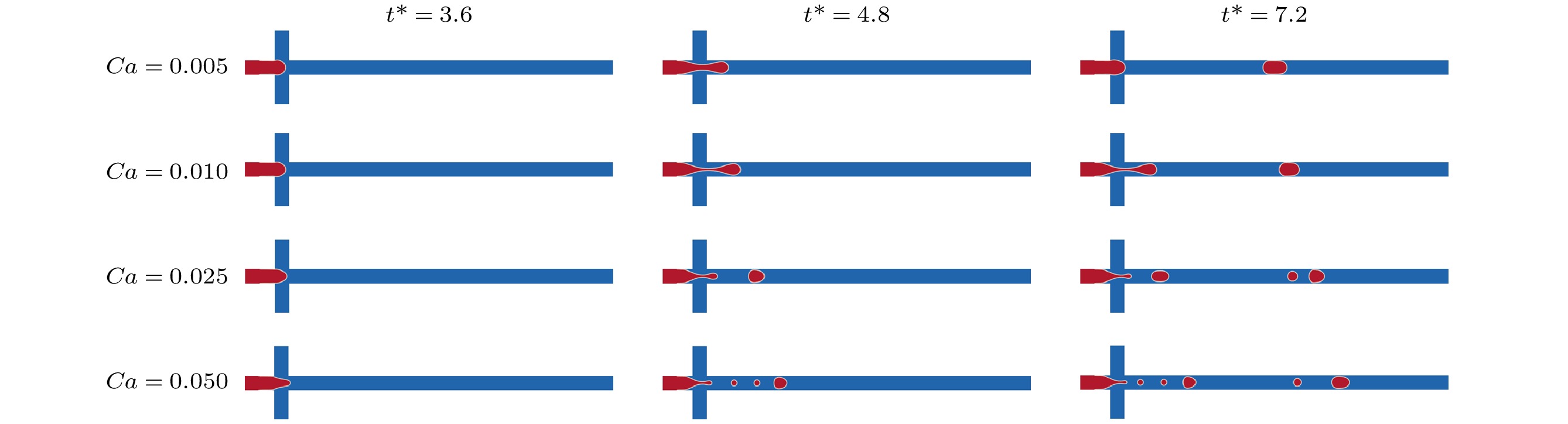

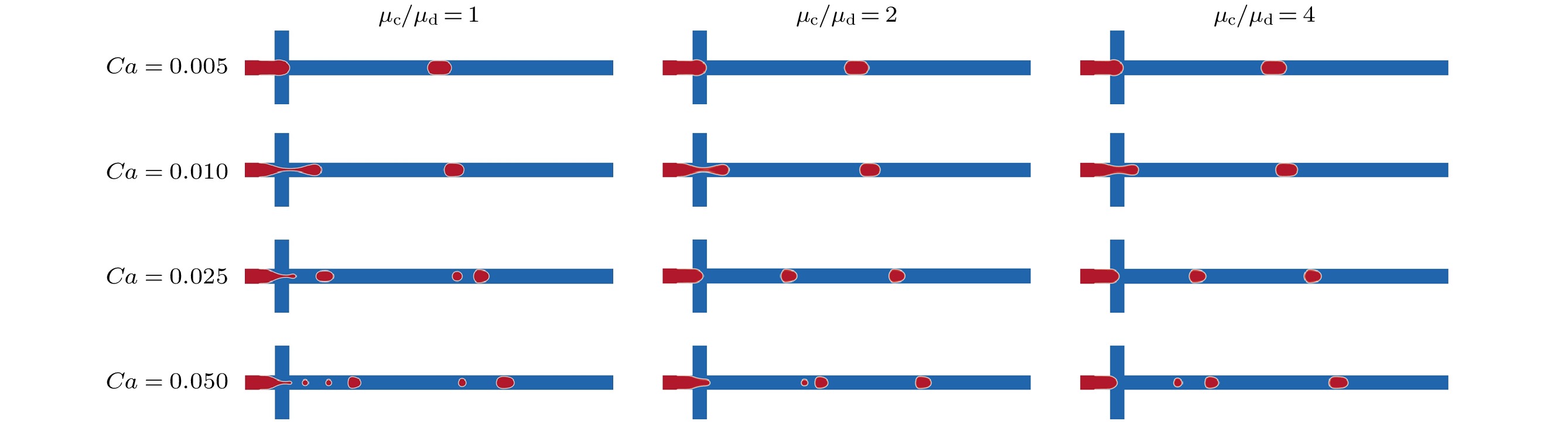

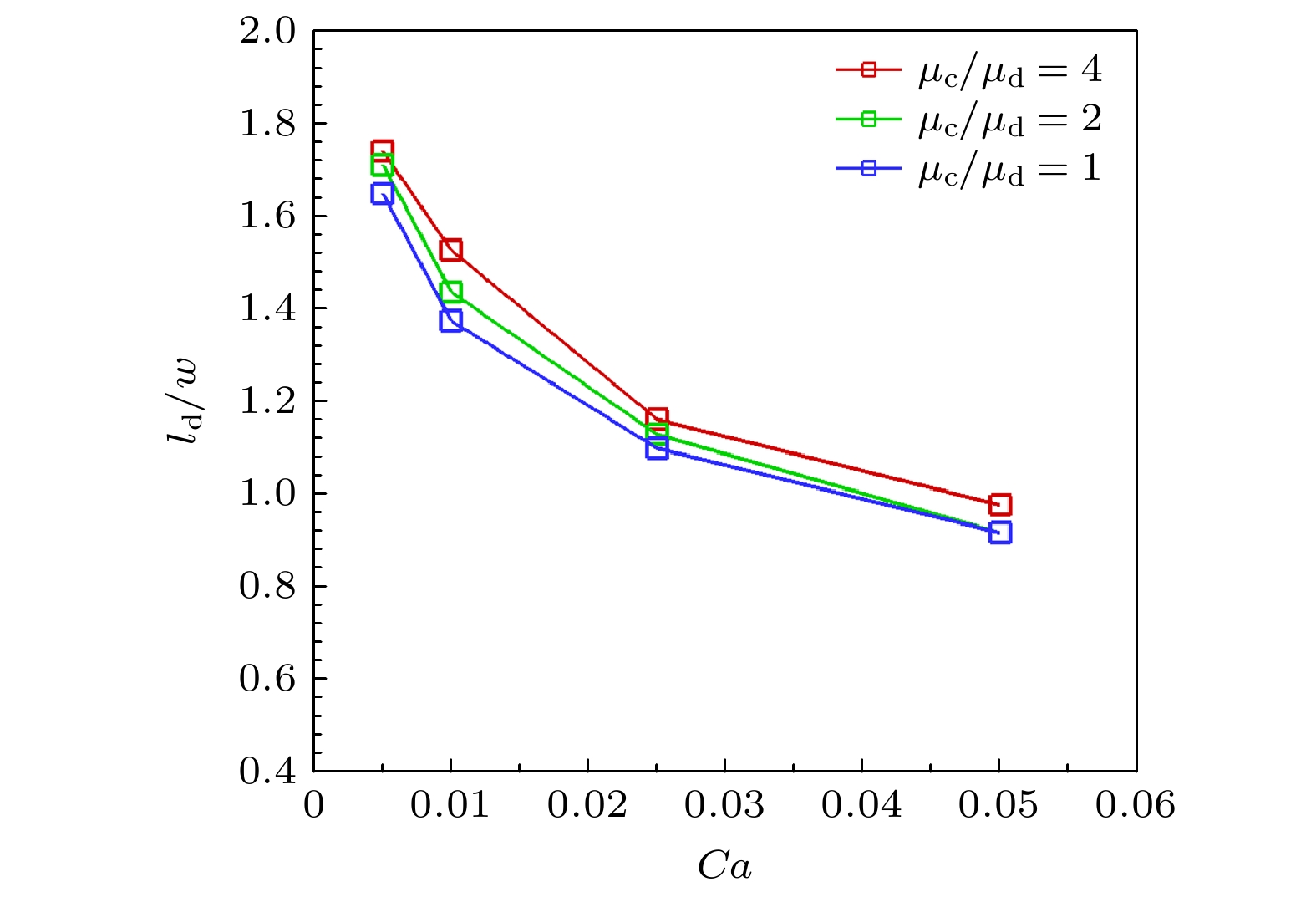

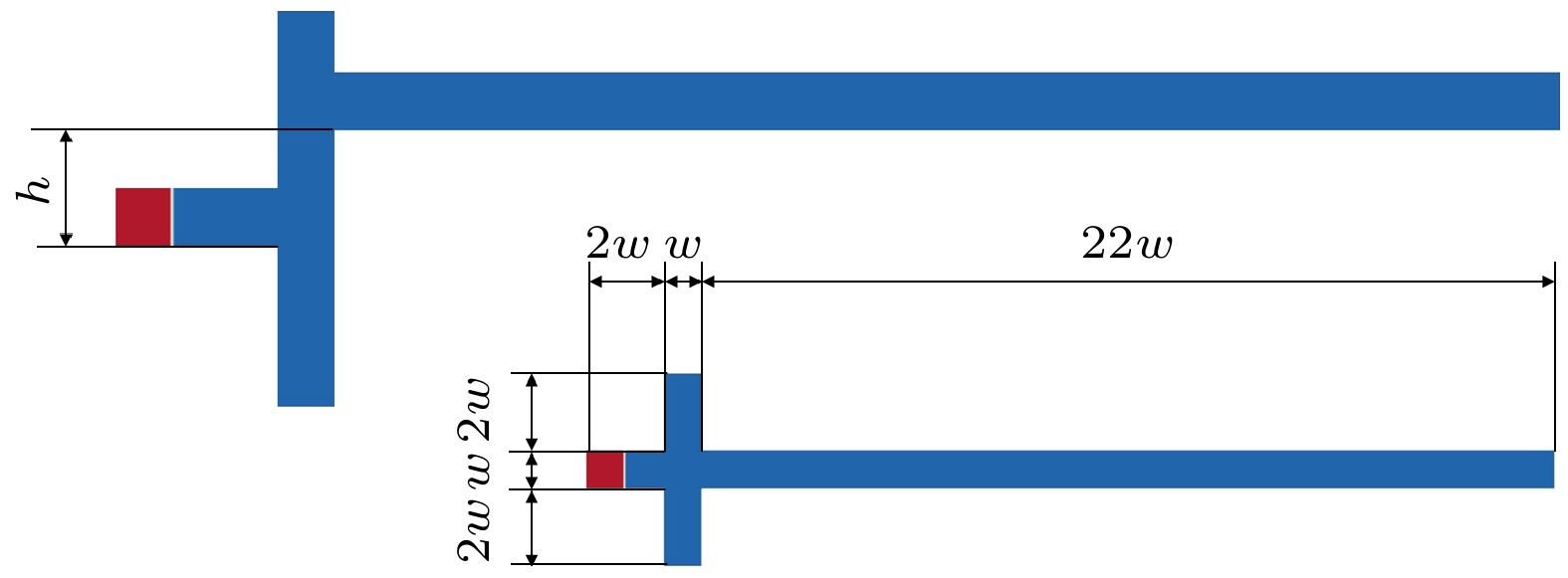

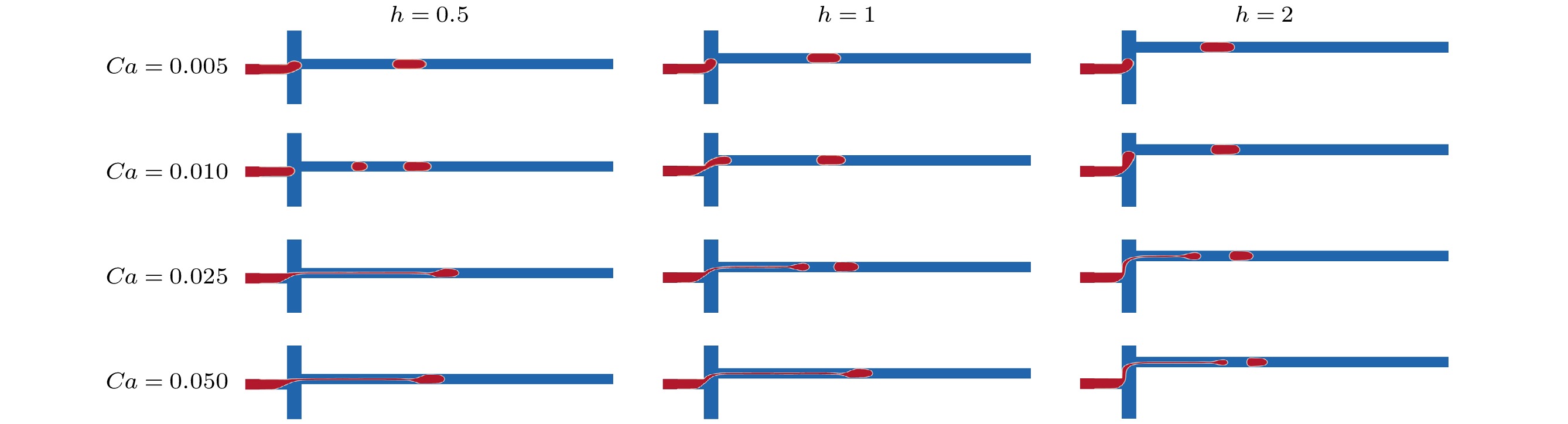

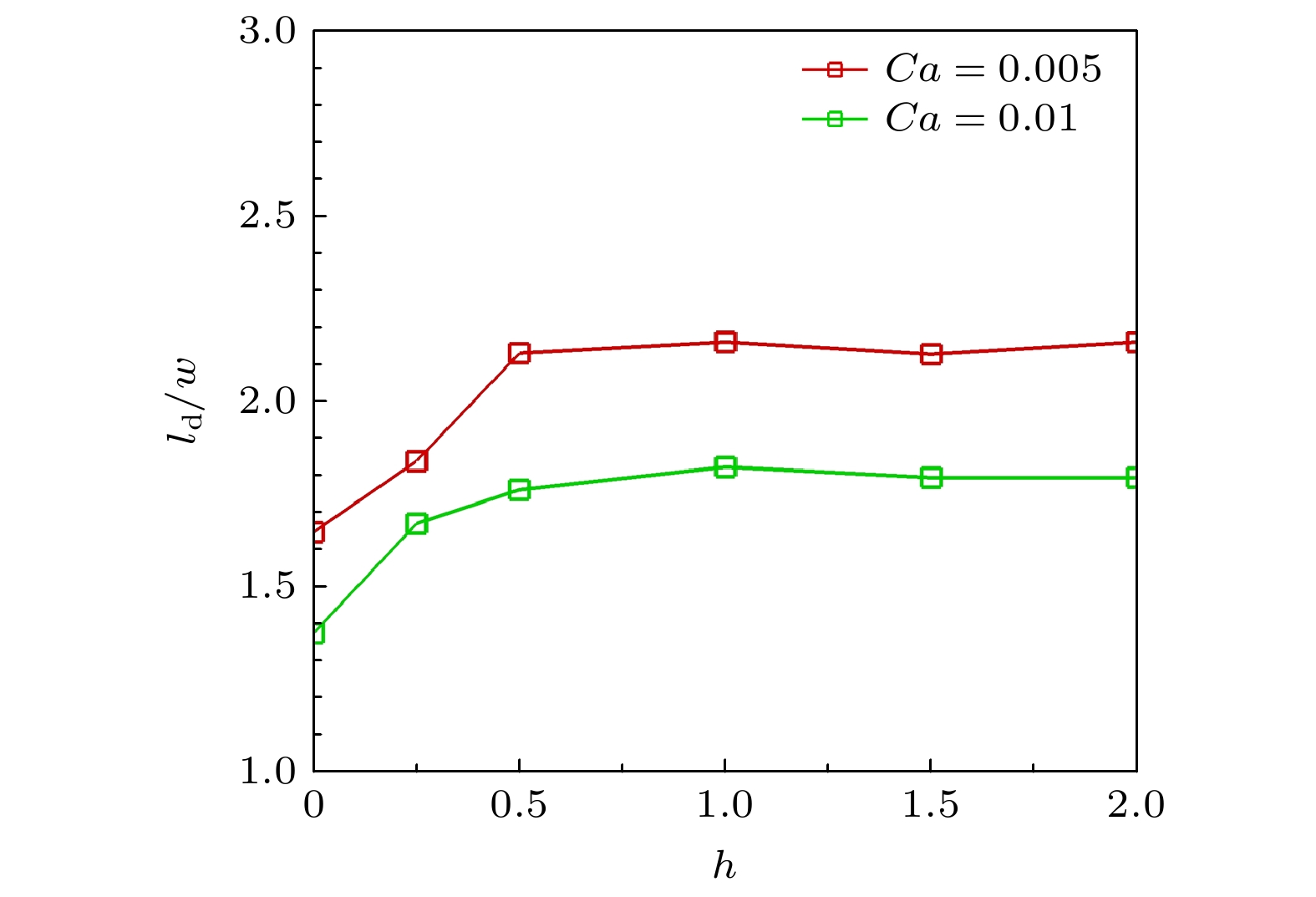

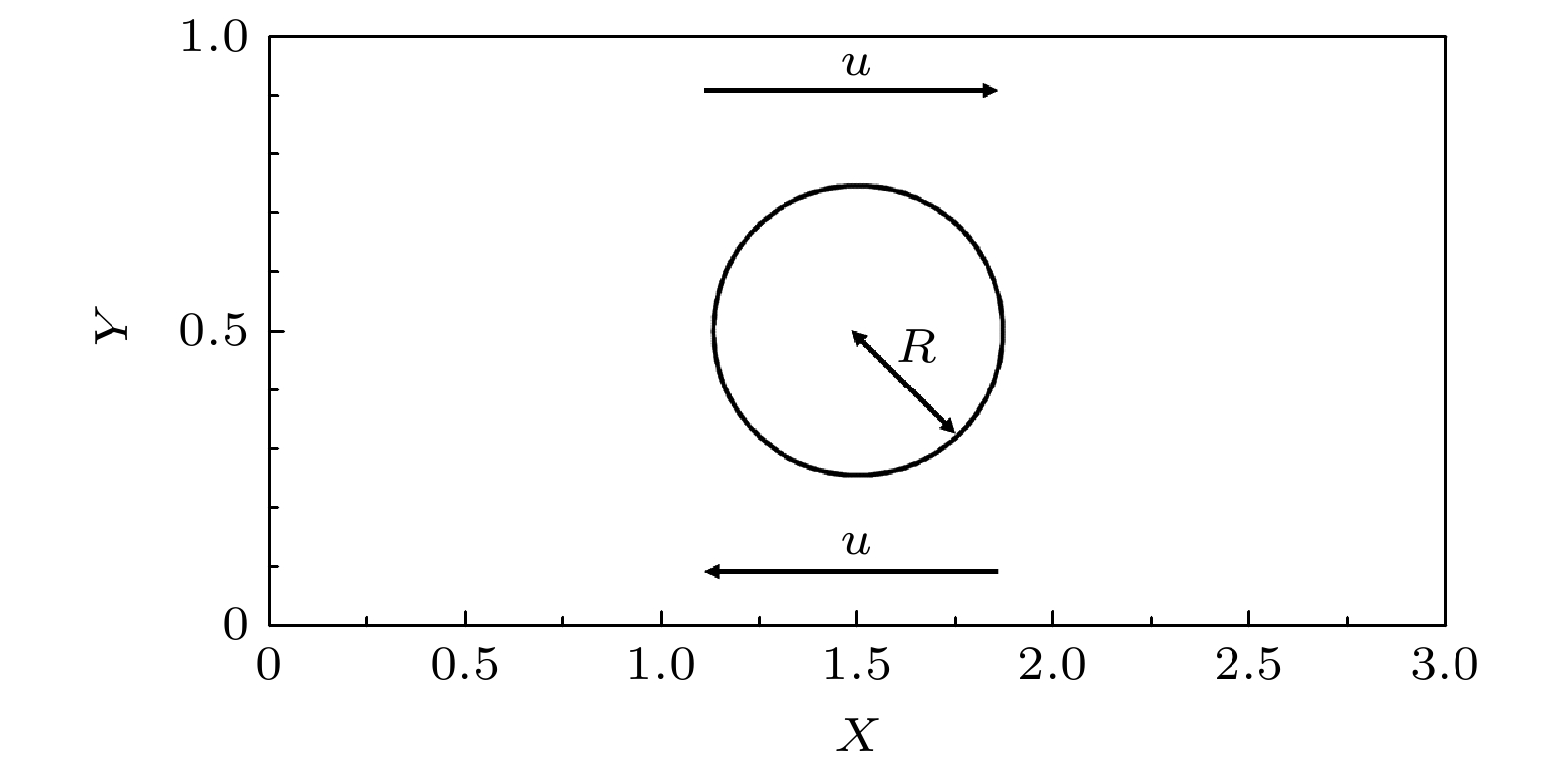

液滴微流控技术在化学分析、生物检测及材料制备等领域具有巨大的应用潜力, 被动生成液滴方法主要依赖微通道几何特性与剪切流动就能够快速实现液滴生成. 其中, 十字微通道作为典型结构, 其流体参数和对称性差异对液滴生成过程的影响尚未得到充分研究. 因此, 本文采用格子Boltzmann方法开展对称与非对称十字微通道内的液滴生成过程的数值模拟研究, 系统地分析了毛细数、黏度比及流道对称性的作用机制. 本文首先通过平板剪切流动下液滴变形和理想固体表面静止液滴这两个经典算例验证了数值模型的计算可靠性, 然后围绕对称十字微通道内水相流体“界面浸入-剪切断裂-液滴迁移和融合”三个流动阶段展开研究, 分析了毛细数和两相黏度比的协同作用机制. 在此基础上, 进一步量化了流道对称性对十字微通道内液滴生成过程的影响. 相关研究结果为微流道设计和液滴微流控的流体参数调控提供了理论依据, 并进一步推动液滴微流控技术的应用和发展.Droplet microfluidics technology possesses significant potential applications in chemical analysis, biological detection, and material preparation. Passive droplet generation method can rapidly achieve droplet formation by using the geometric characteristics of microchannels and shear flow. As a typical structure, the influences of fluid parameters and symmetry differences in cross microchannels on the droplet generation process have not been fully studied. Therefore, this paper uses the lattice Boltzmann method to numerically simulate droplet generation in symmetric and asymmetric cross microchannels, thereby systematically analyzing the action mechanisms of capillary number, viscosity ratio, and microchannel symmetry. First, this study verifies the computational reliability of the numerical model through two classic cases, i.e. the droplet deformation under planar shear flow and stationary droplets on ideal solid surfaces. Then, this work focuses on studying the three flow stages in symmetric cross microchannels, i.e. interface immersion stage, shear-induced breakup stage, and the droplet migration and coalescence stage, and analyzes the synergistic mechanism of capillary number and viscosity ratio. In the symmetric cross microchannel structure, the capillary number is the main factor determining the droplet size in the cross microchannel. With the increase of the capillary number, the surface tension gradually weakens, causing the liquid bridge at the droplet neck to break more easily and generate droplets. In contrast, the effect of the viscosity ratio on the droplet size is relatively small, but it can suppress the generation of sub-droplets and improve the uniformity of droplets by adjusting the viscous resistance of the continuous phase. On this basis, this study further quantifies the influence of microchannel symmetry on the droplet generation process in cross microchannels. In the asymmetric cross microchannel structure, the microchannel deviation breaks the flow symmetry and weakens the cooperative shearing effect of the oil-phase fluid on the immersion structure of the water-phase fluid. When the microchannel deviates within the centerline range of the water-phase microchannel, the droplet size increases significantly with the increase of the microchannel deviation. This is mainly because the oil-phase fluid on the side far from the deviation first squeezes the immersion structure of the water-phase fluid, and then the oil-phase fluid near the deviation side exerts a secondary squeeze on the immersion structure, causing the neck liquid bridge of the immersion structure to continuously elongate and the shear position to shift along the microchannel deviation direction. When the microchannel deviation exceeds the centerline position of the water-phase microchannel, the interface fracture of the water-phase immersion structure mainly relies on the double squeezing effect of the oil-phase fluid and the surface tension of water-phase fluid, and the droplet size tends to be stable. The relevant research results lay a theoretical foundation for microchannel design and fluid parameter regulation in droplet microfluidics and thus further promote the application and development of droplet microfluidic technology.

-

Keywords:

- droplet generation /

- multiphase flow /

- lattice Boltzmann method /

- diffuse interface method /

- microfluidic technology

[1] Zhu P, Wang L 2017 Lab Chip 17 34

Google Scholar

Google Scholar

[2] Cybulski O, Garstecki P, Grzybowski B A 2019 Nat. Phys. 15 706

Google Scholar

Google Scholar

[3] Chen P C, Wu M H, Wang Y N 2014 Microfluid. Nanofluid. 17 275

Google Scholar

Google Scholar

[4] Li X, Li D, Liu X, Chang H 2016 Sens. Actuators, B 229 466

Google Scholar

Google Scholar

[5] Theberge A B, Courtois F, Schaerli Y, Fischlechner M, Abell C, Hollfelder F, Huck W T S 2010 Angew. Chem. Int. Ed. 49 5846

Google Scholar

Google Scholar

[6] Teo A J T, Tan S H, Nguyen N T 2020 Anal. Chem. 92 1147

Google Scholar

Google Scholar

[7] Zhang Q, Li H, Zhu C, Fu T, Ma Y, Li H Z 2018 Colloids Surf. , A 537 572

Google Scholar

Google Scholar

[8] Jin S, Wei X, Liu Z, Ren J, Jiang Z, Abell C, Yu Z 2019 Sens. Actuators, B 291 1

[9] Zhang H, Palit P, Liu Y, Vaziri S, Sun Y 2020 ACS Appl. Mater. Interfaces 12 26936

Google Scholar

Google Scholar

[10] Thorsen T, Roberts R W, Arnold F H, Quake S R 2001 Phys. Rev. Lett. 86 4163

Google Scholar

Google Scholar

[11] Zhang Y Y, Xia H M, Wu J W, Zhang J, Wang Z P 2019 Appl. Phys. Lett. 114 073701

Google Scholar

Google Scholar

[12] Zhang Y Y, Xia H M 2022 Sens. Actuators, B 368 132183

Google Scholar

Google Scholar

[13] Dreyfus R, Tabeling P, Willaime H 2003 Phys. Rev. Lett. 90 144505

Google Scholar

Google Scholar

[14] Tan Y C, Cristini V, Lee A P 2006 Sens. Actuators, B 114 350

Google Scholar

Google Scholar

[15] Chae S K, Lee C H, Lee S H, Kim T S, Kang J Y 2009 Lab Chip 9 1957

Google Scholar

Google Scholar

[16] Nisisako T, Hatsuzawa T 2010 Microfluid. Nanofluid. 9 427

Google Scholar

Google Scholar

[17] Liu H, Zhang Y 2011 Commun. Comput. Phys. 9 1235

Google Scholar

Google Scholar

[18] Rostami B, Morini G L 2019 Exp. Therm. Fluid Sci. 103 191

Google Scholar

Google Scholar

[19] Yu W, Liu X, Zhao Y, Chen Y 2019 Chem. Eng. Sci. 203 259

Google Scholar

Google Scholar

[20] Nozaki Y, Yoon D H, Furuya M, Fujita H, Sekiguchi T, Shoji S 2021 Sens. Actuators, A 331 112917

Google Scholar

Google Scholar

[21] Liu Z, Ma Y, Wang X, Pang Y, Ren Y, Li D 2022 Exp. Therm. Fluid Sci. 139 110739

Google Scholar

Google Scholar

[22] Umbanhowar P B, Prasad V, Weitz D A 2000 Langmuir 16 347

Google Scholar

Google Scholar

[23] Utada A S, Lorenceau E, Link D R, Kaplan P D, Stone H A, Weitz D A 2005 Science 308 537

Google Scholar

Google Scholar

[24] Garstecki P, Fuerstman M J, Whitesides G M 2005 Phys. Rev. Lett. 94 234502

Google Scholar

Google Scholar

[25] Deng C, Wang H, Huang W, Cheng S 2017 Colloids Surf. , A 533 1

Google Scholar

Google Scholar

[26] 刘汉涛, 刘谋斌, 常建忠, 苏铁熊 2013 62 064705

Google Scholar

Google Scholar

Liu H T, Liu M B, Chang J Z, Su T X 2013 Acta Phys. Sin. 62 064705

Google Scholar

Google Scholar

[27] 梁宏, 柴振华, 施保昌 2016 65 204701

Google Scholar

Google Scholar

Liang H, Chai Z H, Shi B C 2016 Acta Phys. Sin. 65 204701

Google Scholar

Google Scholar

[28] 张晓林, 黄军杰 2023 72 024701

Google Scholar

Google Scholar

Zhang X L, Huang J J 2023 Acta Phys. Sin. 72 024701

Google Scholar

Google Scholar

[29] Wang W, Liu Z, Jin Y, Cheng Y 2011 Chem. Eng. J. 173 828

Google Scholar

Google Scholar

[30] Ngo I L, Dang T D, Byon C, Joo S W 2015 Biomicrofluidics 9 024107

Google Scholar

Google Scholar

[31] Liu H, Zhang Y 2011 Phys. Fluids 23 082101

Google Scholar

Google Scholar

[32] Boruah M P, Sarker A, Randive P R, Pati S, Sahu K C 2021 Phys. Fluids 33 122101

Google Scholar

Google Scholar

[33] Wang H, Yuan X, Liang H, Chai Z, Shi B 2019 Capillarity 2 32

[34] Niu X D, Li Y, Ma Y R, Chen M F, Li X, Li Q Z 2018 Phys. Fluids 30 013302

Google Scholar

Google Scholar

[35] Li X, Dong Z Q, Li Y, Wang L P, Niu X D, Yamaguchi H, Li D C, Yu P 2022 Int. J. Multiphase Flow 149 103982

Google Scholar

Google Scholar

[36] Li X, Yu P, Niu X D, Li D C, Yamaguchi H 2021 Appl. Math. Comput. 393 125769

[37] Qian Y H, Humières D D, Lallemand P 1992 Europhys. Lett. 17 479

Google Scholar

Google Scholar

[38] van der Graaf S, Nisisako T, Schroën C G P H, van der Sman R G M, Boom R M 2006 Langmuir 22 4144

Google Scholar

Google Scholar

[39] Ding H, Spelt P D M, Shu C 2007 J. Comput. Phys. 226 2078

Google Scholar

Google Scholar

[40] Liang H, Liu H, Chai Z, Shi B 2019 Phys. Rev. E 99 063306

Google Scholar

Google Scholar

[41] Shi Y, Tang G H, Xia H H 2014 Comput. Fluids 90 155

Google Scholar

Google Scholar

[42] Yue P, Feng J J, Liu C, Shen J 2004 J. Fluid Mech. 515 293

Google Scholar

Google Scholar

[43] Roths T, Friedrich C, Marth M, Honerkamp J 2002 Rheol. Acta 41 211

Google Scholar

Google Scholar

[44] Wang Y, Shu C, Huang H B, Teo C J 2015 J. Comput. Phys. 280 404

Google Scholar

Google Scholar

[45] Li X, Dong Z Q, Wang L P, Niu X D, Yamaguchi H, Li D C, Yu P 2023 Appl. Math. Modell. 117 219

Google Scholar

Google Scholar

-

-

[1] Zhu P, Wang L 2017 Lab Chip 17 34

Google Scholar

Google Scholar

[2] Cybulski O, Garstecki P, Grzybowski B A 2019 Nat. Phys. 15 706

Google Scholar

Google Scholar

[3] Chen P C, Wu M H, Wang Y N 2014 Microfluid. Nanofluid. 17 275

Google Scholar

Google Scholar

[4] Li X, Li D, Liu X, Chang H 2016 Sens. Actuators, B 229 466

Google Scholar

Google Scholar

[5] Theberge A B, Courtois F, Schaerli Y, Fischlechner M, Abell C, Hollfelder F, Huck W T S 2010 Angew. Chem. Int. Ed. 49 5846

Google Scholar

Google Scholar

[6] Teo A J T, Tan S H, Nguyen N T 2020 Anal. Chem. 92 1147

Google Scholar

Google Scholar

[7] Zhang Q, Li H, Zhu C, Fu T, Ma Y, Li H Z 2018 Colloids Surf. , A 537 572

Google Scholar

Google Scholar

[8] Jin S, Wei X, Liu Z, Ren J, Jiang Z, Abell C, Yu Z 2019 Sens. Actuators, B 291 1

[9] Zhang H, Palit P, Liu Y, Vaziri S, Sun Y 2020 ACS Appl. Mater. Interfaces 12 26936

Google Scholar

Google Scholar

[10] Thorsen T, Roberts R W, Arnold F H, Quake S R 2001 Phys. Rev. Lett. 86 4163

Google Scholar

Google Scholar

[11] Zhang Y Y, Xia H M, Wu J W, Zhang J, Wang Z P 2019 Appl. Phys. Lett. 114 073701

Google Scholar

Google Scholar

[12] Zhang Y Y, Xia H M 2022 Sens. Actuators, B 368 132183

Google Scholar

Google Scholar

[13] Dreyfus R, Tabeling P, Willaime H 2003 Phys. Rev. Lett. 90 144505

Google Scholar

Google Scholar

[14] Tan Y C, Cristini V, Lee A P 2006 Sens. Actuators, B 114 350

Google Scholar

Google Scholar

[15] Chae S K, Lee C H, Lee S H, Kim T S, Kang J Y 2009 Lab Chip 9 1957

Google Scholar

Google Scholar

[16] Nisisako T, Hatsuzawa T 2010 Microfluid. Nanofluid. 9 427

Google Scholar

Google Scholar

[17] Liu H, Zhang Y 2011 Commun. Comput. Phys. 9 1235

Google Scholar

Google Scholar

[18] Rostami B, Morini G L 2019 Exp. Therm. Fluid Sci. 103 191

Google Scholar

Google Scholar

[19] Yu W, Liu X, Zhao Y, Chen Y 2019 Chem. Eng. Sci. 203 259

Google Scholar

Google Scholar

[20] Nozaki Y, Yoon D H, Furuya M, Fujita H, Sekiguchi T, Shoji S 2021 Sens. Actuators, A 331 112917

Google Scholar

Google Scholar

[21] Liu Z, Ma Y, Wang X, Pang Y, Ren Y, Li D 2022 Exp. Therm. Fluid Sci. 139 110739

Google Scholar

Google Scholar

[22] Umbanhowar P B, Prasad V, Weitz D A 2000 Langmuir 16 347

Google Scholar

Google Scholar

[23] Utada A S, Lorenceau E, Link D R, Kaplan P D, Stone H A, Weitz D A 2005 Science 308 537

Google Scholar

Google Scholar

[24] Garstecki P, Fuerstman M J, Whitesides G M 2005 Phys. Rev. Lett. 94 234502

Google Scholar

Google Scholar

[25] Deng C, Wang H, Huang W, Cheng S 2017 Colloids Surf. , A 533 1

Google Scholar

Google Scholar

[26] 刘汉涛, 刘谋斌, 常建忠, 苏铁熊 2013 62 064705

Google Scholar

Google Scholar

Liu H T, Liu M B, Chang J Z, Su T X 2013 Acta Phys. Sin. 62 064705

Google Scholar

Google Scholar

[27] 梁宏, 柴振华, 施保昌 2016 65 204701

Google Scholar

Google Scholar

Liang H, Chai Z H, Shi B C 2016 Acta Phys. Sin. 65 204701

Google Scholar

Google Scholar

[28] 张晓林, 黄军杰 2023 72 024701

Google Scholar

Google Scholar

Zhang X L, Huang J J 2023 Acta Phys. Sin. 72 024701

Google Scholar

Google Scholar

[29] Wang W, Liu Z, Jin Y, Cheng Y 2011 Chem. Eng. J. 173 828

Google Scholar

Google Scholar

[30] Ngo I L, Dang T D, Byon C, Joo S W 2015 Biomicrofluidics 9 024107

Google Scholar

Google Scholar

[31] Liu H, Zhang Y 2011 Phys. Fluids 23 082101

Google Scholar

Google Scholar

[32] Boruah M P, Sarker A, Randive P R, Pati S, Sahu K C 2021 Phys. Fluids 33 122101

Google Scholar

Google Scholar

[33] Wang H, Yuan X, Liang H, Chai Z, Shi B 2019 Capillarity 2 32

[34] Niu X D, Li Y, Ma Y R, Chen M F, Li X, Li Q Z 2018 Phys. Fluids 30 013302

Google Scholar

Google Scholar

[35] Li X, Dong Z Q, Li Y, Wang L P, Niu X D, Yamaguchi H, Li D C, Yu P 2022 Int. J. Multiphase Flow 149 103982

Google Scholar

Google Scholar

[36] Li X, Yu P, Niu X D, Li D C, Yamaguchi H 2021 Appl. Math. Comput. 393 125769

[37] Qian Y H, Humières D D, Lallemand P 1992 Europhys. Lett. 17 479

Google Scholar

Google Scholar

[38] van der Graaf S, Nisisako T, Schroën C G P H, van der Sman R G M, Boom R M 2006 Langmuir 22 4144

Google Scholar

Google Scholar

[39] Ding H, Spelt P D M, Shu C 2007 J. Comput. Phys. 226 2078

Google Scholar

Google Scholar

[40] Liang H, Liu H, Chai Z, Shi B 2019 Phys. Rev. E 99 063306

Google Scholar

Google Scholar

[41] Shi Y, Tang G H, Xia H H 2014 Comput. Fluids 90 155

Google Scholar

Google Scholar

[42] Yue P, Feng J J, Liu C, Shen J 2004 J. Fluid Mech. 515 293

Google Scholar

Google Scholar

[43] Roths T, Friedrich C, Marth M, Honerkamp J 2002 Rheol. Acta 41 211

Google Scholar

Google Scholar

[44] Wang Y, Shu C, Huang H B, Teo C J 2015 J. Comput. Phys. 280 404

Google Scholar

Google Scholar

[45] Li X, Dong Z Q, Wang L P, Niu X D, Yamaguchi H, Li D C, Yu P 2023 Appl. Math. Modell. 117 219

Google Scholar

Google Scholar

计量

- 文章访问数: 506

- PDF下载量: 22

- 被引次数: 0

下载:

下载: