-

采用分子动力学的方法对纳米液滴撞击高温平板壁面产生的Leidenfrost现象进行了探究, 分析了液滴撞击不同温度壁面对Leidenfrost现象的影响. 结果表明, 随着壁面温度的提升, 液滴蒸发的速度更快, 脱离壁面的时刻越早, 脱离壁面时的速度也越大, 最终悬浮时液滴体积也越大. 通过分析脱离壁面前一时刻液滴内部的密度、温度分布发现, 由于高温壁面具有更高的热通量致使蒸发过程更快进而产生更厚的蒸气层, 该蒸气层将阻碍换热, 使得液滴在壁面温度更高时液滴内部的平均温度越低, 且平均密度越小.

-

关键词:

- 分子动力学 /

- 液滴 /

- Leidenfrost现象

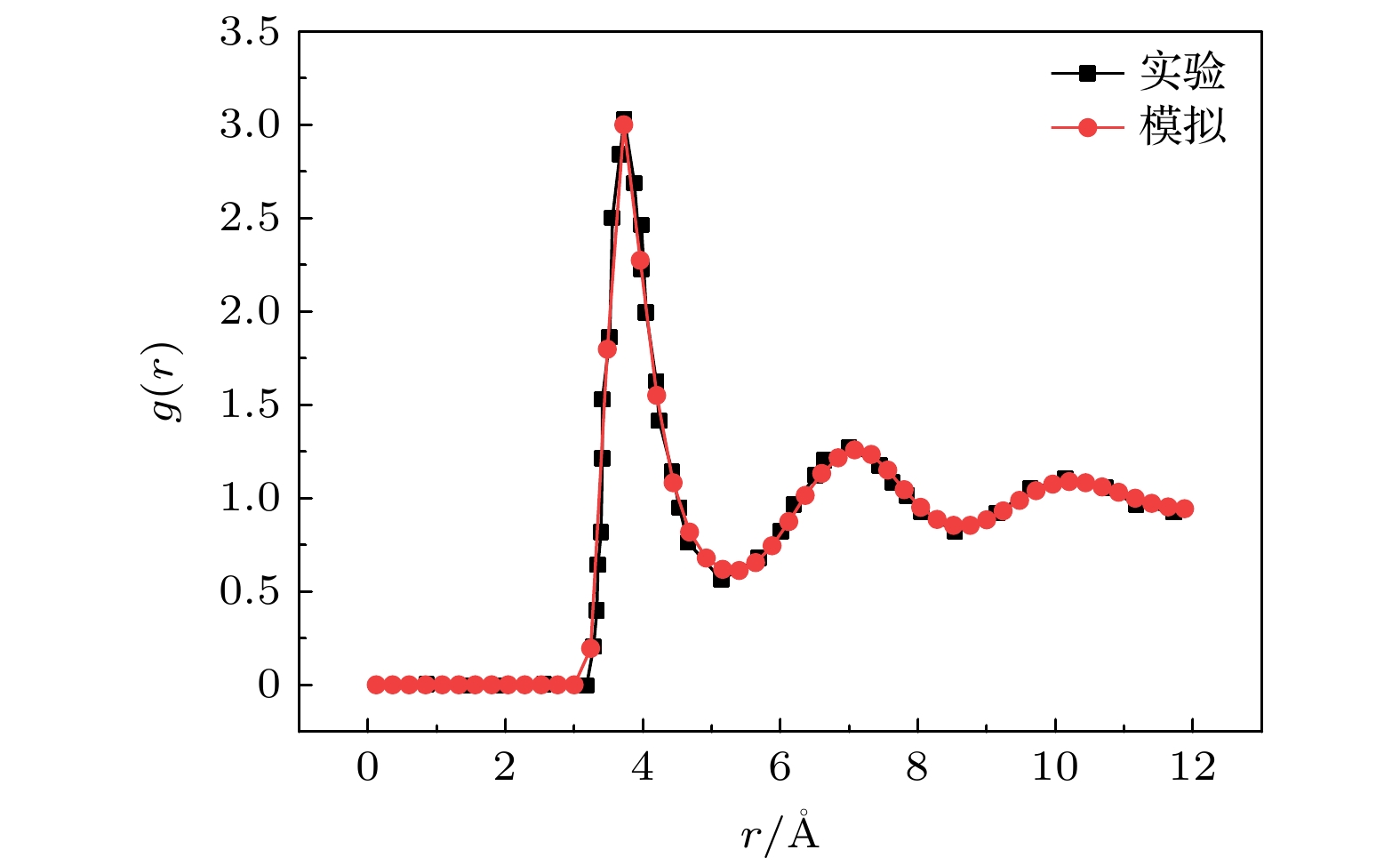

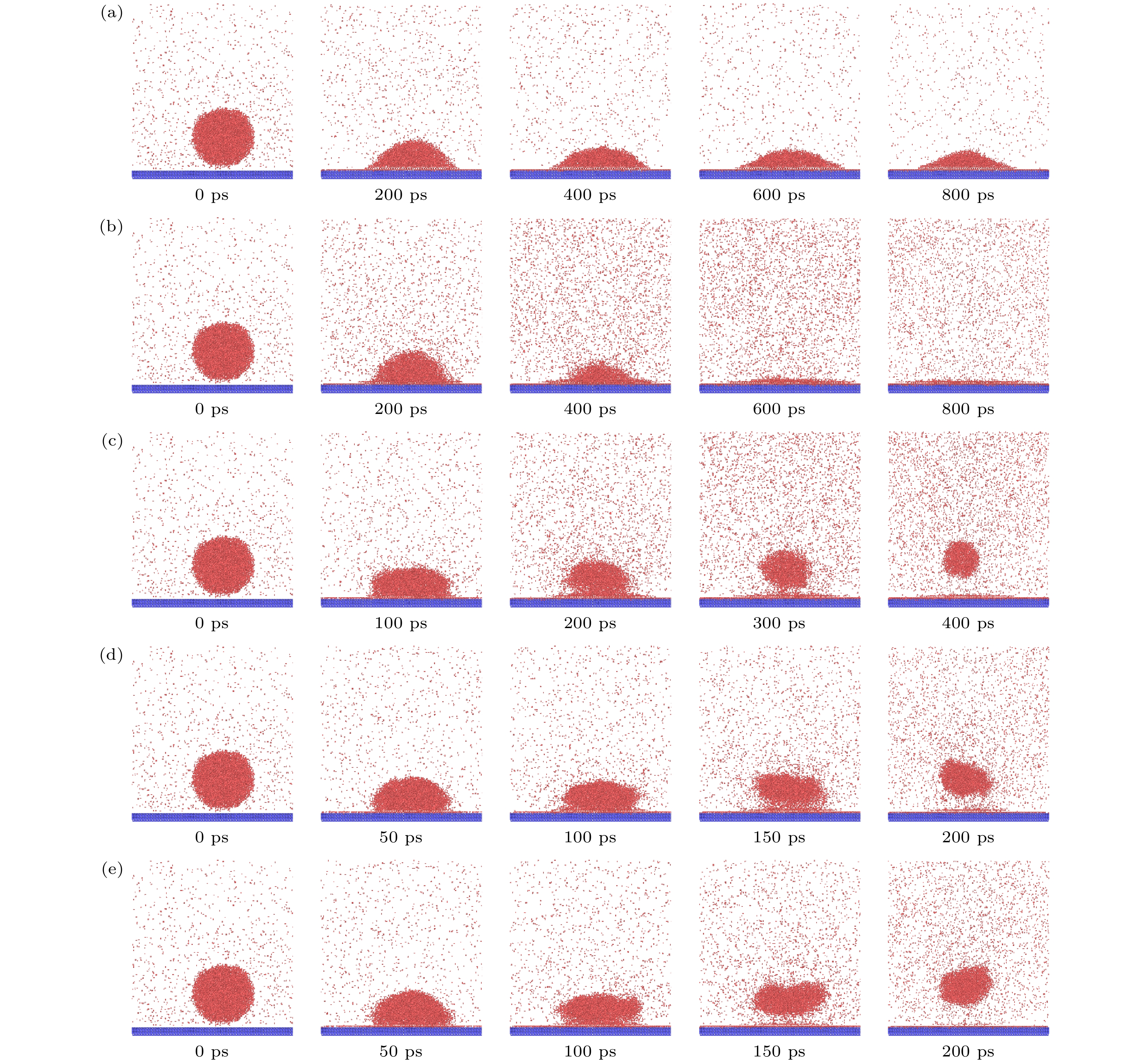

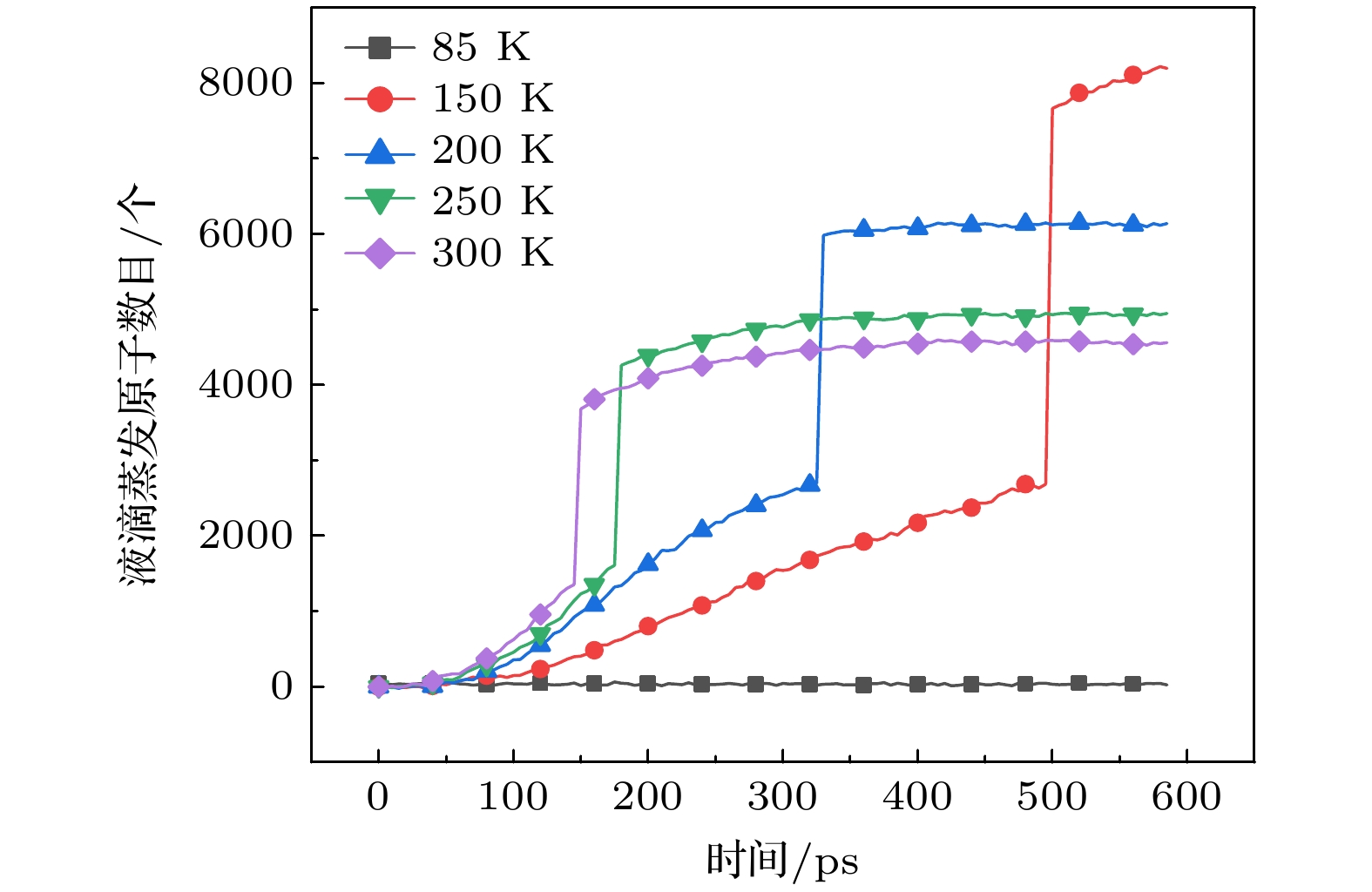

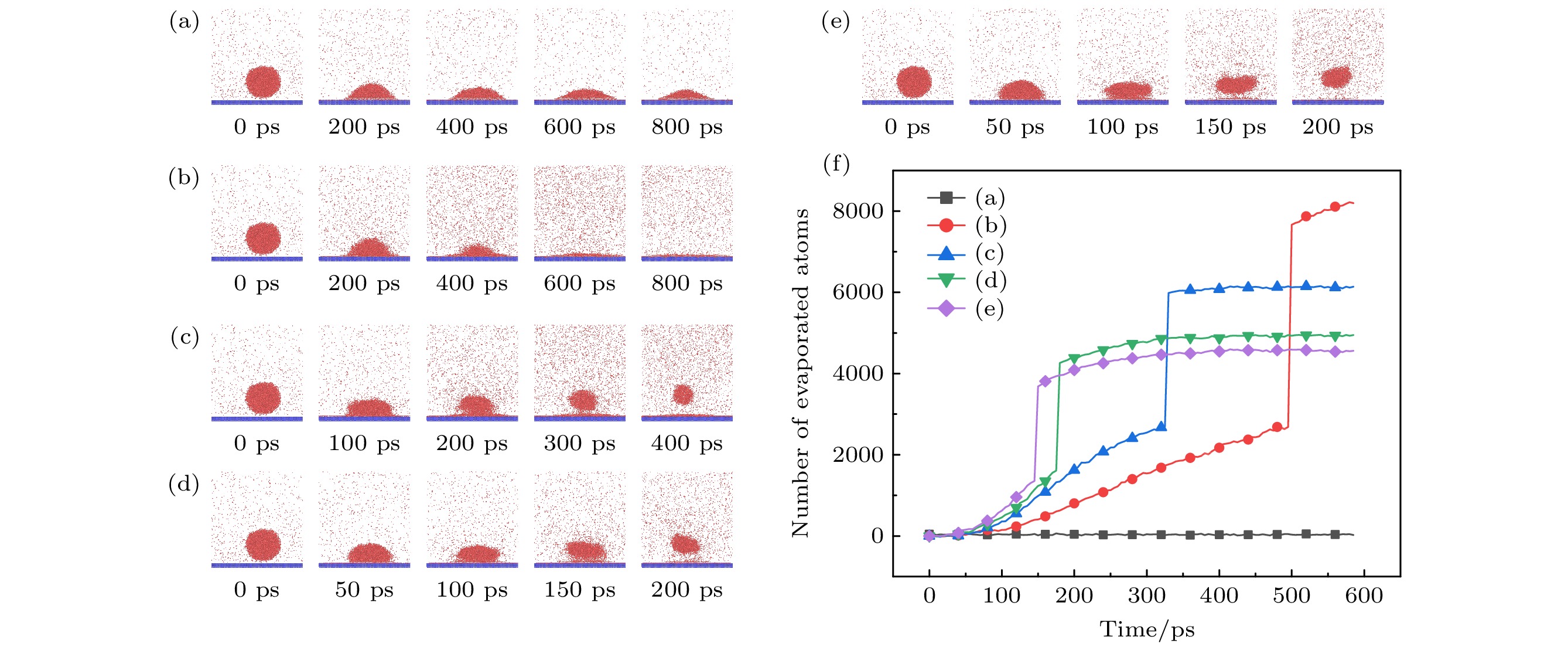

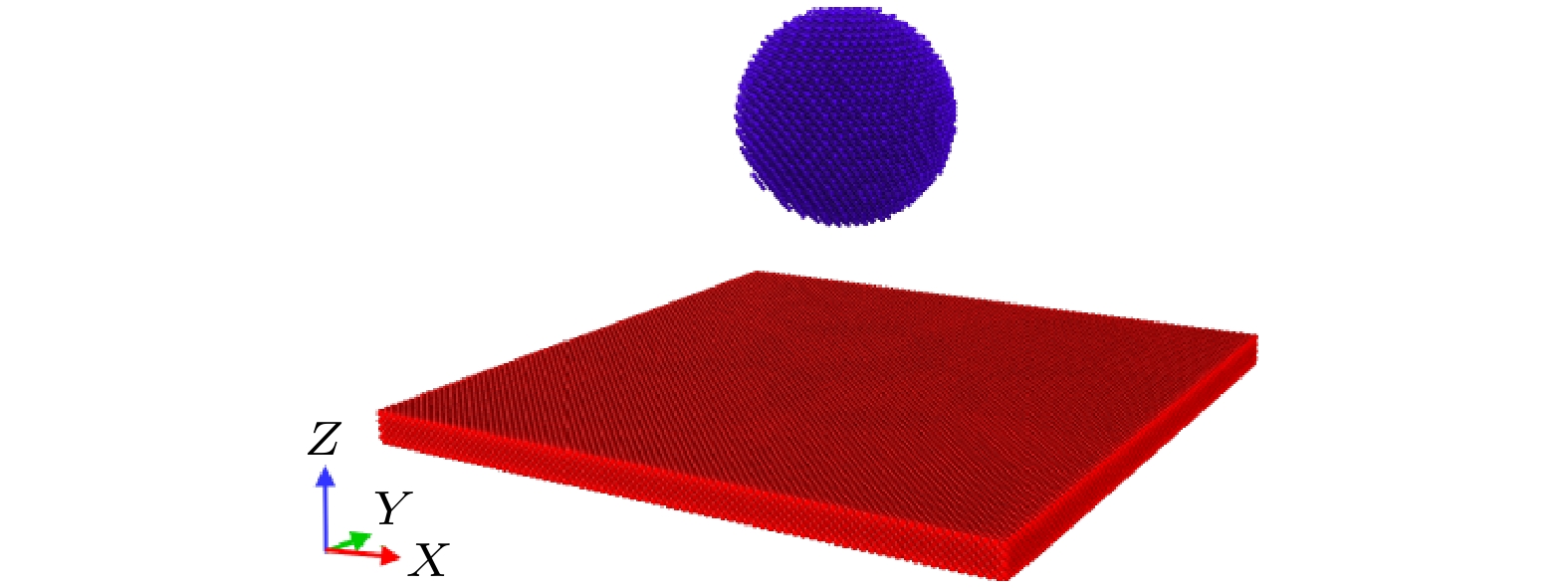

The process of droplet impacting on a high-temperature wall is widely existent in daily life and industrial applications. Most of scholars mainly have focused on experimental and macroscopic research on this phenomenon. In this work, molecular dynamics simulation is conducted to investigate the evolution of droplet and the influence of surface temperature on its evolution, in order to explore the heat transfer mechanism of nanodroplet impacting on high-temperature surface. Droplet containing 10741 argon atoms impacts on the copper plates at temperatures of 85, 150, 200, 250 and 300 K, respectively. The number of droplet evaporation atoms is statistically obtained, the droplet barycenter displacement is analyzed, and the density distribution and temperature distribution inside the droplet are acquired. It is shown that the droplet exhibits different characteristics on the wall at different temperatures. The droplet finally stabilizes on the wall at 85 K as shown in Fig. (a), but when the temperature of the wall rises to 150 K, the droplet evaporates slowly and finally completely as shown in Fig. (b), and for the wall temperatures 200, 250 and 300 K, the Leidenfrost phenomenon is found: the droplet is suspended above the wall as displayed in Figs. (c)–(e). Fig. (f) shows the number of evaporated atoms at different wall temperatures. It also can be seen that the Leidenfrost phenomenon occurs at wall temperatures 200, 250 and 300 K, because for the three conditions there are rise steps and then the numbers of evaporated atoms almost keep constant. For the temperature conditions under which the Leidenfrost phenomenon can occur, the higher the wall temperature, the faster the droplet evaporates, the earlier the detachment occurs from the wall, the greater the droplet detaching velocity, and the larger the final suspending droplet volume. The analyses of the density distribution and temperature distribution of the droplet at the moment when it detaches from the wall show that the evaporation process is faster and a thicker vapor layer is generated due to the higher heat flux of the high-temperature wall, which will hinder the heat exchange, so that the average temperature of the droplet is lower and the average density is smaller.-

Keywords:

- molecular dynamics /

- droplets /

- Leidenfrost phenomenon

[1] 沈胜强, 张洁珊, 梁刚涛 2015 64 134704

Google Scholar

Google Scholar

Shen S Q, Zhang J S, Liang G T 2015 Acta Phys. Sin. 64 134704

Google Scholar

Google Scholar

[2] Visaria M, Mudawar I 2009 IEEE Trans. Compon. Packaging Technol. 32 784

Google Scholar

Google Scholar

[3] Shen S Q, Liang G T, Guo Y L, Liu R, Mu X S 2013 Desalin. Water Treat. 51 830

Google Scholar

Google Scholar

[4] Moreira A L N, Moita A S, Panao M R 2010 Prog. Energy Combust. Sci. 36 54

Google Scholar

Google Scholar

[5] 刘晓华, 赵一鸣, 陈石, 沈胜强, 王斯琦 2017 热科学与技术 16 280

Google Scholar

Google Scholar

Lui X H, Zhao Y M, Chen S, Shen S Q, Wang S Q 2017 J. Therm. Sci. Technol. 16 280

Google Scholar

Google Scholar

[6] 刘晓华, 陈晗, 王开珉, 陈石, 沈胜强 2018 热科学与技术 17 464

Google Scholar

Google Scholar

Liu X H, Chen H, Wang K M, Chen S, Shen S Q 2018 J. Therm. Sci. Technol. 17 464

Google Scholar

Google Scholar

[7] 梁刚涛, 郭亚丽, 沈胜强 2013 62 184703

Google Scholar

Google Scholar

Liang G T, Guo Y L, Shen S Q 2013 Acta Phys. Sin. 62 184703

Google Scholar

Google Scholar

[8] 郭亚丽, 陈桂影, 沈胜强, 张京涛, 王明旭, 曹雪松, 郑周虎 2015 工程热 36 1547

Guo Y L, Chen G Y, Shen S Q, Zhang J T, Wang M X, Cao X S, Zheng Z H 2015 J. Eng. Thermophys. 36 1547

[9] Biance A L, Clanet C, Quéré D 2003 Phys. Fluids 15 1632

Google Scholar

Google Scholar

[10] 荣松, 沈世全, 王天友, 车志钊 2019 68 154701

Google Scholar

Google Scholar

Rong S, Shen S Q, Wang T Y, Che Z Z 2019 Acta Phys. Sin. 68 154701

Google Scholar

Google Scholar

[11] 蔡畅, 刘红, 奚溪, Issam Mudawar 2021 工程热 42 732

Cai C, Liu H, Xi X, Mudawar I 2021 J. Eng. Thermophys. 42 732

[12] 王均毅, 施红, 徐文冰, 胡亮春, 刘欢, 朱信龙 2020 航空计算技术 50 72

Wang J Y, Shi H, Xu W B, Hu L C, Liu H, Zhu X L 2020 Aeronaut. Comput. Tech. 50 72

[13] 张瑜, 宁智, 吕明, 孙春华 2017 燃烧科学与技术 23 451

Zhang Y, Ning Z, Lü M, Sun C H 2017 J. Combust. Sci. Technol. 23 451

[14] Rony M D, Islam M A, Thakur M S H, Islam M, Hasan M N 2023 Int. J. Heat Mass Transfer 209 124107

Google Scholar

Google Scholar

[15] Huang X N, Zhou L P, Du X Z 2023 J. Mol. Liq. 382 121982

Google Scholar

Google Scholar

[16] Biryukov D A, Gerasimov D N, Yurin E I 2020 J. Phys. Conf. Ser. 1683 022007

Google Scholar

Google Scholar

[17] Tuoliken A, Zhou L P, Bai P, Du X Z 2021 Int. J. Heat Mass Transfer. 172 121218

Google Scholar

Google Scholar

[18] Feng R T, Zhao W J, Wu X D, Xue Q J 2012 J. Colloid Interface Sci. 367 450

Google Scholar

Google Scholar

[19] Hashmi A, Xu Y H, Coder B, Osborne P A, Spafford J, Michael G E, Yu G, Xu J 2012 Sci. Rep. 2 797

Google Scholar

Google Scholar

[20] Wells G G, Ledesmaaguilar R, Mchale G, Sefiane K 2015 Nat. Commun. 6 6390

Google Scholar

Google Scholar

[21] Yarnell J L, Katz M J, Wenzel R G, Koenig S H 1973 Phys. Rev. A 7 2130

Google Scholar

Google Scholar

[22] MullerPlathe F 1997 J. Chem. Phys. 106 6082

Google Scholar

Google Scholar

[23] Haile J M 1997 Molecular Dynamics Simulation: Elementary Methods (New York: Wiley-Interscience) p489

[24] 王甜 2015 硕士学位论文 (大连: 大连理工大学)

Wang T 2015 M. S. Thesis (Dalian: Dalian University of Technology

-

表 1 Lennard-Jones (12-6)各原子模拟参数

Table 1. Lennard-Jones (12-6) atomic simulation parameters.

ε/eV σ/Å rc/Å Cu 0.52031 2.29726 12 Ar 0.0104 3.405 12 Cu—Ar 0.07356 2.85113 12 表 2 物性参数对比

Table 2. Comparison of physical property parameters.

本文模拟 实验测量 误差 导热系数/(W⋅m–1·K–1) 0.128 0.132 3.03% 黏度/(10–4 Pa–1·s–1) 2.92 2.8 –4.28% 表 3 不同壁面温度下蒸气层厚度、液滴厚度以及液滴平均密度的统计

Table 3. Statistics of vapor layer thickness, droplet thickness and average droplet density at different wall temperatures.

壁面

温度/K蒸气层

厚度/Å液滴

厚度/Å液滴密度/

(g⋅cm–3)150 0 10 0.95 200 14 50 1.15 250 19 35 1.21 300 23 24 1.29 表 4 不同壁面温度下液滴平均温度、上下温差以及温度梯度

Table 4. Average droplet temperature, the temperature difference between upper and lower temperatures, and the temperature gradient at different wall temperatures.

壁面温度/K 平均温度/K 液滴上下

温差/K温度梯度/

(K·Å–1)150 140 5 0.5 200 121 33 0.65 250 107 41 1.17 300 98 47 1.95 -

[1] 沈胜强, 张洁珊, 梁刚涛 2015 64 134704

Google Scholar

Google Scholar

Shen S Q, Zhang J S, Liang G T 2015 Acta Phys. Sin. 64 134704

Google Scholar

Google Scholar

[2] Visaria M, Mudawar I 2009 IEEE Trans. Compon. Packaging Technol. 32 784

Google Scholar

Google Scholar

[3] Shen S Q, Liang G T, Guo Y L, Liu R, Mu X S 2013 Desalin. Water Treat. 51 830

Google Scholar

Google Scholar

[4] Moreira A L N, Moita A S, Panao M R 2010 Prog. Energy Combust. Sci. 36 54

Google Scholar

Google Scholar

[5] 刘晓华, 赵一鸣, 陈石, 沈胜强, 王斯琦 2017 热科学与技术 16 280

Google Scholar

Google Scholar

Lui X H, Zhao Y M, Chen S, Shen S Q, Wang S Q 2017 J. Therm. Sci. Technol. 16 280

Google Scholar

Google Scholar

[6] 刘晓华, 陈晗, 王开珉, 陈石, 沈胜强 2018 热科学与技术 17 464

Google Scholar

Google Scholar

Liu X H, Chen H, Wang K M, Chen S, Shen S Q 2018 J. Therm. Sci. Technol. 17 464

Google Scholar

Google Scholar

[7] 梁刚涛, 郭亚丽, 沈胜强 2013 62 184703

Google Scholar

Google Scholar

Liang G T, Guo Y L, Shen S Q 2013 Acta Phys. Sin. 62 184703

Google Scholar

Google Scholar

[8] 郭亚丽, 陈桂影, 沈胜强, 张京涛, 王明旭, 曹雪松, 郑周虎 2015 工程热 36 1547

Guo Y L, Chen G Y, Shen S Q, Zhang J T, Wang M X, Cao X S, Zheng Z H 2015 J. Eng. Thermophys. 36 1547

[9] Biance A L, Clanet C, Quéré D 2003 Phys. Fluids 15 1632

Google Scholar

Google Scholar

[10] 荣松, 沈世全, 王天友, 车志钊 2019 68 154701

Google Scholar

Google Scholar

Rong S, Shen S Q, Wang T Y, Che Z Z 2019 Acta Phys. Sin. 68 154701

Google Scholar

Google Scholar

[11] 蔡畅, 刘红, 奚溪, Issam Mudawar 2021 工程热 42 732

Cai C, Liu H, Xi X, Mudawar I 2021 J. Eng. Thermophys. 42 732

[12] 王均毅, 施红, 徐文冰, 胡亮春, 刘欢, 朱信龙 2020 航空计算技术 50 72

Wang J Y, Shi H, Xu W B, Hu L C, Liu H, Zhu X L 2020 Aeronaut. Comput. Tech. 50 72

[13] 张瑜, 宁智, 吕明, 孙春华 2017 燃烧科学与技术 23 451

Zhang Y, Ning Z, Lü M, Sun C H 2017 J. Combust. Sci. Technol. 23 451

[14] Rony M D, Islam M A, Thakur M S H, Islam M, Hasan M N 2023 Int. J. Heat Mass Transfer 209 124107

Google Scholar

Google Scholar

[15] Huang X N, Zhou L P, Du X Z 2023 J. Mol. Liq. 382 121982

Google Scholar

Google Scholar

[16] Biryukov D A, Gerasimov D N, Yurin E I 2020 J. Phys. Conf. Ser. 1683 022007

Google Scholar

Google Scholar

[17] Tuoliken A, Zhou L P, Bai P, Du X Z 2021 Int. J. Heat Mass Transfer. 172 121218

Google Scholar

Google Scholar

[18] Feng R T, Zhao W J, Wu X D, Xue Q J 2012 J. Colloid Interface Sci. 367 450

Google Scholar

Google Scholar

[19] Hashmi A, Xu Y H, Coder B, Osborne P A, Spafford J, Michael G E, Yu G, Xu J 2012 Sci. Rep. 2 797

Google Scholar

Google Scholar

[20] Wells G G, Ledesmaaguilar R, Mchale G, Sefiane K 2015 Nat. Commun. 6 6390

Google Scholar

Google Scholar

[21] Yarnell J L, Katz M J, Wenzel R G, Koenig S H 1973 Phys. Rev. A 7 2130

Google Scholar

Google Scholar

[22] MullerPlathe F 1997 J. Chem. Phys. 106 6082

Google Scholar

Google Scholar

[23] Haile J M 1997 Molecular Dynamics Simulation: Elementary Methods (New York: Wiley-Interscience) p489

[24] 王甜 2015 硕士学位论文 (大连: 大连理工大学)

Wang T 2015 M. S. Thesis (Dalian: Dalian University of Technology

计量

- 文章访问数: 2852

- PDF下载量: 91

- 被引次数: 0

下载:

下载: