-

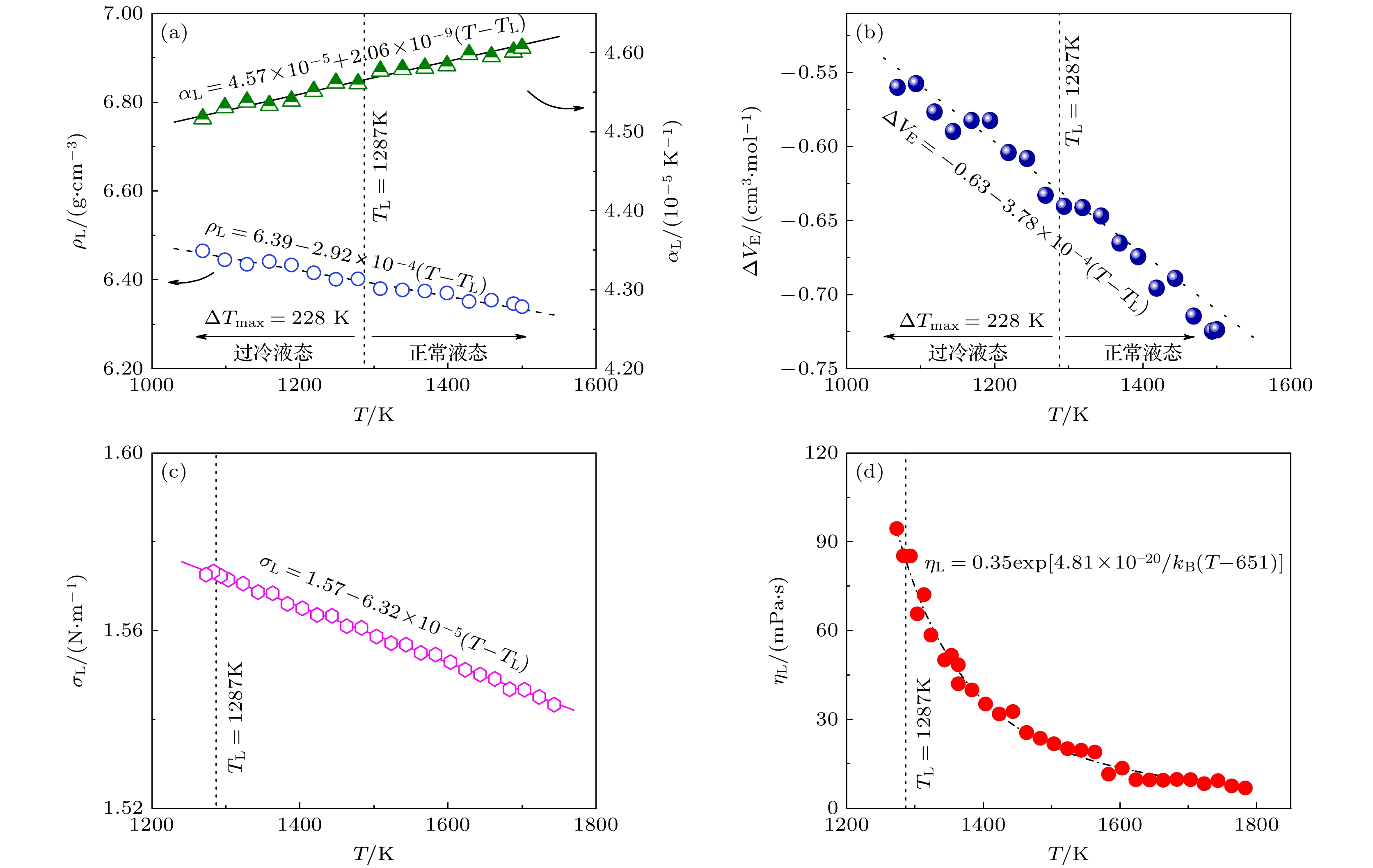

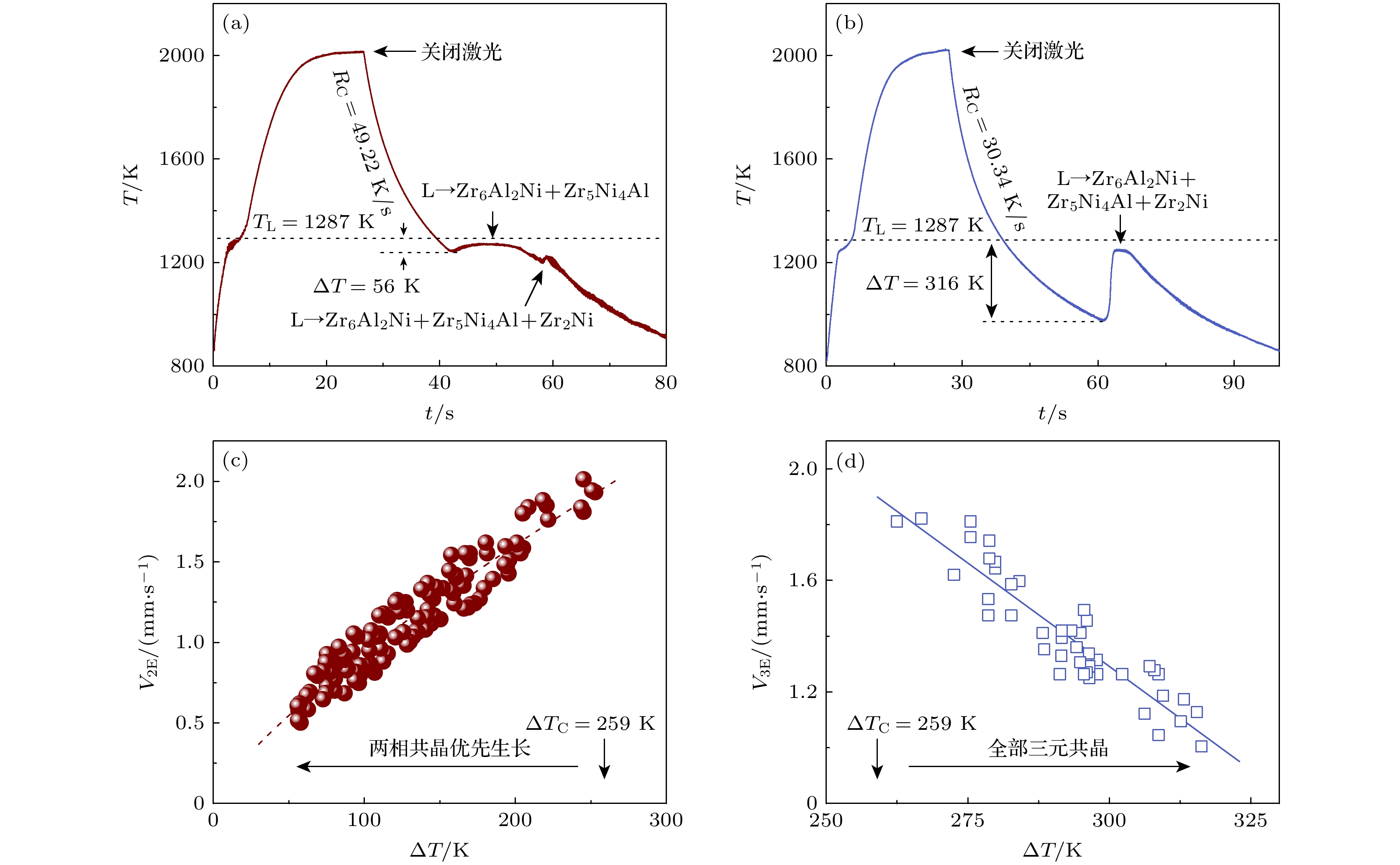

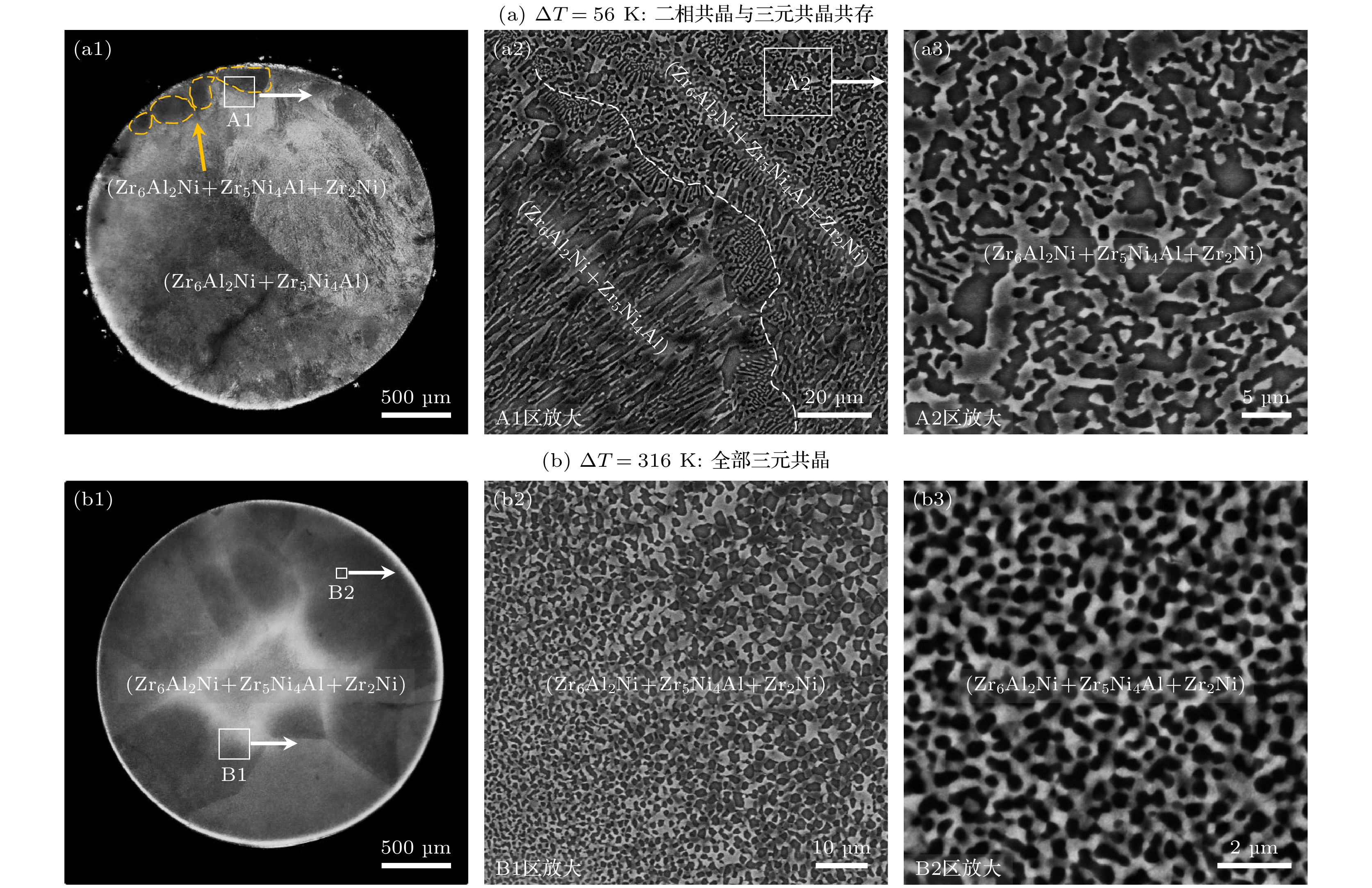

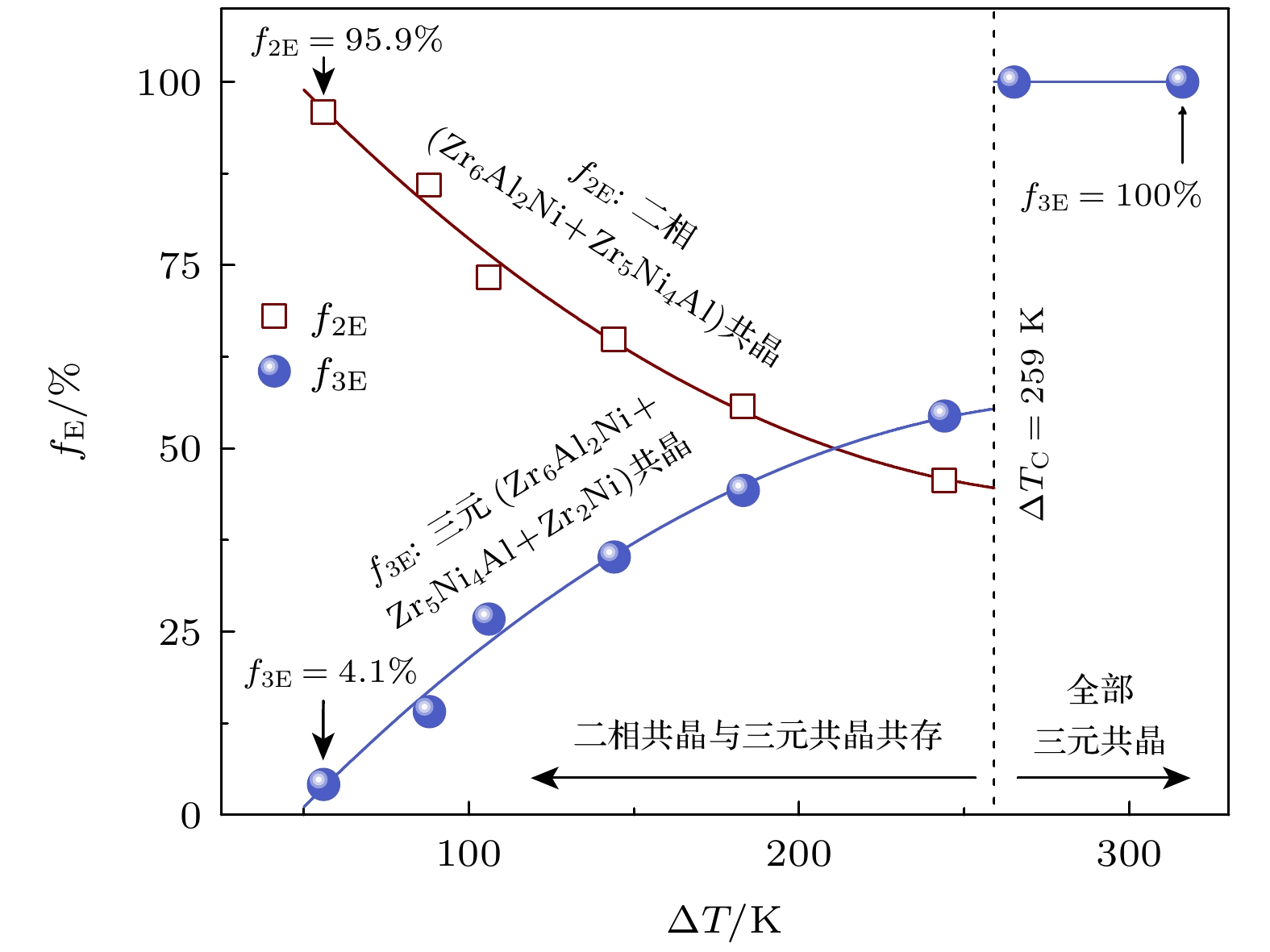

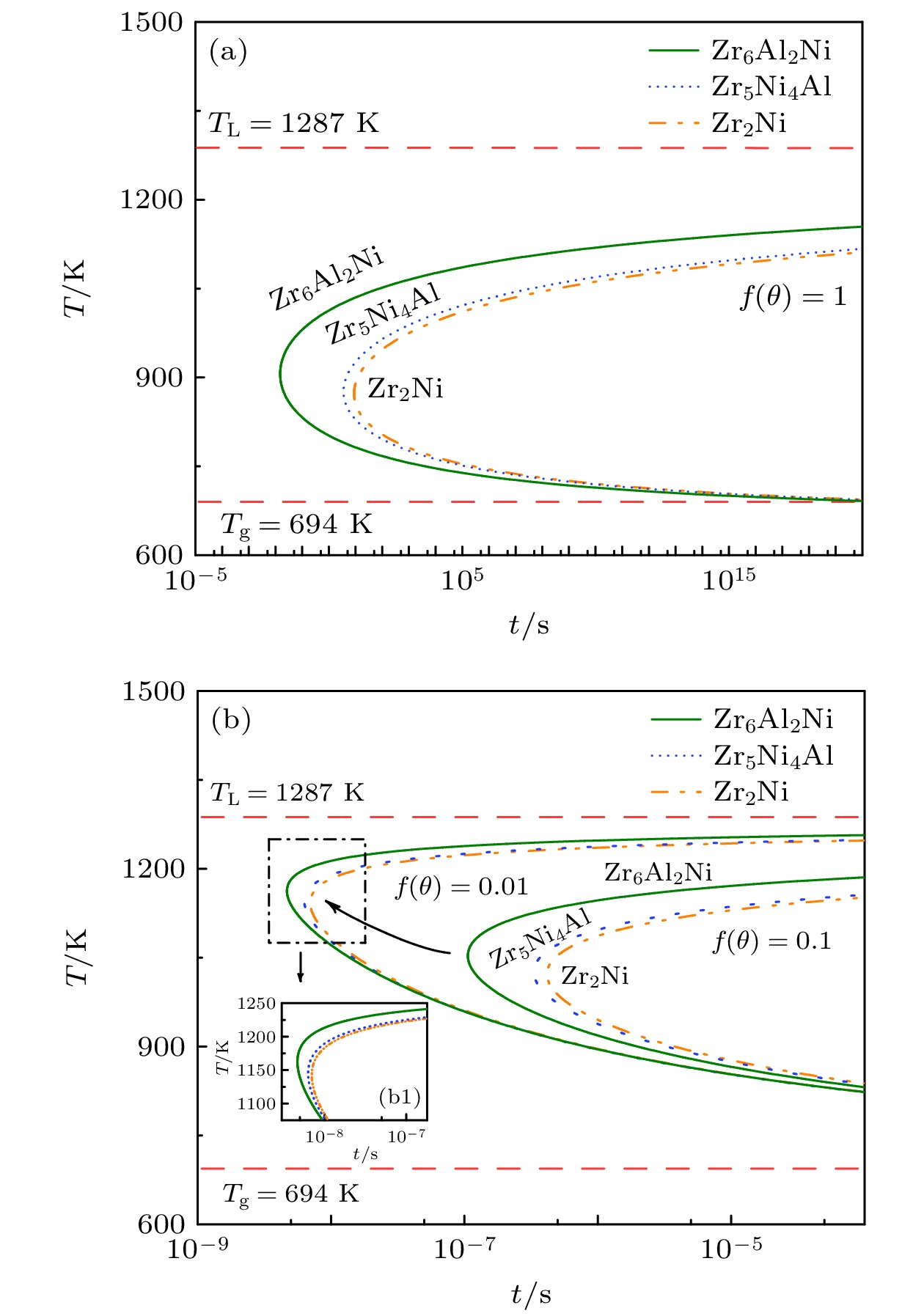

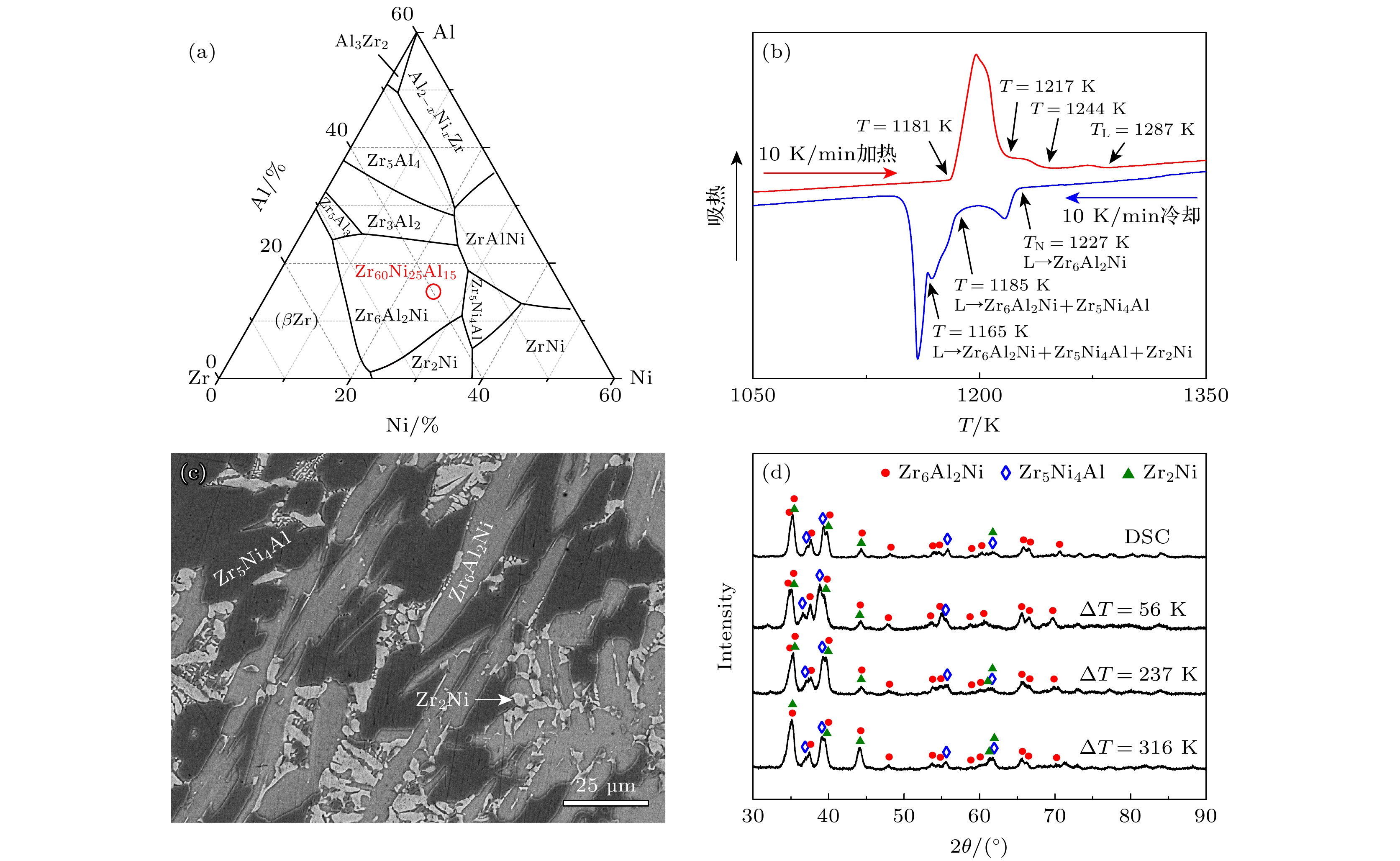

采用静电悬浮实验技术测定了液态Zr60Ni25Al15合金的热物理性质, 并研究了其深过冷快速凝固过程. 实验发现, 液态合金所获得的最大过冷度可达316 K (0.25TL), 其密度和表面张力与温度呈线性关系, 而黏度则随温度呈指数变化. 当过冷度小于259 K时, 凝固过程中发生两次再辉现象, 分别对应着二相(Zr6Al2Ni + Zr5Ni4Al)共晶和三元(Zr6Al2Ni + Zr5Ni4Al + Zr2Ni)共晶的快速生长. 若过冷度超过259 K, 凝固过程只发生一次再辉, 3个化合物相均可从合金熔体中独立形核, 形成三元不规则共晶组织. 理论计算和实验表明, 小过冷时Zr6Al2Ni相优先形核, 而当过冷度足够大时, 三相能够同时形核.In this study, the thermophysical properties and rapid solidification mechanism of highly undercooled liquid Zr60Ni25Al15 alloy are investigated through the electrostatic levitation technique. The maximum undercooling of this alloy reaches 316 K (0.25TL). Both density and surface tension display a linear relationship with temperature, while viscosity is related to temperature exponentially. When alloy undercooling is less than 259 K, two significant recalescence events are observed during solidification, corresponding to the formation of pseudobinary (Zr6Al2Ni + Zr5Ni4Al) eutectic and ternary (Zr6Al2Ni + Zr5Ni4Al + Zr2Ni) eutectic. The growth velocity of the binary eutectic phase gradually increases with further undercooling and reaches a maximum undercooling value of 259 K. In contrast, once undercooling exceeds 259 K, a single recalescence event occurs, leading to the independent nucleation of all three compound phases from alloy melt and the rapid growth of a ternary anomalous eutectic structure. Notably, the growth velocity of the ternary eutectic phase exhibits a gradual decline with further undercooling. This diminishing trend of the growth velocity suggests that further undercooling might entirely suppress crystal growth dynamically at a threshold of 385 K. With classical nucleation theory and the Kolmogorov-Johnson-Mehl-Avrami (KJMA) model, the onsets of crystallization for the three phases are calculated, thereby constructing a time–temperature-transformation (TTT) diagram. This diagram elucidates the competitive nucleation among the three phases in the undercooled melt. Both theoretical and experimental evidence reveal that Zr6Al2Ni phase is primarily nucleated at lower undercooling levels, whereas under higher cooling condition, it is possible for all three phases to nucleate simultaneously.

-

Keywords:

- electrostatic levitation /

- liquid metal /

- rapid solidification /

- eutectic growth

[1] Peng H L, Yang F, Liu S T, Holland-Moritz D, Kordel T, Hansen T, Voigtmann T 2019 Phys. Rev. B 100 104202

Google Scholar

Google Scholar

[2] 饶中浩, 汪双凤, 张艳来, 彭飞飞, 蔡颂恒 2013 62 056601

Google Scholar

Google Scholar

Rao Z H, Wang S F, Zhang Y L, Peng F F, Cai S H 2013 Acta Phys. Sin. 62 056601

Google Scholar

Google Scholar

[3] Yuan C C, Yang F, Kargl F, Holland-Moritz D, Simeoni G G, Meyer A 2015 Phys. Rev. B 91 214203

Google Scholar

Google Scholar

[4] Hou J X, Guo H X, Sun J J, Tian X L, Zhan C W, Qin X B, Chen X C 2006 Phys. Lett. A 358 171

Google Scholar

Google Scholar

[5] Shen Y T, Kim T H, Gangopadhyay A K, Kelton K F 2009 Phys. Rev. Lett. 102 057801

Google Scholar

Google Scholar

[6] 林茂杰, 常健, 吴宇昊, 徐山森, 魏炳波 2017 66 136401

Google Scholar

Google Scholar

Lin M J, Chang J, Wu Y H, Xu S S, Wei B B 2017 Acta Phys. Sin. 66 136401

Google Scholar

Google Scholar

[7] Brillo J, Pommrich A I, Meyer A 2011 Phys. Rev. Lett. 107 165902

Google Scholar

Google Scholar

[8] Su Y, Mohr M, Wunderlich R K, Wang X D, Cao Q P, Zhang D X, Yang Y, Fecht H J, Jiang J Z 2020 J. Mol. Liq. 298 111992

Google Scholar

Google Scholar

[9] Johnson M L, Mauro N A, Vogt A J, Blodgett M E, Pueblo C, Kelton K F 2014 J. Non-Cryst. Solids. 405 211

Google Scholar

Google Scholar

[10] Rodriguez J E, Kreischer C, Volkmann T, Matson D M 2017 Acta Mater. 122 431

Google Scholar

Google Scholar

[11] Li Y H, Zhang W, Dong C, Qiang J B, Makino A, Inoue A 2010 Intermetallics 18 1851

Google Scholar

Google Scholar

[12] Jiang Q K, Wang X D, Nie X P, Zhang G Q, Ma H, Fecht H J, Bendnarcil J 2008 Acta Mater. 56 1785

Google Scholar

Google Scholar

[13] Hua N B, Zhang T 2014 J. Alloys Compd. 602 339

[14] Li C F, Saida J, Matsushida M, Inoue A 2000 Mater. Lett. 44 80

Google Scholar

Google Scholar

[15] Basuki S W, Yang F, Gill E, Rätzke K, Meyer A, Faupel F 2017 Phys. Rev. B 95 024301

Google Scholar

Google Scholar

[16] Li Y, Xu J 2017 Corros. Sci. 128 73

Google Scholar

Google Scholar

[17] Hu L, Wang H P, Li L H, Wei B 2012 Chin. Phys. Lett. 29 064101

Google Scholar

Google Scholar

[18] Ishikawa T, Paradis P F, Yoda S 2001 Rev. Sci. Instrum. 72 2490

Google Scholar

Google Scholar

[19] Chung S K, Thiessen D B, Rhim W K 1996 Rev. Sci. Instrum. 67 3175

Google Scholar

Google Scholar

[20] Jeon S, Kang D H, Lee Y H, Lee S, Lee G W 2016 J. Chem. Phys. 145 174504

Google Scholar

Google Scholar

[21] Takeuchi A, Kato H, Inoue A 2010 Intermetallics 18 406

Google Scholar

Google Scholar

[22] 王磊, 胡亮, 杨尚京, 魏炳波 2018 中国有色金属学报 28 1816

Google Scholar

Google Scholar

Wang L, Hu L, Yang S J, Wei B 2018 Chin. J. Nonferrous Met. 28 1816

Google Scholar

Google Scholar

[23] Mukherjee S, Schroers J, Johnson W L, Rhim W K 2005 Phys. Rev. Lett. 94 245501

Google Scholar

Google Scholar

[24] Wu Y H, Chang J, Wang W L, Wei B 2016 Appl. Phys. Lett. 109 154101

Google Scholar

Google Scholar

[25] Galenko P K, Wonneberger R, Koch S, Ankudinov V, Kharanzhevskiy E, Rettenmayr M 2020 J. Cryst. Growth. 532 125411

Google Scholar

Google Scholar

[26] Fuss T, Ray C S, Lesher C E, Day D E 2006 J. Non-Cryst. Solids 352 2073

Google Scholar

Google Scholar

[27] Fokin V M, Nascimento M, Zanotto E D 2005 J. Non-Cryst. Solids 351 789

Google Scholar

Google Scholar

[28] Torrens-Serra J, Rodríguez-Viejo J, Clavaguera-Mora M T 2007 Phys. Rev. B 76 214111

Google Scholar

Google Scholar

[29] Uhlmann D R 1977 J. Non-Cryst. Solids 25 42

Google Scholar

Google Scholar

[30] Zhao J F, Li M X, H. Wang H P, Wei B 2022 Acta Mater. 237 118127

Google Scholar

Google Scholar

[31] Alford T L, Gale W F, Totemeir T C 2015 Smithells Metals Reference Book (Elsevier) p8

[32] Vinet B, Magnusson L, Fredriksson H, Desré P J 2002 J. Colloid Interface Sci. 255 363

Google Scholar

Google Scholar

[33] Maiorova A V, Kulikova T V, Ryltsev R E 2021 Philos. Mag. 101 1709

Google Scholar

Google Scholar

-

图 3 静电悬浮条件下液态Zr60Ni25Al15合金的凝固过程温度曲线分析 (a) ΔT = 56 K; (b) ΔT = 316 K; (c) 二相共晶生长速度和过冷度的关系, ΔT < ΔTC = 259 K; (d) 三元共晶生长速度和过冷度的关系, $ \Delta T \geqslant \Delta {T_{\text{C}}} = 259{\text{ K}} $

Fig. 3. Solidification characteristics of Zr60Ni25Al15 alloy under electrostatic levitation condition: (a) ΔT = 56 K; (b) ΔT = 316 K; (c) binary eutectic growth velocity versus undercooling, ΔT < ΔTC = 259 K; (d) ternary eutectic growth velocity versus undercooling, ΔT ≥ ΔTC = 259 K

表 1 计算形核C曲线用物性参数

Table 1. Physical parameters used in calculations of time-temperature-transformation curves.

-

[1] Peng H L, Yang F, Liu S T, Holland-Moritz D, Kordel T, Hansen T, Voigtmann T 2019 Phys. Rev. B 100 104202

Google Scholar

Google Scholar

[2] 饶中浩, 汪双凤, 张艳来, 彭飞飞, 蔡颂恒 2013 62 056601

Google Scholar

Google Scholar

Rao Z H, Wang S F, Zhang Y L, Peng F F, Cai S H 2013 Acta Phys. Sin. 62 056601

Google Scholar

Google Scholar

[3] Yuan C C, Yang F, Kargl F, Holland-Moritz D, Simeoni G G, Meyer A 2015 Phys. Rev. B 91 214203

Google Scholar

Google Scholar

[4] Hou J X, Guo H X, Sun J J, Tian X L, Zhan C W, Qin X B, Chen X C 2006 Phys. Lett. A 358 171

Google Scholar

Google Scholar

[5] Shen Y T, Kim T H, Gangopadhyay A K, Kelton K F 2009 Phys. Rev. Lett. 102 057801

Google Scholar

Google Scholar

[6] 林茂杰, 常健, 吴宇昊, 徐山森, 魏炳波 2017 66 136401

Google Scholar

Google Scholar

Lin M J, Chang J, Wu Y H, Xu S S, Wei B B 2017 Acta Phys. Sin. 66 136401

Google Scholar

Google Scholar

[7] Brillo J, Pommrich A I, Meyer A 2011 Phys. Rev. Lett. 107 165902

Google Scholar

Google Scholar

[8] Su Y, Mohr M, Wunderlich R K, Wang X D, Cao Q P, Zhang D X, Yang Y, Fecht H J, Jiang J Z 2020 J. Mol. Liq. 298 111992

Google Scholar

Google Scholar

[9] Johnson M L, Mauro N A, Vogt A J, Blodgett M E, Pueblo C, Kelton K F 2014 J. Non-Cryst. Solids. 405 211

Google Scholar

Google Scholar

[10] Rodriguez J E, Kreischer C, Volkmann T, Matson D M 2017 Acta Mater. 122 431

Google Scholar

Google Scholar

[11] Li Y H, Zhang W, Dong C, Qiang J B, Makino A, Inoue A 2010 Intermetallics 18 1851

Google Scholar

Google Scholar

[12] Jiang Q K, Wang X D, Nie X P, Zhang G Q, Ma H, Fecht H J, Bendnarcil J 2008 Acta Mater. 56 1785

Google Scholar

Google Scholar

[13] Hua N B, Zhang T 2014 J. Alloys Compd. 602 339

[14] Li C F, Saida J, Matsushida M, Inoue A 2000 Mater. Lett. 44 80

Google Scholar

Google Scholar

[15] Basuki S W, Yang F, Gill E, Rätzke K, Meyer A, Faupel F 2017 Phys. Rev. B 95 024301

Google Scholar

Google Scholar

[16] Li Y, Xu J 2017 Corros. Sci. 128 73

Google Scholar

Google Scholar

[17] Hu L, Wang H P, Li L H, Wei B 2012 Chin. Phys. Lett. 29 064101

Google Scholar

Google Scholar

[18] Ishikawa T, Paradis P F, Yoda S 2001 Rev. Sci. Instrum. 72 2490

Google Scholar

Google Scholar

[19] Chung S K, Thiessen D B, Rhim W K 1996 Rev. Sci. Instrum. 67 3175

Google Scholar

Google Scholar

[20] Jeon S, Kang D H, Lee Y H, Lee S, Lee G W 2016 J. Chem. Phys. 145 174504

Google Scholar

Google Scholar

[21] Takeuchi A, Kato H, Inoue A 2010 Intermetallics 18 406

Google Scholar

Google Scholar

[22] 王磊, 胡亮, 杨尚京, 魏炳波 2018 中国有色金属学报 28 1816

Google Scholar

Google Scholar

Wang L, Hu L, Yang S J, Wei B 2018 Chin. J. Nonferrous Met. 28 1816

Google Scholar

Google Scholar

[23] Mukherjee S, Schroers J, Johnson W L, Rhim W K 2005 Phys. Rev. Lett. 94 245501

Google Scholar

Google Scholar

[24] Wu Y H, Chang J, Wang W L, Wei B 2016 Appl. Phys. Lett. 109 154101

Google Scholar

Google Scholar

[25] Galenko P K, Wonneberger R, Koch S, Ankudinov V, Kharanzhevskiy E, Rettenmayr M 2020 J. Cryst. Growth. 532 125411

Google Scholar

Google Scholar

[26] Fuss T, Ray C S, Lesher C E, Day D E 2006 J. Non-Cryst. Solids 352 2073

Google Scholar

Google Scholar

[27] Fokin V M, Nascimento M, Zanotto E D 2005 J. Non-Cryst. Solids 351 789

Google Scholar

Google Scholar

[28] Torrens-Serra J, Rodríguez-Viejo J, Clavaguera-Mora M T 2007 Phys. Rev. B 76 214111

Google Scholar

Google Scholar

[29] Uhlmann D R 1977 J. Non-Cryst. Solids 25 42

Google Scholar

Google Scholar

[30] Zhao J F, Li M X, H. Wang H P, Wei B 2022 Acta Mater. 237 118127

Google Scholar

Google Scholar

[31] Alford T L, Gale W F, Totemeir T C 2015 Smithells Metals Reference Book (Elsevier) p8

[32] Vinet B, Magnusson L, Fredriksson H, Desré P J 2002 J. Colloid Interface Sci. 255 363

Google Scholar

Google Scholar

[33] Maiorova A V, Kulikova T V, Ryltsev R E 2021 Philos. Mag. 101 1709

Google Scholar

Google Scholar

计量

- 文章访问数: 3360

- PDF下载量: 162

- 被引次数: 0

下载:

下载: