-

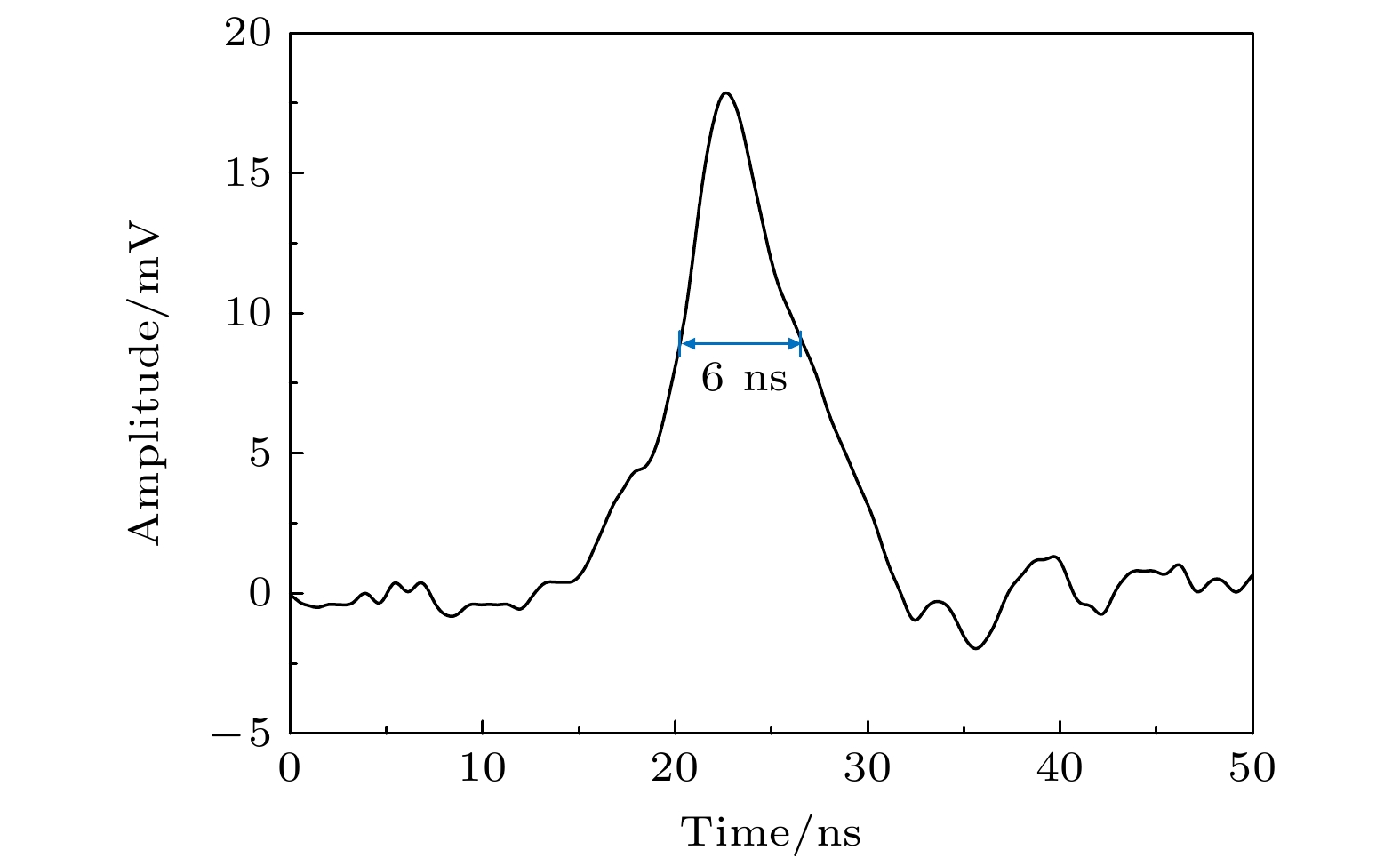

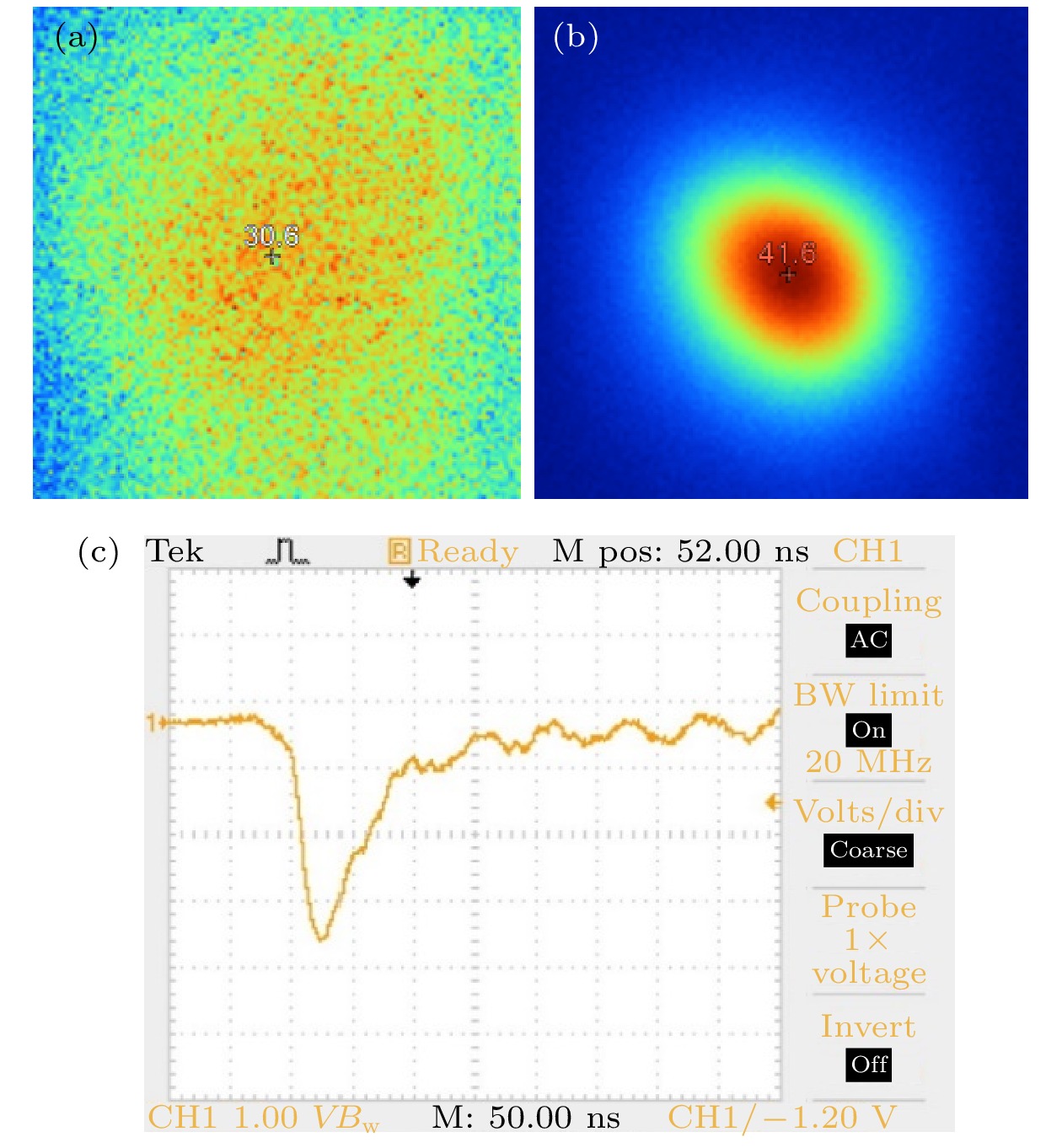

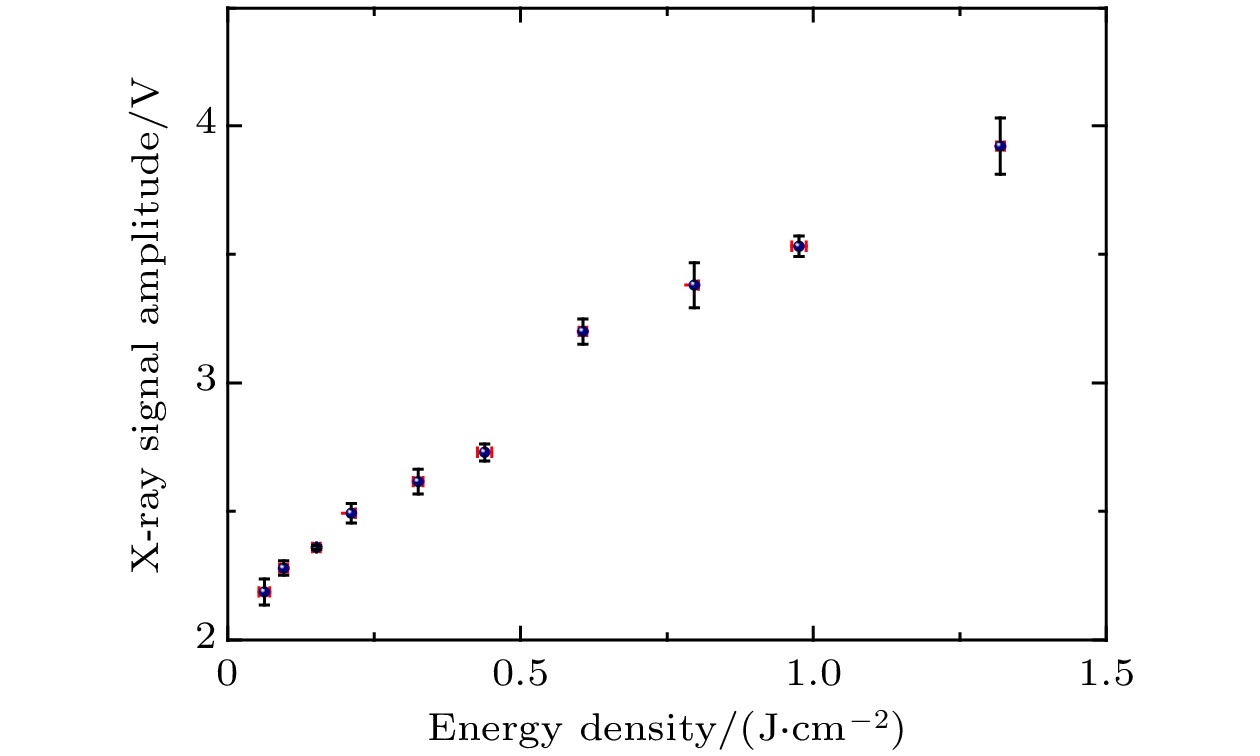

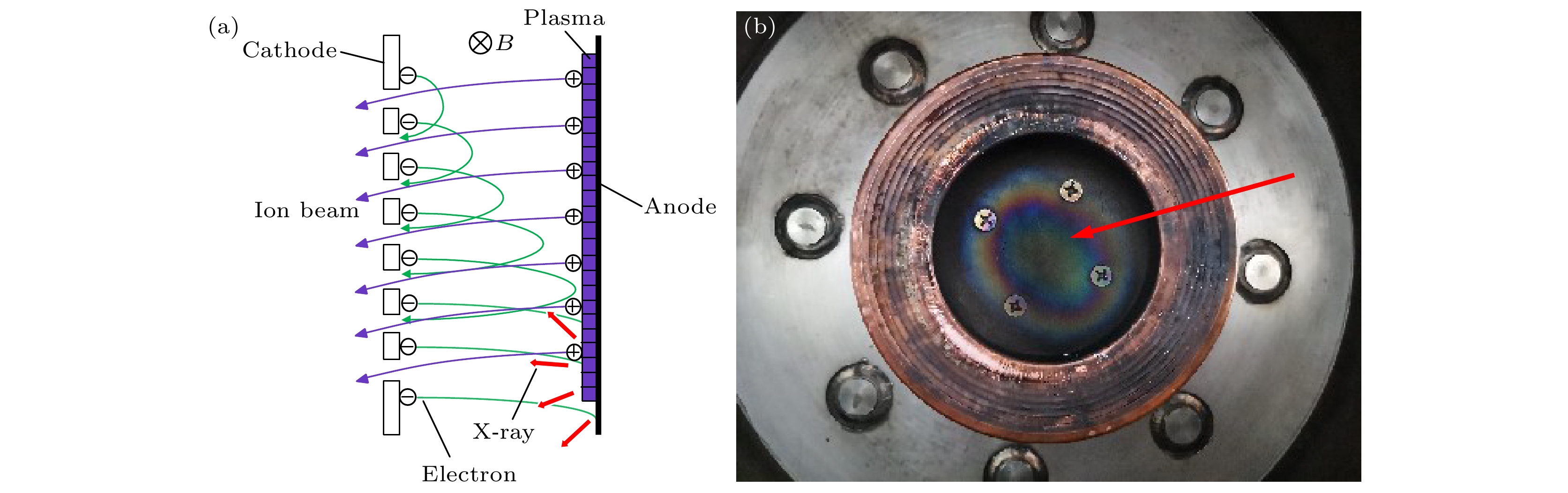

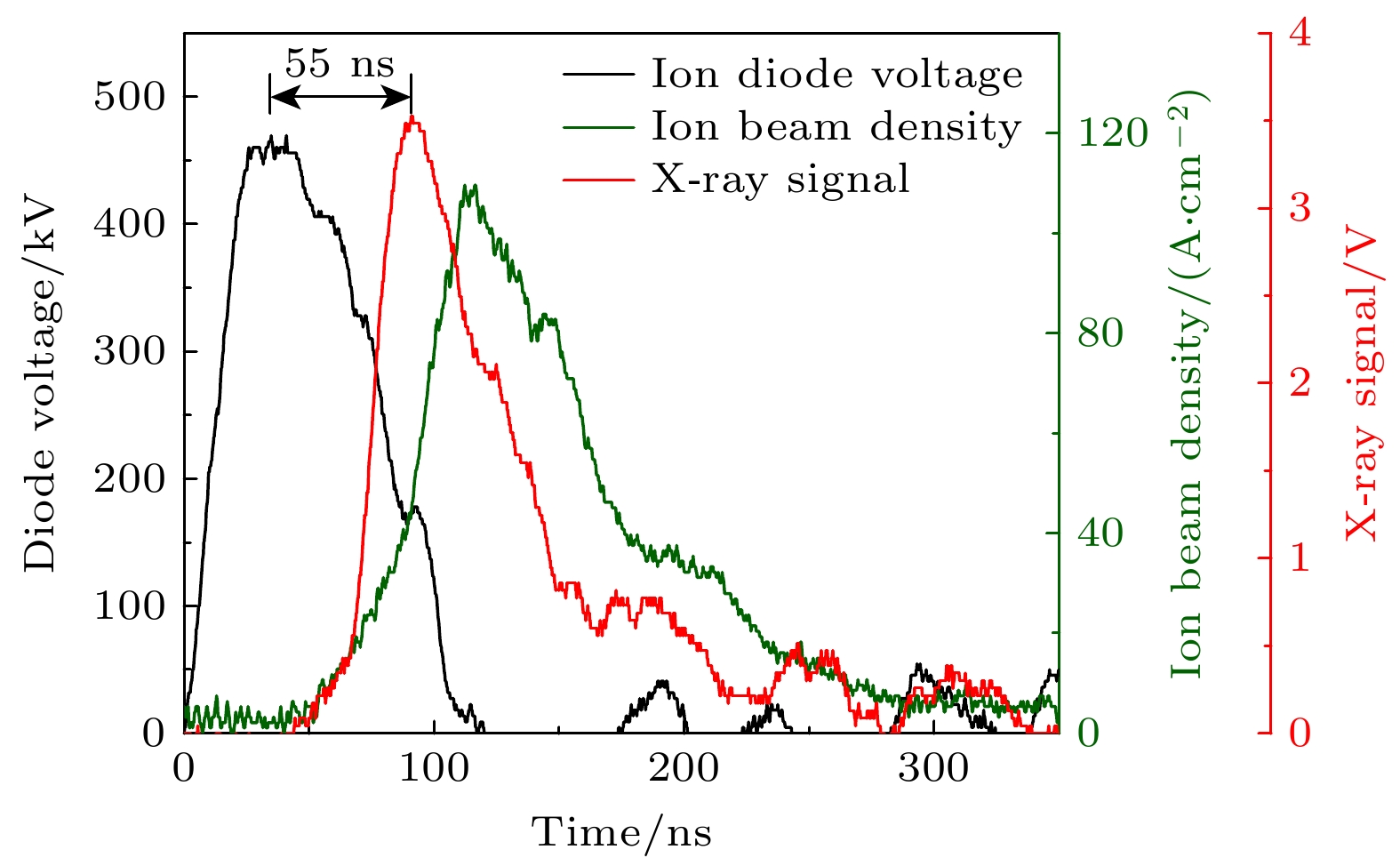

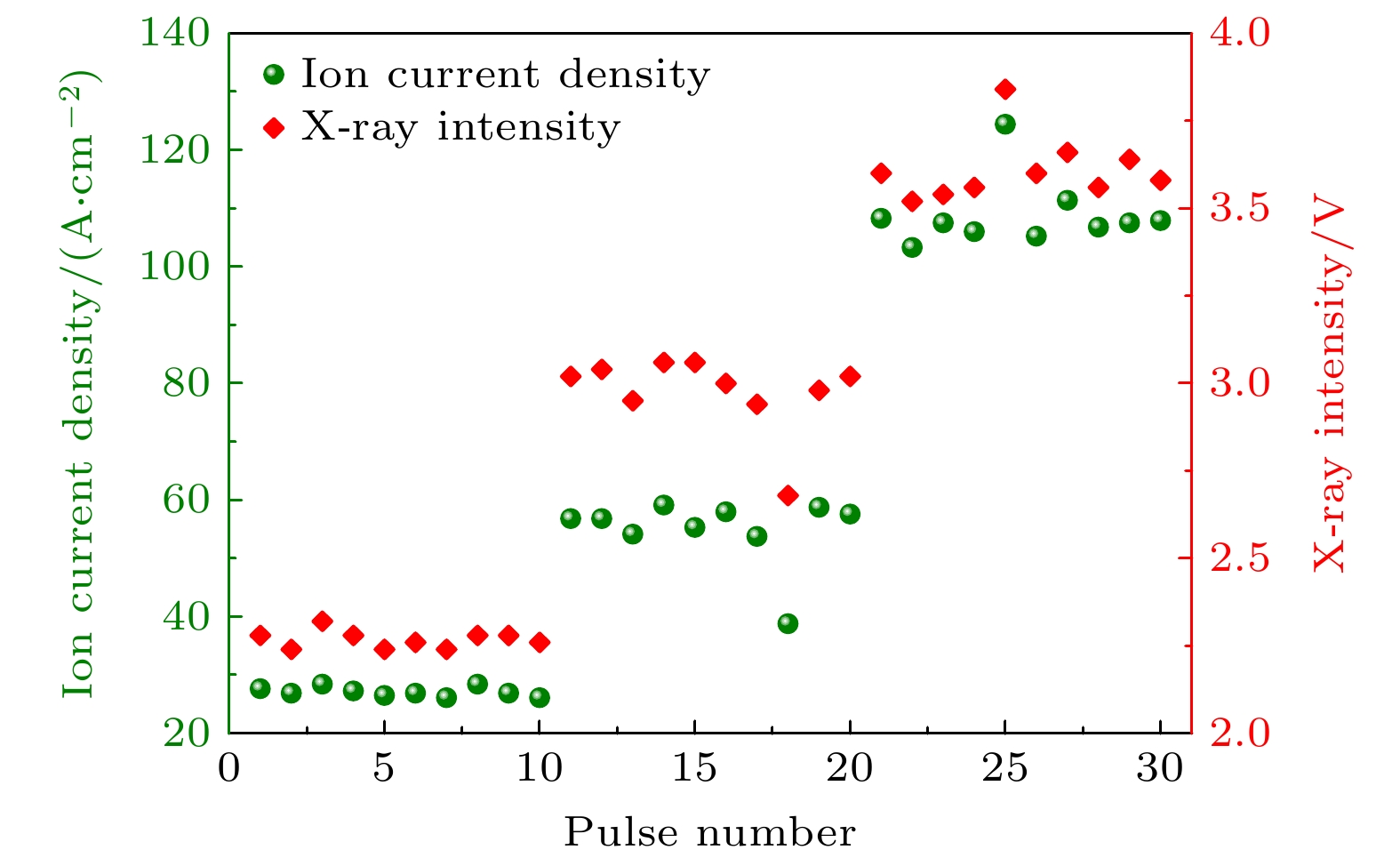

强流脉冲离子束辐照后的材料表面状态对束流强度具有极高的敏感性. 因此, 在辐照实验中监测束流输出的稳定性, 并及时识别出参数抖动较大的脉冲, 对于实验结果的分析和表面改性效果的优化具有重要意义. 本文利用塑料闪烁体构建了一种时间分辨为6 ns的快响应脉冲X射线诊断系统, 成功捕获了外磁绝缘离子束二极管工作时产生的X射线. 同时, 通过红外相机和法拉第筒对离子束流的能量密度和电流密度进行测量. 分析结果显示, 轫致辐射强度和离子束发射强度均取决于二极管加速电压, 导致X射线强度和离子束流能量密度呈现正相关趋势. 当离子电流密度发生抖动时, X射线信号幅值表现出良好的变化跟随性, 能够对偏离预设参数区间的脉冲做出响应. 这说明本文提出的非拦截式诊断方法能够有效地实时监测强流脉冲离子束束流输出的稳定性.Intense pulsed ion beam (IPIB) technology has made remarkable progress in surface modification, mixing, polishing, film deposition, and nano powder synthesis in recent years. However, the surface properties of materials under IPIB irradiation are highly sensitive to beam intensity variations. Deviations from acceptable parameter range can change the surface characteristics and increase prevalence of defects. Consequently, the real-time online monitoring of beam stability during irradiation experiments and promptly identifying of pulses exhibiting significant parameter jitter are of significance in accurately analyzing results and optimizing surface modification. This study presents a fast-response pulse X-ray diagnostic system by employing EJ-200 plastic scintillator, 9266FLB photomultiplier tube, and Tektronic TDS 2024 four-channel oscilloscope. Single particle test demonstrates that the system achieves a time resolution of 6 ns, meeting the requirements for temporal response to detecting pulse X-ray signals with a half-width of ~80 ns. By adjusting the insulation magnetic field strength of the ion diode, the IPIB output level is regulated. The diagnostic system successfully captures X-rays emitted by the external magnetic insulated ion diode operating at different output levels. Simultaneously, the ion beam energy density is measured by using an infrared camera. To mitigate diagnostic errors stemming from target ablation, the maximum energy density is controlled to be below 1.32 J/cm2. Analysis results establish a positive correlation between X-ray intensity and ion beam energy density. This relationship arises from the influence of the insulating magnetic field adjustment on the diode's operating voltage, which subsequently affects the bremsstrahlung radiant intensity and ion beam emission intensity. This correlation offers the potential for the real-time monitoring of IPIB beam output stability by utilizing X-ray signals. To further corroborate the synchronized changes in pulse X-ray intensity and ion beam intensity, Faraday cup is employed as an alternative to infrared imaging method for measuring ion current density. Results demonstrate that the amplitude of the X-ray signal changes synchronously with fluctuations of ion current density. It is worth noting that when the output intensity of ion beam deviates significantly (more than 10% of the preset value), the diagnostic system will respond quickly. These findings validate the efficacy of the proposed non-interceptive diagnostic method of real-time monitoring the intense pulsed ion beam output stability.

-

Keywords:

- intense pulsed ion beam /

- beam output stability /

- real-time monitoring /

- pulsed X-ray diagnostic system

[1] Humphries S 1980 Nucl. Fusion 20 1549

Google Scholar

Google Scholar

[2] Van Devender J P 1986 Plasma Phys. Control. Fusion 28 841

Google Scholar

Google Scholar

[3] Long K A, Tahir N A 1982 Phys. Lett. A 91 451

Google Scholar

Google Scholar

[4] 杨海亮, 邱爱慈, 张嘉生, 何小平, 孙剑锋, 彭建昌, 汤俊萍, 任书庆, 欧阳晓平, 张国光, 黄建军, 杨莉, 王海洋, 李洪玉, 李静雅 2004 53 406

Google Scholar

Google Scholar

Yang H L, Qiu A C, Zhang J S, He X P, Sun J F, Peng J C, Tang J P, Ren S Q, Ouyang X P, Zhang G G, Huang J J, Yang L, Wang H Y, Li H Y, Li J Y 2004 Acta Phys. Sin. 53 406

Google Scholar

Google Scholar

[5] Mach H, Rogers D W O 1983 IEEE Trans. Nucl. Sci. 30 1514

Google Scholar

Google Scholar

[6] Baumung K, Bluhm H J, Goel B, Hoppé P, Karow H U, Rusch D, Fortov V E, Kanel G I, Razorenov S V, Utkin A V, Vorobjev O Y 1996 Laser Part. Beams 14 181

Google Scholar

Google Scholar

[7] Zhong H W, Zhang J, Shen J, Liang G Y, Zhang S J, Huang W Y, Xu M F, Yu X, Yan S, Efimovich Remnev G, Le X Y 2019 Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. with Mater. Atoms 461 226

Google Scholar

Google Scholar

[8] Yu X, Zhang S J, Stepanov A V, Shamanin V I, Zhong H W, Liang G Y, Xu M F, Zhang N, Kuang S, Ren J, Shang X, Yan S, Remnev G E, Le X Y 2020 Surf. Coatings Technol. 384 125351

Google Scholar

Google Scholar

[9] 张世健, 喻晓, 钟昊玟, 梁国营, 许莫非, 张楠, 任建慧, 匡仕成, 颜莎, Gennady Efimovich Remnev, 乐小云 2020 69 115202

Google Scholar

Google Scholar

Zhang S J, Yu X, Zhong H W, Liang G Y, Xu M F, Zhang N, Ren J H, Kuang S C, Yan S, Gennady E R, Le X Y 2020 Acta Phys. Sin. 69 115202

Google Scholar

Google Scholar

[10] Le X Y, Zhao W J, Yan S, Han B X, Xiang W 2002 Surf. Coatings Technol. 158 – 159 14

[11] 张锋刚, 朱小鹏, 王明阳, 雷明凯 2011 金属学报 47 958

Zhang F G, Zhu X P, Wang M Y, Lei M K 2011 Acta Metall. Sin. 47 958

[12] Zhang S J, Yu X, Zhang J, Shen J, Zhong H W, Liang G Y, Xu M, Zhang N, Ren J, Kuang S, Shang X, Adegboyega O, Yan S, Remnev G E, Le X Y 2021 Vacuum 187 110154

Google Scholar

Google Scholar

[13] Zhao W J, Remnev G E, Yan S, Opekounov M S, Le X Y, Matvienko V M, Han B X, Xue J M, Wang Y G 2000 Rev. Sci. Instrum. 71 1045

Google Scholar

Google Scholar

[14] Yan S, Le X Y, Zhao W J, Shang Y J, Wang Y, Xue J 2007 Surf. Coatings Technol. 201 4817

Google Scholar

Google Scholar

[15] Xu M F, Yu X, Zhang S J, Yan S, Tarbokov V, Remnev G, Le X Y 2023 Materials (Basel) 16 3028

[16] Yu X, Shen J, Zhong H W, Zhang J, Yan S, Zhang G L, Zhang X, Le X Y 2015 Vacuum 120 116

Google Scholar

Google Scholar

[17] Hashimoto Y, Yatsuzuka M 2000 Vacuum 59 313

Google Scholar

Google Scholar

[18] Prasad S V, Renk T J, Kotula P G, DebRoy T 2011 Mater. Lett. 65 4

Google Scholar

Google Scholar

[19] Suzuki T, Saikusa T, Suematu H, Jiang W, Yatsui K 2003 Surf. Coatings Technol. 169 – 170 491

[20] Zhu Q, Jiang W, Yatsui K 1999 J. Appl. Phys. 86 5279

Google Scholar

Google Scholar

[21] Shulov V A, Novikov A S, Paikin A G, Belov A B, Lvov A F, Remnev G E 2007 Surf. Coatings Technol. 201 8654

Google Scholar

Google Scholar

[22] Zhang J, Zhong H W, Shen J, Yu X, Yan S, Le X Y 2020 Surf. Coatings Technol. 388 125599

Google Scholar

Google Scholar

[23] Kovivchak V S, Panova T V, Mikhailov K A, Knyazev E V 2013 J. Surf. Investig. 7 531

Google Scholar

Google Scholar

[24] Zhang Q, Mei X X, Guan T, Zhang X N, Remnev G E, Pavlov S K, Wang Y N 2019 Fusion Eng. Des. 138 16

Google Scholar

Google Scholar

[25] Mei X X, Zhang X N, Liu X, Wang Y N 2017 Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. with Mater. Atoms 406 697

Google Scholar

Google Scholar

[26] Gerdin G, Stygar W, Venneri F 1981 J. Appl. Phys. 52 3269

Google Scholar

Google Scholar

[27] Christodoulides C E, Freeman J H 1976 Nucl. Instruments Methods 135 13

Google Scholar

Google Scholar

[28] Davis H A, Bartsch R R, Olson J C, Rej D J, Waganaar W J 1997 J. Appl. Phys. 82 3223

Google Scholar

Google Scholar

[29] Ryzhkov V A, Stepanov A V, Pyatkov I N, Remnev G E 2021 Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers, Detect. Assoc. Equip. 1013 165671

Google Scholar

Google Scholar

[30] Ryzhkov V A, Pyatkov I N, Remnev G E 2021 Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers, Detect. Assoc. Equip. 998 165190

Google Scholar

Google Scholar

[31] Pushkarev A I, Isakova Y I, Yu X, Khailov I P 2013 Rev. Sci. Instrum. 84

[32] Dong Z H, Liu C, Han X G, Lei M K 2007 Surf. Coatings Technol. 201 5054

Google Scholar

Google Scholar

[33] Masugata K, Chishiro E, Yatsui K 1998 Proceedings of the 12th International Conference on High-Power Particle Beams Haifa, Israel, June 12, 1998 pp222–225

[34] 杨海亮, 邱爱慈, 孙剑锋, 何小平, 汤俊萍, 王海洋, 李洪玉, 李静雅, 任书庆, 黄建军, 张嘉生, 彭建昌, 欧阳晓平, 张国光 2004 原子能科学技术 38 204

Yang H L, Qiu A C, Sun J F, He X P, Tang J P, Wang H Y, Li H Y, Li J Y, Ren S Q, Huang J J, Zhang J S, Peng J C, Ouyang X P, Zhang G G 2004 Atom. Ener. Sci. Tech. 38 204

[35] Yu X, Shen J, Isakova Y I, Zhong H W, Zhang J, Yan S, Zhang G L, Zhang X F, Le X Y 2015 Vacuum 122 12

Google Scholar

Google Scholar

[36] 屈苗, 喻晓, 张洁, 沈杰, 钟昊玟, 张艳燕, 颜莎, 张小富, 张高龙, 乐小云 2015 强激光与粒子束 27 216

Google Scholar

Google Scholar

Qu M, Yu X, Zhang J, Shen J, Zhong H W, Zhang Y Y, Yan S, Zhang X F, Zhang G L, Le X Y 2015 High Power Laser and Particle Beams 27 7

Google Scholar

Google Scholar

[37] 刘庆兆 1994 脉冲辐射场诊断技术 (北京: 科学出版社) 第98页

Liu Q Z 1994 Pulse Radiation Field Diagnosis Technology (Beijing: Science Press) p98

[38] 郑志鹏, 祝玉灿, 邵毓莺, 孙汉生 1986 核电子学与探测技术 6 112

Zheng Z P, Zhu Y C, Shao Y Y, Sun H S 1986 Nucl. Elec. and Det. Tech. 6 112

[39] Xu M F, Kuang S, Yu X, Zhang S J, Yan S, Remnev G E, Le X 2023 Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. with Mater. Atoms 537 38

Google Scholar

Google Scholar

[40] 陈伯显, 张智 2011 核辐射物理及探测学 (哈尔滨: 哈尔滨工程大学出版社) 第146页

Chen B X, Zhang Z 2011 Nuclear Radiation Physics and Detection (Harbin: Harbin Engineering University Press) p146

-

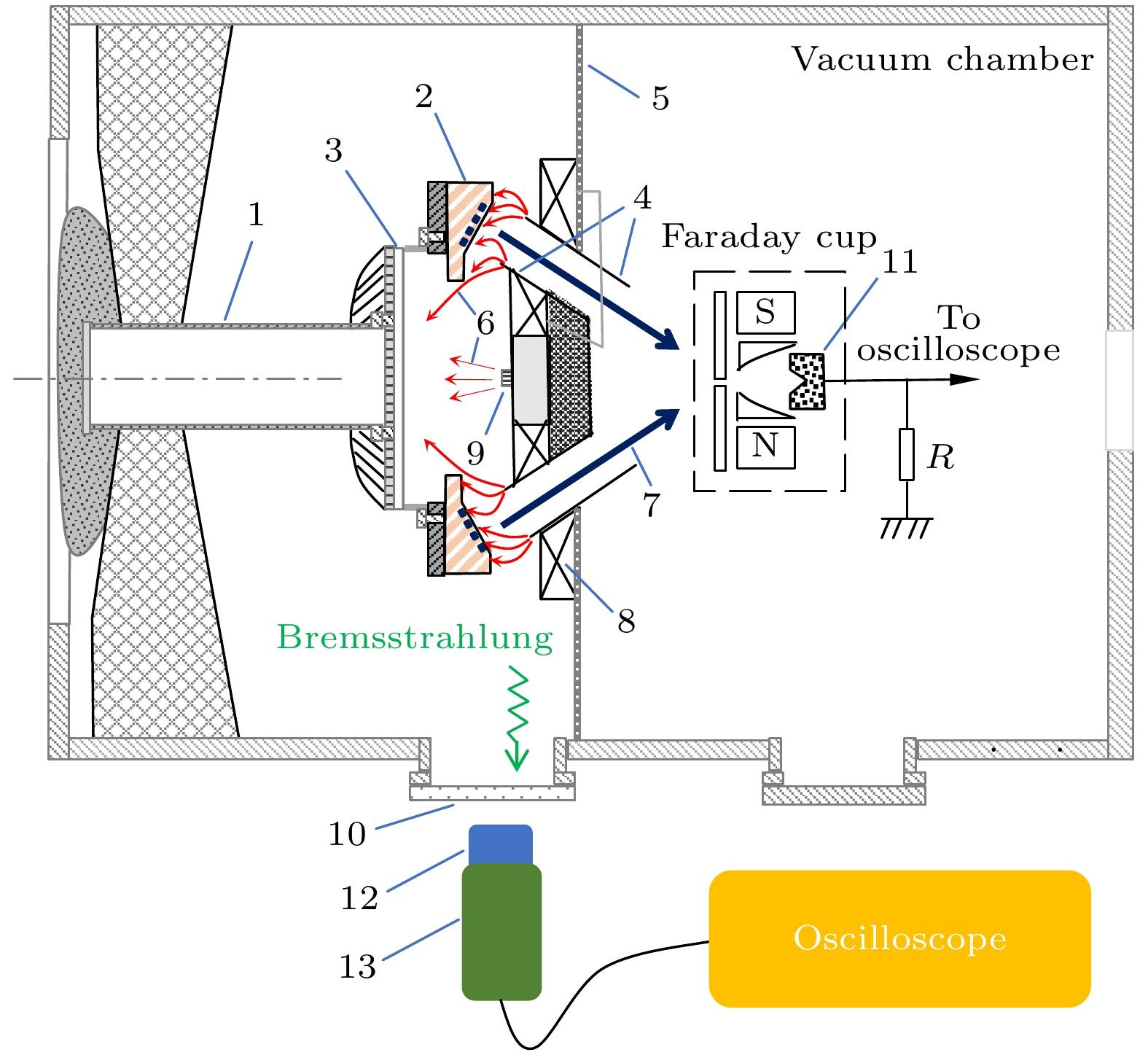

图 1 诊断方法示意图. 1-高压端柱; 2-阳极; 3-阳极托盘; 4-阴极; 5-阴极支撑盘; 6-电子; 7-离子束; 8-绝缘磁场线圈; 9-磁场线圈固定器; 10-有机玻璃观察窗; 11-CaF2窗口; 12-EJ-200塑料闪烁体; 13-9266 FLB光电倍增管

Fig. 1. Diagnostic method diagram. 1- High voltage input; 2-anode; 3- anode tray; 4-cathode; 5-cathode support plate; 6- electron; 7-ion beam; 8-insulated magnetic field coils; 9- magnetic field coils fixer; 10- organic glass observation window; 11-CaF2 window; 12-EJ-200 plastic scintillator; 13-9266 FLB photomultiplier tube.

图 3 红外相机在(a) IPIB辐照前、(b) IPIB辐照后从热沉靶背面捕获的红外图像, 以及(c)诊断系统捕获的脉冲X射线信号波形

Fig. 3. The infrared image captured by the infrared camera from the backside of the heat sink target before (a) IPIB irradiation, (b) after IPIB irradiation, and (c) the pulse X-ray signal waveform captured by the diagnostic system.

图 6 实验装置示意图. 1-高压端柱; 2-阳极; 3-阳极托盘; 4-阴极; 5-阴极支撑盘; 6-电子; 7-离子束; 8-绝缘磁场线圈; 9-磁场线圈固定器; 10-有机玻璃观察窗; 11-石墨收集体; 12-EJ-200塑料闪烁体; 13-9266 FLB光电倍增管

Fig. 6. Schematic diagram of experimental equipment. 1- High voltage input; 2-anode; 3- anode tray; 4-cathode; 5-cathode support plate; 6- electron; 7-ion beam; 8- insulated magnetic field coils; 9- magnetic field coils fixer; 10-organic glass observation window; 11-graphite collector; 12-EJ-200 plastic scintillator; 13-9266 FLB photomultiplier tube.

-

[1] Humphries S 1980 Nucl. Fusion 20 1549

Google Scholar

Google Scholar

[2] Van Devender J P 1986 Plasma Phys. Control. Fusion 28 841

Google Scholar

Google Scholar

[3] Long K A, Tahir N A 1982 Phys. Lett. A 91 451

Google Scholar

Google Scholar

[4] 杨海亮, 邱爱慈, 张嘉生, 何小平, 孙剑锋, 彭建昌, 汤俊萍, 任书庆, 欧阳晓平, 张国光, 黄建军, 杨莉, 王海洋, 李洪玉, 李静雅 2004 53 406

Google Scholar

Google Scholar

Yang H L, Qiu A C, Zhang J S, He X P, Sun J F, Peng J C, Tang J P, Ren S Q, Ouyang X P, Zhang G G, Huang J J, Yang L, Wang H Y, Li H Y, Li J Y 2004 Acta Phys. Sin. 53 406

Google Scholar

Google Scholar

[5] Mach H, Rogers D W O 1983 IEEE Trans. Nucl. Sci. 30 1514

Google Scholar

Google Scholar

[6] Baumung K, Bluhm H J, Goel B, Hoppé P, Karow H U, Rusch D, Fortov V E, Kanel G I, Razorenov S V, Utkin A V, Vorobjev O Y 1996 Laser Part. Beams 14 181

Google Scholar

Google Scholar

[7] Zhong H W, Zhang J, Shen J, Liang G Y, Zhang S J, Huang W Y, Xu M F, Yu X, Yan S, Efimovich Remnev G, Le X Y 2019 Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. with Mater. Atoms 461 226

Google Scholar

Google Scholar

[8] Yu X, Zhang S J, Stepanov A V, Shamanin V I, Zhong H W, Liang G Y, Xu M F, Zhang N, Kuang S, Ren J, Shang X, Yan S, Remnev G E, Le X Y 2020 Surf. Coatings Technol. 384 125351

Google Scholar

Google Scholar

[9] 张世健, 喻晓, 钟昊玟, 梁国营, 许莫非, 张楠, 任建慧, 匡仕成, 颜莎, Gennady Efimovich Remnev, 乐小云 2020 69 115202

Google Scholar

Google Scholar

Zhang S J, Yu X, Zhong H W, Liang G Y, Xu M F, Zhang N, Ren J H, Kuang S C, Yan S, Gennady E R, Le X Y 2020 Acta Phys. Sin. 69 115202

Google Scholar

Google Scholar

[10] Le X Y, Zhao W J, Yan S, Han B X, Xiang W 2002 Surf. Coatings Technol. 158 – 159 14

[11] 张锋刚, 朱小鹏, 王明阳, 雷明凯 2011 金属学报 47 958

Zhang F G, Zhu X P, Wang M Y, Lei M K 2011 Acta Metall. Sin. 47 958

[12] Zhang S J, Yu X, Zhang J, Shen J, Zhong H W, Liang G Y, Xu M, Zhang N, Ren J, Kuang S, Shang X, Adegboyega O, Yan S, Remnev G E, Le X Y 2021 Vacuum 187 110154

Google Scholar

Google Scholar

[13] Zhao W J, Remnev G E, Yan S, Opekounov M S, Le X Y, Matvienko V M, Han B X, Xue J M, Wang Y G 2000 Rev. Sci. Instrum. 71 1045

Google Scholar

Google Scholar

[14] Yan S, Le X Y, Zhao W J, Shang Y J, Wang Y, Xue J 2007 Surf. Coatings Technol. 201 4817

Google Scholar

Google Scholar

[15] Xu M F, Yu X, Zhang S J, Yan S, Tarbokov V, Remnev G, Le X Y 2023 Materials (Basel) 16 3028

[16] Yu X, Shen J, Zhong H W, Zhang J, Yan S, Zhang G L, Zhang X, Le X Y 2015 Vacuum 120 116

Google Scholar

Google Scholar

[17] Hashimoto Y, Yatsuzuka M 2000 Vacuum 59 313

Google Scholar

Google Scholar

[18] Prasad S V, Renk T J, Kotula P G, DebRoy T 2011 Mater. Lett. 65 4

Google Scholar

Google Scholar

[19] Suzuki T, Saikusa T, Suematu H, Jiang W, Yatsui K 2003 Surf. Coatings Technol. 169 – 170 491

[20] Zhu Q, Jiang W, Yatsui K 1999 J. Appl. Phys. 86 5279

Google Scholar

Google Scholar

[21] Shulov V A, Novikov A S, Paikin A G, Belov A B, Lvov A F, Remnev G E 2007 Surf. Coatings Technol. 201 8654

Google Scholar

Google Scholar

[22] Zhang J, Zhong H W, Shen J, Yu X, Yan S, Le X Y 2020 Surf. Coatings Technol. 388 125599

Google Scholar

Google Scholar

[23] Kovivchak V S, Panova T V, Mikhailov K A, Knyazev E V 2013 J. Surf. Investig. 7 531

Google Scholar

Google Scholar

[24] Zhang Q, Mei X X, Guan T, Zhang X N, Remnev G E, Pavlov S K, Wang Y N 2019 Fusion Eng. Des. 138 16

Google Scholar

Google Scholar

[25] Mei X X, Zhang X N, Liu X, Wang Y N 2017 Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. with Mater. Atoms 406 697

Google Scholar

Google Scholar

[26] Gerdin G, Stygar W, Venneri F 1981 J. Appl. Phys. 52 3269

Google Scholar

Google Scholar

[27] Christodoulides C E, Freeman J H 1976 Nucl. Instruments Methods 135 13

Google Scholar

Google Scholar

[28] Davis H A, Bartsch R R, Olson J C, Rej D J, Waganaar W J 1997 J. Appl. Phys. 82 3223

Google Scholar

Google Scholar

[29] Ryzhkov V A, Stepanov A V, Pyatkov I N, Remnev G E 2021 Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers, Detect. Assoc. Equip. 1013 165671

Google Scholar

Google Scholar

[30] Ryzhkov V A, Pyatkov I N, Remnev G E 2021 Nucl. Instruments Methods Phys. Res. Sect. A Accel. Spectrometers, Detect. Assoc. Equip. 998 165190

Google Scholar

Google Scholar

[31] Pushkarev A I, Isakova Y I, Yu X, Khailov I P 2013 Rev. Sci. Instrum. 84

[32] Dong Z H, Liu C, Han X G, Lei M K 2007 Surf. Coatings Technol. 201 5054

Google Scholar

Google Scholar

[33] Masugata K, Chishiro E, Yatsui K 1998 Proceedings of the 12th International Conference on High-Power Particle Beams Haifa, Israel, June 12, 1998 pp222–225

[34] 杨海亮, 邱爱慈, 孙剑锋, 何小平, 汤俊萍, 王海洋, 李洪玉, 李静雅, 任书庆, 黄建军, 张嘉生, 彭建昌, 欧阳晓平, 张国光 2004 原子能科学技术 38 204

Yang H L, Qiu A C, Sun J F, He X P, Tang J P, Wang H Y, Li H Y, Li J Y, Ren S Q, Huang J J, Zhang J S, Peng J C, Ouyang X P, Zhang G G 2004 Atom. Ener. Sci. Tech. 38 204

[35] Yu X, Shen J, Isakova Y I, Zhong H W, Zhang J, Yan S, Zhang G L, Zhang X F, Le X Y 2015 Vacuum 122 12

Google Scholar

Google Scholar

[36] 屈苗, 喻晓, 张洁, 沈杰, 钟昊玟, 张艳燕, 颜莎, 张小富, 张高龙, 乐小云 2015 强激光与粒子束 27 216

Google Scholar

Google Scholar

Qu M, Yu X, Zhang J, Shen J, Zhong H W, Zhang Y Y, Yan S, Zhang X F, Zhang G L, Le X Y 2015 High Power Laser and Particle Beams 27 7

Google Scholar

Google Scholar

[37] 刘庆兆 1994 脉冲辐射场诊断技术 (北京: 科学出版社) 第98页

Liu Q Z 1994 Pulse Radiation Field Diagnosis Technology (Beijing: Science Press) p98

[38] 郑志鹏, 祝玉灿, 邵毓莺, 孙汉生 1986 核电子学与探测技术 6 112

Zheng Z P, Zhu Y C, Shao Y Y, Sun H S 1986 Nucl. Elec. and Det. Tech. 6 112

[39] Xu M F, Kuang S, Yu X, Zhang S J, Yan S, Remnev G E, Le X 2023 Nucl. Instruments Methods Phys. Res. Sect. B Beam Interact. with Mater. Atoms 537 38

Google Scholar

Google Scholar

[40] 陈伯显, 张智 2011 核辐射物理及探测学 (哈尔滨: 哈尔滨工程大学出版社) 第146页

Chen B X, Zhang Z 2011 Nuclear Radiation Physics and Detection (Harbin: Harbin Engineering University Press) p146

计量

- 文章访问数: 4493

- PDF下载量: 82

- 被引次数: 0

下载:

下载: