-

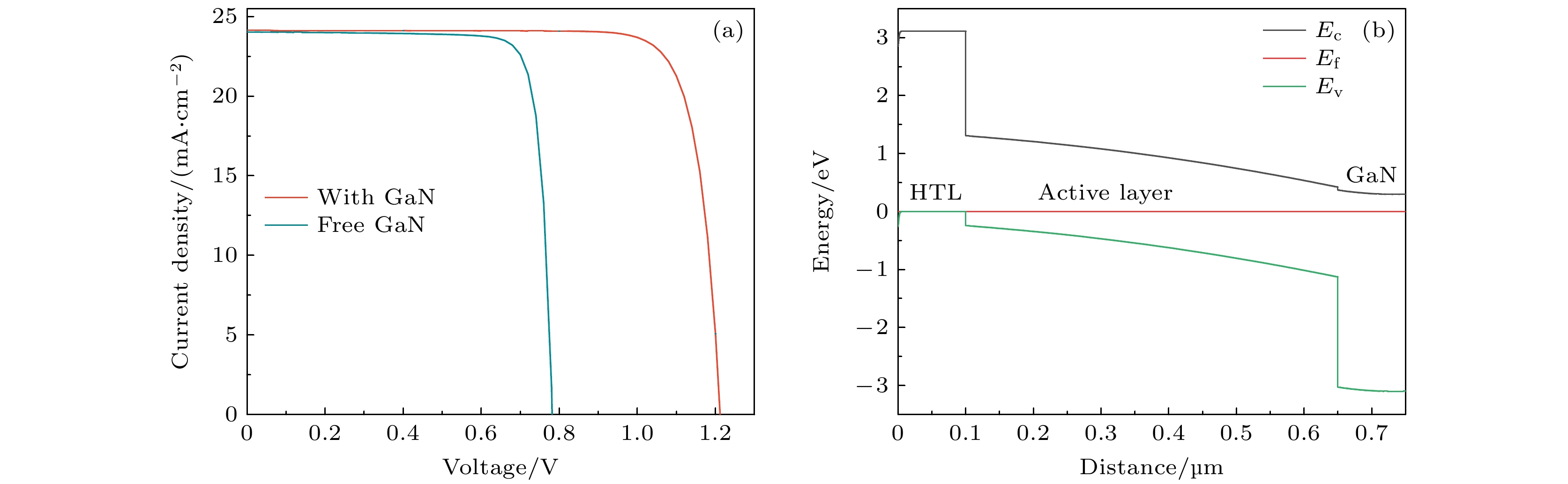

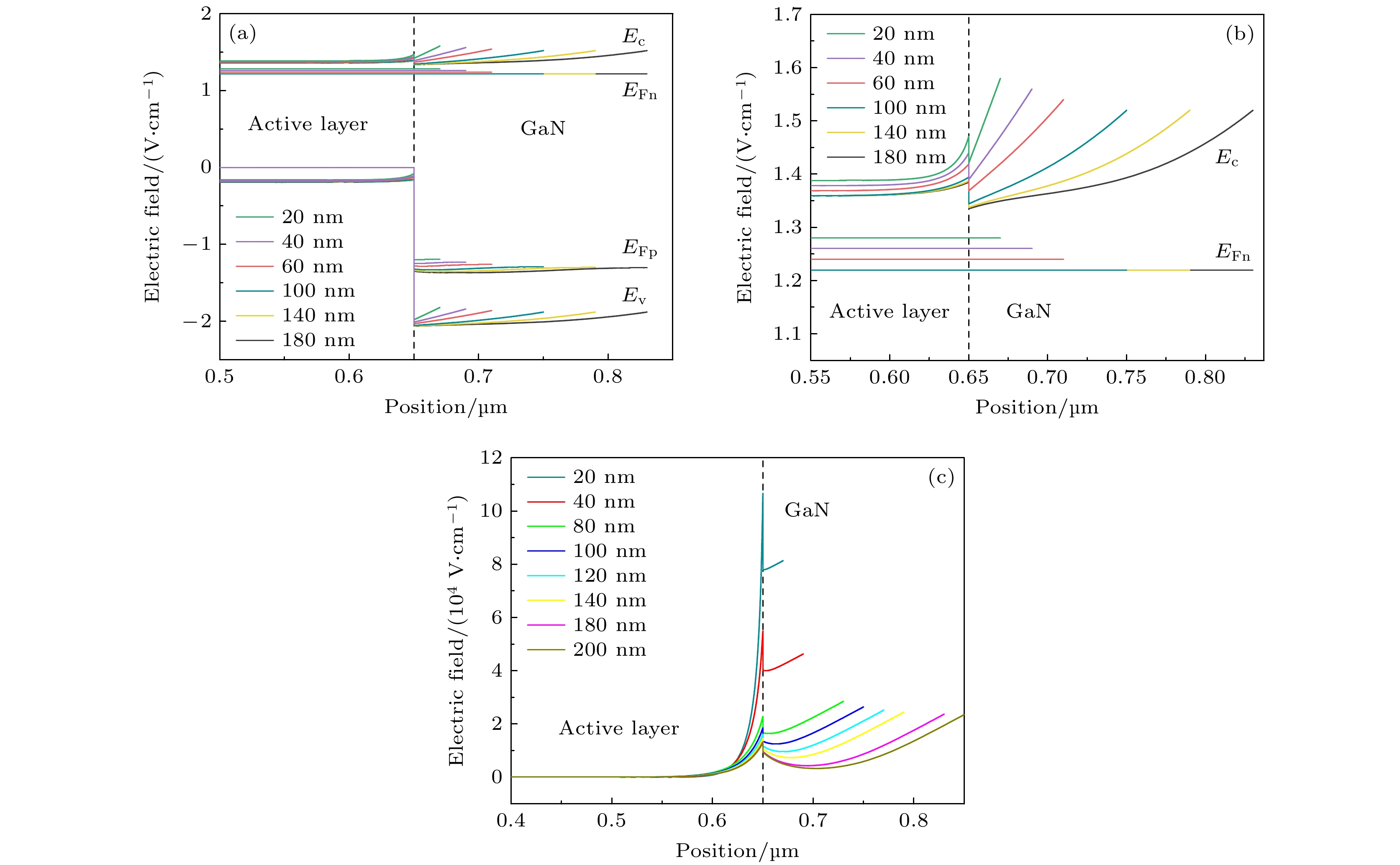

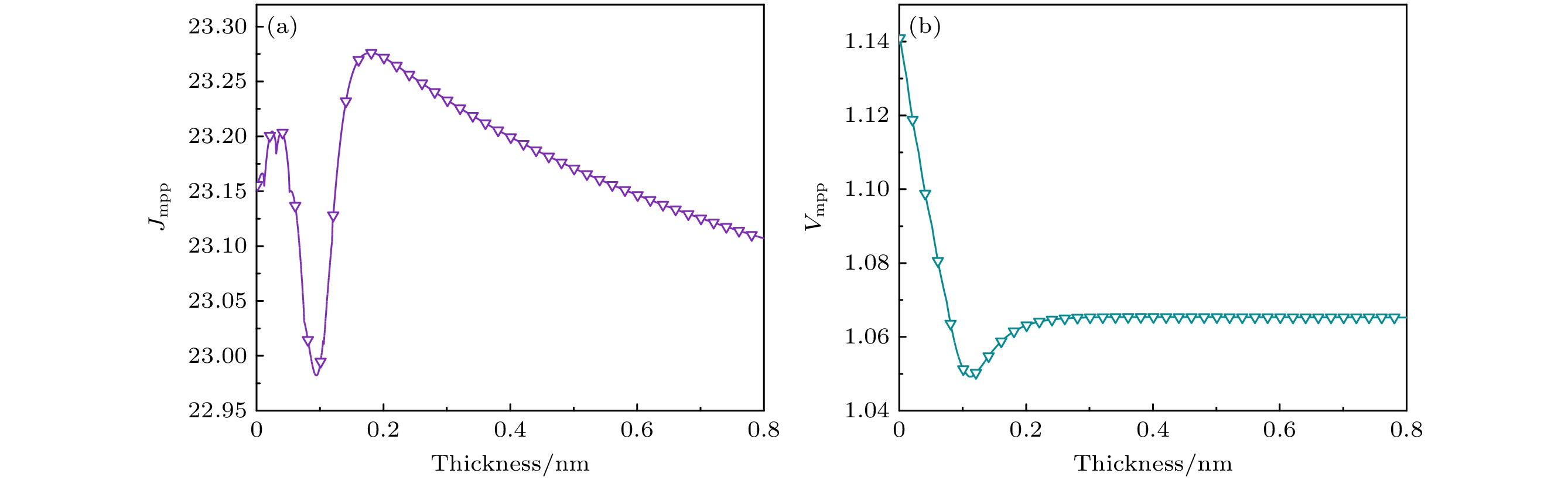

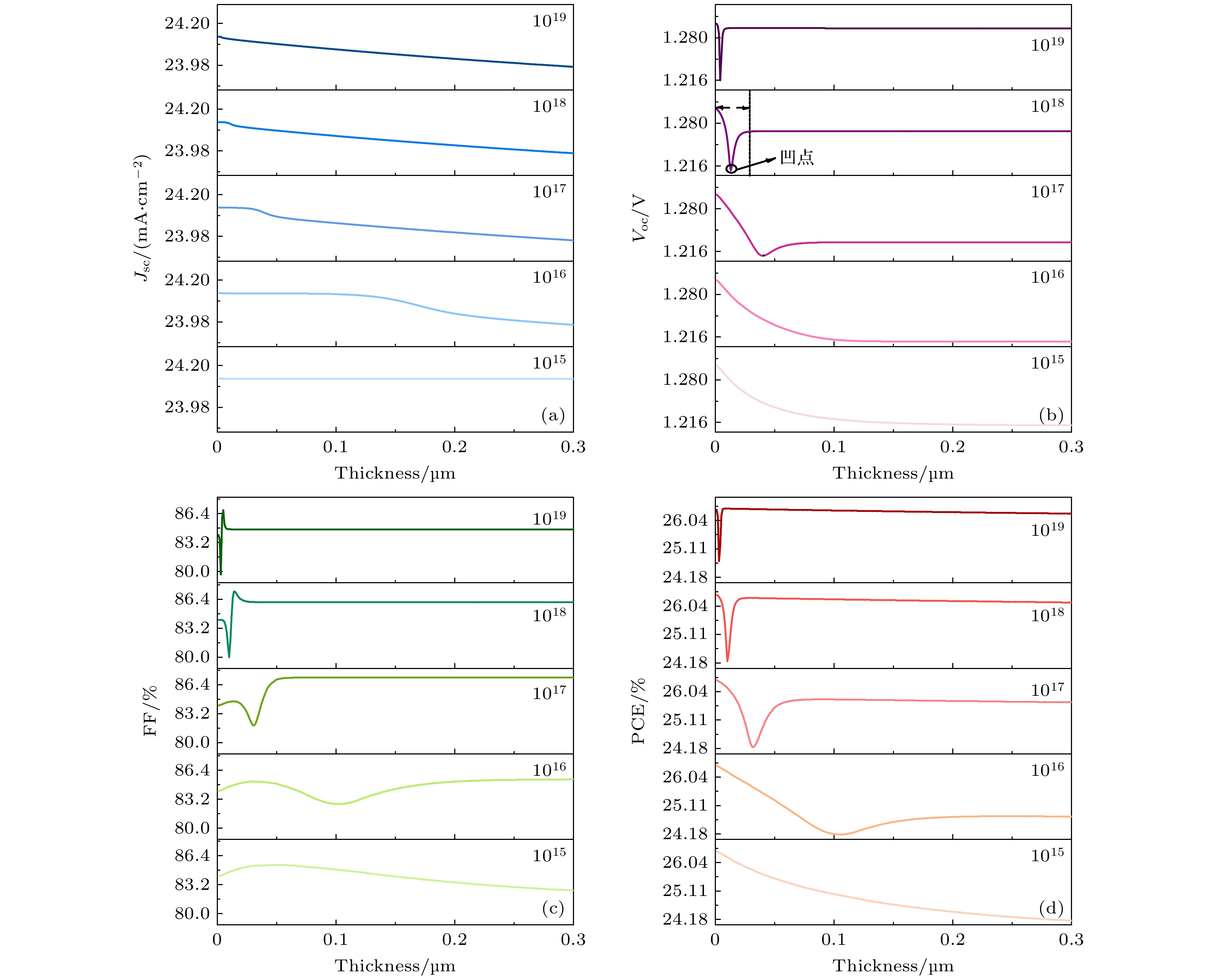

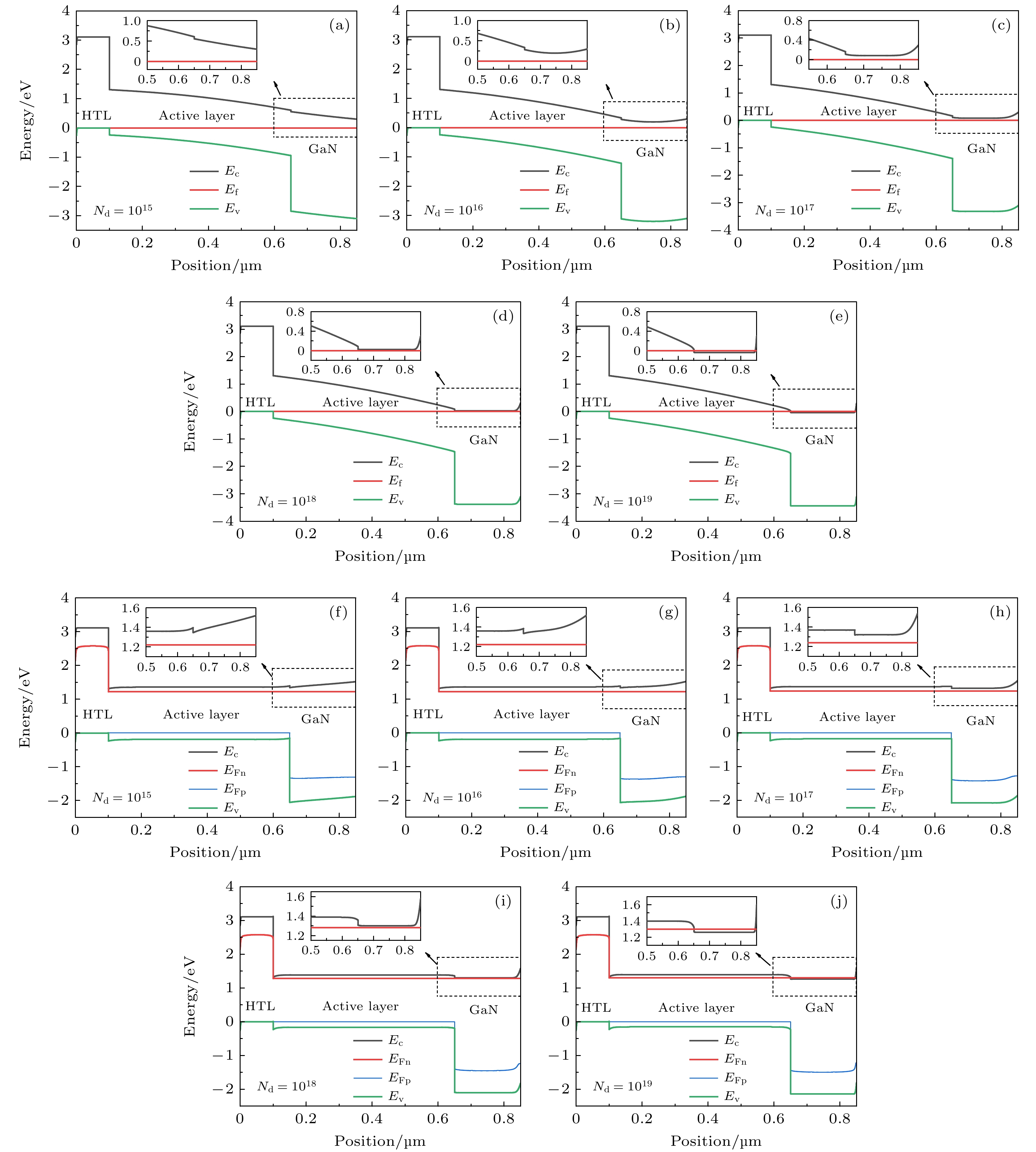

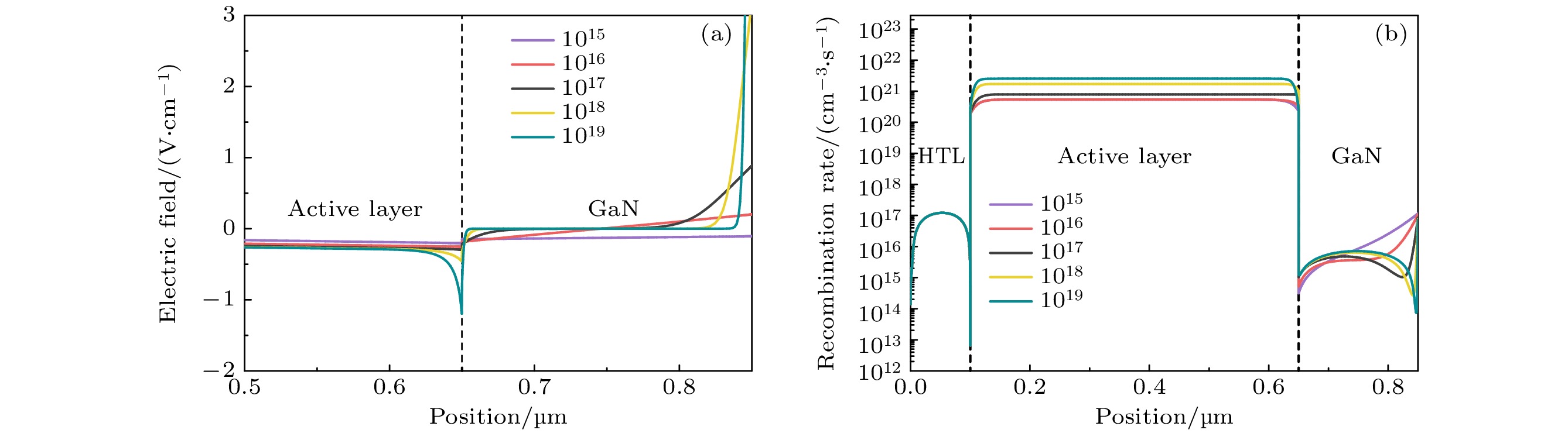

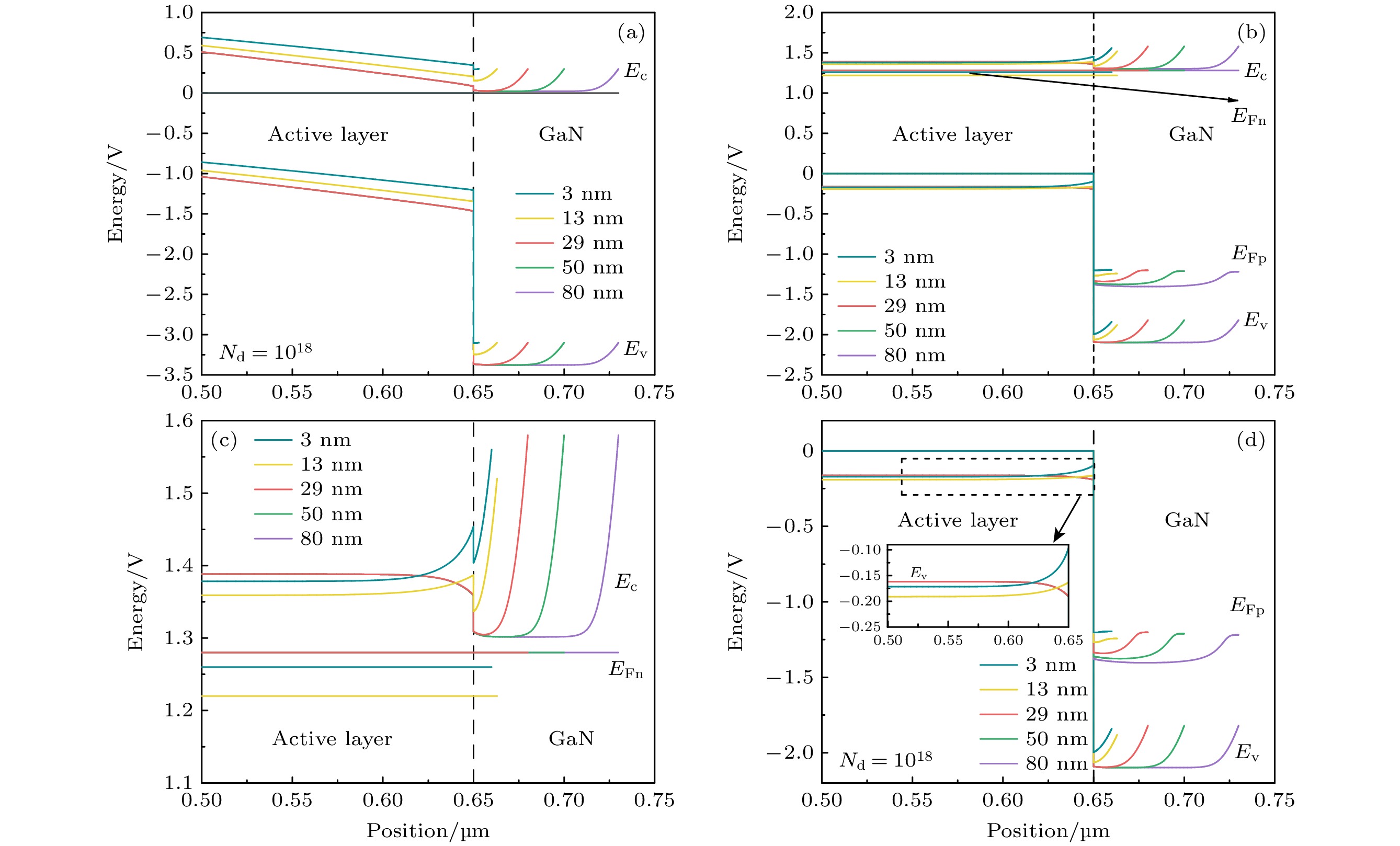

GaN基半导体在光电子、电子器件已具有重要应用, 如何结合其良好的电学特性进行其他应用方面的理论或实验探索, 是当前新的研究课题. 本文利用 SCAPS-1D软件从理论上计算了GaN在FTO/GaN/ (FAPbI3)0.85(MAPbBr3)0.15/HTL电池结构中电子传输的理论机制. 结果表明, 引入GaN后, 电池的开路电压, 转换效率明显提高. 通过进一步分析准费米能级分裂、界面电场、界面复合率、耗尽层厚度等因素的变化规律, 分析了GaN的厚度和掺杂浓度对电池开路电压等器件参数的影响, 并从GaN作为电子传输层的物理机制方面进行了讨论.GaN-based semiconductor has been used in optoelectronics and electronic devices. It is a new research topic at present that how its good electrical properties are integrated together to explore other applications in theory or experiment. In this work, SCAPS-1D software is used to calculate the mechanism of GaN electron transport in an FTO/GaN/(FAPbI3)0.85(MAPbBr3)0.15/HTL perovskite solar cell (PSC) structure. The results show that when GaN is used in PSC, the Voc increases from 0.78 V to 1.21 V, PCE increases from 15.87% to 24.18%, and that the small conduction band cliff formed between GaN and the active layer can improve the efficiency of the cell. Quasi-Fermi level splitting, interfacial electric field, interfacial recombination rate and depletion zone thickness at different doping concentrations s are analyzed. The influences of GaN thickness and doping concentration on open-circuit voltage and other device parameters are investigated. The physical mechanism of GaN as an electron transport layer is discussed. With the increase of the thickness, the Jsc of this solar cell decreases gradually, but the change range is not large (24.13—23.83 mA/cm2). The Voc decreases from 1.30 V to 1.21 V when the thickness of GaN exceeds 100nm, and then keeps stable. The power conversion efficiency changing regularity appears in the form of “pits” —first decreases, then increases, and finally keeps stable, with the highest efficiency being 24.76% and the corresponding GaN thickness being 245 nm. The FF shows a trend, which is first decreasing, then increasing, and finally leveling off. In the case of the doping concentration and thickness change at the same time, during the increase of doping concentration, the Jsc decreases gradually with the increase of thickness, but the overall change range is small, and the open-circuit voltage, filling factor and conversion efficiency all show “pits” changes. When the thickness of GaN is 200 nm, with the concentration of GaN doping increasing, the quasi Fermi level splitting increases, and the strength of the built-in electric field between the active layer and the GaN layer increases, thus providing a greater driving force for carrier separation, resulting in a larger potential difference Δμ, and thus a larger Voc. With the increase of doping concentration, the recombination rate of the active layer/GaN layer interface and the recombination rate inside the active layer increase, which leads the value of Jsc to decrease. It is found that the position of the “concave point” of Voc under the change of GaN thickness is determined by varying the GaN doping concentration, the width of GaN depletion region between GaN/FTO, and the width of GaN depletion region between GaN/active layer determine the width of the whole “pit”. In summary, the cell parameters can be improved by simultaneously changing the thickness and doping concentration of GaN.

-

Keywords:

- GaN /

- perovskite solar cell /

- open-circuit voltage

[1] Koblmuller G, Wu F, Mates T, Speck J S, Fernandez-Garrido S, Calleja E 2007 Appl. Phys. Lett. 91 221905

Google Scholar

Google Scholar

[2] Yildirim M A, Teker K 2021 Nano 16 2150021

Google Scholar

Google Scholar

[3] Leijtens T, Eperon G E, Pathak S, Abate A, Lee M M, Snaith H J 2013 Nat. Commun. 4 2885

Google Scholar

Google Scholar

[4] Luo Y Q, Khoram P, Brittman S, Zhu Z Y, Lai B, Ong S P, Garnett E C, Fenning D P 2017 Adv. Mater. 29 1703451

Google Scholar

Google Scholar

[5] Bischak C G, Hetherington C L, Wu H, Aloni S, Ogletree D F, Limmer D T, Ginsberg N S 2017 Nano Lett. 17 1028

Google Scholar

Google Scholar

[6] Dequilettes D W, Zhang W, Burlakov V M, et al. 2016 Nat. Commun. 7 11683

Google Scholar

Google Scholar

[7] Raoui Y, Ez-Zahraouy H, Tahiri N, El Bounagui O, Ahmad S, Kazim S 2019 Sol. Energy 193 948

Google Scholar

Google Scholar

[8] Mandadapu U, Vedanayakam S V, Thyagarajan K, Reddy M R, Babu B J 2017 Int. J. Energy Res. 7 1603

[9] Okamoto Y, Suzuki Y 2016 J. Phys. Chem. C 120 13995

Google Scholar

Google Scholar

[10] Qiu P, Wei H Y, An Y L, et al. 2020 Ceram. Int. 46 5765

Google Scholar

Google Scholar

[11] Wei H Y, Wu J H, Qiu P, et al. 2019 J. Mater. Chem. A 7 25347

Google Scholar

Google Scholar

[12] Lee K J, Min J W, Turedi B, et al. 2020 ACS Energy Lett. 5 3295

Google Scholar

Google Scholar

[13] Lin S, Zhang B P, Lu T Y, Zheng J C, Pan H Q, Chen H T, Lin C J, Li X R, Zhou J R 2021 Acs Omega 6 26689

Google Scholar

Google Scholar

[14] Chen P, Bai Y, Wang L Z 2021 Small Struct. 2 2000050

Google Scholar

Google Scholar

[15] Mahesh S, Ball J M, Oliver R D J, Mcmeekin D P, Nayak P K, Johnston M B, Snaith H J 2020 Energy Environ. Sci. 13 258

Google Scholar

Google Scholar

[16] Wang P Y, Li R J, Chen B B, Hou F H, Zhang J, Zhao Y, Zhang X D 2020 Adv. Mater. 32 1905766

Google Scholar

Google Scholar

[17] Zhou X Y, Hu M M, Liu C, Zhang L Z, Zhong X W, Li X N, Tian Y Q, Cheng C, Xu B M A 2019 Nano Energy 63 103866

Google Scholar

Google Scholar

[18] Han W B, Ren G H, Liu J M, Li Z Q, Bao H C, Liu C Y, Guo W B 2020 ACS Appl. Mater. Interfaces 12 49297

Google Scholar

Google Scholar

[19] Stolterfoht M, Caprioglio P, Wolff C M, et al. 2019 Energy Environ. Sci. 12 2778

Google Scholar

Google Scholar

[20] Burgelman M, Nollet P, Degrave S 2000 Thin Solid Films 361 527

Google Scholar

Google Scholar

[21] Bal S S, Basak A, Singh U P 2022 Opt. Mater. 127 112282

Google Scholar

Google Scholar

[22] Kumar P, Shankar G, Pradhan B 2022 Mater. Today Proc. 66 3392

Google Scholar

Google Scholar

[23] Jafarzadeh F, Aghili H, Nikbakht H, Javadpour S 2022 Sol. Energy 236 195

Google Scholar

Google Scholar

[24] Muth J F, Lee J E, Shmagin I K, Kolbas R M, Casey H C, Keller B P, Mishra U K, Denbaars 1997 Appl. Phys. Lett. 71 2572

Google Scholar

Google Scholar

[25] Levinshtein M E, Rumyantsev S L, Shur M S 2001 Properties of Advanced Semiconductor Materials: GaN, AIN, InN, BN, SiC, SiGe (John Wiley & Sons) pp1–28

[26] Zhang D Y, Xu P, Wu T, Ou Y M, Yang X T, Sun A X, Cui B, Sun H W, Hua Y 2019 J. Mater. Chem. A 7 5221

Google Scholar

Google Scholar

[27] Jeyakumar R, Bag A, Nekovei R, Radhakrishnan R 2020 J. Electron. Mater. 49 3533

Google Scholar

Google Scholar

[28] Minemoto T, Murata M 2015 Sol. Energy Mater Sol. Cells 133 8

Google Scholar

Google Scholar

[29] 甘永进, 蒋曲博, 覃斌毅, 毕雪光, 李清流 2021 70 038801

Google Scholar

Google Scholar

Gan Y J, Jiang Q B, Qin B Y, Bi X G, Li Q L 2021 Acta. Phys. Sin. 70 038801

Google Scholar

Google Scholar

[30] He Y Z, Xu L Y, Yang C, Guo X W, Li S R 2021 Nanomaterials 11 2321

Google Scholar

Google Scholar

[31] Gan Y J, Bi X G, Liu Y C, Qin B Y, Li Q L, Jiang Q B, Mo P 2020 Energies 13 5907

Google Scholar

Google Scholar

[32] Tan K, Lin P, Wang G, Liu Y, Xu Z C, Lin Y X 2016 Solid State Electron. 126 75

Google Scholar

Google Scholar

[33] Turcu M, Rau U 2003 J. Phys. Chem. Solids 64 1591

Google Scholar

Google Scholar

[34] Tanaka K, Minemoto T, Takakura H 2009 Sol. Energy 83 477

Google Scholar

Google Scholar

[35] Leijtens T, Eperon G E, Barker A J, et al. 2016 Energy Environ. Sci. 9 3472

Google Scholar

Google Scholar

[36] Stolterfoht M, Wolff C M, Marquez J A, et al. 2018 Nat. Energy 3 847

Google Scholar

Google Scholar

[37] Caprioglio P, Stolterfoht M, Wolff C M, Unold T, Rech B, Albrecht S, Neher D 2019 Adv. Energy Mater. 9 1901631

Google Scholar

Google Scholar

[38] Ran C X, Xu J T, Gao W Y, Huang C M, Dou S X 2018 Chem. Soc. Rev. 47 4581

Google Scholar

Google Scholar

[39] Duha A U, Borunda M F 2022 Opt. Mater. 123 111891

Google Scholar

Google Scholar

[40] 肖友鹏, 王涛, 魏秀琴, 周浪 2017 66 108801

Google Scholar

Google Scholar

Xiao Y P, Wang T, Wei X Q, Zhou L 2017 Acta. Phys. Sin. 66 108801

Google Scholar

Google Scholar

[41] Trukhanov V A, Bruevich V V, Paraschuk D Y 2011 Phys. Rev. B 84 205318

Google Scholar

Google Scholar

[42] Shao Y C, Yuan Y B, Huang J S 2016 Nat. Energy 1 15001

Google Scholar

Google Scholar

[43] Edri E, Kirmayer S, Henning A, Mukhopadhyay S, Gartsman K, Rosenwaks Y, Hodes G, Cahen D 2014 Nano Lett. 14 1000

Google Scholar

Google Scholar

[44] Deng Y H, Ni Z Y, Palmstrom A F, Zhao J J, Xu S, Van Brackle C H, Xiao X, Zhu K, Huang J S 2020 Joule 4 1949

Google Scholar

Google Scholar

[45] Xu G Y, Xue R M, Stuard S J, Ade H, Zhang C J, Yao J L, Li Y W, Li Y F 2021 Adv. Mater. 33 2006753

Google Scholar

Google Scholar

[46] Wang D, Wu C C, Luo W, Guo X, Qu B, Xiao L X, Chen Z J 2018 ACS Appl. Energy Mater. 1 2215

Google Scholar

Google Scholar

[47] Minemoto T, Matsui T, Takakura H, et al. 2001 Sol. Energy Mater Sol. Cells 67 83

Google Scholar

Google Scholar

[48] Nollet P, Kontges M, Burgelman M, Degrave D S, Reineke-Koch R 2003 Thin Solid Films 431 414

Google Scholar

Google Scholar

[49] Belarbi M, Zeggai O, Khettaf S, Louhibi-Fasla S 2022 Semicond. Sci. Tech. 37 095016

Google Scholar

Google Scholar

[50] Ghosh S, Porwal S, Singh T 2022 Optik 256 168749

Google Scholar

Google Scholar

-

表 1 模拟中使用的参数

Table 1. Parameters used in the simulation.

参数 GaN 活性层 HTL 厚度/μm 0.10 0.55 0.10 带隙/eV 3.40[24] 1.55[11] 3.11 电子亲和势/eV 4.10[25] 4.05[26] 2.25 介电常数 (relative) 8.90 6.50 3.00 导带有效态密度/(1018 cm–3) 2.30 2.20 2.20[27] 价带有效态密度/(1019 cm–3) 4.60 1.80 1.80[27] 电子热速度/(107 cm·s–1) 1.00 1.00 1.00 空穴热速度/(107 cm·s–1) 1.00 1.00 1.00 电子迁移率/(102 cm·V–1·s–1) 10.0 5.00 1.00 空穴迁移率/(cm·V–1·s–1) 100 60 50 浅均匀掺杂施主浓度 ND/(1016 cm–3) 1.00 — — 浅均匀掺杂受主浓度 NA/(1015 cm–3) — 1.00 1.00×103[27] 缺陷浓度/(1015 cm–3) 1.00 1.00×10–2 1.00 表 2 GaN与活性层、活性层与空穴传输层之间的参数

Table 2. Parameters of GaN/active and active/HTL layer interfaces.

参数 GaN/活性层界面 活性层/HTL界面 缺陷类型 中性 中性 电子捕获截面/(10–19 cm2) 1.0 1.0 空穴捕获截面/(10–19 cm2) 1.0 1.0 能量分布 单一 单一 缺陷能级Et的参考 高于最高价带能级 高于最高价带能级 相对于参考能级的能量/eV 0.6 0.6 缺陷密度/(1010 cm–3) 1.0×105 1.0 表 3 有GaN与无GaN时电池模拟参数对比

Table 3. Comparison of solar cell simulation parameters with and without GaN.

Samples Jsc/ (mA·cm–2) Voc/V FF/% PCE/% Vmpp /V Jmpp / (mA·cm–2) With GaN 24.12 1.21 82.67 24.18 1.05 22.99 Free GaN 24.03 0.78 84.44 15.87 0.69 22.93 表 4 GaN/FTO耗尽区宽度与Voc变化宽度对比

Table 4. Comparison between depletion width of GaN/FTO interface and Voc variation width.

Parameters Nd/cm–3 1015 1016 1017 1018 1019 GaN/FTO异质结中GaN耗尽区厚度/nm — — 84.00 29.46 9.18 Voc随厚度变化的凹点宽度/nm — — 84.00 29.00 9.00 活性层/GaN异质结中GaN耗尽区厚度/nm — — 40.17 13.65 3.80 Voc随厚度变化的凹点位置/nm — — 40.00 13.00 3.00 -

[1] Koblmuller G, Wu F, Mates T, Speck J S, Fernandez-Garrido S, Calleja E 2007 Appl. Phys. Lett. 91 221905

Google Scholar

Google Scholar

[2] Yildirim M A, Teker K 2021 Nano 16 2150021

Google Scholar

Google Scholar

[3] Leijtens T, Eperon G E, Pathak S, Abate A, Lee M M, Snaith H J 2013 Nat. Commun. 4 2885

Google Scholar

Google Scholar

[4] Luo Y Q, Khoram P, Brittman S, Zhu Z Y, Lai B, Ong S P, Garnett E C, Fenning D P 2017 Adv. Mater. 29 1703451

Google Scholar

Google Scholar

[5] Bischak C G, Hetherington C L, Wu H, Aloni S, Ogletree D F, Limmer D T, Ginsberg N S 2017 Nano Lett. 17 1028

Google Scholar

Google Scholar

[6] Dequilettes D W, Zhang W, Burlakov V M, et al. 2016 Nat. Commun. 7 11683

Google Scholar

Google Scholar

[7] Raoui Y, Ez-Zahraouy H, Tahiri N, El Bounagui O, Ahmad S, Kazim S 2019 Sol. Energy 193 948

Google Scholar

Google Scholar

[8] Mandadapu U, Vedanayakam S V, Thyagarajan K, Reddy M R, Babu B J 2017 Int. J. Energy Res. 7 1603

[9] Okamoto Y, Suzuki Y 2016 J. Phys. Chem. C 120 13995

Google Scholar

Google Scholar

[10] Qiu P, Wei H Y, An Y L, et al. 2020 Ceram. Int. 46 5765

Google Scholar

Google Scholar

[11] Wei H Y, Wu J H, Qiu P, et al. 2019 J. Mater. Chem. A 7 25347

Google Scholar

Google Scholar

[12] Lee K J, Min J W, Turedi B, et al. 2020 ACS Energy Lett. 5 3295

Google Scholar

Google Scholar

[13] Lin S, Zhang B P, Lu T Y, Zheng J C, Pan H Q, Chen H T, Lin C J, Li X R, Zhou J R 2021 Acs Omega 6 26689

Google Scholar

Google Scholar

[14] Chen P, Bai Y, Wang L Z 2021 Small Struct. 2 2000050

Google Scholar

Google Scholar

[15] Mahesh S, Ball J M, Oliver R D J, Mcmeekin D P, Nayak P K, Johnston M B, Snaith H J 2020 Energy Environ. Sci. 13 258

Google Scholar

Google Scholar

[16] Wang P Y, Li R J, Chen B B, Hou F H, Zhang J, Zhao Y, Zhang X D 2020 Adv. Mater. 32 1905766

Google Scholar

Google Scholar

[17] Zhou X Y, Hu M M, Liu C, Zhang L Z, Zhong X W, Li X N, Tian Y Q, Cheng C, Xu B M A 2019 Nano Energy 63 103866

Google Scholar

Google Scholar

[18] Han W B, Ren G H, Liu J M, Li Z Q, Bao H C, Liu C Y, Guo W B 2020 ACS Appl. Mater. Interfaces 12 49297

Google Scholar

Google Scholar

[19] Stolterfoht M, Caprioglio P, Wolff C M, et al. 2019 Energy Environ. Sci. 12 2778

Google Scholar

Google Scholar

[20] Burgelman M, Nollet P, Degrave S 2000 Thin Solid Films 361 527

Google Scholar

Google Scholar

[21] Bal S S, Basak A, Singh U P 2022 Opt. Mater. 127 112282

Google Scholar

Google Scholar

[22] Kumar P, Shankar G, Pradhan B 2022 Mater. Today Proc. 66 3392

Google Scholar

Google Scholar

[23] Jafarzadeh F, Aghili H, Nikbakht H, Javadpour S 2022 Sol. Energy 236 195

Google Scholar

Google Scholar

[24] Muth J F, Lee J E, Shmagin I K, Kolbas R M, Casey H C, Keller B P, Mishra U K, Denbaars 1997 Appl. Phys. Lett. 71 2572

Google Scholar

Google Scholar

[25] Levinshtein M E, Rumyantsev S L, Shur M S 2001 Properties of Advanced Semiconductor Materials: GaN, AIN, InN, BN, SiC, SiGe (John Wiley & Sons) pp1–28

[26] Zhang D Y, Xu P, Wu T, Ou Y M, Yang X T, Sun A X, Cui B, Sun H W, Hua Y 2019 J. Mater. Chem. A 7 5221

Google Scholar

Google Scholar

[27] Jeyakumar R, Bag A, Nekovei R, Radhakrishnan R 2020 J. Electron. Mater. 49 3533

Google Scholar

Google Scholar

[28] Minemoto T, Murata M 2015 Sol. Energy Mater Sol. Cells 133 8

Google Scholar

Google Scholar

[29] 甘永进, 蒋曲博, 覃斌毅, 毕雪光, 李清流 2021 70 038801

Google Scholar

Google Scholar

Gan Y J, Jiang Q B, Qin B Y, Bi X G, Li Q L 2021 Acta. Phys. Sin. 70 038801

Google Scholar

Google Scholar

[30] He Y Z, Xu L Y, Yang C, Guo X W, Li S R 2021 Nanomaterials 11 2321

Google Scholar

Google Scholar

[31] Gan Y J, Bi X G, Liu Y C, Qin B Y, Li Q L, Jiang Q B, Mo P 2020 Energies 13 5907

Google Scholar

Google Scholar

[32] Tan K, Lin P, Wang G, Liu Y, Xu Z C, Lin Y X 2016 Solid State Electron. 126 75

Google Scholar

Google Scholar

[33] Turcu M, Rau U 2003 J. Phys. Chem. Solids 64 1591

Google Scholar

Google Scholar

[34] Tanaka K, Minemoto T, Takakura H 2009 Sol. Energy 83 477

Google Scholar

Google Scholar

[35] Leijtens T, Eperon G E, Barker A J, et al. 2016 Energy Environ. Sci. 9 3472

Google Scholar

Google Scholar

[36] Stolterfoht M, Wolff C M, Marquez J A, et al. 2018 Nat. Energy 3 847

Google Scholar

Google Scholar

[37] Caprioglio P, Stolterfoht M, Wolff C M, Unold T, Rech B, Albrecht S, Neher D 2019 Adv. Energy Mater. 9 1901631

Google Scholar

Google Scholar

[38] Ran C X, Xu J T, Gao W Y, Huang C M, Dou S X 2018 Chem. Soc. Rev. 47 4581

Google Scholar

Google Scholar

[39] Duha A U, Borunda M F 2022 Opt. Mater. 123 111891

Google Scholar

Google Scholar

[40] 肖友鹏, 王涛, 魏秀琴, 周浪 2017 66 108801

Google Scholar

Google Scholar

Xiao Y P, Wang T, Wei X Q, Zhou L 2017 Acta. Phys. Sin. 66 108801

Google Scholar

Google Scholar

[41] Trukhanov V A, Bruevich V V, Paraschuk D Y 2011 Phys. Rev. B 84 205318

Google Scholar

Google Scholar

[42] Shao Y C, Yuan Y B, Huang J S 2016 Nat. Energy 1 15001

Google Scholar

Google Scholar

[43] Edri E, Kirmayer S, Henning A, Mukhopadhyay S, Gartsman K, Rosenwaks Y, Hodes G, Cahen D 2014 Nano Lett. 14 1000

Google Scholar

Google Scholar

[44] Deng Y H, Ni Z Y, Palmstrom A F, Zhao J J, Xu S, Van Brackle C H, Xiao X, Zhu K, Huang J S 2020 Joule 4 1949

Google Scholar

Google Scholar

[45] Xu G Y, Xue R M, Stuard S J, Ade H, Zhang C J, Yao J L, Li Y W, Li Y F 2021 Adv. Mater. 33 2006753

Google Scholar

Google Scholar

[46] Wang D, Wu C C, Luo W, Guo X, Qu B, Xiao L X, Chen Z J 2018 ACS Appl. Energy Mater. 1 2215

Google Scholar

Google Scholar

[47] Minemoto T, Matsui T, Takakura H, et al. 2001 Sol. Energy Mater Sol. Cells 67 83

Google Scholar

Google Scholar

[48] Nollet P, Kontges M, Burgelman M, Degrave D S, Reineke-Koch R 2003 Thin Solid Films 431 414

Google Scholar

Google Scholar

[49] Belarbi M, Zeggai O, Khettaf S, Louhibi-Fasla S 2022 Semicond. Sci. Tech. 37 095016

Google Scholar

Google Scholar

[50] Ghosh S, Porwal S, Singh T 2022 Optik 256 168749

Google Scholar

Google Scholar

计量

- 文章访问数: 7717

- PDF下载量: 289

- 被引次数: 0

下载:

下载: