-

黏弹性流体广泛存在于自然界和工业生产中, 对其复杂流变特性的研究具有重要的学术价值和应用意义. 本文提出一种改进的光滑粒子动力学方法, 对基于eXtended Pom-Pom模型的黏弹性流动进行了数值模拟. 为了提高计算精度, 采用一种不含核导数计算的核梯度修正离散格式. 为了防止粒子穿透固壁, 提出一种增强型的边界处理技术. 为了消除张力不稳定性, 将人工应力耦合到动量守恒方程中. 运用改进光滑粒子动力学方法数值模拟了基于eXtended Pom-Pom模型的黏弹性Poiseuille流和黏弹性液滴撞击固壁问题, 通过与解析解或有限差分方法解的比较以及对数值收敛性的评价, 验证了改进光滑粒子动力学方法的有效性和优势, 并在此基础上, 深入分析了Reyonlds数、Weissenberg数、溶剂黏度比、各向异性参数、松弛时间比和分子链臂数等流变参数对流动过程的影响.

-

关键词:

- 光滑粒子动力学 /

- eXtended Pom-Pom模型 /

- Poiseuille流 /

- 液滴

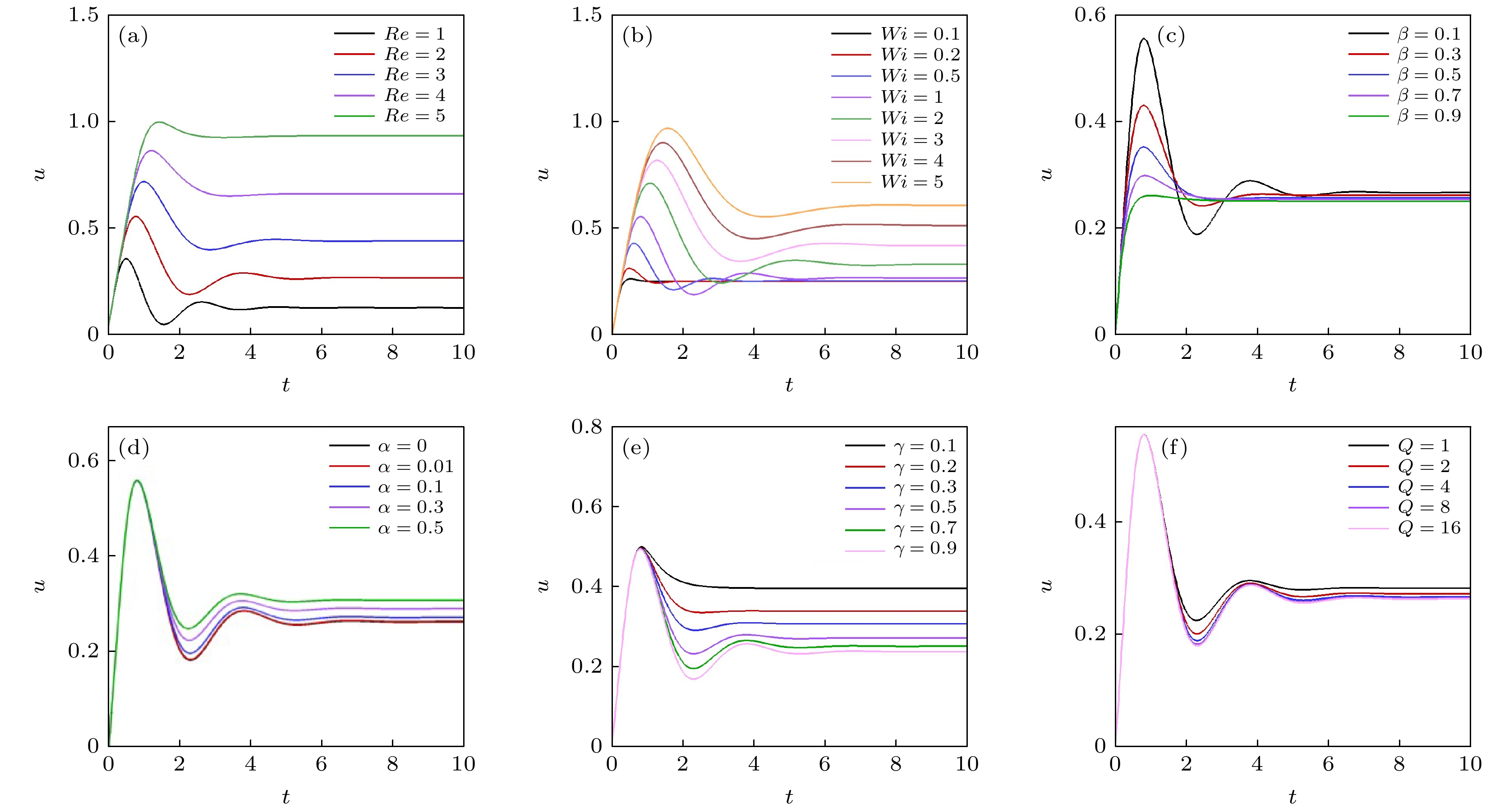

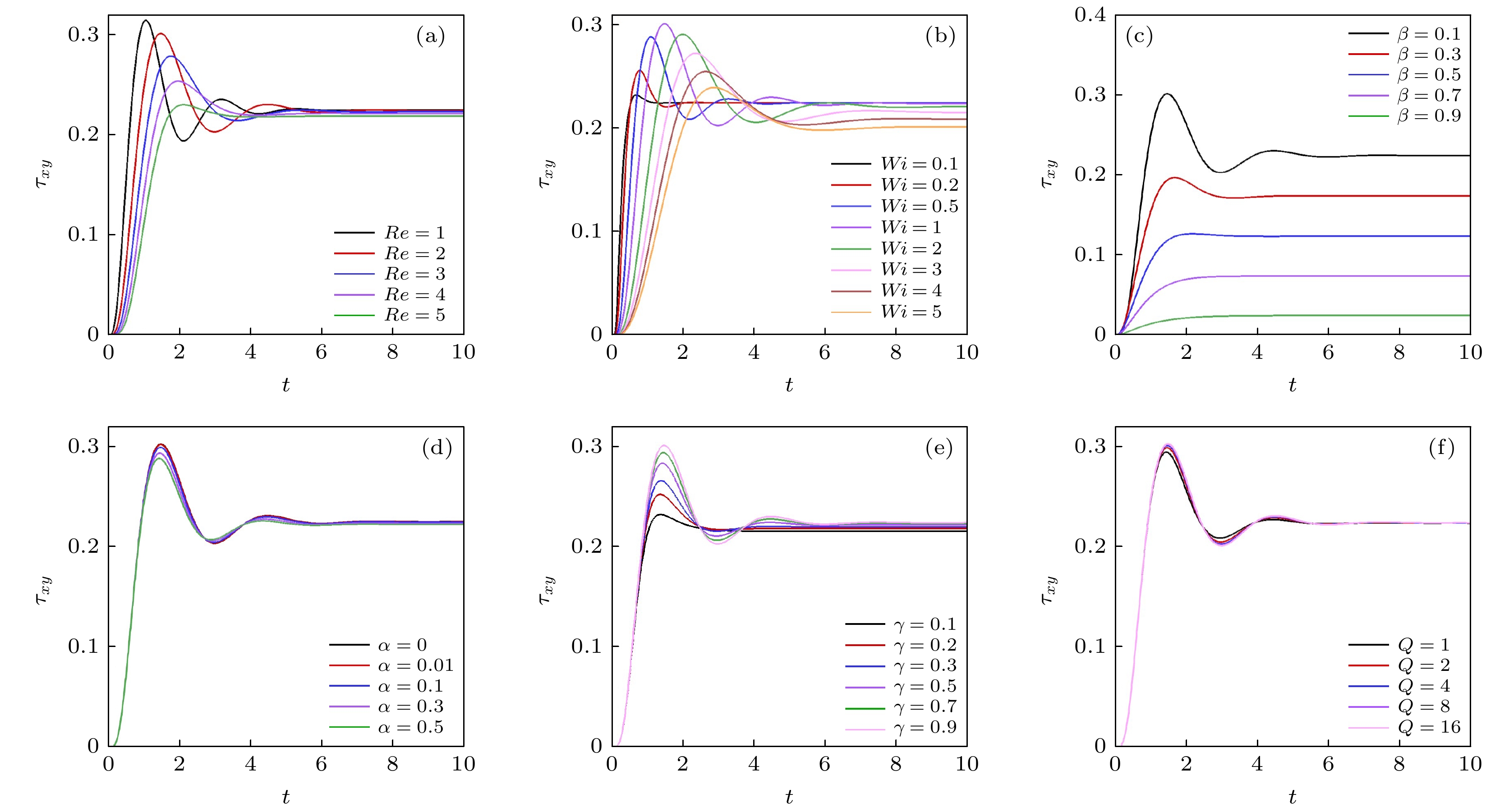

Viscoelastic fluids widely exist in nature and industrial production, and the study of their complex rheological properties has important academic value and application significance. In this work, an improved smoothed particle hydrodynamics (SPH) method is proposed to numerically simulate the viscoelastic flow based on the eXtended Pom-Pom (XPP) model. In order to improve the accuracy of the calculation, a kernel gradient correction discrete format without kernel derivative calculation is adopted. In order to prevent fluid particles from penetrating the solid wall, an enhanced boundary processing technology is proposed. To eliminate the tensile instability, an artificial stress is coupled into the momentum equation of conservation. Based on the XPP model, the viscoelastic Poiseuille flow and the viscoelastic droplet impacting solid wall problem are simulated by using the improved SPH method. The effectiveness and advantages of the improved SPH method are verified by comparing the SPH solutions with the solutions from the analytical method or finite difference method. The convergence of the improved SPH method is further evaluated by using several different particle sizes. On this basis, the influences of rheological parameters such as Reyonlds number Re, Weissenberg number Wi, solvent viscosity ratio β, anisotropy parameter α, relaxation time ratio γ and molecular chain arm number Q on the flow process are analyzed in depth. For the viscoelastic Poiseuille flow, the bigger the value of Re, Wi, and α, the larger the steady-state velocity is; the larger the value of γ and Q, the smaller the steady-state velocity is; the larger the value of β, the weaker the velocity overshoot is, but it does not affect the steady-state velocity. For the viscoelastic droplet problem, the larger the value of Re and Wi, the faster the droplet spreads; the larger the value of β, the weaker the droplet shrinkage behavior is, but it does not affect the final spreading width of droplet; the larger the value of α, the larger the droplet’s spreading width is; the larger the value of γ is, the stronger the droplet shrinkage behavior is; the larger the value of Q, the weaker its influence on the droplet’s spread width is. The improved SPH method in this paper can effectively describe the complex rheological properties and the free surface variation characteristics of viscoelastic fluid based on XPP model.-

Keywords:

- smoothed particle hydrodynamics /

- eXtended Pom-Pom model /

- Poiseuille flow /

- droplet

[1] Viezel C, Tomé M F, Pinho F T, McKee S 2020 J. Non-newton Fluid Mech. 285 104338

Google Scholar

Google Scholar

[2] Li B, Chen L, Joo S 2021 Case Stud. Therm. Eng. 26 101109

Google Scholar

Google Scholar

[3] Li S, Liu W K 2007 Meshfree Particle Methods (Springer Science & Business Media) p68

[4] Gingold R A, Monaghan J J 1977 Mon. Not. R. Astron. Soc. 181 375

Google Scholar

Google Scholar

[5] Lucy L B 1977 Astron. J. 82 1013

Google Scholar

Google Scholar

[6] 马理强, 刘谋斌, 常建忠, 苏铁熊, 刘汉涛 2012 61 244701

Google Scholar

Google Scholar

Ma L Q, Liu M B, Chang J Z, Su T X, Liu H T 2012 Acta Phys. Sin. 61 244701

Google Scholar

Google Scholar

[7] 邵绪强, 梅鹏, 陈文新 2021 70 234701

Google Scholar

Google Scholar

Shao X Q, Mei P, Chen W X 2021 Acta Phys. Sin. 70 234701

Google Scholar

Google Scholar

[8] Macià F, Merino-Alonso P E, Souto-Iglesias A 2022 Comput. Methods Appl. Mech. Eng. 397 115045

Google Scholar

Google Scholar

[9] Xu X, Dey M, Qiu M, Feng J J 2020 Appl. Math. Model. 83 719

Google Scholar

Google Scholar

[10] Liu M B, Zhang Z L, Feng D L 2017 Comput. Mech. 60 513

Google Scholar

Google Scholar

[11] Zhang C, Rezavand M, Hu X 2021 J. Comput. Phys. 429 110028

Google Scholar

Google Scholar

[12] Liu W K, Jun S, Zhang Y F 1995 Int. J. Numer. Methods Fluid 20 1081

Google Scholar

Google Scholar

[13] Liu M B, Liu G R 2006 Appl. Numer. Math. 56 19

Google Scholar

Google Scholar

[14] Fang J, Parriaux A, Rentschler M, Ancey C 2009 Appl. Numer. Math. 59 251

Google Scholar

Google Scholar

[15] Yang X, Liu M, Peng S 2014 Comput. Fluids 92 199

Google Scholar

Google Scholar

[16] Antuono M, Sun P N, Marrone S, Colagrossi A 2021 Comput. Fluids 216 104806

Google Scholar

Google Scholar

[17] Lyu H G, Sun P N 2022 Appl. Math. Model 101 214

Google Scholar

Google Scholar

[18] Monaghan J J, Kajtar J B 2009 Comput. Phys. Commun. 180 1811

Google Scholar

Google Scholar

[19] Morris J P, Fox P J, Zhu Y 1997 J. Comput. Phys. 136 214

Google Scholar

Google Scholar

[20] Liu M B, Shao J R, Chang J Z 2012 Sci. China Technol. Sci. 55 244

Google Scholar

Google Scholar

[21] Fang J, Owens R G, Tacher L, Parriaux A 2006 J. Non-newton Fluid Mech. 139 68

Google Scholar

Google Scholar

[22] Hashemi M R, Fatehi R, Manzari M T 2011 J. Non-newton Fluid Mech. 166 1239

Google Scholar

Google Scholar

[23] Xu X, Deng X L 2016 Comput. Phys. Commun. 201 43

Google Scholar

Google Scholar

[24] Ozgen O, Kallmann M, Brown E 2019 Comput. Animat. Virtual Worlds 30 e1870

Google Scholar

Google Scholar

[25] Vahabi M, Kamkari B 2019 Eur. J. Mech. B. Fluids 75 1

[26] King J R C, Lind S J 2021 J. Non-newton Fluid Mech. 293 104556

Google Scholar

Google Scholar

[27] Verbeeten W M H, Peters G W M, Baaijens F P T 2001 J. Rheol. 45 823

Google Scholar

Google Scholar

[28] O'connor J, Domínguez J M, Rogers B D, Lind S J, Stansby P K 2022 Comput. Phys. Commun. 273 108263

Google Scholar

Google Scholar

[29] Jiang T, Ouyang J, Ren J L, Yang B, Xu X 2012 Comput. Phys. Commun. 183 50

Google Scholar

Google Scholar

[30] Xu X, Yu P 2018 Comput. Mech. 62 963

Google Scholar

Google Scholar

[31] Monaghan J J 2000 J. Comput. Phys. 159 290

Google Scholar

Google Scholar

[32] Gray J P, Monaghan J J, Swift R P 2001 Comput. Methods Appl. Mech. Eng. 190 6641

Google Scholar

Google Scholar

[33] Waters N D, King M J 1970 Rheol. Acta 9 345

Google Scholar

Google Scholar

[34] Oishi C M, Martins F P, Tomé M F, Alves M A 2012 J. Non-newton Fluid Mech. 169 91

Google Scholar

Google Scholar

-

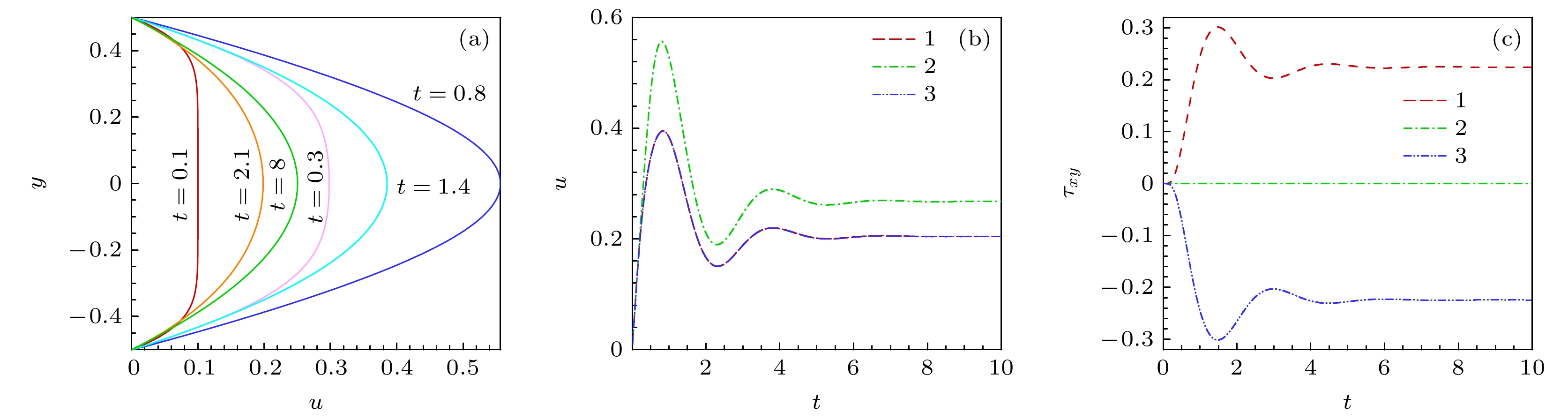

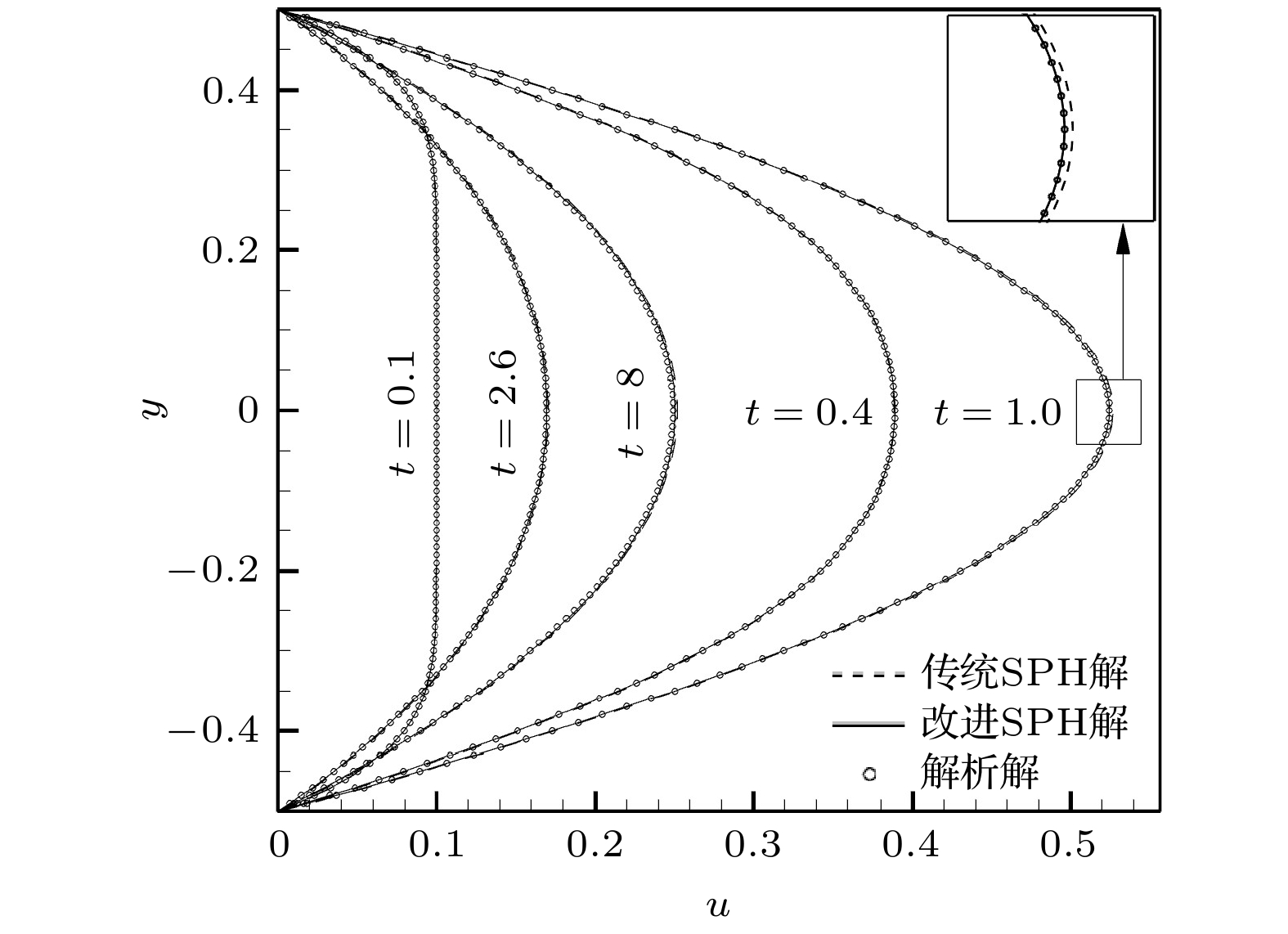

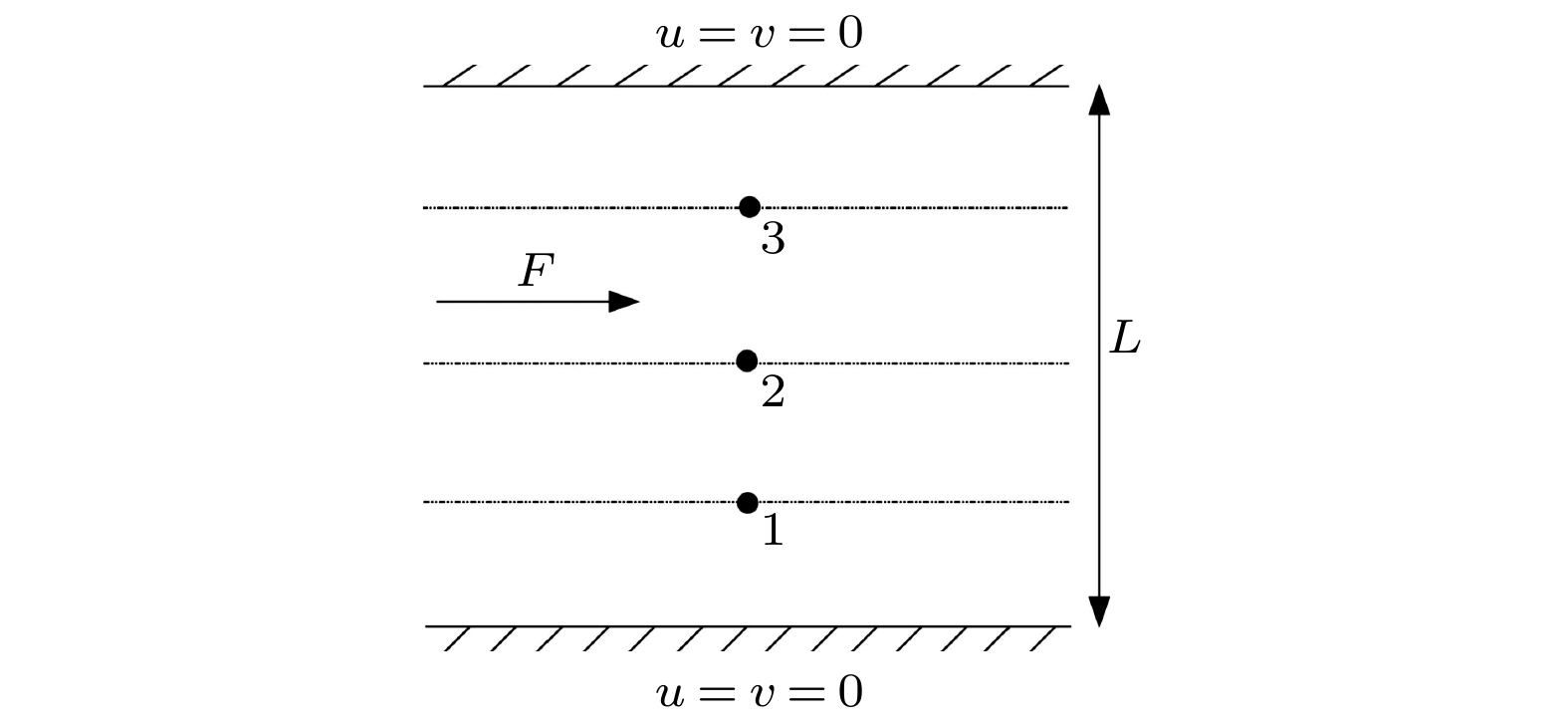

图 2 基于XPP模型的黏弹性Poiseuille流的SPH模拟 (Re = 2, Wi = 1, β = 0.1, α = 0.01, γ = 0.9, Q = 4) (a) 速度分布图; (b) 空间点1—3速度u随时间的变化; (c) 空间点1—3弹性剪切应力τxy随时间的变化

Fig. 2. SPH simulation of viscoelastic Poiseuille flow based on XPP model (Re = 2, Wi = 1, β = 0.1, α = 0.01, γ = 0.9, Q = 4): (a) Velocity profile; (b) time change of velocity u at points 1 to 3; (c) time change of elastic shear stress τxy at points 1 to 3.

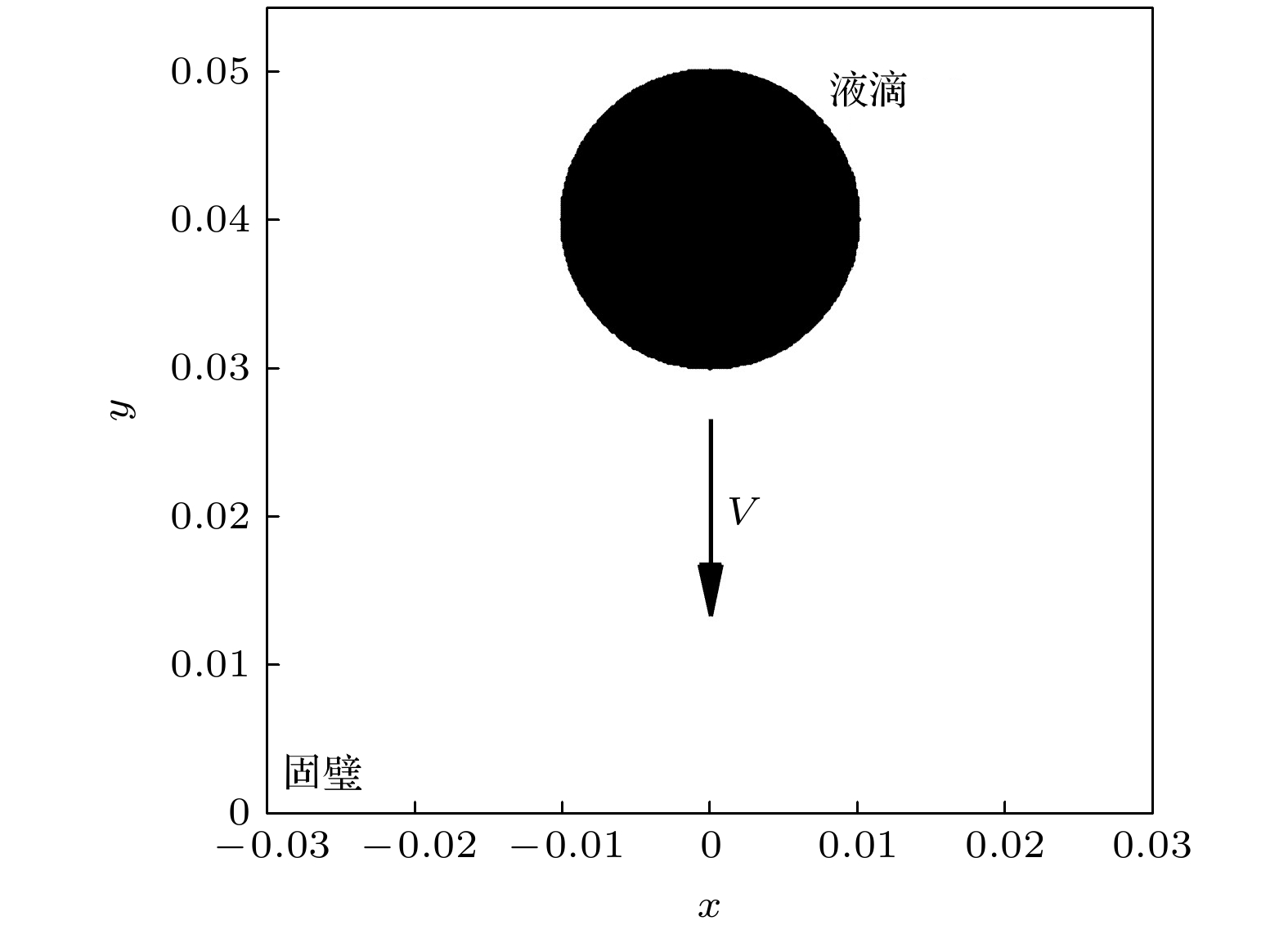

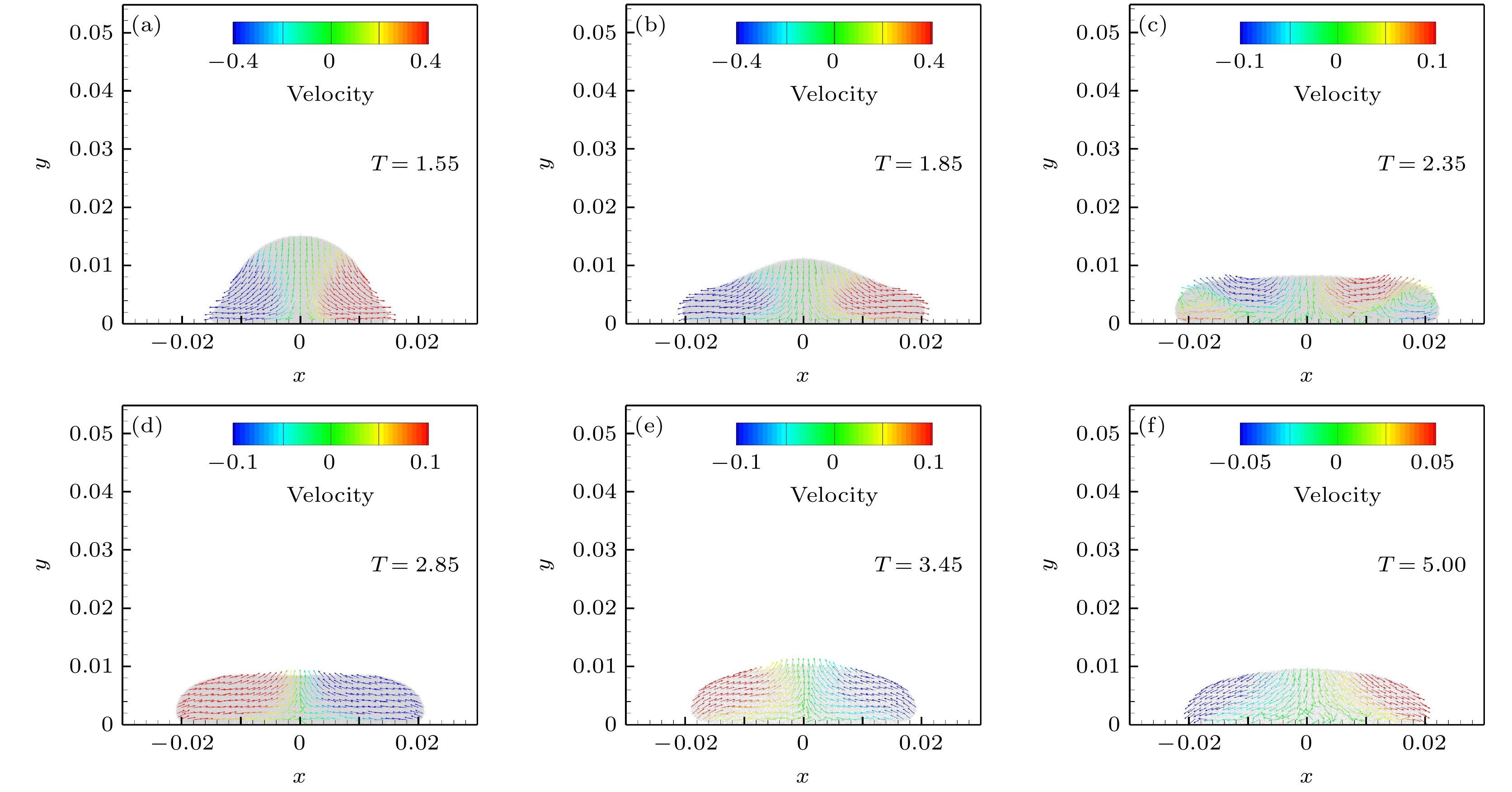

图 10 基于XPP模型的液滴撞击固壁问题的SPH模拟(Re = 5, Wi = 1, β = 0.1, α = 0.01, γ = 0.9, Q = 4) (a) T = 1.55; (b) T = 1.85; (c) T = 2.35; (d) T = 2.85; (e) T = 3.45; (f) T = 5.00

Fig. 10. SPH simulation of droplet impacting solid wall problem based on XPP model (Re = 5, Wi = 1, β = 0.1, α = 0.01, γ = 0.9, Q = 4): (a) T = 1.55; (b) T = 1.85; (c) T = 2.35; (d) T = 2.85; (e) T = 3.45; (f) T = 5.00.

-

[1] Viezel C, Tomé M F, Pinho F T, McKee S 2020 J. Non-newton Fluid Mech. 285 104338

Google Scholar

Google Scholar

[2] Li B, Chen L, Joo S 2021 Case Stud. Therm. Eng. 26 101109

Google Scholar

Google Scholar

[3] Li S, Liu W K 2007 Meshfree Particle Methods (Springer Science & Business Media) p68

[4] Gingold R A, Monaghan J J 1977 Mon. Not. R. Astron. Soc. 181 375

Google Scholar

Google Scholar

[5] Lucy L B 1977 Astron. J. 82 1013

Google Scholar

Google Scholar

[6] 马理强, 刘谋斌, 常建忠, 苏铁熊, 刘汉涛 2012 61 244701

Google Scholar

Google Scholar

Ma L Q, Liu M B, Chang J Z, Su T X, Liu H T 2012 Acta Phys. Sin. 61 244701

Google Scholar

Google Scholar

[7] 邵绪强, 梅鹏, 陈文新 2021 70 234701

Google Scholar

Google Scholar

Shao X Q, Mei P, Chen W X 2021 Acta Phys. Sin. 70 234701

Google Scholar

Google Scholar

[8] Macià F, Merino-Alonso P E, Souto-Iglesias A 2022 Comput. Methods Appl. Mech. Eng. 397 115045

Google Scholar

Google Scholar

[9] Xu X, Dey M, Qiu M, Feng J J 2020 Appl. Math. Model. 83 719

Google Scholar

Google Scholar

[10] Liu M B, Zhang Z L, Feng D L 2017 Comput. Mech. 60 513

Google Scholar

Google Scholar

[11] Zhang C, Rezavand M, Hu X 2021 J. Comput. Phys. 429 110028

Google Scholar

Google Scholar

[12] Liu W K, Jun S, Zhang Y F 1995 Int. J. Numer. Methods Fluid 20 1081

Google Scholar

Google Scholar

[13] Liu M B, Liu G R 2006 Appl. Numer. Math. 56 19

Google Scholar

Google Scholar

[14] Fang J, Parriaux A, Rentschler M, Ancey C 2009 Appl. Numer. Math. 59 251

Google Scholar

Google Scholar

[15] Yang X, Liu M, Peng S 2014 Comput. Fluids 92 199

Google Scholar

Google Scholar

[16] Antuono M, Sun P N, Marrone S, Colagrossi A 2021 Comput. Fluids 216 104806

Google Scholar

Google Scholar

[17] Lyu H G, Sun P N 2022 Appl. Math. Model 101 214

Google Scholar

Google Scholar

[18] Monaghan J J, Kajtar J B 2009 Comput. Phys. Commun. 180 1811

Google Scholar

Google Scholar

[19] Morris J P, Fox P J, Zhu Y 1997 J. Comput. Phys. 136 214

Google Scholar

Google Scholar

[20] Liu M B, Shao J R, Chang J Z 2012 Sci. China Technol. Sci. 55 244

Google Scholar

Google Scholar

[21] Fang J, Owens R G, Tacher L, Parriaux A 2006 J. Non-newton Fluid Mech. 139 68

Google Scholar

Google Scholar

[22] Hashemi M R, Fatehi R, Manzari M T 2011 J. Non-newton Fluid Mech. 166 1239

Google Scholar

Google Scholar

[23] Xu X, Deng X L 2016 Comput. Phys. Commun. 201 43

Google Scholar

Google Scholar

[24] Ozgen O, Kallmann M, Brown E 2019 Comput. Animat. Virtual Worlds 30 e1870

Google Scholar

Google Scholar

[25] Vahabi M, Kamkari B 2019 Eur. J. Mech. B. Fluids 75 1

[26] King J R C, Lind S J 2021 J. Non-newton Fluid Mech. 293 104556

Google Scholar

Google Scholar

[27] Verbeeten W M H, Peters G W M, Baaijens F P T 2001 J. Rheol. 45 823

Google Scholar

Google Scholar

[28] O'connor J, Domínguez J M, Rogers B D, Lind S J, Stansby P K 2022 Comput. Phys. Commun. 273 108263

Google Scholar

Google Scholar

[29] Jiang T, Ouyang J, Ren J L, Yang B, Xu X 2012 Comput. Phys. Commun. 183 50

Google Scholar

Google Scholar

[30] Xu X, Yu P 2018 Comput. Mech. 62 963

Google Scholar

Google Scholar

[31] Monaghan J J 2000 J. Comput. Phys. 159 290

Google Scholar

Google Scholar

[32] Gray J P, Monaghan J J, Swift R P 2001 Comput. Methods Appl. Mech. Eng. 190 6641

Google Scholar

Google Scholar

[33] Waters N D, King M J 1970 Rheol. Acta 9 345

Google Scholar

Google Scholar

[34] Oishi C M, Martins F P, Tomé M F, Alves M A 2012 J. Non-newton Fluid Mech. 169 91

Google Scholar

Google Scholar

计量

- 文章访问数: 5843

- PDF下载量: 86

- 被引次数: 0

下载:

下载: