-

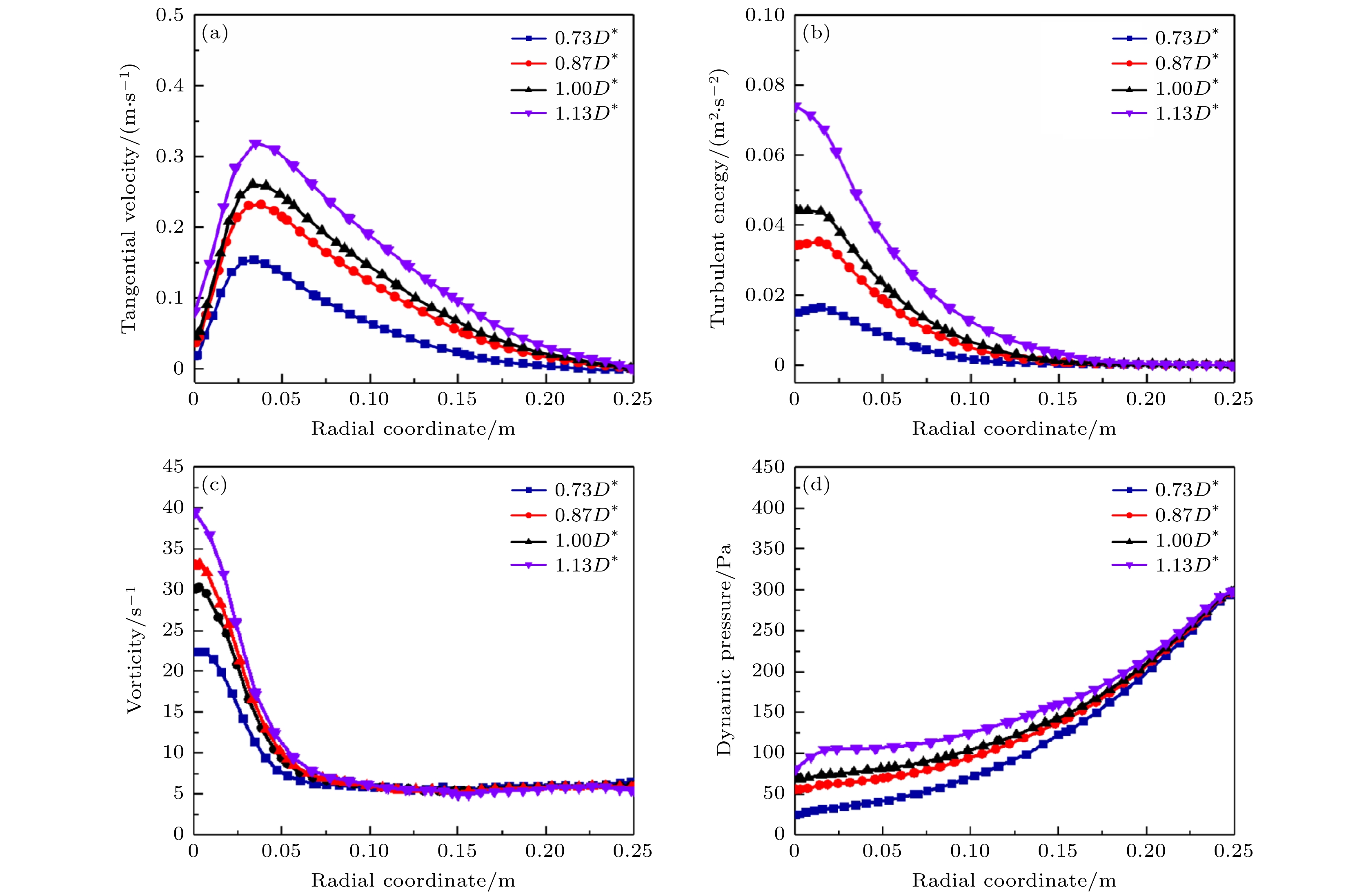

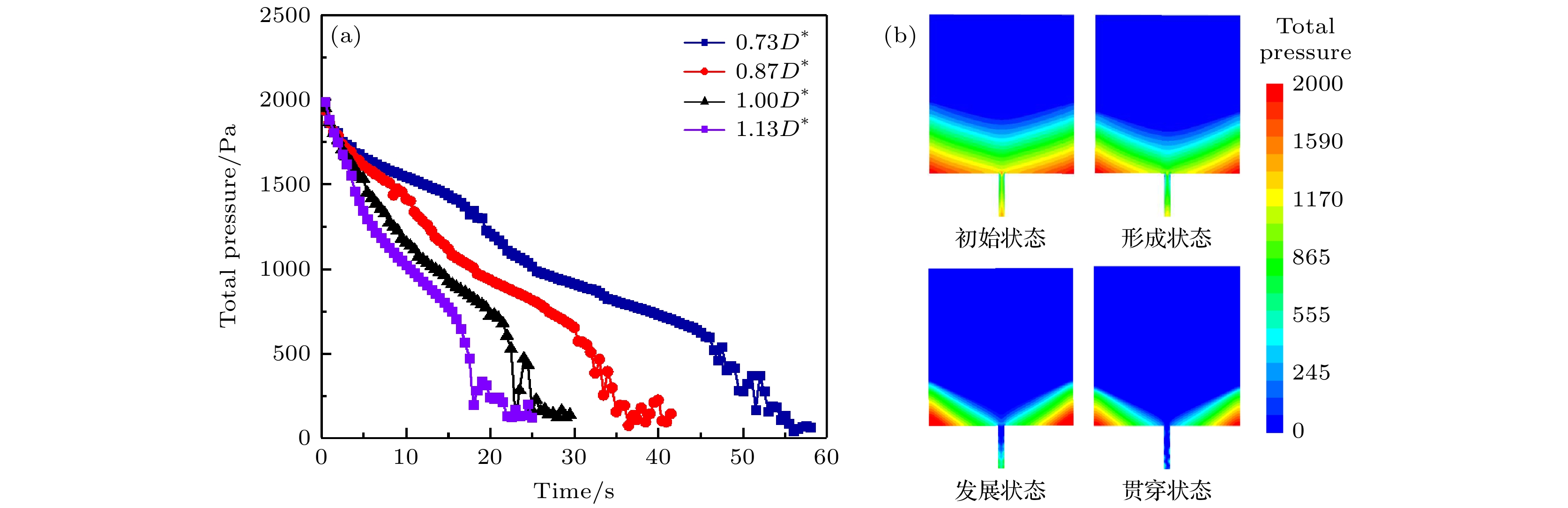

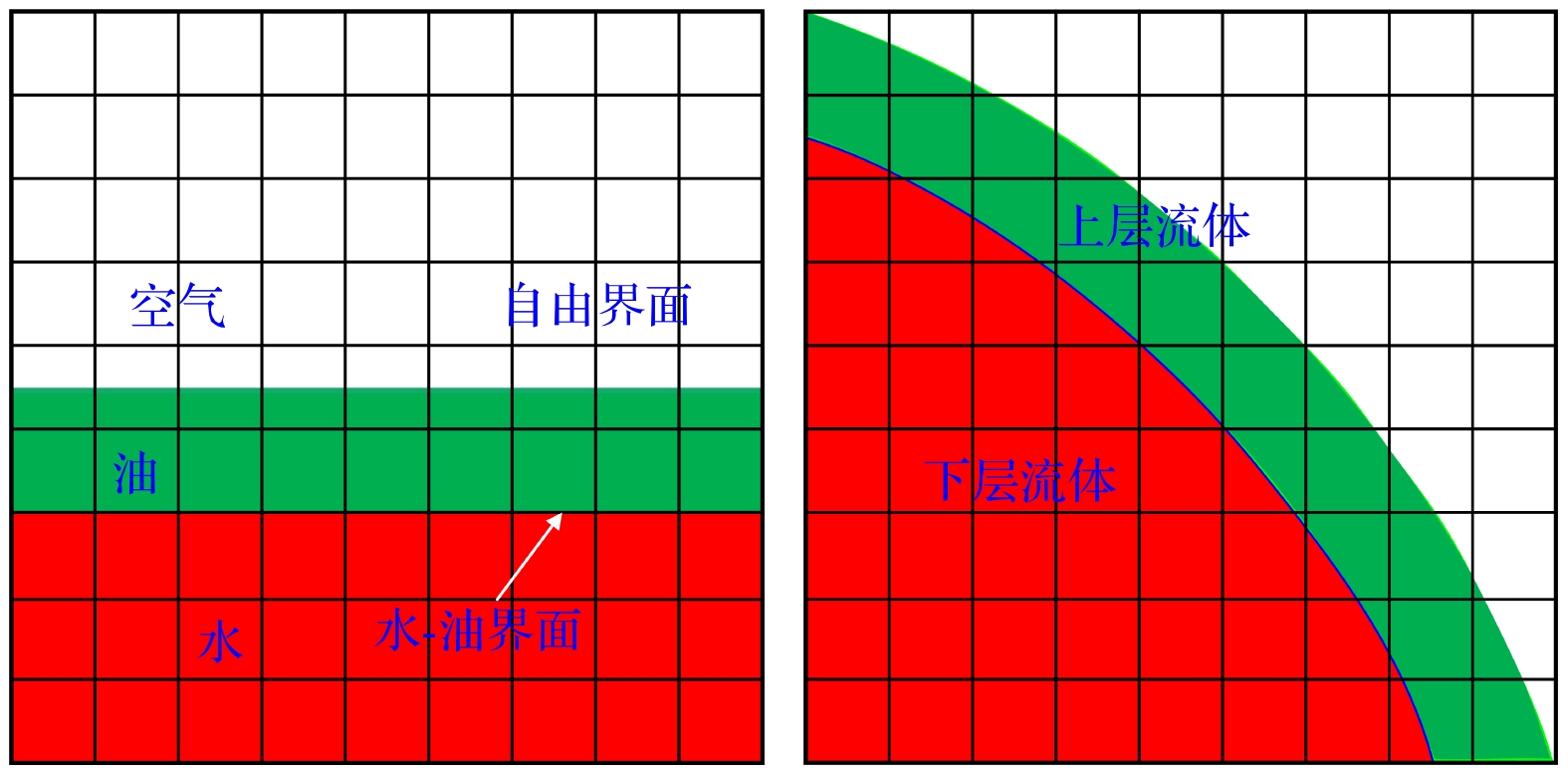

含自由液面的汇流旋涡抽吸演变中存在多相耦合、物质传输、能量剧烈交换等物理过程, 其中所涉及的多相流体耦合输运机理是具有高度非线性特征的复杂动力学问题, 多相黏滞耦合输运动力学建模与数值求解具有较高难度. 针对上述问题, 提出一种含自由液面的汇流旋涡多相耦合输运建模与求解方法. 基于水平集-流体体积耦合(CLSVOF)计算方法, 结合连续表面张力模型和可实现(k-ε)湍流模型, 建立含自由液面的汇流旋涡多相耦合输运动力学模型; 利用一种有效的体积修正方案来计算高速旋转多相流, 保证流场质量守恒和无散度的速度场; 结合相间耦合求解策略对多相流体分布与多相界面进行精确追踪. 基于旋流场多特征物理变量, 得到多相耦合界面动态演变与跨尺度涡团输运规律, 揭示了多相耦合输运过程与压力脉动特性之间的相互作用机理. 研究结果表明: 多相耦合输运过程是流体介质过渡的关键状态, 旋涡微团受到不同时空扰动模式在界面处形成层层螺纹波形; 旋涡多相耦合输运过程随着水口尺度增大而增强, 且耦合能量激波引起非线性压力脉动现象. 研究结果可为旋涡输运机理、涡团跨尺度求解、流型追踪等方面的研究提供有益借鉴.

-

关键词:

- 自由汇流旋涡 /

- 多相耦合输运 /

- 水平集-流体体积耦合方法 /

- 体积修正 /

- 压力脉动

In the evolution of confluence sink vortex with a free surface, there exists some physical processes , such as multiphase coupling, mass transfer, and intensive energy exchange. Here, the transport mechanism of multiphase coupling is a complex dynamic problem with highly nonlinear characteristics. The mechanical modeling and numerical solution of multiphase viscous coupled transport are facing a significant challenge. To address the above problem, a method of modeling and solving multiphase coupling transport of the free sink vortex is proposed. Based on the coupled level set and volume-of-fluid (CLSVOF) method, a multiphase coupling transport model of the free sink vortex is set up with a continuous surface tension model and a realizable (k-ε) turbulence model. By using an effective volumetric correction scheme, the high-speed rotating flow is calculated, and the mass conservation of flow field and the velocity field without divergence are ensured. Then, an interphase coupling solution approach accurately traces the multiphase fluid distribution and multiphase interface. The multiphase coupling interface and cross-scale vortex cluster transport laws are obtained according to the multi-characteristic physical variables. The interaction mechanism between the multiphase coupling transport process and the pressure pulsation characteristics is revealed. The results show that the multiphase coupling transport is the critical state of the fluid medium transition. The vortex microclusters are subjected to different spatiotemporal disturbance modes and form the layered threaded waveforms at the interface. With the increase of the nozzle sizes, the multiphase coupling process is strengthened, and the coupling energy shock causes nonlinear pressure pulsation. This study can offer valuable references to the researches of the vortex transport mechanism, cross-scale solution of vortex cluster, and flow pattern tracking.-

Keywords:

- free sink vortex /

- multiphase coupling transport /

- coupled level set and volume-of-fluid method /

- volume correction /

- pressure pulsation

[1] Li L, Tan D P, Yin Z C, Wang T, Fan X H, Wang R H 2021 Renew. Energ. 175 887

Google Scholar

Google Scholar

[2] Tan D P, Li L, Yin Z C, Li D F, Zhu Y L, Zheng S 2021 Int. J. Heat Mass Transfer. 150 119250

Google Scholar

Google Scholar

[3] 谭大鹏, 杨涛, 赵军 2016 65 054701

Google Scholar

Google Scholar

Tan D P, Tao Y, Zhao J 2016 Acta Phys. Sin. 65 054701

Google Scholar

Google Scholar

[4] Li L, Tan D P, Wang T, Yin Z C, Fan X H, Wang R H 2021 Energy 216 119136

Google Scholar

Google Scholar

[5] Aboelkassem Y, Georgicis V 2007 J. Fluids Eng. Trans. ASME 129 1073

Google Scholar

Google Scholar

[6] Chen Y C, Huang S L, Li Z Y, Chang C C, Chu C C 2013 J. Fluid Mech. 733 134

Google Scholar

Google Scholar

[7] Tan Y F, Ni Y S, Wu J F, Li L, Tan D P 2023 Int. J. Adv. Manuf. Technol. DOI: 10.1007/s00170-022-10761-8 (in Press)

[8] Tahershamsi A, Rahimzadeh H, Monshizadeh M, Sarkardeh H 2018 Meccanica 53 3269

Google Scholar

Google Scholar

[9] Tan D P, Ni Y S, Zhang L B 2017 J. Iron Steel Res. Int. 24 669

Google Scholar

Google Scholar

[10] Morales R D, Dávila–Maldonado O, Calderón I 2013 ISIJ Int. 53 782

Google Scholar

Google Scholar

[11] Yang M, Liu S, Xu W H 2020 ACS Omega 5 31332

Google Scholar

Google Scholar

[12] Škerlavaj A, Škerget L, Ravnik J 2014 Eng. Appl. Comp. Fluid Mech. 8 193

Google Scholar

Google Scholar

[13] Ahn S H, Xiao Y X, Wang Z W, Zhou X Z, Luo Y Y 2017 Renew. Energ. 101 617

Google Scholar

Google Scholar

[14] Li L, Qi H, Yin Z C, Li D F, Zhu Z L, Tangwarodomnukun V, Tan D P 2020 Powder Technol. 360 462

Google Scholar

Google Scholar

[15] Zheng G A, Gu Z H, Xu W X, Li Q H, Tan Y F, Wang C Y, Li L 2023 Proesses 11 42

Google Scholar

Google Scholar

[16] Ling K, Zhang S, Wu P Z, Yang S Y, Tao W Q 2019 Int. J. Heat Mass Transf. 143 118565

Google Scholar

Google Scholar

[17] Tan D P, Li L, Zhu Y L, Zheng S, Yin Z C, Li D F 2019 J. Zhejiang Univ.-SCI A 20 61

Google Scholar

Google Scholar

[18] 谭大鹏, 计时鸣, 李培玉 2010 中国科学-技术科学 53 2378

Google Scholar

Google Scholar

Tan D P, Ji S M, Li P Y 2010 Sci. China-Technol. Sci. 53 2378

Google Scholar

Google Scholar

[19] Duan G T, Chen B, Zhang X M, Wang Y C 2017 Comput. Method Appl. Eng. 320 133

Google Scholar

Google Scholar

[20] Qian J Y, Zhao L, Li X J, Li Q Q, Jin Z J 2022 J. Zhejiang Univ.-SCI A. 23 783

Google Scholar

Google Scholar

[21] Tan D P, Li L, Zhu Y L, Zheng S, Ruan H J, Jiang X Y 2018 IEEE Trans. Ind. Inform. 14 2881

Google Scholar

Google Scholar

[22] Wang J X, Gao S B, Tang Z J, Tan D P 2021 J. Intell.Manuf. DOI: 10.1007/s10845-021-01854-4 (in Press)

[23] Tan D P, Zhang L B 2014 Sens. Actuator. B 202 1257

Google Scholar

Google Scholar

[24] Pan Y, Ji S M, Tan D P, Cao H Q 2020 Int. J. Manuf. Technol. 109 2587

Google Scholar

Google Scholar

[25] Li L, Yang Y S, Xu W X, Lu B, Gu Z H, Yang J G, Tan D P 2021 Appl. Sci. 12 8538

Google Scholar

Google Scholar

[26] Yin Z C, Ni Y S, Li L, Wang T, Wu J F, Li Z, Tan D P 2022 J. Zhejiang Univ.-SCI A DOI: 10.1631/jzus.A2200014 (in Press)

[27] Li L, Xu W X, Tan Y F, Yang Y S, Yang J G, Tan D P 2023 Mech. Syst. Signal Process 189 110058

Google Scholar

Google Scholar

[28] Gen J Q, Ji S M, Tan D P 2018 J. Adv. Manuf. Technol. 95 1069

Google Scholar

Google Scholar

[29] Ruan Y M, Yao Y, Shen S Y, Wang B, Wang B, Zhang J Y, Huang J K 2020 Steel Res. Int. 91 1900616

Google Scholar

Google Scholar

[30] Zheng S H Yu Y K, Qiu M Z, Wang L M, Tan D P 2021 Appl. Math. Model. 91 934

Google Scholar

Google Scholar

[31] Ge M, Ji S M, Tan D P 2021 J. Adv. Manuf. Technol. 114 3419

Google Scholar

Google Scholar

[32] Wang Y Y, Zhang Y L, Tan D P 2021 Chinese J. Mech. Eng. 34 30

Google Scholar

Google Scholar

[33] Ahmadi M H B, Yang Z Y 2020 Energy 207 118167

Google Scholar

Google Scholar

[34] Kaiser J M J, Adami S, Akhatov I S, Adams N A 2020 Int. J. Heat Mass Transf. 155 119800

Google Scholar

Google Scholar

[35] Meng Q F, Wu C Q, Su Y, Li J, Pang J B 2019 J. Clean. Prod. 210 1150

Google Scholar

Google Scholar

[36] Deshpande S S, Trujillo M F, Wu X, Chahine G 2012 Int. J. Heat Fluid Flow 34 1

Google Scholar

Google Scholar

[37] Yin Z C, Wan Y H, Fang H, Li L, Wang T, Wang Z, Tan DP 2022 Appl. Intel. DOI: 10.1007/s10489-022-04226-4 (in Press)

[38] Wang T, Li L, Yin Z C, Xie Z W, Wu J F, Zhang Y C, Tan D P 2022 P. I. Mech. Eng. C J. Mec. 236 11196

Google Scholar

Google Scholar

[39] Li L, Lu J F, Fang H, Yin Z C, Wang T, Wang R H, Fan X H, Zhao L J, Tan D P, Wan Y H 2020 IEEE Access 8 27649

Google Scholar

Google Scholar

[40] Park I S, Sohn C H 2011 Int. Commun. Heat Mass Transf. 38 1044

Google Scholar

Google Scholar

-

图 5 流体力学模型与边界条件 (a) 流体域模型; (b) 区域A的局部视角; (c) 区域B的局部视角; (d) 容器顶部视角. 1-入口壁面; 2-固定壁面; 3-出口壁面

Fig. 5. Fluid dynamic mechanic model and boundary conditions: (a) Fluid-domain model; (b) local view of region A; (c) local view of region B; (d) top view of the container. 1-inlet wall; 2-fixed wall; 3-out wall.

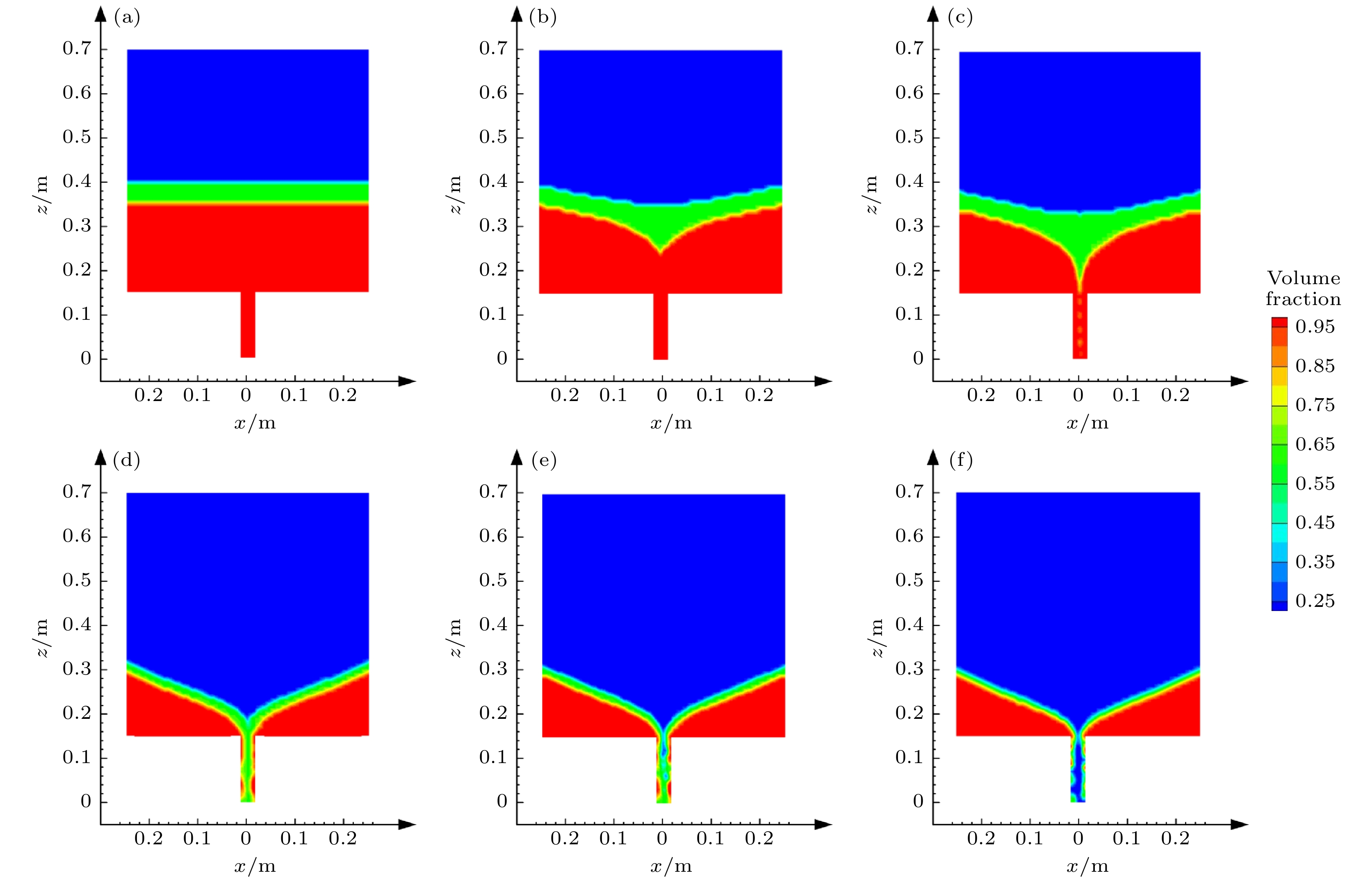

图 8 含自由液面的汇流旋涡体积分数云图 (a) t = 1.00 s; (b) t = 3.50 s; (c) t = 6.00 s; (d) t = 21.50 s; (e) t = 23.00 s; (f) t = 25.00 s

Fig. 8. Volume fraction cloud chart of the sink vortex with a free-liquid surface (ω0 = 1.0π rad/s): (a) t = 1.00 s; (b) t = 3.50 s; (c) t = 6.00 s; (d) t = 21.50 s; (e) t = 23.00 s; (f) t = 25.00 s.

表 1 流体动力学模型的边界条件.

Table 1. Boundary conditions of the fluid dynamic model.

项 属性 入口 零法向梯度压力入口 出口 无回流平均压力出口 壁面 无滑移壁面(流体在壁面处的

速度或相对速度为零)重力/N 9.81 重力方向 z轴负方向 水相高度/m 0.2 气相高度/m 0.3 油相高度/m 0.05 表 2 流体介质的物理参数.

Table 2. Physical parameters of fluid mediums.

介质 密度/

(kg·m–3)运动黏度/

(m2·s–1)动力黏度/

(Pa·s)表面张力/

(N·m–1)接触角/(°) 温度/

℃水 998.2 1.01×10–6 1.01×10–3 1.8×10–2 (油水) 135 20 油 730 1.01×10–6 2.4×10–3 2.6×10–2 (油气) 135 20 空气 1.225 1.48×10–5 1.79×10–5 7.3×10–2 (水气) 135 20 -

[1] Li L, Tan D P, Yin Z C, Wang T, Fan X H, Wang R H 2021 Renew. Energ. 175 887

Google Scholar

Google Scholar

[2] Tan D P, Li L, Yin Z C, Li D F, Zhu Y L, Zheng S 2021 Int. J. Heat Mass Transfer. 150 119250

Google Scholar

Google Scholar

[3] 谭大鹏, 杨涛, 赵军 2016 65 054701

Google Scholar

Google Scholar

Tan D P, Tao Y, Zhao J 2016 Acta Phys. Sin. 65 054701

Google Scholar

Google Scholar

[4] Li L, Tan D P, Wang T, Yin Z C, Fan X H, Wang R H 2021 Energy 216 119136

Google Scholar

Google Scholar

[5] Aboelkassem Y, Georgicis V 2007 J. Fluids Eng. Trans. ASME 129 1073

Google Scholar

Google Scholar

[6] Chen Y C, Huang S L, Li Z Y, Chang C C, Chu C C 2013 J. Fluid Mech. 733 134

Google Scholar

Google Scholar

[7] Tan Y F, Ni Y S, Wu J F, Li L, Tan D P 2023 Int. J. Adv. Manuf. Technol. DOI: 10.1007/s00170-022-10761-8 (in Press)

[8] Tahershamsi A, Rahimzadeh H, Monshizadeh M, Sarkardeh H 2018 Meccanica 53 3269

Google Scholar

Google Scholar

[9] Tan D P, Ni Y S, Zhang L B 2017 J. Iron Steel Res. Int. 24 669

Google Scholar

Google Scholar

[10] Morales R D, Dávila–Maldonado O, Calderón I 2013 ISIJ Int. 53 782

Google Scholar

Google Scholar

[11] Yang M, Liu S, Xu W H 2020 ACS Omega 5 31332

Google Scholar

Google Scholar

[12] Škerlavaj A, Škerget L, Ravnik J 2014 Eng. Appl. Comp. Fluid Mech. 8 193

Google Scholar

Google Scholar

[13] Ahn S H, Xiao Y X, Wang Z W, Zhou X Z, Luo Y Y 2017 Renew. Energ. 101 617

Google Scholar

Google Scholar

[14] Li L, Qi H, Yin Z C, Li D F, Zhu Z L, Tangwarodomnukun V, Tan D P 2020 Powder Technol. 360 462

Google Scholar

Google Scholar

[15] Zheng G A, Gu Z H, Xu W X, Li Q H, Tan Y F, Wang C Y, Li L 2023 Proesses 11 42

Google Scholar

Google Scholar

[16] Ling K, Zhang S, Wu P Z, Yang S Y, Tao W Q 2019 Int. J. Heat Mass Transf. 143 118565

Google Scholar

Google Scholar

[17] Tan D P, Li L, Zhu Y L, Zheng S, Yin Z C, Li D F 2019 J. Zhejiang Univ.-SCI A 20 61

Google Scholar

Google Scholar

[18] 谭大鹏, 计时鸣, 李培玉 2010 中国科学-技术科学 53 2378

Google Scholar

Google Scholar

Tan D P, Ji S M, Li P Y 2010 Sci. China-Technol. Sci. 53 2378

Google Scholar

Google Scholar

[19] Duan G T, Chen B, Zhang X M, Wang Y C 2017 Comput. Method Appl. Eng. 320 133

Google Scholar

Google Scholar

[20] Qian J Y, Zhao L, Li X J, Li Q Q, Jin Z J 2022 J. Zhejiang Univ.-SCI A. 23 783

Google Scholar

Google Scholar

[21] Tan D P, Li L, Zhu Y L, Zheng S, Ruan H J, Jiang X Y 2018 IEEE Trans. Ind. Inform. 14 2881

Google Scholar

Google Scholar

[22] Wang J X, Gao S B, Tang Z J, Tan D P 2021 J. Intell.Manuf. DOI: 10.1007/s10845-021-01854-4 (in Press)

[23] Tan D P, Zhang L B 2014 Sens. Actuator. B 202 1257

Google Scholar

Google Scholar

[24] Pan Y, Ji S M, Tan D P, Cao H Q 2020 Int. J. Manuf. Technol. 109 2587

Google Scholar

Google Scholar

[25] Li L, Yang Y S, Xu W X, Lu B, Gu Z H, Yang J G, Tan D P 2021 Appl. Sci. 12 8538

Google Scholar

Google Scholar

[26] Yin Z C, Ni Y S, Li L, Wang T, Wu J F, Li Z, Tan D P 2022 J. Zhejiang Univ.-SCI A DOI: 10.1631/jzus.A2200014 (in Press)

[27] Li L, Xu W X, Tan Y F, Yang Y S, Yang J G, Tan D P 2023 Mech. Syst. Signal Process 189 110058

Google Scholar

Google Scholar

[28] Gen J Q, Ji S M, Tan D P 2018 J. Adv. Manuf. Technol. 95 1069

Google Scholar

Google Scholar

[29] Ruan Y M, Yao Y, Shen S Y, Wang B, Wang B, Zhang J Y, Huang J K 2020 Steel Res. Int. 91 1900616

Google Scholar

Google Scholar

[30] Zheng S H Yu Y K, Qiu M Z, Wang L M, Tan D P 2021 Appl. Math. Model. 91 934

Google Scholar

Google Scholar

[31] Ge M, Ji S M, Tan D P 2021 J. Adv. Manuf. Technol. 114 3419

Google Scholar

Google Scholar

[32] Wang Y Y, Zhang Y L, Tan D P 2021 Chinese J. Mech. Eng. 34 30

Google Scholar

Google Scholar

[33] Ahmadi M H B, Yang Z Y 2020 Energy 207 118167

Google Scholar

Google Scholar

[34] Kaiser J M J, Adami S, Akhatov I S, Adams N A 2020 Int. J. Heat Mass Transf. 155 119800

Google Scholar

Google Scholar

[35] Meng Q F, Wu C Q, Su Y, Li J, Pang J B 2019 J. Clean. Prod. 210 1150

Google Scholar

Google Scholar

[36] Deshpande S S, Trujillo M F, Wu X, Chahine G 2012 Int. J. Heat Fluid Flow 34 1

Google Scholar

Google Scholar

[37] Yin Z C, Wan Y H, Fang H, Li L, Wang T, Wang Z, Tan DP 2022 Appl. Intel. DOI: 10.1007/s10489-022-04226-4 (in Press)

[38] Wang T, Li L, Yin Z C, Xie Z W, Wu J F, Zhang Y C, Tan D P 2022 P. I. Mech. Eng. C J. Mec. 236 11196

Google Scholar

Google Scholar

[39] Li L, Lu J F, Fang H, Yin Z C, Wang T, Wang R H, Fan X H, Zhao L J, Tan D P, Wan Y H 2020 IEEE Access 8 27649

Google Scholar

Google Scholar

[40] Park I S, Sohn C H 2011 Int. Commun. Heat Mass Transf. 38 1044

Google Scholar

Google Scholar

计量

- 文章访问数: 5969

- PDF下载量: 108

- 被引次数: 0

下载:

下载: