-

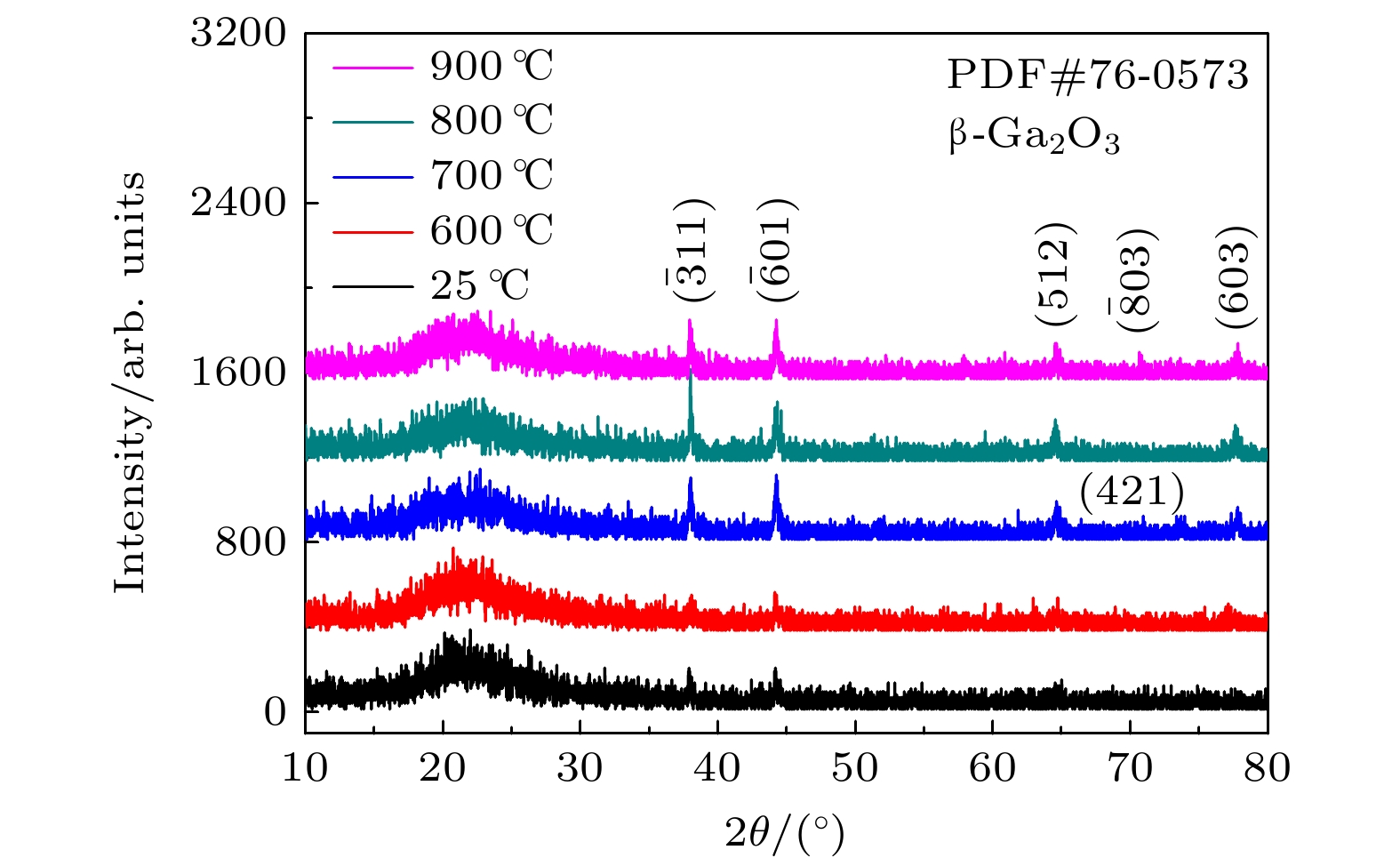

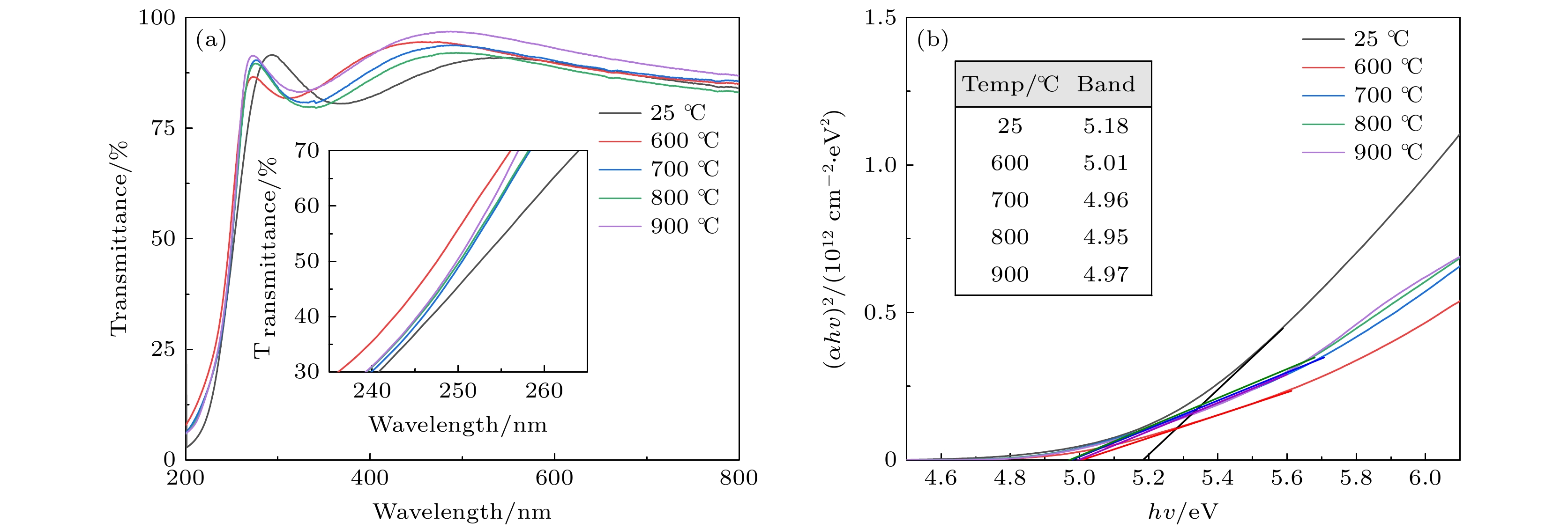

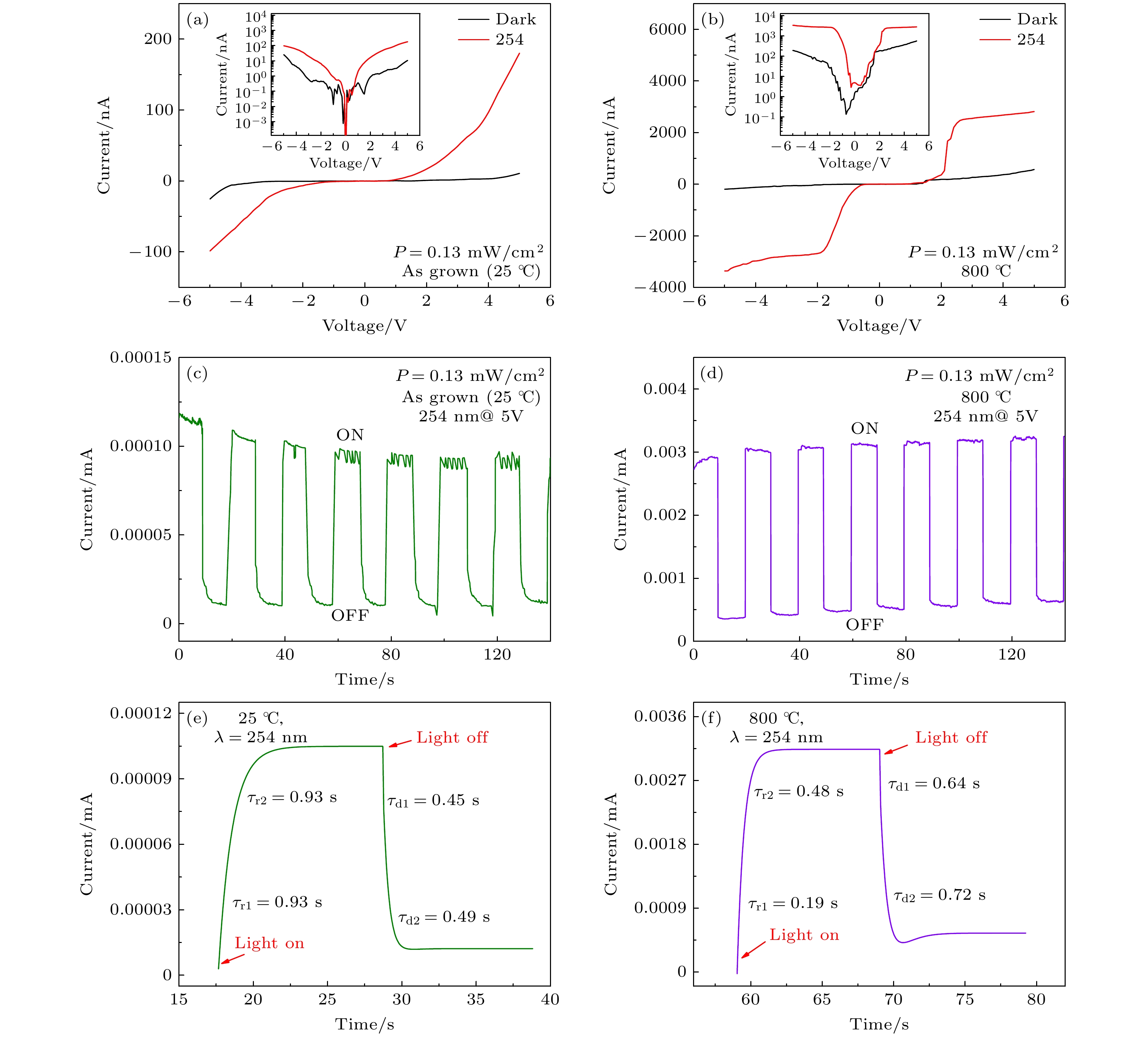

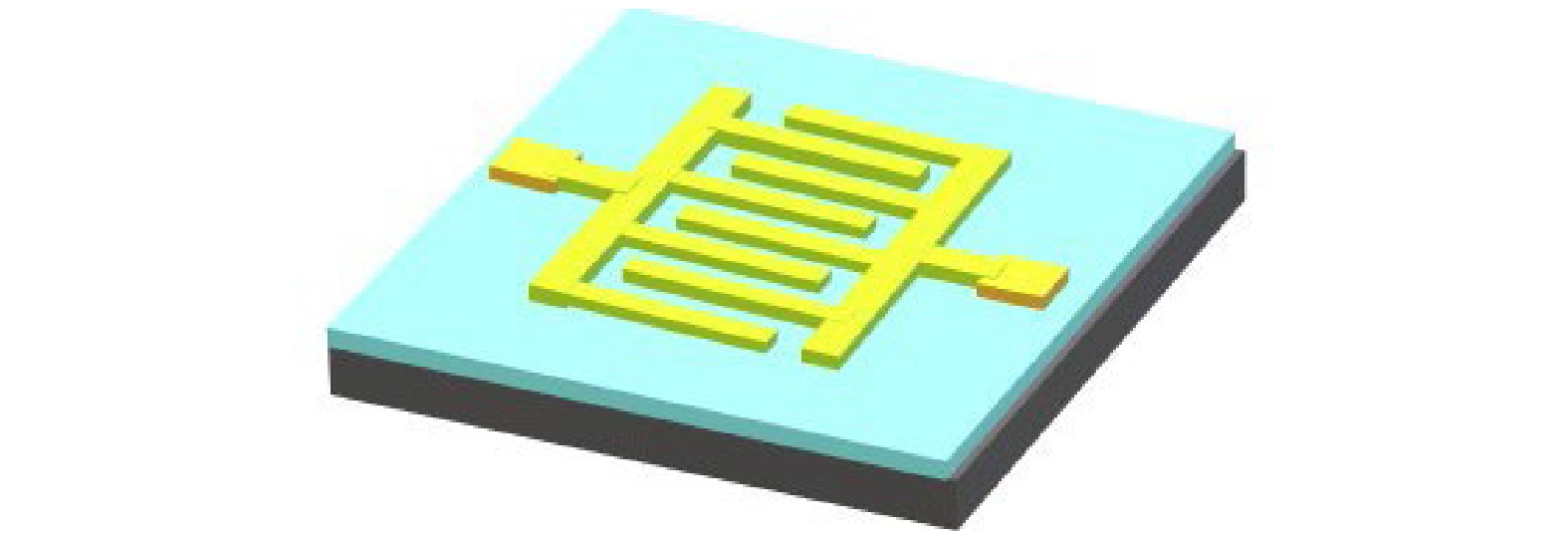

采用射频磁控溅射法在石英基底上制备Ga2O3薄膜, 并在氩气气氛中控制不同的退火温度进行后退火, 通过对样品的晶体结构、透射率、表面形貌和光学带隙等性质进行测试分析, 发现退火工艺可以提升薄膜的结晶质量, 但同时高温退火也容易使得薄膜中的氧元素逸出薄膜外形成氧空位, 选取800 ℃ 退火后样品制备成金属-半导体-金属(metal-semiconductor-metal, MSM)型光电探测器件, 并与未退火样品器件对比发现在1.1 V的反向偏压下, 800 ℃ 的光暗电流比为 1021.3、响应度为0.106 A/W、比探测率为1.61 × 1012 Jones, 分别是未退火器件的7.5, 195和38.3倍, 外量子效率相较于未退火样品提升了51.6%, 上升时间(0.19/0.48 s)相较于未退火样品(0.93/0.93 s)减小, 下降时间(0.64/0.72 s)与未退火样品(0.45/0.49 s)相比有所增大, 表明氧空位的增加可以减缓光生载流子的复合来达到延长载流子寿命的效果, 最后详细分析了退火后氧空位的增多导致探测器性能参数提高的机理.In this work, gallium oxide (Ga2O3) thin films are deposited on quartz substrates by radio frequency magnetron sputtering at room temperature and annealed in argon atmosphere at different temperatures. The influences of annealing temperatures in the argon atmosphere on crystal structure, transmittance, surface morphology, and optical band gap of the samples are investigated in detail. It is found that the annealing process can improve the crystalline quality of the film, but high-temperature annealing can also easily cause oxygen elements in the film to escape from the film to form oxygen vacancies, which is evidenced by XPS test results. To obtain the effect of the annealing process on the performance of gallium oxide thin film detector, the metal-semiconductor-metal (MSM) photodetector based on the sample annealed at 800 °C, which is compared with untreated sample operated at a reverse bias voltage of 1.1 V, can achieve excellent comprehensive photo-detection properties for 254 nm ultraviolet light: the light-dark current ratio (I254/Idark), responsivity and specific detectivity are as high as 1021.3, 0.106 A/W and 1.61 × 1012 Jones, respectively, which are 7.5, 195 and 38.3 times those of the unannealed sample device. And the external quantum efficiency is improved by 51.6%. The rise time of sample detector (0.19/0.48 s) annealed at 800 ℃ decreases compared with that of the unannealed sample (0.93/0.93 s), and the descent time of 800 ℃ detector (0.64/0.72 s)increases compared with that of the unannealed sample (0.45/0.49 s), respectively. By comparing the parameters with those of other current gallium oxide-based MSM photodetectors, it is found that the detector parameters of this work have some gaps compared with the current optimal parameters, which is attributed to the fact that the quartz substrate is selected for this work and not the sapphire substrate that is better matching with gallium oxide, resulting in the poor quality of the film compared with that of the sample on the sapphire substrate, and in this work, the photodetector has the high light-dark current ratio (PDCR) and detection rate (D*). In the end, the mechanism of increasing oxygen vacancies after being annealed, which leads to the improvement of detector performance parameters, is analyzed in detail.

-

Keywords:

- gallium oxide /

- RF magnetron sputtering /

- post-annealing temperature /

- solar-blind photodetector

[1] Liu X Z, Guo P, Sheng T, Qian L X, Zhang W L, Li Y R 2016 Opt. Mater. 51 203

Google Scholar

Google Scholar

[2] Xu J J, Zheng W, Huang F 2019 J. Mater. Chem. C 7 8753

Google Scholar

Google Scholar

[3] Wang H, Ma J, Cong L, Zhou H, Li P, Fei L, Li B, Xu H, Liu Y 2021 Mater. Today Phys. 20 100464

Google Scholar

Google Scholar

[4] Xie C, Lu X T, Liang Y, Chen H H, Wang L, Wu C Y, Wu D, Yang W H, Luo L B 2021 J. Mater. Sci. Technol. 72 189

Google Scholar

Google Scholar

[5] Guo X C, Hao N H, Guo D Y, Wu Z P, An Y H, Chu X L, Li L H, Li P G, Lei M, Tang W H 2016 J. Alloys Compd. 660 136

Google Scholar

Google Scholar

[6] Lu N Y, Gu Y, Weng Y Y, Da Z C, Ding Y 2019 Mater. Res. Express 6 095033

Google Scholar

Google Scholar

[7] Wang L, Gu D W, Shen L J 2017 Solid State Sci. 72 10

Google Scholar

Google Scholar

[8] Yu M, Wang H Q, Wei W, Peng B, Yuan L, Hu J C, Zhang Y M, Jia R X 2021 Appl. Surf. Sci. 568 150826

Google Scholar

Google Scholar

[9] Ghosh S, Baral M, Kamparath R, Singh S D, Gangul T 2019 Appl. Phys. Lett. 115 251603

Google Scholar

Google Scholar

[10] Kaur D, Kumar M 2021 Adv. Opt. Mater. 3 2002160

Google Scholar

Google Scholar

[11] Wang D, Ma X C, Xiao H D, Chen R R, Le Yong, Luan C N, Zhang B, Ma J 2022 Mater. Res. Bull. 149 111718

Google Scholar

Google Scholar

[12] Mukhopadhyay P, Hatipoglu I, Sakthivel T S, Hunter D A, Edwards P R, Martin R W, Naresh-Kumar G, Seal S, Schoenfeld W V 2021 Adv. Photonics Res. 2 2000067

Google Scholar

Google Scholar

[13] Jeong S H, Vu Ti K O, Kim E K 2021 J. Alloys Compd. 877 160291

Google Scholar

Google Scholar

[14] Yu M, Lv C D, Yu J G, Shen Y M, Yuan L, Hu J C, Zhang S N, Cheng H J, Zhang Y M, Jia R X 2020 Mater. Today Commun. 25 101532

Google Scholar

Google Scholar

[15] Shen H, Yin Y N, Tian K, Baskaran K, Duan L B, Zhao X R, Tiwari A 2018 J. Alloys Compd. 766 601

Google Scholar

Google Scholar

[16] Patila V, Lee B T, Jeong S H 2022 J. Alloys Compd. 894 162551

Google Scholar

Google Scholar

[17] Li M Q, Yang N, Wang G G, Zhang H Y, Han J C 2019 Appl. Surf. Sci. 471 694

Google Scholar

Google Scholar

[18] Zhang Y J, Yan J L, Li Q S, Qu C, Zhang L Y, Li T 2011 Physica B 406 3079

Google Scholar

Google Scholar

[19] Goyal A, Yadav B S, Thakur O P, Kapoor A K, Muralidharan R 2014 J. Alloys Compd. 583 214

Google Scholar

Google Scholar

[20] Feng Z Q, Huang L, Feng Q, Li X, Zhang H, Tang W h, Zhang J C, Hao Y 2018 Opt. Mater. Express 8 2229

Google Scholar

Google Scholar

[21] Tien C H, Hsiao B W, Chen C M, Chen M I, Chiang J L, Wuu D S 2020 Ceram. Int. 46 24147

Google Scholar

Google Scholar

[22] Singh A K, Gupta M, Sathe V, Katharria Y S 2021 Superlattice Microst. 156 106976

Google Scholar

Google Scholar

[23] Yu J G, Nie Z Z, Dong L P, Yuan L, Li D J, Huang Y, Zhang L C, Zhang Y M, Jia R X 2019 J. Alloys Compd. 798 458

Google Scholar

Google Scholar

[24] Wang H Y, Tang C M, Yang W J, Zhao J J, Liu L H, Mu J X, Zhang Y P, Zeng C Y 2022 Ceram. Int. 48 3481

Google Scholar

Google Scholar

[25] Cui R R, Zhang J, Luo Z J, Guo X, Ding Z, Deng C Y 2021 Chinese Phys. B 2 028505

Google Scholar

Google Scholar

[26] Wei P, Zhu D M, Huang S S, Zhou W C, Luo F 2013 Appl. Surf. Sci. 285P 577

[27] Zhou H T, Cong L J, Ma J G, Chen M Z, Song D Y, Wang H B, Li P, Li B S, Xu H Y, Liu Y C 2020 J. Alloys Compd. 847 156536

Google Scholar

Google Scholar

[28] Han J F, Yang D Z, Ma D G, Qiao W Q, Wang Z Y 2019 Org. Electron. 68 242

Google Scholar

Google Scholar

[29] Gong. X, Tong M, Xia Y J, Cai W Z, Moon J S, Cao Y, Yu G, Shieh C L, Nilsson B, Heeger A J 2009 Science 325 1665

Google Scholar

Google Scholar

[30] 周树仁, 张红, 莫慧兰, 刘浩文, 熊元强, 李泓霖, 孔春阳, 叶利娟, 李万俊 2021 70 178503

Google Scholar

Google Scholar

Zhou S R, Zhang H, Mo H L, Liu H W, Xiong Y Q, Li H L, Kong C Y, Ye L J, Li W J 2021 Acta Phys. Sin. 70 178503

Google Scholar

Google Scholar

[31] Xu R, Ma X C, Chen Y H, Mei Y, Ying L Y, Zhang B P, Long H 2022 Mat. Sci. Semicon. Proc. 144 106621

Google Scholar

Google Scholar

[32] Zhou S, Peng X, Liu H W, Zhang Z F, Ye L J, Li H L, Xiong Y Q, Niu L B, Chen F L, Fang L, Kong C Y, Li W J, Yang X, Zhang A H 2022 Opt. Mater. Express 12 327

[33] Wang Q L, Huang P, Liu Q, Li Y X, Qu Q L, Li M K, Homewood K P, Lu Y M, He Y B 2020 J. Alloys Compd. 834 155036

Google Scholar

Google Scholar

-

图 7 室温下生长样品 (a) 和800 ℃ 退火样品 (b) 在黑暗环境下及254 nm 紫外光源照射下的I-V图像和半对数图像以及在5 V偏压下, 25 ℃ (c), 800 ℃ (d)的I-T图像及其双指数拟合I-T图像 (e) 和 (f)

Fig. 7. I-V images and semi-logarithmic images of samples grown at room temperature (a) and annealed at 800 ℃ (b) in the dark under 254 nm UV light source and under 5 V bias, the I-T image of 25 ℃ (c), 800 ℃ (d) and its bi-exponential fitting I-T images (e), (f).

图 8 光开启时 (a) 和光关闭后 (b) 氧化镓MSM器件能带示意图, 途径1表示光生载流子的产生 (a) 与复合 (b), 途径2表示氧空位缺陷捕获 (a) 和释放 (b) 光生电子

Fig. 8. Schematic diagram of the energy band of the gallium oxide MSM device when the light is turned on (a) and after the light is turned off (b). Pathway 1 represents the generation (a) and recombination (b) of photogenerated carriers, and pathway 2 represents oxygen vacancy defect trapping (a) and release (b) photogenerated electrons.

表 1 在5 V偏压下I-T双指数拟合图像响应时间参数表

Table 1. I-T Bi-exponential fitted image response time parameters at 5 V bias.

Photodetector τr1/s τr2/s τd1/s τd2/s 25 ℃ 0.93 0.93 0.45 0.49 800 ℃ 0.19 0.48 0.64 0.72 表 2 在–1.1 V偏压下的探测器参数汇总表

Table 2. Summary table of detector parameters at –1.1 V bias.

Photodetector Idark/nA PDCR(I254/Idark) Rλ/(A·W–1) EQE/% D*/Jones 25 ℃ 0.0262 136 5.54 × 10–4 0.2 4.21 × 1010 800 ℃ 0.677 1021.3 0.106 51.8 1.61 × 1012 表 3 当前氧化镓基MSM结构光电探测器主要性能参数汇总表

Table 3. Comparison of main performance parameters of current gallium oxide-based MSM photodetectors

Photodetector Method Id/nA PDCR R254/

(A·W–1)D*/Jones Ref. Ga2O3/Al2O3 Sol-gel 0.125@15 V 673 0.04 4.6 × 1011 [14] Ga2O3/SiC Sputtering 7.6@10 V 383 2.6 1.6 × 1012 [17] Ga2O3/Al2O3 PLD 0.1@20 V 520 60 — [27] N:Ga2O3/Al2O3 Sputtering 0.01@10 V — 0.013 6.1 × 1010 [30] Ga2O3/Al2O3 MOCVD 0.17@10 V 4.53 9.4 0.17 × 1012 [31] Ga2O3/Al2O3 Sputtering 8.2 × 10–5@10 V 3.58 × 105 1.93 6.53 × 1013 [32] Ga2O3/Quartz Sputtering 0.677@1.1 V 1021.3 0.106 1.61 × 1012 This work -

[1] Liu X Z, Guo P, Sheng T, Qian L X, Zhang W L, Li Y R 2016 Opt. Mater. 51 203

Google Scholar

Google Scholar

[2] Xu J J, Zheng W, Huang F 2019 J. Mater. Chem. C 7 8753

Google Scholar

Google Scholar

[3] Wang H, Ma J, Cong L, Zhou H, Li P, Fei L, Li B, Xu H, Liu Y 2021 Mater. Today Phys. 20 100464

Google Scholar

Google Scholar

[4] Xie C, Lu X T, Liang Y, Chen H H, Wang L, Wu C Y, Wu D, Yang W H, Luo L B 2021 J. Mater. Sci. Technol. 72 189

Google Scholar

Google Scholar

[5] Guo X C, Hao N H, Guo D Y, Wu Z P, An Y H, Chu X L, Li L H, Li P G, Lei M, Tang W H 2016 J. Alloys Compd. 660 136

Google Scholar

Google Scholar

[6] Lu N Y, Gu Y, Weng Y Y, Da Z C, Ding Y 2019 Mater. Res. Express 6 095033

Google Scholar

Google Scholar

[7] Wang L, Gu D W, Shen L J 2017 Solid State Sci. 72 10

Google Scholar

Google Scholar

[8] Yu M, Wang H Q, Wei W, Peng B, Yuan L, Hu J C, Zhang Y M, Jia R X 2021 Appl. Surf. Sci. 568 150826

Google Scholar

Google Scholar

[9] Ghosh S, Baral M, Kamparath R, Singh S D, Gangul T 2019 Appl. Phys. Lett. 115 251603

Google Scholar

Google Scholar

[10] Kaur D, Kumar M 2021 Adv. Opt. Mater. 3 2002160

Google Scholar

Google Scholar

[11] Wang D, Ma X C, Xiao H D, Chen R R, Le Yong, Luan C N, Zhang B, Ma J 2022 Mater. Res. Bull. 149 111718

Google Scholar

Google Scholar

[12] Mukhopadhyay P, Hatipoglu I, Sakthivel T S, Hunter D A, Edwards P R, Martin R W, Naresh-Kumar G, Seal S, Schoenfeld W V 2021 Adv. Photonics Res. 2 2000067

Google Scholar

Google Scholar

[13] Jeong S H, Vu Ti K O, Kim E K 2021 J. Alloys Compd. 877 160291

Google Scholar

Google Scholar

[14] Yu M, Lv C D, Yu J G, Shen Y M, Yuan L, Hu J C, Zhang S N, Cheng H J, Zhang Y M, Jia R X 2020 Mater. Today Commun. 25 101532

Google Scholar

Google Scholar

[15] Shen H, Yin Y N, Tian K, Baskaran K, Duan L B, Zhao X R, Tiwari A 2018 J. Alloys Compd. 766 601

Google Scholar

Google Scholar

[16] Patila V, Lee B T, Jeong S H 2022 J. Alloys Compd. 894 162551

Google Scholar

Google Scholar

[17] Li M Q, Yang N, Wang G G, Zhang H Y, Han J C 2019 Appl. Surf. Sci. 471 694

Google Scholar

Google Scholar

[18] Zhang Y J, Yan J L, Li Q S, Qu C, Zhang L Y, Li T 2011 Physica B 406 3079

Google Scholar

Google Scholar

[19] Goyal A, Yadav B S, Thakur O P, Kapoor A K, Muralidharan R 2014 J. Alloys Compd. 583 214

Google Scholar

Google Scholar

[20] Feng Z Q, Huang L, Feng Q, Li X, Zhang H, Tang W h, Zhang J C, Hao Y 2018 Opt. Mater. Express 8 2229

Google Scholar

Google Scholar

[21] Tien C H, Hsiao B W, Chen C M, Chen M I, Chiang J L, Wuu D S 2020 Ceram. Int. 46 24147

Google Scholar

Google Scholar

[22] Singh A K, Gupta M, Sathe V, Katharria Y S 2021 Superlattice Microst. 156 106976

Google Scholar

Google Scholar

[23] Yu J G, Nie Z Z, Dong L P, Yuan L, Li D J, Huang Y, Zhang L C, Zhang Y M, Jia R X 2019 J. Alloys Compd. 798 458

Google Scholar

Google Scholar

[24] Wang H Y, Tang C M, Yang W J, Zhao J J, Liu L H, Mu J X, Zhang Y P, Zeng C Y 2022 Ceram. Int. 48 3481

Google Scholar

Google Scholar

[25] Cui R R, Zhang J, Luo Z J, Guo X, Ding Z, Deng C Y 2021 Chinese Phys. B 2 028505

Google Scholar

Google Scholar

[26] Wei P, Zhu D M, Huang S S, Zhou W C, Luo F 2013 Appl. Surf. Sci. 285P 577

[27] Zhou H T, Cong L J, Ma J G, Chen M Z, Song D Y, Wang H B, Li P, Li B S, Xu H Y, Liu Y C 2020 J. Alloys Compd. 847 156536

Google Scholar

Google Scholar

[28] Han J F, Yang D Z, Ma D G, Qiao W Q, Wang Z Y 2019 Org. Electron. 68 242

Google Scholar

Google Scholar

[29] Gong. X, Tong M, Xia Y J, Cai W Z, Moon J S, Cao Y, Yu G, Shieh C L, Nilsson B, Heeger A J 2009 Science 325 1665

Google Scholar

Google Scholar

[30] 周树仁, 张红, 莫慧兰, 刘浩文, 熊元强, 李泓霖, 孔春阳, 叶利娟, 李万俊 2021 70 178503

Google Scholar

Google Scholar

Zhou S R, Zhang H, Mo H L, Liu H W, Xiong Y Q, Li H L, Kong C Y, Ye L J, Li W J 2021 Acta Phys. Sin. 70 178503

Google Scholar

Google Scholar

[31] Xu R, Ma X C, Chen Y H, Mei Y, Ying L Y, Zhang B P, Long H 2022 Mat. Sci. Semicon. Proc. 144 106621

Google Scholar

Google Scholar

[32] Zhou S, Peng X, Liu H W, Zhang Z F, Ye L J, Li H L, Xiong Y Q, Niu L B, Chen F L, Fang L, Kong C Y, Li W J, Yang X, Zhang A H 2022 Opt. Mater. Express 12 327

[33] Wang Q L, Huang P, Liu Q, Li Y X, Qu Q L, Li M K, Homewood K P, Lu Y M, He Y B 2020 J. Alloys Compd. 834 155036

Google Scholar

Google Scholar

计量

- 文章访问数: 9264

- PDF下载量: 212

- 被引次数: 0

下载:

下载: