-

近年来, CH(NH2)2PbI3(FAPbI3)由于其带隙接近理想值而受到了广泛关注, 成为钙钛矿太阳能电池中最具吸引力的光电功能材料. 然而由碘甲脒 (FAI) 和碘化铅 (PbI2)作为前驱体制备的传统钙钛矿层化学计量比不精准, 缺陷密度大, 稳定性差且结晶度较低, 导致钙钛矿太阳能电池性能很难进一步提高. 本文采用FAPbI3单晶制备的钙钛矿薄膜具有高结晶度, 高稳定性, 精确的化学计量比和低缺陷密度. 单晶钙钛矿薄膜的晶粒尺寸大, 晶界少, 导致晶界处缺陷较少, 提高了钙钛矿太阳能电池的短路电流密度(JSC)和开路电压(VOC), 使其光电转换效率有了大幅度的提高. 本文为制备高稳定性、高结晶度和低缺陷密度的钙钛矿太阳能电池提供了一种有效策略.In recent years, CH(NH2)2PbI3 (FAPbI3) has received extensive attention due to the suitable band gap, becoming the most attractive photoelectric functional material in perovskite solar cells. However, the traditional perovskite layer prepared by formamidine iodide (FAI) and lead iodide (PbI2) has inaccurate stoichiometric ratio, high defect density, low stability, and low crystallinity, which makes it challenging to improve the performance of perovskite solar cells further. In this paper, the perovskite film prepared by FAPbI3 single crystal has high crystallinity, high stability, accurate stoichiometric ratio and low defect density. The single crystal derived perovskite film has a large grain size and few grain boundaries, resulting in fewer defects in the grain boundaries, which improves the short-circuit current density (JSC) and open-circuit voltage (VOC) of perovskite solar cells, and greatly improves the photoelectric conversion efficiency. This work provides an efficient strategy for fabricating perovskite solar cells with high stability, high crystallinity, and low defect density.

-

Keywords:

- single crystal /

- perovskite solar cells /

- crystallinity /

- defect density

[1] Eperon G E, Stranks S D, Menelaou C, Johnston M B, Herz L M, Snaith H 2014 Energy Environ. Sci. 7 982

Google Scholar

Google Scholar

[2] De Wolf S, Holovsky J, Moon S J, Löper P, Niesen B, Ledinsky M, Haug F J, Yum J H, Ballif 2014 Phys. Chem. Lett. 5 1035

Google Scholar

Google Scholar

[3] Stranks S, Eperon G, Grancini G, Menelaou C, Alcocer M, Leijtens T, Herz L, Petrozza A, Snaith H 2013 Science 342 341

[4] Chen C W, Hsiao S Y, Chen C Y, Kang H W, Huang Z Y, Lin H W 2015 Mater. Chem. 3 9152

Google Scholar

Google Scholar

[5] Su H, Lin X, Wang Y, Liu X, Qin Z, Shi Q 2022 Sci. China Chem. 65 467

[6] Wang B, Iocozzia J, Zhang M, Ye M, Yan S, Jin H, Wang S, Zou Z, Lin Z 2019 Chem. Soc. Rev. 48 4854

Google Scholar

Google Scholar

[7] Zhang M, Cui X, Wang Y, Wang B, Ye M, Wang W, Ma C, Lin Z. 2020 Nano Energy 71 104620

Google Scholar

Google Scholar

[8] Zhang M, Ye M, Wang W, Ma C, Wang S, Liu Q, Lian T, Huang J, Lin Z 2020 Adv. Mater. 32 2000999

Google Scholar

Google Scholar

[9] Cui X, Chen Y, Zhang M, Harn Y W, Qi J, Gao L, Wang Z L, Huang J, Yang Y, Lin Z 2020 Energy Environ. Sci. 13 1743

Google Scholar

Google Scholar

[10] Dunlap-Shohl W A, Zhou Y, Padture N P, Mitzi D B 2019 Chem. Rev. 119 3193

Google Scholar

Google Scholar

[11] Lee J W, Seol D J, Cho A N, Park N G 2014 Adv. Mater. 26 4991

Google Scholar

Google Scholar

[12] Dong Q, Fang Y, Shao Y, Mulligan P, Qiu J, Cao L, Huang J 2015 Science 347 967

Google Scholar

Google Scholar

[13] Shi D, Adinolfi V, Comin R, Yuan, Alarousu M E, Buin A, Chen Y, Hoogland S, Rothenberger A, Katsiev K, Losovyj Y, Zhang X, Dowben P A, Mohammed O F, Sargent E H, Bakr O M 2015 Science 347 519

Google Scholar

Google Scholar

[14] De Quilettes D W, Vorpahl S M, Stranks S D, Nagaoka H, Eperon G E, Ziffer M E, Snaith H J, Ginger D S 2015 Science 348 683

Google Scholar

Google Scholar

[15] Prochowicz D, Franckevičius M, Cieślak A M, Zakeeruddin S M, Grätzel M, Lewiński J 2015 Mater. Chem. A 3 20772

Google Scholar

Google Scholar

[16] Zhang Y N, Cui R, Xiong L H, Pang D W 2018 Nanomedicine Nanotechnology, Biol. Med. 14 1813

[17] Zhang Y, Zhang X, Xu X, Munyalo J M, Liu L, Liu X, Lu M, Zhao Y 2019 Mol. Liq. 280 360

Google Scholar

Google Scholar

[18] Hanul M, Maengsuk K, Seung-Un L, Hyeonwoo K, Gwisu K. Keunsu C, Hee L 2019 Science 366 749

Google Scholar

Google Scholar

[19] Zhang Y, Seo S, Lim S Y, Kim Y, Kim S, Lee K, Lee S, Shin H, Cheong H, Park N 2020 ACS Energy Lett. 5 360

Google Scholar

Google Scholar

[20] Heo J H, Im S H 2016 Nanoscale 8 2554

Google Scholar

Google Scholar

[21] Chen Z, Türedi B, Alsalloum A, Yang C, Zheng X, Gereige I, AlSaggaf A, Mohammed O, Bakr O 2019 ACS Energy Lett. 4 1412

Google Scholar

Google Scholar

[22] Yen H, Liang P, Chueh C, Yang Z, Wang H 2016 ACS Appl. Mater. Interfaces 8 14513

Google Scholar

Google Scholar

[23] Cheng X, Yang S, Cao B, Tao X, Chen Z 2020 Adv. Funct. Mater. 30 1905021

Google Scholar

Google Scholar

[24] Jiang X, Fu X, Ju D, Yang S, Chen Z, Tao X 2020 ACS Energy Lett. 5 1797

Google Scholar

Google Scholar

[25] Kim M, Kim G H, Lee T K, Choi I W, Choi H W, Jo Y, Yoon Y J, Kim J W, Lee J, Huh D, Lee H, Kwak S K, Kim J Y, Kim D S 2019 Joule 3 2179

Google Scholar

Google Scholar

[26] Kim J H, Williams S T, Cho N, Chueh C C, Jen A K Y 2015 Adv. Energy Mater. 5 1401229

Google Scholar

Google Scholar

[27] Zhang Y, Kim S G, Lee D, Shin H, Park N G 2019 Energy Environ. Sci. 12 308

Google Scholar

Google Scholar

[28] Son D Y, Lee J W, Choi Y J, Jang I H, Lee S, Yoo P J, Shin H, Ahn N. Choi M, Kim D, Park N G 2016 Nat. Energy 1 16081

Google Scholar

Google Scholar

[29] He M, Li B, Cui X, Jiang B, He Y, Chen Y, O’Neil D, Szymanski P, Ei-Sayed M A, Huang J, Lin Z 2017 Nat. Commun. 8 16045

Google Scholar

Google Scholar

[30] Wu B, Fu K, Yantara N, Xing G, Sun S, Sum T C, Mathews N 2015 Adv. Energy Mater. 5 1500829

Google Scholar

Google Scholar

[31] Li C, Song Z, Zhao D, Xiao C, Subedi B, Shrestha N, Junda M M, Wang C, Jiang C S, Al-Jassim M, Ellingson R J, Podraza N J, Zhu K, Yan Y 2019 Adv. Energy Mater. 9 1803135

Google Scholar

Google Scholar

[32] Galatopoulos F, Savva A, Papadas I T, Choulis S A 2017 APL Mater. 5 76102

Google Scholar

Google Scholar

[33] Sun C, Pan F, Bin H, Zhang J, Xue L, Qiu B, Wei Z, Zhang Z G, Li Y 2018 Nat. Commun. 9 743

Google Scholar

Google Scholar

-

图 1 FAPbI3单晶、晶体粉末和有机卤化物盐钙钛矿作为前驱体制备的钙钛矿薄膜在湿度为40%的环境下放置1天(a), 3天(b) 和5天(c)的XRD图谱

Fig. 1. Powder XRD patterns of FAPbI3 single crystals, crystal powders and organic halide salt perovskite as precursors prepared for perovskite thin films placed under 40% humidity for 1 day (a), 3 days (b) and 5 days (c).

图 3 FAPbI3单晶、晶体粉末和有机卤化物盐钙钛矿作为前驱体制备的钙钛矿薄膜的稳态 PL光谱(a)和瞬态(TRPL)光谱(b); FAPbI3单晶、晶体粉末和有机卤化物盐制备的钙钛矿薄膜的平均寿命统计(c); FTO/TiO2 ETL/钙钛矿/PCBM/Ag 结构的纯电子器空间电荷限制电流(SCLC)(d); FAPbI3单晶、晶体粉末和有机卤化物盐制备的器件的暗电流密度-电压(J-V)特性(e); FAPbI3单晶、晶体粉末和有机卤化物盐制备的器件的电化学阻抗谱(EIS)(f)

Fig. 3. Steady-state PL spectra (a) and time-resolved PL (TRPL) spectra (b) of perovskite films prepared from FAPbI3 single crystal, crystal powders and organic halide salt; average lifetime statistics of perovskite films of FAPbI3 single crystal, crystal powders and organic halide salt (c); space charge limited current (SCLC) plots of electron-only devices with an architecture of FTO/TiO2 ETL/Perovskite/PCBM/Ag based on FAPbI3 single crystal, crystal powders and organic halide salt perovskite (d); dark current density-voltage (J-V) characteristics of FAPbI3 single crystal, crystal powders and organic halide salt devices (e); electrochemical impedance spectroscopy (EIS) of FAPbI3 single crystal, crystal powders and organic halide salt devices (f).

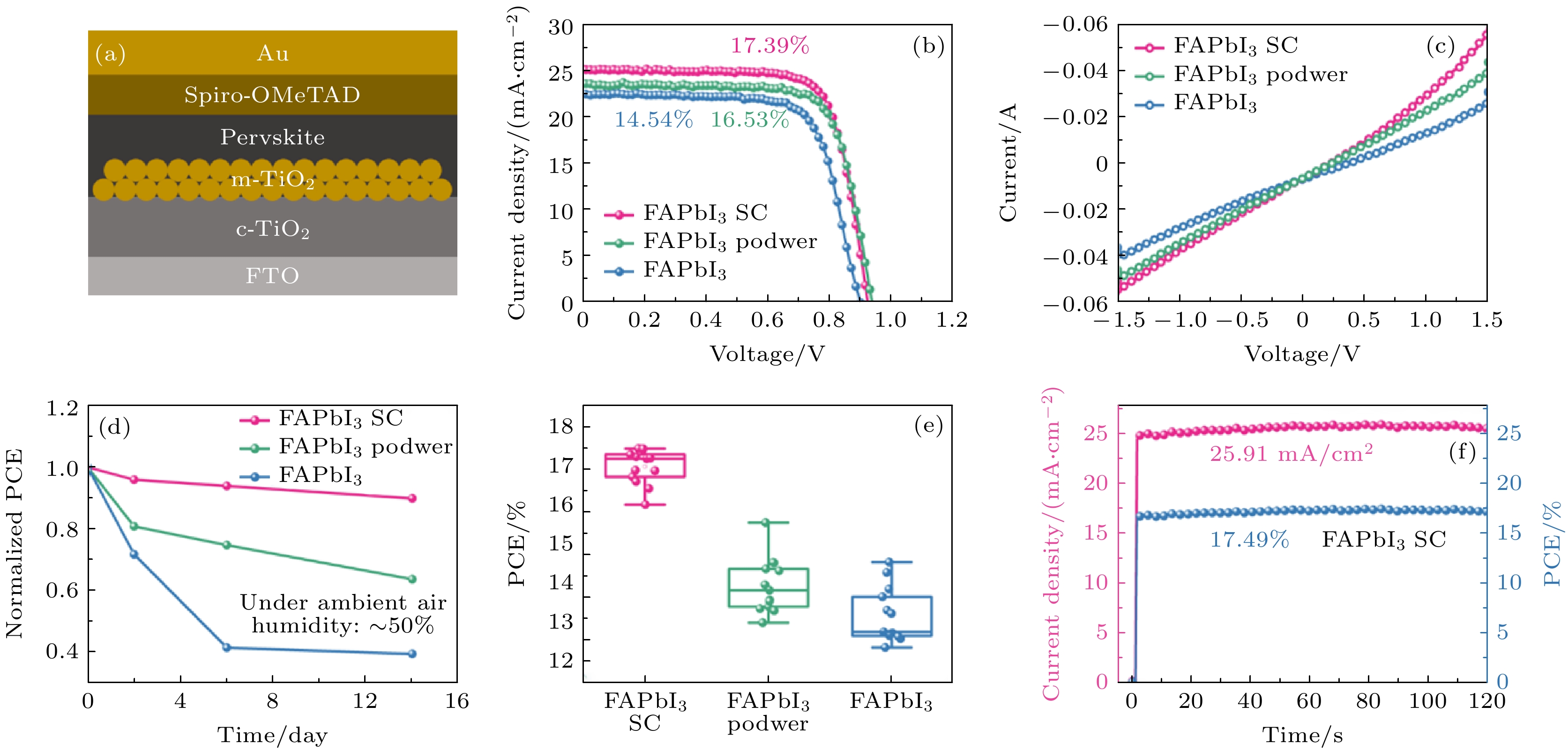

图 4 (a) 钙钛矿太阳能电池结构示意图; (b) FAPbI3单晶、晶体粉末和有机卤化物盐制备的钙钛矿太阳能电池的J-V曲线图; (c) FAPbI3单晶、晶体粉末和有机卤化物盐制备的钙钛矿太阳能电池的I-V曲线图; (d) 在没有封装的环境条件下FAPbI3单晶、晶体粉末和有机卤化物盐制备器件的稳定性; (e) FAPbI3单晶、晶体粉末和有机卤化物盐制备的钙钛矿太阳能电池PCE统计图; (f) FAPbI3单晶制备的钙钛矿太阳能电池稳态效率和电流密度

Fig. 4. (a) Device structure of perovskite solar cells; (b) J-V curves of perovskite solar cells prepared by FAPbI3 single crystal, crystal powders and organic halide salt; (c) I-V curves of perovskite solar cells prepared by FAPbI3 single crystal, crystal powders and organic halide salt; (d) PCE stability test of the unencapsulated devices prepared by FAPbI3 single crystal, crystal powders and organic halide salt for 14 days in ambient environment; (e) photoelectric conversion efficiency statistics of perovskite solar cells prepared by FAPbI3 single crystal, crystal powders and organic halide salt; (f) steady-state efficiency and current density of perovskite solar cells prepared by FAPbI3 single crystal.

表 1 FAPbI3单晶、晶体粉末和有机卤化物盐钙钛矿薄膜器件的瞬态(TRPL)光谱性能参数.

Table 1. Time-resolved PL (TRPL) performance parameters of FAPbI3 single crystal, crystal powders and organic halide salt perovskite thin film devices.

A1 τ1/ns A2 τ2/ns Τave/ns 有机卤化物盐 0.1432 19.53 0.5698 3.713 12.715 晶体粉末 0.1520 20.90 0.5652 4.40 13.66 单晶 0.1823 112.4 0.441 16.6 87.19 -

[1] Eperon G E, Stranks S D, Menelaou C, Johnston M B, Herz L M, Snaith H 2014 Energy Environ. Sci. 7 982

Google Scholar

Google Scholar

[2] De Wolf S, Holovsky J, Moon S J, Löper P, Niesen B, Ledinsky M, Haug F J, Yum J H, Ballif 2014 Phys. Chem. Lett. 5 1035

Google Scholar

Google Scholar

[3] Stranks S, Eperon G, Grancini G, Menelaou C, Alcocer M, Leijtens T, Herz L, Petrozza A, Snaith H 2013 Science 342 341

[4] Chen C W, Hsiao S Y, Chen C Y, Kang H W, Huang Z Y, Lin H W 2015 Mater. Chem. 3 9152

Google Scholar

Google Scholar

[5] Su H, Lin X, Wang Y, Liu X, Qin Z, Shi Q 2022 Sci. China Chem. 65 467

[6] Wang B, Iocozzia J, Zhang M, Ye M, Yan S, Jin H, Wang S, Zou Z, Lin Z 2019 Chem. Soc. Rev. 48 4854

Google Scholar

Google Scholar

[7] Zhang M, Cui X, Wang Y, Wang B, Ye M, Wang W, Ma C, Lin Z. 2020 Nano Energy 71 104620

Google Scholar

Google Scholar

[8] Zhang M, Ye M, Wang W, Ma C, Wang S, Liu Q, Lian T, Huang J, Lin Z 2020 Adv. Mater. 32 2000999

Google Scholar

Google Scholar

[9] Cui X, Chen Y, Zhang M, Harn Y W, Qi J, Gao L, Wang Z L, Huang J, Yang Y, Lin Z 2020 Energy Environ. Sci. 13 1743

Google Scholar

Google Scholar

[10] Dunlap-Shohl W A, Zhou Y, Padture N P, Mitzi D B 2019 Chem. Rev. 119 3193

Google Scholar

Google Scholar

[11] Lee J W, Seol D J, Cho A N, Park N G 2014 Adv. Mater. 26 4991

Google Scholar

Google Scholar

[12] Dong Q, Fang Y, Shao Y, Mulligan P, Qiu J, Cao L, Huang J 2015 Science 347 967

Google Scholar

Google Scholar

[13] Shi D, Adinolfi V, Comin R, Yuan, Alarousu M E, Buin A, Chen Y, Hoogland S, Rothenberger A, Katsiev K, Losovyj Y, Zhang X, Dowben P A, Mohammed O F, Sargent E H, Bakr O M 2015 Science 347 519

Google Scholar

Google Scholar

[14] De Quilettes D W, Vorpahl S M, Stranks S D, Nagaoka H, Eperon G E, Ziffer M E, Snaith H J, Ginger D S 2015 Science 348 683

Google Scholar

Google Scholar

[15] Prochowicz D, Franckevičius M, Cieślak A M, Zakeeruddin S M, Grätzel M, Lewiński J 2015 Mater. Chem. A 3 20772

Google Scholar

Google Scholar

[16] Zhang Y N, Cui R, Xiong L H, Pang D W 2018 Nanomedicine Nanotechnology, Biol. Med. 14 1813

[17] Zhang Y, Zhang X, Xu X, Munyalo J M, Liu L, Liu X, Lu M, Zhao Y 2019 Mol. Liq. 280 360

Google Scholar

Google Scholar

[18] Hanul M, Maengsuk K, Seung-Un L, Hyeonwoo K, Gwisu K. Keunsu C, Hee L 2019 Science 366 749

Google Scholar

Google Scholar

[19] Zhang Y, Seo S, Lim S Y, Kim Y, Kim S, Lee K, Lee S, Shin H, Cheong H, Park N 2020 ACS Energy Lett. 5 360

Google Scholar

Google Scholar

[20] Heo J H, Im S H 2016 Nanoscale 8 2554

Google Scholar

Google Scholar

[21] Chen Z, Türedi B, Alsalloum A, Yang C, Zheng X, Gereige I, AlSaggaf A, Mohammed O, Bakr O 2019 ACS Energy Lett. 4 1412

Google Scholar

Google Scholar

[22] Yen H, Liang P, Chueh C, Yang Z, Wang H 2016 ACS Appl. Mater. Interfaces 8 14513

Google Scholar

Google Scholar

[23] Cheng X, Yang S, Cao B, Tao X, Chen Z 2020 Adv. Funct. Mater. 30 1905021

Google Scholar

Google Scholar

[24] Jiang X, Fu X, Ju D, Yang S, Chen Z, Tao X 2020 ACS Energy Lett. 5 1797

Google Scholar

Google Scholar

[25] Kim M, Kim G H, Lee T K, Choi I W, Choi H W, Jo Y, Yoon Y J, Kim J W, Lee J, Huh D, Lee H, Kwak S K, Kim J Y, Kim D S 2019 Joule 3 2179

Google Scholar

Google Scholar

[26] Kim J H, Williams S T, Cho N, Chueh C C, Jen A K Y 2015 Adv. Energy Mater. 5 1401229

Google Scholar

Google Scholar

[27] Zhang Y, Kim S G, Lee D, Shin H, Park N G 2019 Energy Environ. Sci. 12 308

Google Scholar

Google Scholar

[28] Son D Y, Lee J W, Choi Y J, Jang I H, Lee S, Yoo P J, Shin H, Ahn N. Choi M, Kim D, Park N G 2016 Nat. Energy 1 16081

Google Scholar

Google Scholar

[29] He M, Li B, Cui X, Jiang B, He Y, Chen Y, O’Neil D, Szymanski P, Ei-Sayed M A, Huang J, Lin Z 2017 Nat. Commun. 8 16045

Google Scholar

Google Scholar

[30] Wu B, Fu K, Yantara N, Xing G, Sun S, Sum T C, Mathews N 2015 Adv. Energy Mater. 5 1500829

Google Scholar

Google Scholar

[31] Li C, Song Z, Zhao D, Xiao C, Subedi B, Shrestha N, Junda M M, Wang C, Jiang C S, Al-Jassim M, Ellingson R J, Podraza N J, Zhu K, Yan Y 2019 Adv. Energy Mater. 9 1803135

Google Scholar

Google Scholar

[32] Galatopoulos F, Savva A, Papadas I T, Choulis S A 2017 APL Mater. 5 76102

Google Scholar

Google Scholar

[33] Sun C, Pan F, Bin H, Zhang J, Xue L, Qiu B, Wei Z, Zhang Z G, Li Y 2018 Nat. Commun. 9 743

Google Scholar

Google Scholar

计量

- 文章访问数: 12411

- PDF下载量: 401

- 被引次数: 0

下载:

下载: