-

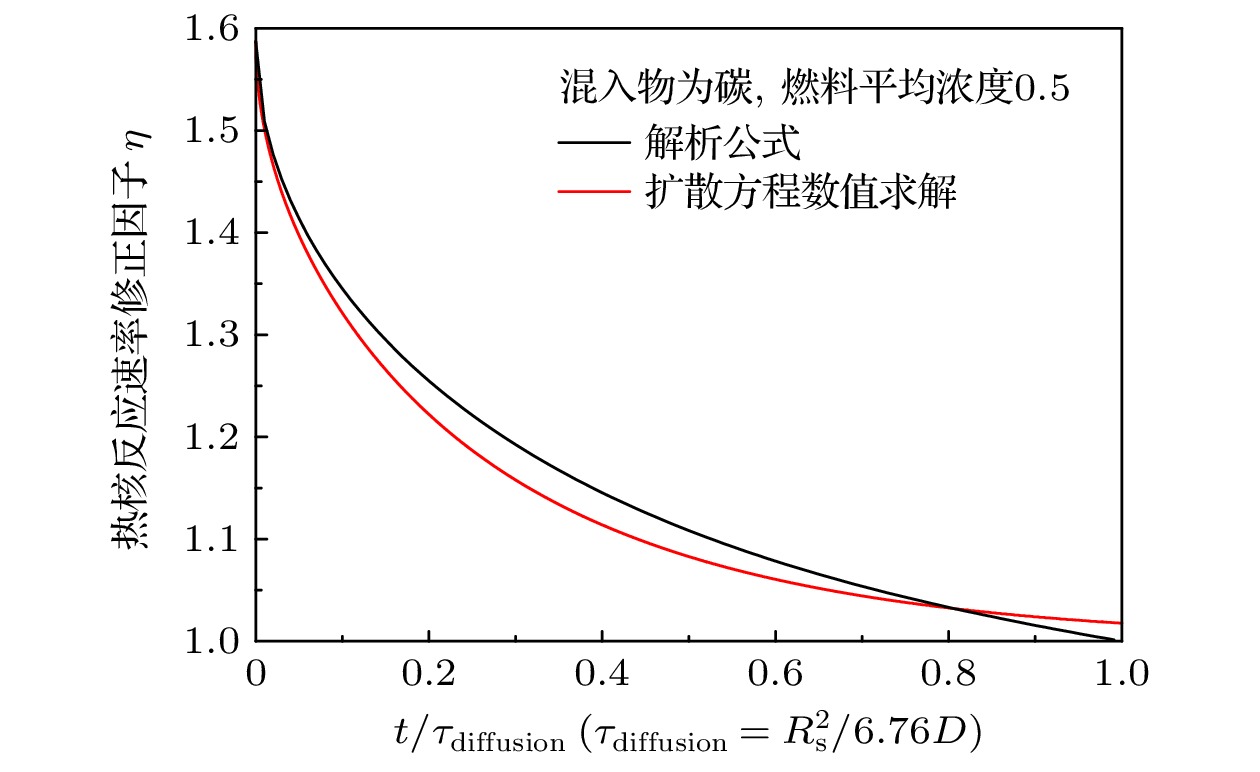

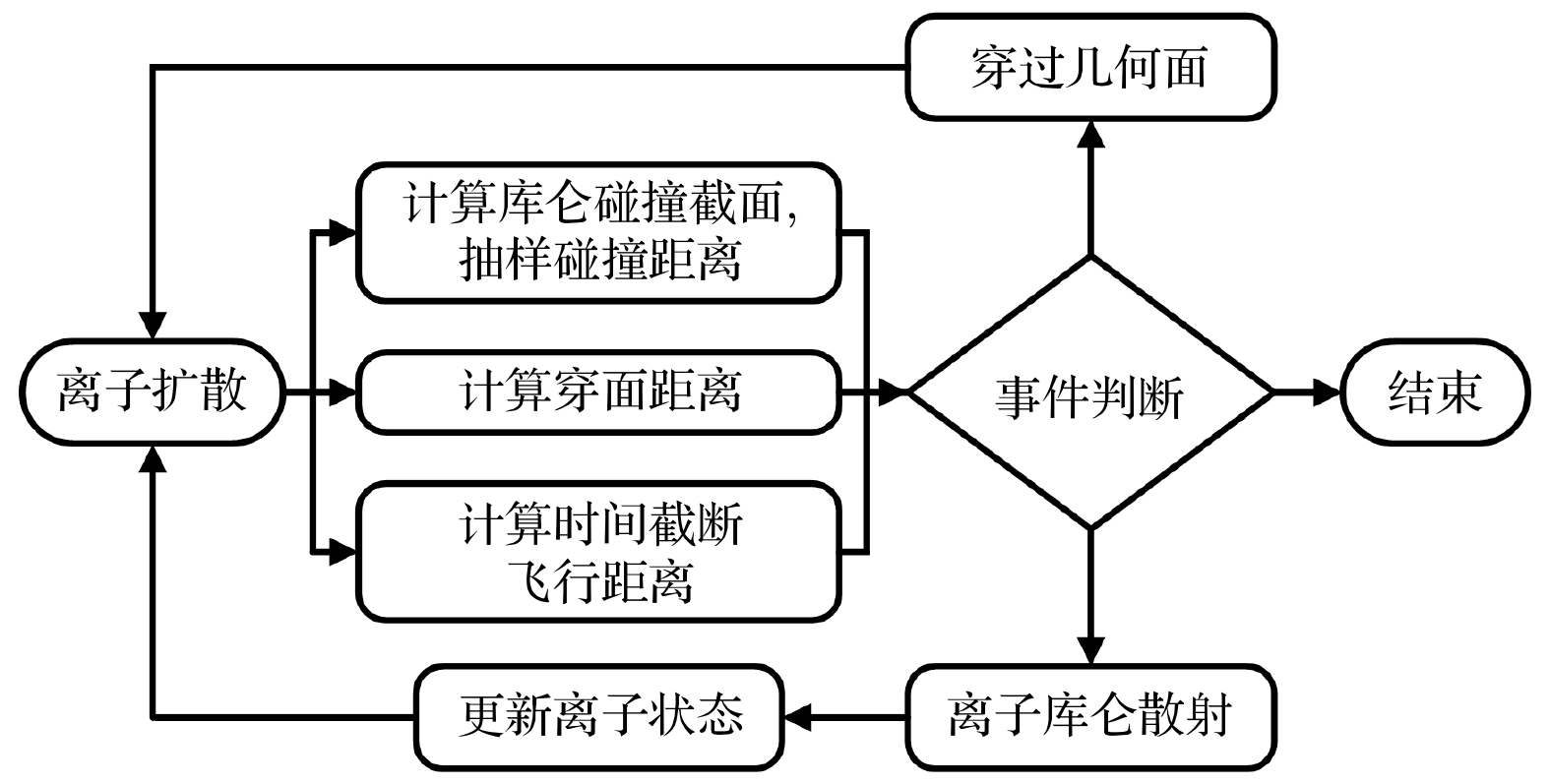

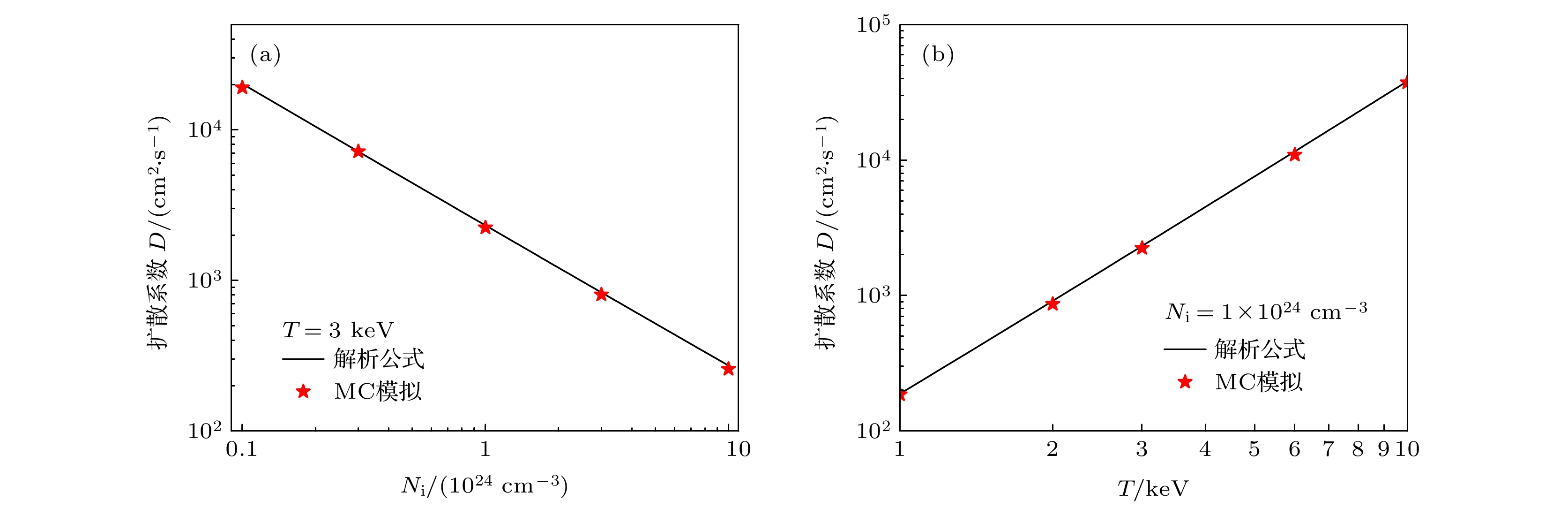

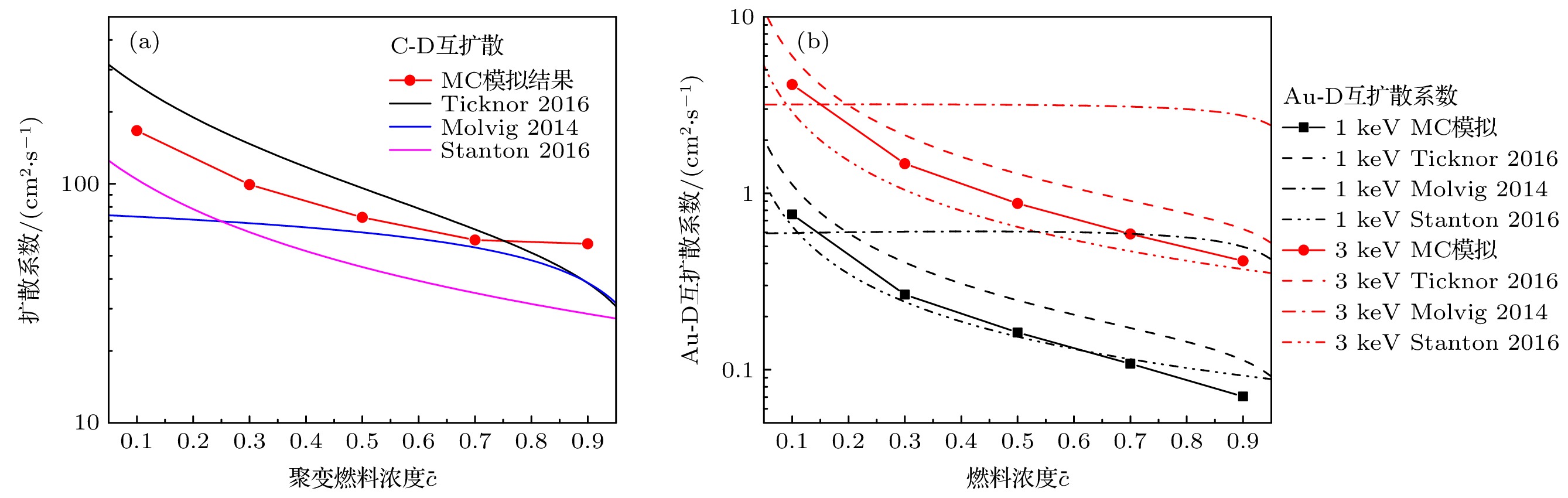

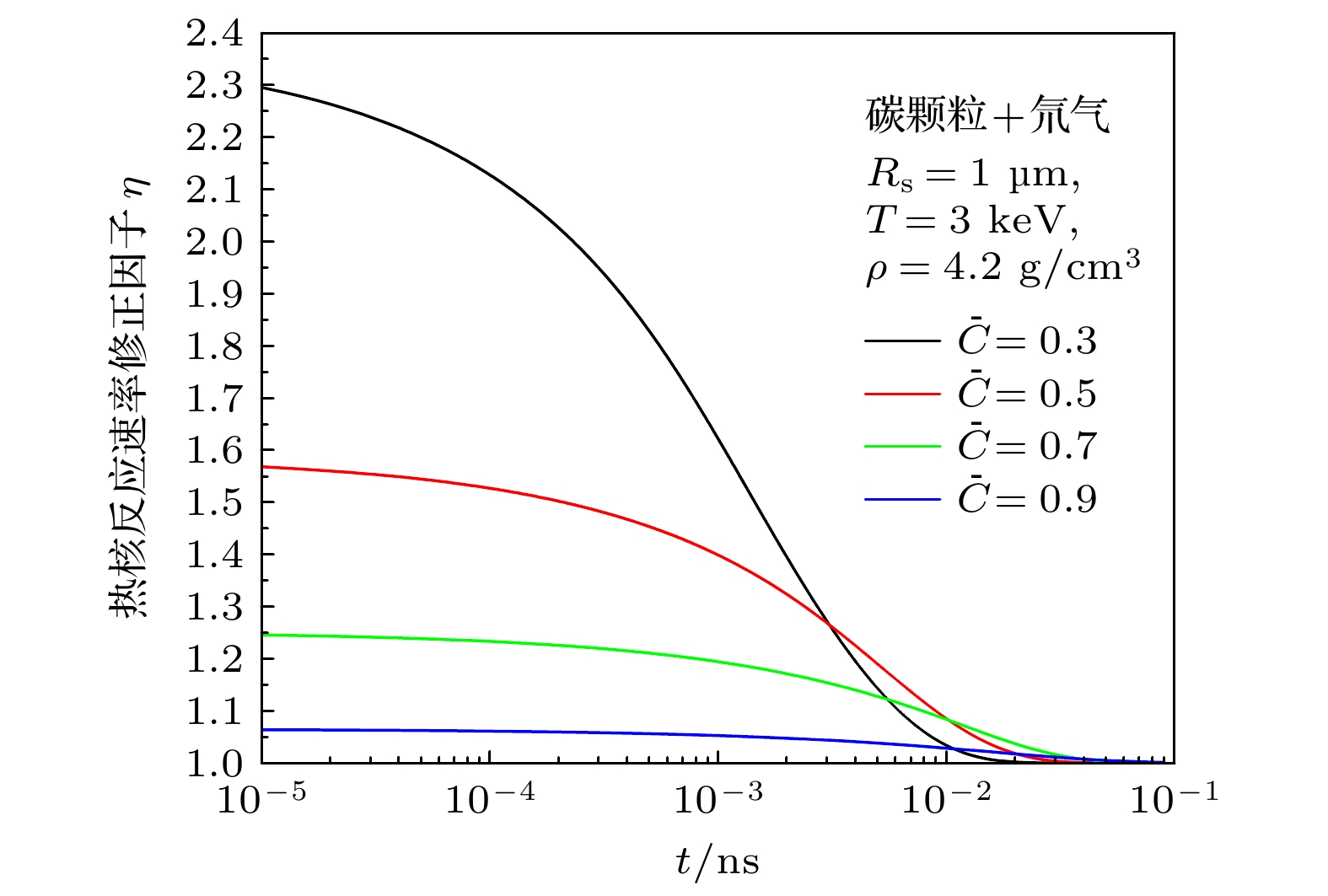

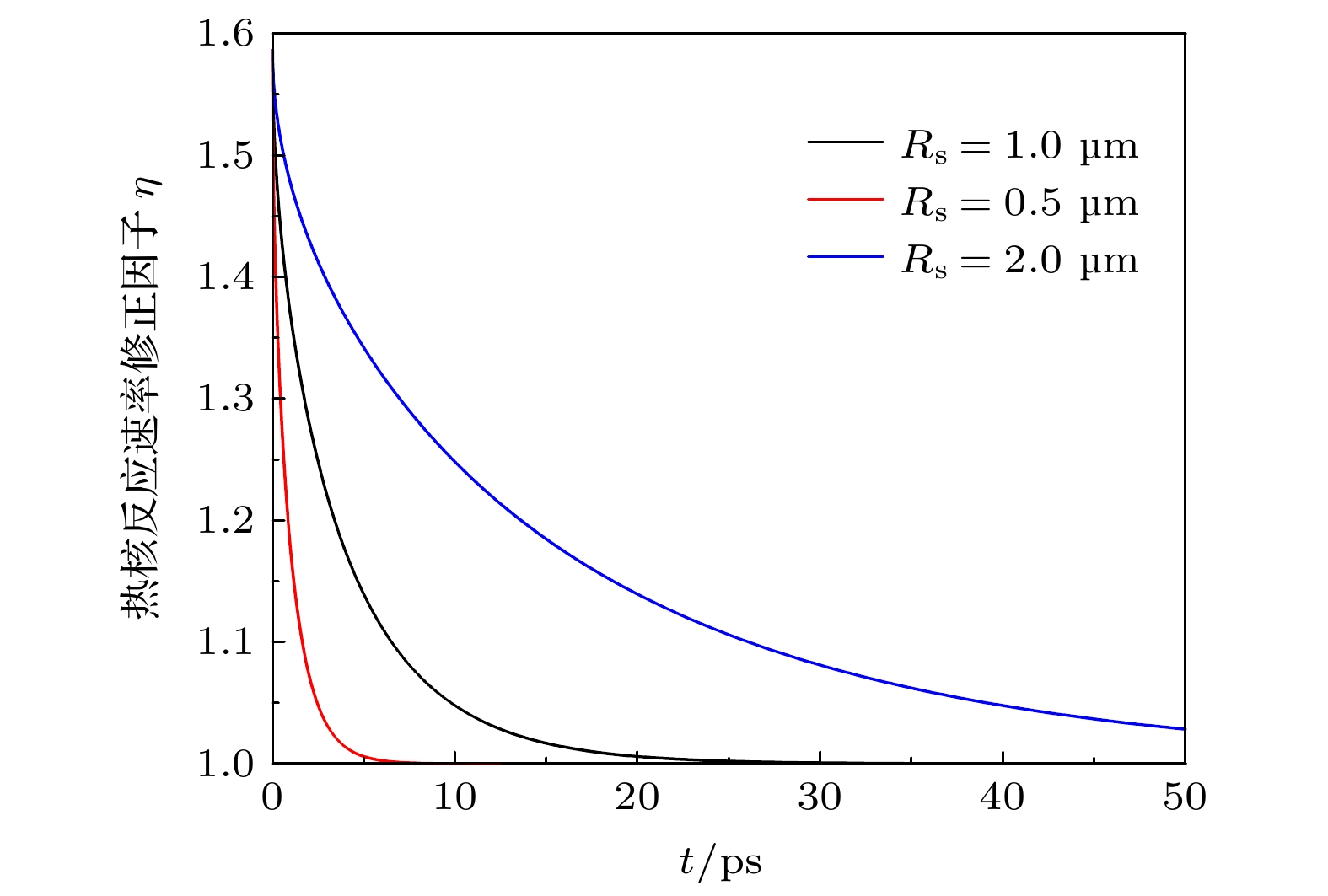

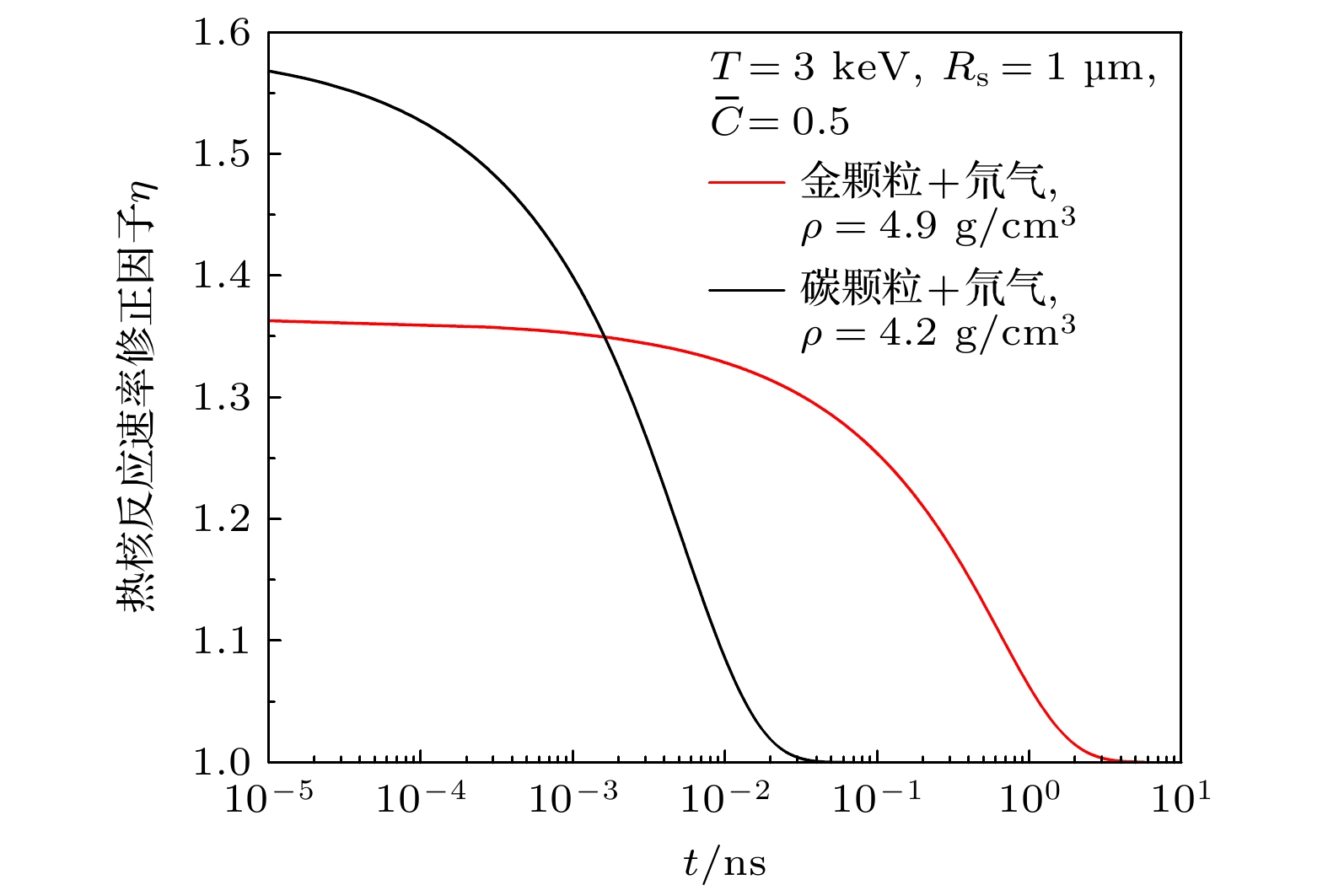

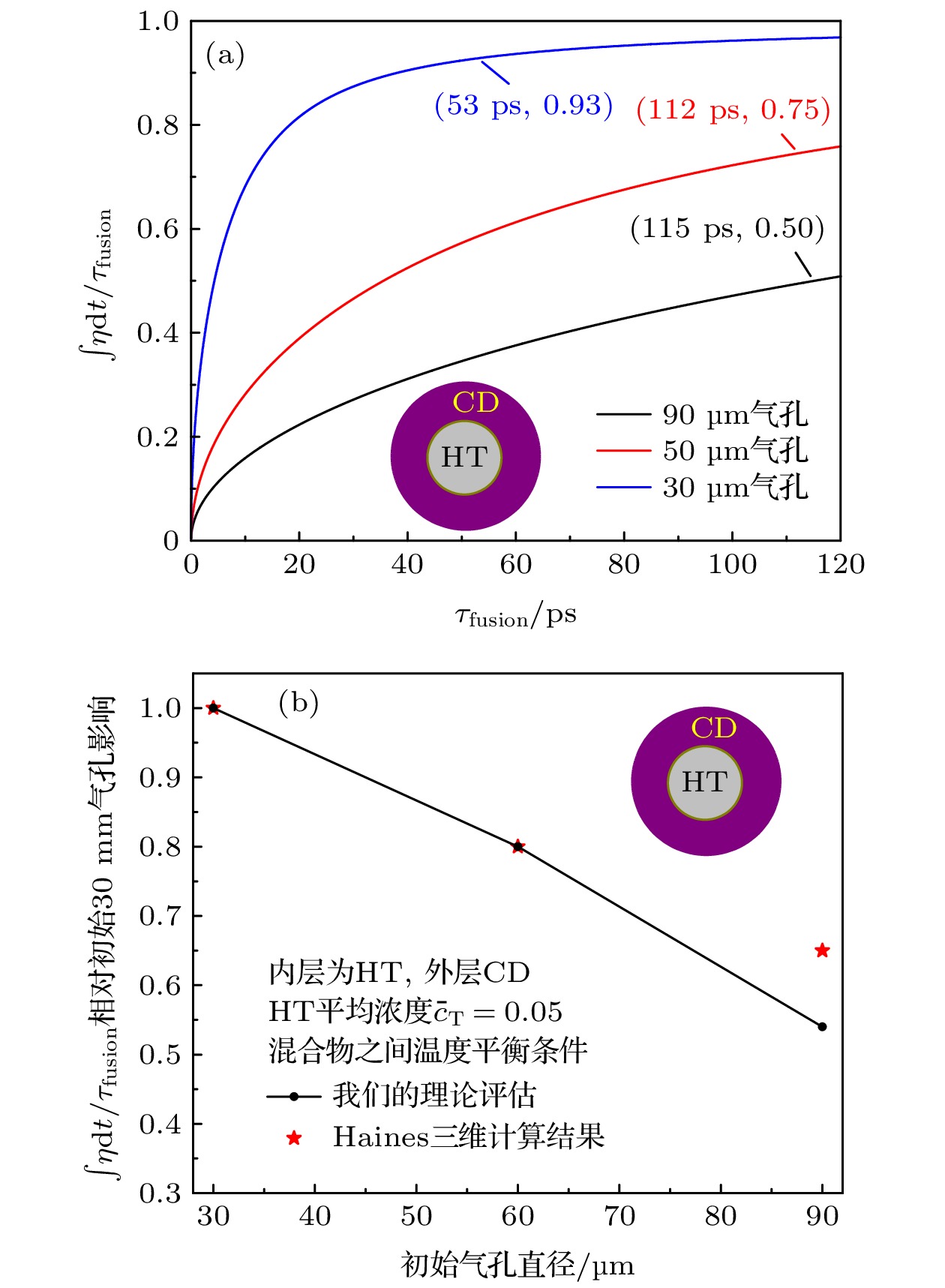

激光驱动惯性约束聚变中壳层材料和聚变燃料的混合是影响聚变点火燃烧性能的关键物理问题, 聚变过程中混合物形态的演化及相应热核反应速率的物理建模直接影响数值模拟的置信度, 具有重要的科学意义和应用价值. 本文以扩散混合机制下混合形态随时间的演化规律及其对热核反应速率的影响为研究对象, 基于热力学平衡与理想气体物态方程假设, 通过解析分析与一维球几何扩散方程数值解的对比研究, 揭示了扩散混合主导下热核反应速率随混合形态演化的物理规律. 研究发现, 混合量主要通过影响燃料的体积份额直接影响热核反应速率, 由混合非均匀尺度和扩散系数共同决定的扩散时间直接影响热核反应速率的时间演化行为. 进一步利用蒙特卡罗方法直接模拟扩散过程得到的互扩散系数, 定量分析了燃料中混入低Z、高Z材料时热核反应速率随时间演化的差异, 通过与美国非均匀混合效应实验典型数值模拟结果进行对比分析, 验证了理论评估的可靠性. 本工作对我国惯性约束聚变混合效应实验的设计和改进具有重要参考意义.Mixing between shell material and gas fuel, caused by hydrodynamic instability, isolated defects, or kinetic effects, is the key to understand the degradation of implosion performance in the research of inertial confinement fusion. Understanding the mixing mechanism and reducing its impact is of extreme importance to achieve the ignition and high gain. The impact of mixing morphology on thermonuclear reaction rate in sub grid level has gradually attracted people’s attention in recent years due to its direct influence on burn rate and fusion process, the study on physical model of thermonuclear reaction rate in different mix morphology has important scientific significance and application value. In the paper, the dependence of thermonuclear reaction rate on mass distribution of different fuel concentrations at sub grid scale is derived. Based on thermodynamic equilibrium and ideal gas equation of state, the physical law of the evolution of the thermonuclear reaction rate with mix morphology under the dominance of diffusion mixing is revealed through analytical formula and numerical solution of diffusion equation in one-dimensional spherical geometry. It is convinced that the mixing amount directly affects the thermonuclear reaction rate by mainly affecting the volume fraction of the fuel, and the mixing diffusion time determined by heterogeneous mixing scale and diffusion coefficient directly affects the evolution behavior of the thermonuclear reaction rate. Furthermore, based on mutual diffusion coefficient obtained from direct simulation of diffusion process by Monte Carlo method, the difference of impact to thermonuclear reaction rate for low-Z Carbon and high-Z gold mixing is quantitatively investigated. Heterogeneous mix size with 0.1 μm, 0.01 μm respectively for the low-Z and high-Z mixing can be treated as atomic mix in burn rate aspect, and heterogeneous mix size with 10 μm, 1 μm respectively for the low-Z and high-Z mixing can be treated as ideal chunk mix in burn rate aspect, and heterogeneous mix size in the middle state needs to be evaluated by using the heterogeneous mixing model of thermonuclear reaction rate in the paper. Finally, the physical model is compared with 3D simulation results of the heterogeneous mixing effect experiment called “MARBLE Campaign” carried out on OMEGA laser facility, which is designed as a separated reactant experiments and capsules are filled with deuterated foam and HT gas pores of different size, covering typical mix morphology from atomic mix to chunk mix, which validate the reliability of the theoretical evaluation about the evolution of mixing morphology and its impact to thermonuclear reaction rate. This work is significant for the design and improvement of inertial confinement fusion mixing effect experiment in China.

-

Keywords:

- mix morphology /

- heterogeneous mix /

- thermonuclear reaction rate /

- mutual diffusion coefficient

[1] Cabot W H, Cook A W 2006 Nat. Phys. 2 562

Google Scholar

Google Scholar

[2] Zhou Y 2017 Phys. Rep. 720-722 1

Google Scholar

Google Scholar

[3] Zhou Y 2017 Phys. Rep. 723-725 1

Google Scholar

Google Scholar

[4] Orth C D 2016 Phys. Plasmas 23 022706

Google Scholar

Google Scholar

[5] Weber C R, Clark D S, Pak A, Alfonso N, Bachmann B, Hopkins L F B, Bunn T, Crippen J, Divol L, Dittrich T, Kritcher A L, Landen O L, Le Pape B S, MacPhee A G, Marley E, Masse L P, Milovich J L, Nikroo A, Patel P K, Pickworth L A, Rice N, Smalyuk V A, Stadermann M 2020 Phys. Plasmas 27 032703

Google Scholar

Google Scholar

[6] Hammel B A, Tommasini R, Clark D S, Field J, Stadermann M, Weber C 2016 J. Phys. Conf. Ser. 717 012021

Google Scholar

Google Scholar

[7] Murphy T J, Douglas M R, Fincke J R, Olson R E, Cobble J A, Haines B M, Hamilton C E, Lee M N, Oertel J A, Parra-Vasquez N A G, Randolph R B, Schmidt D W, Shah R C, Smidt J M, Tregillis I L 2016 J. Phys. Conf. Ser. 717 012072

Google Scholar

Google Scholar

[8] Murphy T J, Albright B J, Douglas M R, Cardenas T, Cooley J H, Day T H, Denissen N A, Gore R A, Gunderson M A, Haack J R, Haines B M, Hamilton C E, Hartouni E P, Kim Y, Kozlowski P M, Lee M N, Oertel J A, Olson R E, Yin L 2021 High Energy Density Phys. 38 100929

Google Scholar

Google Scholar

[9] Haines B M, Shah R C, Smidt J M, Albright B J, Cardenas T, Douglas M R, Forrest C, Glebov V Y, Gunderson M A, Hamilton C E, Henderson K C, Kim Y, Lee M N, Murphy T J, Oertel J A, Olson R E, Patterson B M, Randolph R B, Schmidt D W 2020 Nat. Commun. 11 544

Google Scholar

Google Scholar

[10] Haines B M, Shah R C, Smidt J M, Albright B J, Cardenas T, Douglas M R, Forrest C, Glebov V Y, Gunderson M A, Hamilton C, Henderson K, Kim Y, Lee M N, Murphy T J, Oertel J A, Olson R E, Patterson B M, Randolph R B, Schmidt D 2020 Phys. Plasmas 27 102701

Google Scholar

Google Scholar

[11] Moses E I, Atherton J, Lagin L, Larson D, Keane C, MacGowan B, Patterson R, Spaeth M, Van Wonterghem B, Wegner P, Kauffman R 2016 J. Phys. Conf. Ser. 688 012073

Google Scholar

Google Scholar

[12] Boehly T R, Brown D L, Craxton R S, Keck R L, Knauer J P, Kelly J H, Kessler T J, Kumpan S A, Bucks S J, Letzring S A, Marshall F J, McCrory R L, Morse S F B, Seka W, Soures J M, Verdon C P 1997 Opt. Commun. 133 495

Google Scholar

Google Scholar

[13] Pu Y D, Luo X, Zhang L, Sun C K, Hu Z M, Shen G, Wang X R, Tang Q, Yuan Z, Wang F, Yang D, Yang J M, Jiang S E, Ding Y K, Wang J G 2020 Phys. Rev. E 102 023204

Google Scholar

Google Scholar

[14] Peng H, Zhang X M, Wei X, Zheng W, Jing F, Sui Z, Fan D, Lin Z 1999 Proc. SPIE 3492 25

[15] Ristorcelli J R 2017 Phys. Fluids 29 020705

Google Scholar

Google Scholar

[16] Cook A W, Riley J J 1994 Phys. Fluids 6 2868

Google Scholar

Google Scholar

[17] Dimotakis P E 2005 Annu. Rev. Fluid Mech. 37 329

Google Scholar

Google Scholar

[18] Girimaji S S 1991 Combust. Sci. Tech. 78 177

Google Scholar

Google Scholar

[19] Ticknor C, Kress J D, Collins L A, Clérouin J, Arnault P, Decoster A 2016 Phys. Rev. E 93 063208

Google Scholar

Google Scholar

[20] Molvig K, Simakov A N, Vold E L 2014 Phys. Plasmas 21 092709

Google Scholar

Google Scholar

[21] Stanton L G, Murillo M S 2016 Phys. Rev. E 93 043203

Google Scholar

Google Scholar

[22] White A J, Ticknor C, Meyer E R, Kress J D, Collins L A 2019 Phys. Rev. E 100 033213

Google Scholar

Google Scholar

[23] 查普曼 L, 考林 T G 著 (刘大有, 王伯懿 译) 1970 非均匀气体的数学理论 (北京: 科学出版社) 第137—139页

Chapman S, Cowling T G (translated by Liu D Y, Wang B Y) 1970 The Mathematical Theory of Non-uniform Gases (Beijing: Science Press) pp137–139 (in Chinese)

[24] Brueckner K A, Jorna S 1974 Rev. Mod. Phys. 46 325

Google Scholar

Google Scholar

-

图 6 蒙卡模拟的离子数密度分布随时间演化行为与扩散方程数值解的比较 (数值解的扩散系数为2243

$ {\rm{cm}}^2/{\rm{s}} $ , 到心时间为0.9 ns)Fig. 6. Comparison between time evolution of ion number density distribution simulated by MC and numerical solution of diffusion equation. (diffusion coefficient of numerical solution is 2243

$ {\rm{cm}}^2/{\rm{s}} $ , time of diffusion to center is 0.9 ns) -

[1] Cabot W H, Cook A W 2006 Nat. Phys. 2 562

Google Scholar

Google Scholar

[2] Zhou Y 2017 Phys. Rep. 720-722 1

Google Scholar

Google Scholar

[3] Zhou Y 2017 Phys. Rep. 723-725 1

Google Scholar

Google Scholar

[4] Orth C D 2016 Phys. Plasmas 23 022706

Google Scholar

Google Scholar

[5] Weber C R, Clark D S, Pak A, Alfonso N, Bachmann B, Hopkins L F B, Bunn T, Crippen J, Divol L, Dittrich T, Kritcher A L, Landen O L, Le Pape B S, MacPhee A G, Marley E, Masse L P, Milovich J L, Nikroo A, Patel P K, Pickworth L A, Rice N, Smalyuk V A, Stadermann M 2020 Phys. Plasmas 27 032703

Google Scholar

Google Scholar

[6] Hammel B A, Tommasini R, Clark D S, Field J, Stadermann M, Weber C 2016 J. Phys. Conf. Ser. 717 012021

Google Scholar

Google Scholar

[7] Murphy T J, Douglas M R, Fincke J R, Olson R E, Cobble J A, Haines B M, Hamilton C E, Lee M N, Oertel J A, Parra-Vasquez N A G, Randolph R B, Schmidt D W, Shah R C, Smidt J M, Tregillis I L 2016 J. Phys. Conf. Ser. 717 012072

Google Scholar

Google Scholar

[8] Murphy T J, Albright B J, Douglas M R, Cardenas T, Cooley J H, Day T H, Denissen N A, Gore R A, Gunderson M A, Haack J R, Haines B M, Hamilton C E, Hartouni E P, Kim Y, Kozlowski P M, Lee M N, Oertel J A, Olson R E, Yin L 2021 High Energy Density Phys. 38 100929

Google Scholar

Google Scholar

[9] Haines B M, Shah R C, Smidt J M, Albright B J, Cardenas T, Douglas M R, Forrest C, Glebov V Y, Gunderson M A, Hamilton C E, Henderson K C, Kim Y, Lee M N, Murphy T J, Oertel J A, Olson R E, Patterson B M, Randolph R B, Schmidt D W 2020 Nat. Commun. 11 544

Google Scholar

Google Scholar

[10] Haines B M, Shah R C, Smidt J M, Albright B J, Cardenas T, Douglas M R, Forrest C, Glebov V Y, Gunderson M A, Hamilton C, Henderson K, Kim Y, Lee M N, Murphy T J, Oertel J A, Olson R E, Patterson B M, Randolph R B, Schmidt D 2020 Phys. Plasmas 27 102701

Google Scholar

Google Scholar

[11] Moses E I, Atherton J, Lagin L, Larson D, Keane C, MacGowan B, Patterson R, Spaeth M, Van Wonterghem B, Wegner P, Kauffman R 2016 J. Phys. Conf. Ser. 688 012073

Google Scholar

Google Scholar

[12] Boehly T R, Brown D L, Craxton R S, Keck R L, Knauer J P, Kelly J H, Kessler T J, Kumpan S A, Bucks S J, Letzring S A, Marshall F J, McCrory R L, Morse S F B, Seka W, Soures J M, Verdon C P 1997 Opt. Commun. 133 495

Google Scholar

Google Scholar

[13] Pu Y D, Luo X, Zhang L, Sun C K, Hu Z M, Shen G, Wang X R, Tang Q, Yuan Z, Wang F, Yang D, Yang J M, Jiang S E, Ding Y K, Wang J G 2020 Phys. Rev. E 102 023204

Google Scholar

Google Scholar

[14] Peng H, Zhang X M, Wei X, Zheng W, Jing F, Sui Z, Fan D, Lin Z 1999 Proc. SPIE 3492 25

[15] Ristorcelli J R 2017 Phys. Fluids 29 020705

Google Scholar

Google Scholar

[16] Cook A W, Riley J J 1994 Phys. Fluids 6 2868

Google Scholar

Google Scholar

[17] Dimotakis P E 2005 Annu. Rev. Fluid Mech. 37 329

Google Scholar

Google Scholar

[18] Girimaji S S 1991 Combust. Sci. Tech. 78 177

Google Scholar

Google Scholar

[19] Ticknor C, Kress J D, Collins L A, Clérouin J, Arnault P, Decoster A 2016 Phys. Rev. E 93 063208

Google Scholar

Google Scholar

[20] Molvig K, Simakov A N, Vold E L 2014 Phys. Plasmas 21 092709

Google Scholar

Google Scholar

[21] Stanton L G, Murillo M S 2016 Phys. Rev. E 93 043203

Google Scholar

Google Scholar

[22] White A J, Ticknor C, Meyer E R, Kress J D, Collins L A 2019 Phys. Rev. E 100 033213

Google Scholar

Google Scholar

[23] 查普曼 L, 考林 T G 著 (刘大有, 王伯懿 译) 1970 非均匀气体的数学理论 (北京: 科学出版社) 第137—139页

Chapman S, Cowling T G (translated by Liu D Y, Wang B Y) 1970 The Mathematical Theory of Non-uniform Gases (Beijing: Science Press) pp137–139 (in Chinese)

[24] Brueckner K A, Jorna S 1974 Rev. Mod. Phys. 46 325

Google Scholar

Google Scholar

计量

- 文章访问数: 4771

- PDF下载量: 83

- 被引次数: 0

下载:

下载: