-

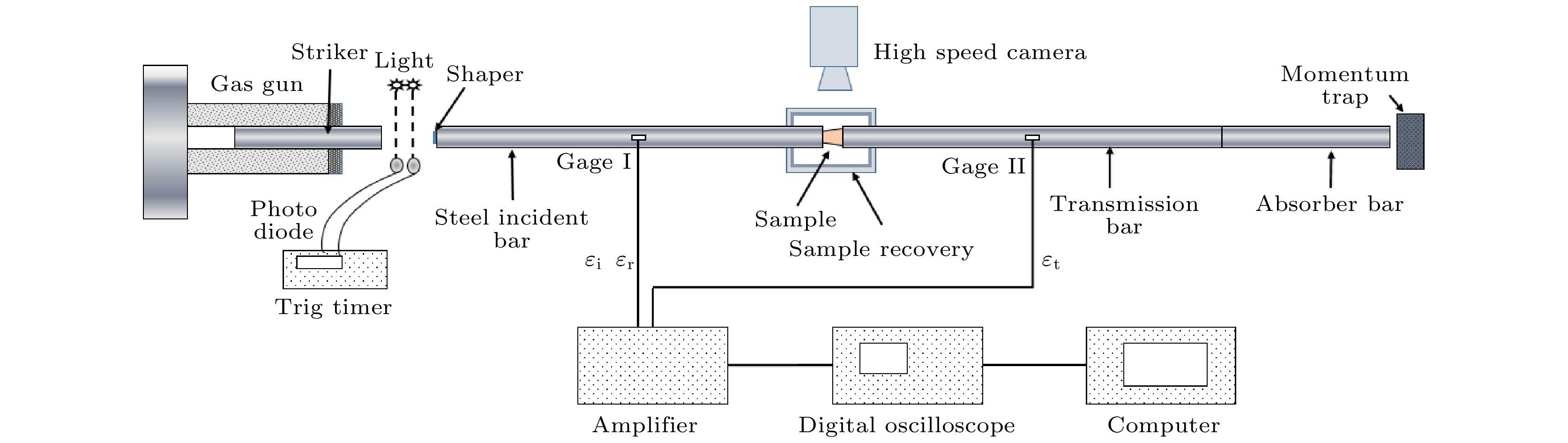

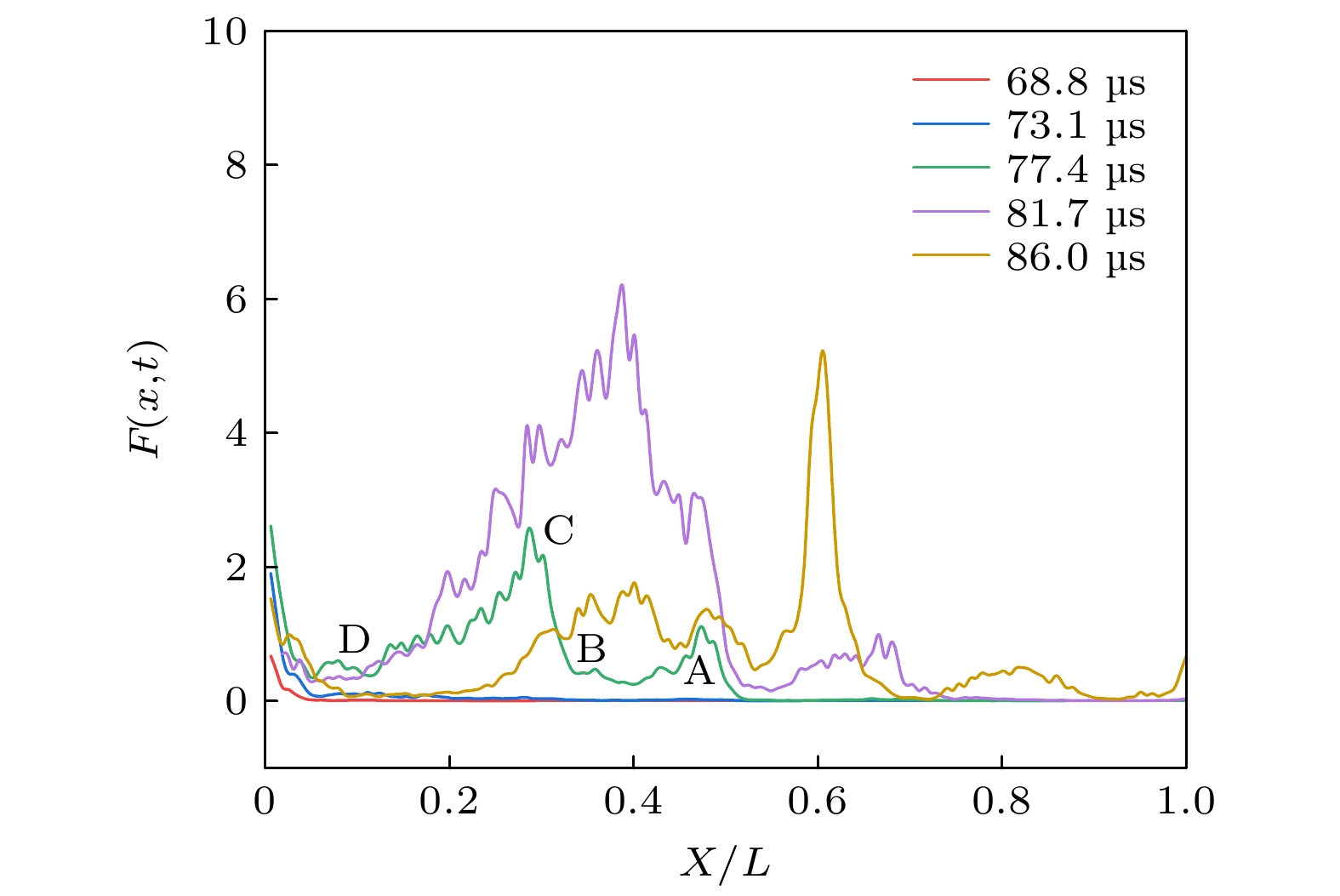

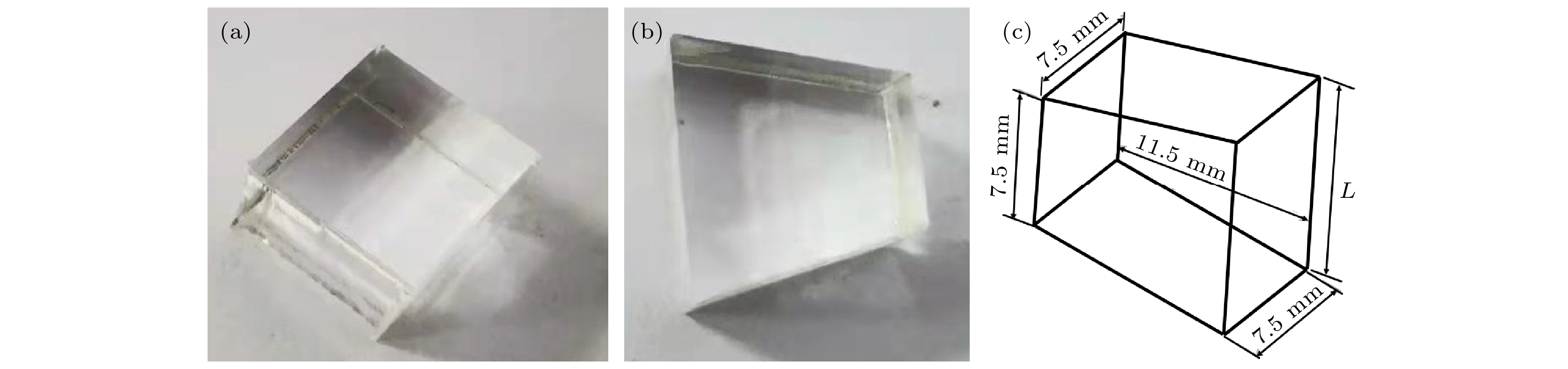

应用霍普金森压杆(SHPB)实验装置, 通过改变透射杆为钢杆和铝杆, 对立方体聚甲基丙烯酸甲酯(PMMA)试样和两种梯台PMMA试样进行动态压缩实验. 利用高速摄影记录试样的压缩过程, 并结合力位移曲线分析试样的破碎过程, 探讨了冲击载荷作用下PMMA试样变形和广义扩散阻力的演化. 结果表明: 试样的破坏模式主要为接触端局部产生失效阵面, 然后失效阵面向试样内部扩展. 立方体试样在低速冲击下, 失效阵面优先在透射端产生; 在高速冲击下, 失效阵面在入射端先产生. 通过改变试样形状和透射杆材质后, 阵面的产生存在明显的弛豫现象, 并且失效阵面仅在入射端产生. 梯台试样破碎前的压缩变形是非均匀的, 试样内部应力状态和变形状态随着截面增加逐渐变小, 并且呈线性扩散分布. 通过应变分布结合剪切激活扩散方程, 得到失效阵面扩散过程中的广义扩散阻力分布情况; 失效阵面前后广义扩散阻力先增加后减小, 阻力的幅值与局部应变能的释放有关.Dynamic compression experiments on cubic polymethyl methacrylate (PMMA) specimens and two kinds of trapezoid PMMA specimens are carried by changing the transmission bars into steel bar and aluminum bar on the experimental device of split Hopkinson pressure bar (SHPB). The compression processes of PMMA specimens are recorded by high-speed photography, and the breakage processes of PMMA specimens are analyzed based on the force displacement curves and high-speed images. The evolutions of deformation and diffusion resistances of PMMA specimens under impact loading are discussed. The results show that the failure of the sample is caused mainly by the partial failure front at the contact end, and then the failure front propagates to the inside of the sample, leading the sample to break. The failure front of cubic sample is generated preferentially at the transmission end under low speed impact and at the incident end under the higher speed impact. After changing the shape of the specimen and the material of the transmission bar, the relaxation phenomenon is prominent, and the failure front occurs only at the incident end. The compressive deformation of the trapezoid sample before breakage is non-uniform, and the stress and strain in the sample gradually decrease with the increase of the cross section, and show a linear diffusion distribution. The strain distribution and shear activation diffusion equation are used to obtain the generalized diffusion resistance distribution of the failure front. The generalized diffusion resistance increases first in front of the failure front and decreases after the failure front, and the amplitude of the generalized diffusion resistance is related to the release of local strain energy.

[1] 徐松林, 单俊芳, 王鹏飞 2020 现代应用物理 11 30101

Google Scholar

Google Scholar

Xu S L, Shan J F, Wang P F 2020 Mod. Appl. Phys. 11 30101

Google Scholar

Google Scholar

[2] 马棋棋, 熊迅, 郑宇轩, 周风华 2019 高压 33 044101

Google Scholar

Google Scholar

Ma Q Q, Xiong X, Zheng Y X, Zhou F H 2019 Chin. J. High Pressure Phys. 33 044101

Google Scholar

Google Scholar

[3] Huang J, Xu S, Hu S 2013 Rock Mech. Rock Eng. 47 1727

[4] 陈兴, 马刚, 周伟, 赖国伟, 来志强 2018 67 146102

Google Scholar

Google Scholar

Chen X, Ma G, Zhou W, Lai G W, Lai Z Q 2018 Acta Phys. Sin. 67 146102

Google Scholar

Google Scholar

[5] Jiang H B, Xu S L, Shan J F, Wang D R, Liu Y G, Zhou L J, Wang P F 2019 Powder Technol. 353 359

Google Scholar

Google Scholar

[6] Shan J, Xu S, Liu Y G, Zhou L J, Wang P F 2018 Powder Technol. 330 317

Google Scholar

Google Scholar

[7] Potapov A V, Campbell C S 1997 Powder Technol. 93 13

Google Scholar

Google Scholar

[8] Rasorenov S V, Kanel G I, Fortov V E, Abasehov M M 1991 Int. J. High Pressure Res. 6 225

Google Scholar

Google Scholar

[9] Espinosa H D 1998 Mech. Mater. 29 219

Google Scholar

Google Scholar

[10] 冯晓伟, 李俊承, 王洪波, 常敬臻 2016 65 166201

Google Scholar

Google Scholar

Feng X W, Li J C, Wang H B, Chang J Z 2016 Acta Phys. Sin. 65 166201

Google Scholar

Google Scholar

[11] Anderson Jr C E, Bigger R P, Weiss C E 2014 Int. J. Appl. Glass Sci. 5 374

Google Scholar

Google Scholar

[12] Huang J Y, Li Y, Liu Q C, Zhou X M, Liu L W, Liu C L, Zhu H M, Luo S N 2015 Phys. Rev. B 92 144101

Google Scholar

Google Scholar

[13] Sheikh M Z, Atif M, Li Y L, Zhou F H, Raza M A, Dar U A, Gao G Z, Wang Y M 2021 Constr. Build. Mater. 288 123088

Google Scholar

Google Scholar

[14] 易洪昇, 徐松林, 单俊芳, 张鸣 2017 爆炸与冲击 37 913

Google Scholar

Google Scholar

Yi H S, Xu S L, Shan J F, Zhang M 2017 Explosion and Shock Waves 37 913

Google Scholar

Google Scholar

[15] 宋一平, 苗春贺, 单俊芳, 王鹏飞, 徐松林 2022 爆炸与冲击 42 073103

Google Scholar

Google Scholar

Song Y P, Miao C H, Shan J F, Wang P F, Xu S L 2022 Explosion and Shock Waves 42 073103

Google Scholar

Google Scholar

[16] 方继松, 王珠, 熊迅, 郑宇轩, 周凤华 2020 高压 34 014101

Google Scholar

Google Scholar

Fang J S, Wang Z, Xiong X, Zheng Y X, Zhou F H 2020 Chin. J. High Pressure Phys. 34 014101

Google Scholar

Google Scholar

[17] Miao C H, Xu S L, Song Y P, Xie Y S, Yuan L Z, Wang P F 2022 Powder Technol. 397 117081

Google Scholar

Google Scholar

[18] Liu D, Shen L, Guillard F, Einav I 2016 Int. J. Impact Eng. 93 222

Google Scholar

Google Scholar

[19] 简世豪, 苗春贺, 张磊, 单俊芳, 王鹏飞, 徐松林 2021 高压 35 024202

Google Scholar

Google Scholar

Jian S H, Miao C H, Zhang L, Shan J F, Wang P F, Xu S L 2021 Chin. J. High Pressure Phys. 35 024202

Google Scholar

Google Scholar

[20] Xing H Z, Zhang Q B, Braithwaite C H, Pan B, Zhao J 2017 Rock Mech. Rock Eng. 50 1611

Google Scholar

Google Scholar

[21] Zhou L, Xu S, Shan J, Liu Y, Wang P 2018 Mech. Mater. 123 1

Google Scholar

Google Scholar

[22] Grady D 2017 Phys. Shock Impact (Vol. 1) (London: IOP Publishing) pp2-57–2-68

[23] Mott N F 1947 Proc. R. Soc. London, Ser. A 189 300

Google Scholar

Google Scholar

[24] Feng R 2000 J. Appl. Phys. 87 1693

Google Scholar

Google Scholar

[25] 刘占芳, 常敬臻, 姚国文, 张凯, 李建鹏 2006 力学学报 38 626

Google Scholar

Google Scholar

Liu Z F, Chang J Z, Yao G W, Zhang K, Li J P 2006 Chin. J. Theor. Appl. Mech. 38 626

Google Scholar

Google Scholar

-

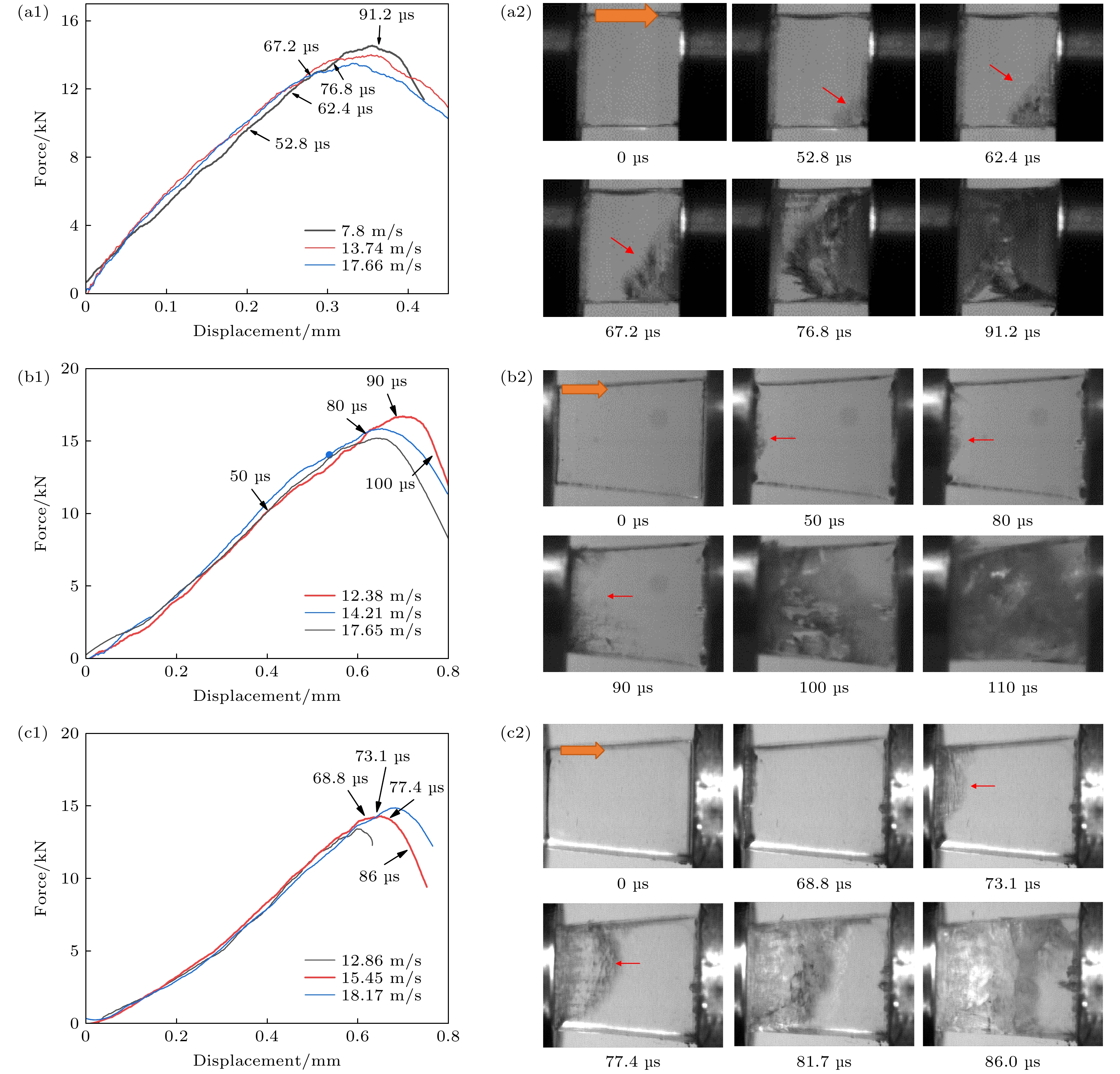

图 3 冲击过程中的载荷位移曲线和破碎过程 (a1) 透射杆为钢杆时立方体试样的力位移曲线; (a2) 冲击速度为7.8 m/s时立方体试样的破坏过程; (b1)透射杆为钢杆时梯台试样Ⅰ的力位移曲线; (b2) 梯台试样Ⅰ的破坏过程(冲击速度为12.38 m/s); (c1)透射杆为铝杆时梯台试样Ⅰ的力位移曲线; (c2) 透射杆为铝杆时梯台试样Ⅰ的破坏过程(冲击速度为15.45 m/s). 橙色箭头表示冲击方向

Fig. 3. Load displacement curve and crushing process during impact: (a1) Load displacement curve of cube sample under steel transmission bar; (a2) cube sample deformation process under impact velocity of 7.8 m/s; (b1) load displacement curve of trapezoid sample Ⅰ under steel transmission bar; (b2) trapezoid sample Ⅰ under steel transmission bar (impact velocity of 12.38 m/s); (c1) load displacement curve of trapezoid sample Ⅰ under aluminum transmission bar; (c2) trapezoid sample Ⅰ under aluminum transmission bar (impact velocity of 15.45 m/s). The orange arrow denotes the impact direction.

图 4 梯台试样Ⅰ在钢杆下的应变分布 (冲击速度13.3 m/s) (a) DIC计算区域; (b) 高速摄影图片; (c) 2D等效剪应变场(箭头表示冲击方向)

Fig. 4. Strain distribution of trapezoid sample Ⅰ under steel transmission bar (impact velocity of 13.3 m/s): (a) Area of DIC calculation; (b) high speed images; (c) 2D equivalent shear strain field (The arrow denotes the impact direction).

图 6 沿冲击方向的平均等效剪应变分布 (a) 梯台试样Ⅰ在冲击速度为13.3 m/s、透射杆为钢杆时的应变分布; (b) 梯台试样Ⅰ在冲击速度为16.21 m/s、透射杆为铝杆时的应变分布

Fig. 6. Average equivalent shear strain distribution along impact direction: (a) Trapezoid sample Ⅰ under steel transmission bar (impact velocity of 13.3 m/s); (b) trapezoid sample Ⅰ under aluminum transmission bar (impact velocity of 16.21 m/s).

表 1 试样两端应力差统计

Table 1. Statistics of stress differences between two ends of sample.

试样 透射杆 应变率/s–1 应力差异 立方体 钢杆 600 <2.5% 梯台Ⅰ 500 20.4%—22.1% 梯台Ⅱ 600 33.8%—35.2% 梯台Ⅰ 铝杆 600 23.3%—25.5% 梯台Ⅱ 750 37.2%—43.1% -

[1] 徐松林, 单俊芳, 王鹏飞 2020 现代应用物理 11 30101

Google Scholar

Google Scholar

Xu S L, Shan J F, Wang P F 2020 Mod. Appl. Phys. 11 30101

Google Scholar

Google Scholar

[2] 马棋棋, 熊迅, 郑宇轩, 周风华 2019 高压 33 044101

Google Scholar

Google Scholar

Ma Q Q, Xiong X, Zheng Y X, Zhou F H 2019 Chin. J. High Pressure Phys. 33 044101

Google Scholar

Google Scholar

[3] Huang J, Xu S, Hu S 2013 Rock Mech. Rock Eng. 47 1727

[4] 陈兴, 马刚, 周伟, 赖国伟, 来志强 2018 67 146102

Google Scholar

Google Scholar

Chen X, Ma G, Zhou W, Lai G W, Lai Z Q 2018 Acta Phys. Sin. 67 146102

Google Scholar

Google Scholar

[5] Jiang H B, Xu S L, Shan J F, Wang D R, Liu Y G, Zhou L J, Wang P F 2019 Powder Technol. 353 359

Google Scholar

Google Scholar

[6] Shan J, Xu S, Liu Y G, Zhou L J, Wang P F 2018 Powder Technol. 330 317

Google Scholar

Google Scholar

[7] Potapov A V, Campbell C S 1997 Powder Technol. 93 13

Google Scholar

Google Scholar

[8] Rasorenov S V, Kanel G I, Fortov V E, Abasehov M M 1991 Int. J. High Pressure Res. 6 225

Google Scholar

Google Scholar

[9] Espinosa H D 1998 Mech. Mater. 29 219

Google Scholar

Google Scholar

[10] 冯晓伟, 李俊承, 王洪波, 常敬臻 2016 65 166201

Google Scholar

Google Scholar

Feng X W, Li J C, Wang H B, Chang J Z 2016 Acta Phys. Sin. 65 166201

Google Scholar

Google Scholar

[11] Anderson Jr C E, Bigger R P, Weiss C E 2014 Int. J. Appl. Glass Sci. 5 374

Google Scholar

Google Scholar

[12] Huang J Y, Li Y, Liu Q C, Zhou X M, Liu L W, Liu C L, Zhu H M, Luo S N 2015 Phys. Rev. B 92 144101

Google Scholar

Google Scholar

[13] Sheikh M Z, Atif M, Li Y L, Zhou F H, Raza M A, Dar U A, Gao G Z, Wang Y M 2021 Constr. Build. Mater. 288 123088

Google Scholar

Google Scholar

[14] 易洪昇, 徐松林, 单俊芳, 张鸣 2017 爆炸与冲击 37 913

Google Scholar

Google Scholar

Yi H S, Xu S L, Shan J F, Zhang M 2017 Explosion and Shock Waves 37 913

Google Scholar

Google Scholar

[15] 宋一平, 苗春贺, 单俊芳, 王鹏飞, 徐松林 2022 爆炸与冲击 42 073103

Google Scholar

Google Scholar

Song Y P, Miao C H, Shan J F, Wang P F, Xu S L 2022 Explosion and Shock Waves 42 073103

Google Scholar

Google Scholar

[16] 方继松, 王珠, 熊迅, 郑宇轩, 周凤华 2020 高压 34 014101

Google Scholar

Google Scholar

Fang J S, Wang Z, Xiong X, Zheng Y X, Zhou F H 2020 Chin. J. High Pressure Phys. 34 014101

Google Scholar

Google Scholar

[17] Miao C H, Xu S L, Song Y P, Xie Y S, Yuan L Z, Wang P F 2022 Powder Technol. 397 117081

Google Scholar

Google Scholar

[18] Liu D, Shen L, Guillard F, Einav I 2016 Int. J. Impact Eng. 93 222

Google Scholar

Google Scholar

[19] 简世豪, 苗春贺, 张磊, 单俊芳, 王鹏飞, 徐松林 2021 高压 35 024202

Google Scholar

Google Scholar

Jian S H, Miao C H, Zhang L, Shan J F, Wang P F, Xu S L 2021 Chin. J. High Pressure Phys. 35 024202

Google Scholar

Google Scholar

[20] Xing H Z, Zhang Q B, Braithwaite C H, Pan B, Zhao J 2017 Rock Mech. Rock Eng. 50 1611

Google Scholar

Google Scholar

[21] Zhou L, Xu S, Shan J, Liu Y, Wang P 2018 Mech. Mater. 123 1

Google Scholar

Google Scholar

[22] Grady D 2017 Phys. Shock Impact (Vol. 1) (London: IOP Publishing) pp2-57–2-68

[23] Mott N F 1947 Proc. R. Soc. London, Ser. A 189 300

Google Scholar

Google Scholar

[24] Feng R 2000 J. Appl. Phys. 87 1693

Google Scholar

Google Scholar

[25] 刘占芳, 常敬臻, 姚国文, 张凯, 李建鹏 2006 力学学报 38 626

Google Scholar

Google Scholar

Liu Z F, Chang J Z, Yao G W, Zhang K, Li J P 2006 Chin. J. Theor. Appl. Mech. 38 626

Google Scholar

Google Scholar

计量

- 文章访问数: 5227

- PDF下载量: 58

- 被引次数: 0

下载:

下载: