-

以石墨烯为基质构筑的纳米孔隙存在两种壁面结构, 水滴浸润纳米孔隙在微流动方面至关重要. 本文鉴于实验报道的石墨烯结构, 构建了两种石墨烯纳米孔隙, 利用全原子分子动力学模拟方法研究了纳米水滴浸润两种纳米孔隙. 发现两种不同排列石墨烯构筑相同尺度的纳米孔隙展现出完全不同的浸润特点, 一种是放置在纳米孔隙入口处的水滴会自发浸润孔隙, 另一种是水滴完全不会浸润孔隙. 通过分析两种纳米孔隙结构, 总结出了产生上述现象主要归因于纳米孔隙内外表面的润湿性差异. 建立了纳米孔隙内外表面完全一样的结构, 构建了水滴浸润纳米孔隙的润湿性相图, 给出了水滴浸润纳米孔隙的一般性规律.The infiltration of water droplets in nanochannels is of great importance in microfluidics. In this paper, two types of graphene nanochannels with different wall structures are constructed based on the experimentally reported graphene structure, and the infiltrations of water nanodroplet in the two nanochannels are investigated by performing all-atom molecular dynamics simulation. It is found that the two nanochannels with the same size, composed of different graphene arrays, exhibit completely different infiltration properties: water droplets cannot infiltrate into the multilayer stacked channels, but can wet the vertical array channels spontaneously and completely. By analyzing the structures of the two nanochannels, the novel phenomenon is mainly attributed to the difference in wettability between the inner surface and the outer surface of the nanochannel. From the perspective of energy, the potential energy of water droplets in the multilayer stacked channels is higher than that outside the channels, while the potential energy of water droplets in the vertical array channels is lower than that outside the channels. Therefore, water droplets can spontaneously infiltrate into the latter ones. The van der Waals interaction between the droplet and the channels and the Coulomb interaction inside the droplet play a dominant role in spontaneously infiltrating the water droplets, while the van der Waals interaction inside the droplet has little effect on the infiltration behavior. In addition, through a series of simulations of water droplets wetting the nanochannels with identical inner surface and outer surface, the wettability phase diagram of water droplets infiltration into nanochannels is established, which represents the general law of water droplet infiltration into nanochannels.

-

Keywords:

- nanochannel /

- water nanodroplet /

- wettability /

- graphene

[1] Kavokine N, Netz R R, Bocquet L 2021 Annu. Rev. Fluid Mech. 53 377

Google Scholar

Google Scholar

[2] 张烨, 张冉, 常青, 李桦 2019 68 20190248

Google Scholar

Google Scholar

Zhang Y, Zhang R, Chang Q, Li H 2019 Acta Phys. Sin. 68 20190248

Google Scholar

Google Scholar

[3] 李文, 马骁婧, 徐进良, 王艳, 雷俊鹏 2021 70 126101

Google Scholar

Google Scholar

Li W, Ma X J, Xu J L, Wang Y, Lei J P 2021 Acta Phys. Sin. 70 126101

Google Scholar

Google Scholar

[4] Shen A, Liu Y, Ali S F 2020 Capillarity 3 1

Google Scholar

Google Scholar

[5] Zhang J, Xie Z, Hao S Q, Li Z, Yao J, Kou J L 2022 Energy Fuels 36 1507

Google Scholar

Google Scholar

[6] Lee C, Wei X D, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[7] Balandin A A 2011 Nat. Mater. 10 569

Google Scholar

Google Scholar

[8] Li X, Tao L, Chen Z F, Fang H, Li X S, Wang X R, Xu J B, Zhu H W 2017 Appl. Phys. Rev. 4 021306

Google Scholar

Google Scholar

[9] Chen C X, Lin Y, Zhou W, Gong M, He Z Y, Shi F Y, Li X Y, Wu J Z, Lam K T, Wang J N 2021 Nat. Electron. 4 653

Google Scholar

Google Scholar

[10] Stoller M D, Park S J, Zhu Y W, An J H, Ruoff R S 2008 Nano Lett. 8 3498

Google Scholar

Google Scholar

[11] Hao S Q, Xie Z, Li Z, Kou J L, Wu F M 2021 Nanoscale 13 15963

Google Scholar

Google Scholar

[12] Xie Q, Alibakhshi M A, Jiao S, Xu Z, Hempel M, Kong J, Park H G, Duan C 2018 Nat. Nanotechnol. 13 238

Google Scholar

Google Scholar

[13] Su J Y, Zhao Y Z, Fang C 2018 Nanotechnology 29 225706

Google Scholar

Google Scholar

[14] Chen L, Shi G S, Shen J, Peng B Q, Zhang B W, Wang Y Z, Bian F G, Wang J J, Li D Y, Qian Z, Xu G, Liu G P, Zeng J R, Zhang L J, Yang Y Z, Zhou G Q, Wu M H, Jin W Q, Li J Y, Fang H P 2017 Nature 550 380

Google Scholar

Google Scholar

[15] Jiang J, Yan L, Fang H P 2021 Chin. Phys. Lett. 38 106801

Google Scholar

Google Scholar

[16] Qiu H, Zhou W Q, Guo W L 2021 ACS Nano 15 18848

Google Scholar

Google Scholar

[17] Min S K, Kim W Y, Cho Y, Kim K S 2011 Nat. Nanotechnol. 6 162

Google Scholar

Google Scholar

[18] Jin Y, Tao R, Li Z 2019 Electrophoresis 40 859

Google Scholar

Google Scholar

[19] Algara-Siller G, Lehtinen O, Wang F C, Nair R R, Kaiser U, Wu H A, Geim A K, Grigorieva I V 2015 Nature 519 443

Google Scholar

Google Scholar

[20] 王奉超, 朱银波, 吴恒安 2018 中国科学: 物理学 力学 天文学 48 094609

Google Scholar

Google Scholar

Wang F C, Zhu Y B, Wu H A 2018 Sci. Sin. Phys. Mech. Astron. 48 094609

Google Scholar

Google Scholar

[21] Celebi K, Buchheim J, Wyss R M, Droudian A, Gasser P, Shorubalko I, Kye J I, Lee C H, Park H G 2014 Science 344 289

Google Scholar

Google Scholar

[22] Radha B, Esfandiar A, Wang F C, Rooney A P, Gopinadhan K, Keerthi A, Mishchenko A, Janardanan A, Blake P, Fumagalli L, Lozada-Hidalgo M, Garaj S, Haigh S J, Grigorieva I V, Wu H A, Geim A K 2016 Nature 538 222

Google Scholar

Google Scholar

[23] Katagiri G, Ishida H, Ishitani A 1988 Carbon 26 565

Google Scholar

Google Scholar

[24] Choi G B, Hong S, Wee J H, Kim D W, Seo T H, Nomura K, Nishihara H, Kim Y A 2020 Nano Lett. 20 5885

Google Scholar

Google Scholar

[25] Wei Y, Jia C Q 2015 Carbon 87 10

Google Scholar

Google Scholar

[26] Włoch J, Terzyk A P, Kowalczyk P, Korczeniewski E D, Kaneko K 2017 Carbon 115 571

Google Scholar

Google Scholar

[27] Fujiwara K, Shibahara M 2013 Nanoscale Microscale Thermophys. Eng. 17 1

Google Scholar

Google Scholar

[28] Fujiwara K, Shibahara M 2015 J. Nanosci. Nanotechnol. 15 3143

Google Scholar

Google Scholar

[29] Wang S R, Zhang Y, Abidi N, Cabrales L 2009 Langmuir 25 11078

Google Scholar

Google Scholar

[30] Li G Z, Wang S S, Zeng J, Yu J 2021 Carbon 171 111

Google Scholar

Google Scholar

[31] Humphrey W, Dalke A, Schulten K 1996 J. Mol. Graphics 14 33

Google Scholar

Google Scholar

[32] Hess B, Kutzner C, Van D S D, Lindahl E 2008 J. Chem. Theory Comput. 4 435

Google Scholar

Google Scholar

[33] Bussi G, Donadio D, Parrinello M 2007 J. Chem. Phys. 126 014101

Google Scholar

Google Scholar

[34] Berendsen H J C, Grigera J R, Straatsma T P 1987 J. Phys. Chem. 91 6269

Google Scholar

Google Scholar

[35] Werder T, Walther J H, Jaffe R L, Halicioglu T, Koumoutsakos P 2003 J. Phys. Chem. B 107 1345

Google Scholar

Google Scholar

[36] Essmann U, Perera L, Berkowitz M L, Darden T, Lee H, Pedersen L G 1995 J. Chem. Phys. 103 8577

Google Scholar

Google Scholar

[37] Kaminski G A, Friesner R A, Tirado-Rives J, Jorgensen W L 2001 J. Phys. Chem. B 105 6474

Google Scholar

Google Scholar

[38] Kou J L, Zhou X Y, Lu H J, Xu Y S, Wu F M, Fan J T 2012 Soft Matter 8 12111

Google Scholar

Google Scholar

[39] Fan C F, Caǧin T 1995 J. Chem. Phys. 103 9053

Google Scholar

Google Scholar

[40] Lee J H, Kim C, Tokman M, Colvin M E 2021 J. Phys. Chem. C 125 6933

Google Scholar

Google Scholar

[41] Kou J L, Lu H J, Wu F M, Fan J T 2011 Europhys. Lett. 96 56008

Google Scholar

Google Scholar

[42] Liu Q C, Xu B X 2015 Langmuir 31 9070

Google Scholar

Google Scholar

[43] Zangi R, Zhou R, Berne B J 2009 J. Am. Chem. Soc. 131 1535

Google Scholar

Google Scholar

[44] Koishi T, Yasuoka K, Fujikawa S, Ebisuzaki T, Zeng X C 2009 Proc. Natl. Acad. Sci. U.S.A. 106 8435

Google Scholar

Google Scholar

[45] Koishi T, Yasuoka K, Fujikawa S, Zeng X C 2011 ACS Nano 5 6834

Google Scholar

Google Scholar

[46] Zhu C Q, Gao, Y R, Huang Y Y, Li H, Meng S, Francisco J S, Zeng X C 2017 Nanoscale 9 18240

Google Scholar

Google Scholar

[47] Khan S, Singh J K 2014 Mol. Simul. 40 458

Google Scholar

Google Scholar

-

图 3 (a) ESC(红色)和BPC(蓝色)孔隙内水分子数目随时间的变化趋势, 插图Ⅰ和Ⅱ分别为ESC和BPC模型最终浸润状态的模拟快照; (b) 不同尺寸水滴浸润ESC和BPC模型的最终浸润状态

Fig. 3. (a) Evolution of the number of water molecules in the nanochannel of ESC (red) and BPC (blue) with time, insets I, II are the simulation snapshots of the final infiltration states with ESC model and BPC model, respectively; (b) final infiltration states of ESC and BPC models with different sizes of water droplets.

图 4 (a) 石墨烯基面(蓝色)和边缘面(红色)的面密度大小, L为垂直于该面统计的厚度; (b) 水滴在层叠基底和阵列基底上的接触角轮廓图

Fig. 4. (a) Area density of graphene basal plane (blue) and edge surface (red), L is the statistical thickness perpendicular to the surface; (b) contact angles profiles of water droplets on the laminated substrate and the array substrate, respectively.

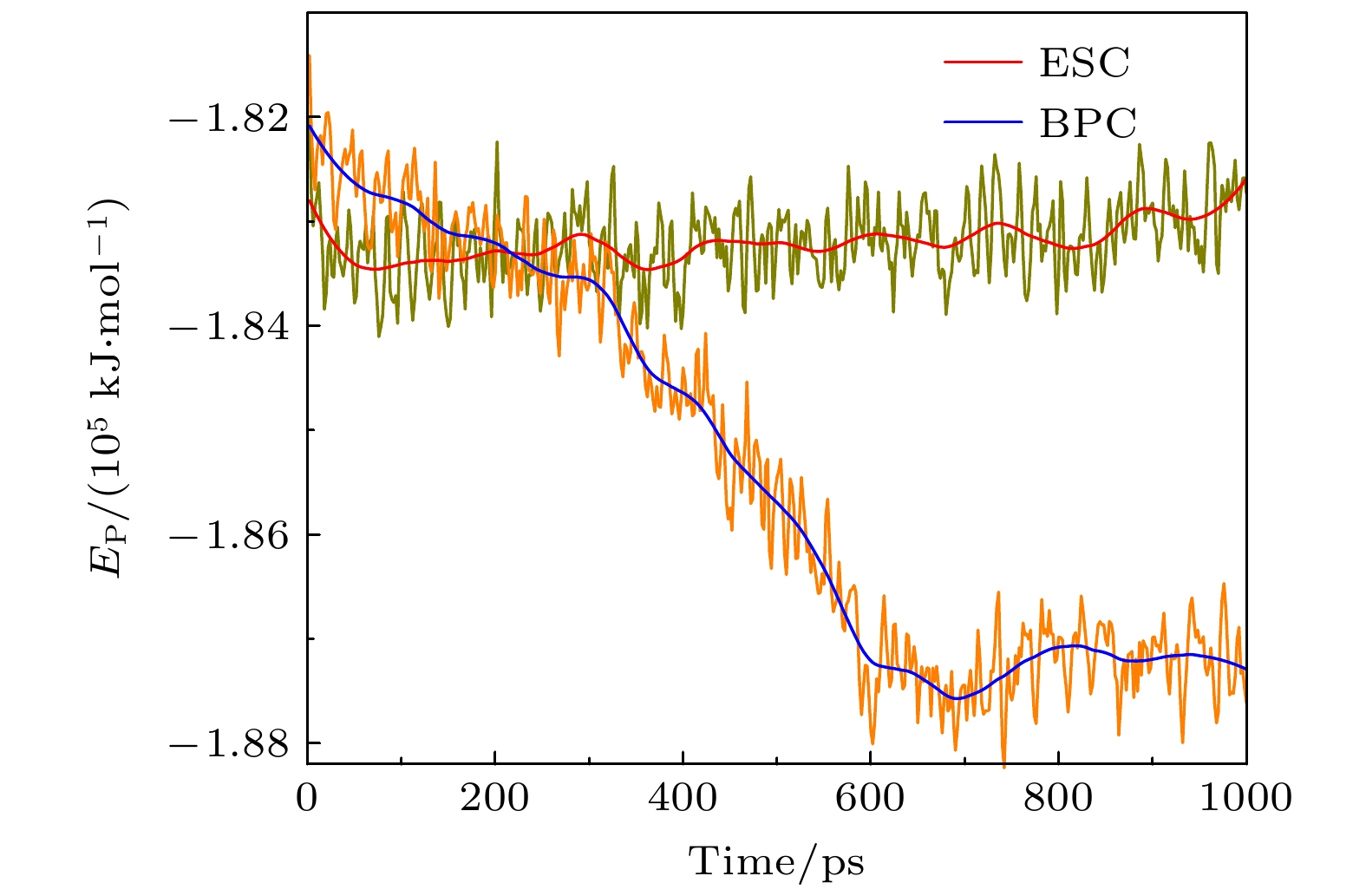

图 6 两种系统水滴浸润孔隙过程能量变化 (a) 水与孔隙之间的范德瓦耳斯作用 (EVdW(SOL-C)); (b) 水与水之间范德瓦耳斯作用 (EVdW(SOL-SOL)); (c) 水与水之间的库伦作用 (ECoul(SOL-SOL)); (d) 水与孔隙之间的范德瓦耳斯作用和水与水之间的库伦作用之和

Fig. 6. Energy evolution in the process of water droplets infiltrating nanochannel in two systems: (a) Van der Waals interaction between water and nanochannel, EVdW(SOL-C); (b) Van der Waals interaction between water and water, EVdW(SOL-SOL); (c) Coulomb interaction between water and water, ECoul(SOL-SOL); (d) sum of Van der Waals interaction between water and nanochannel and Coulomb interaction between water and water.

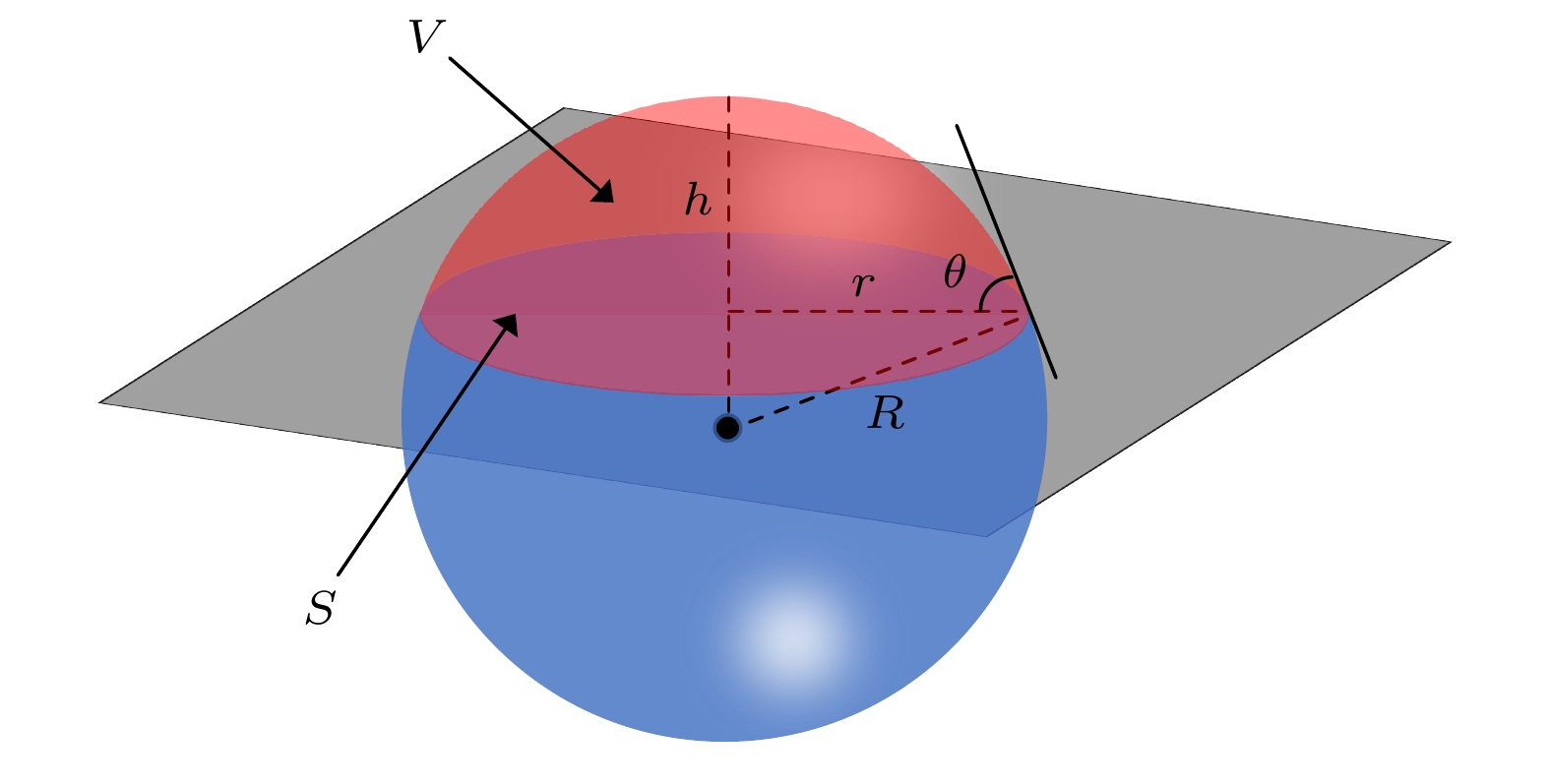

图 7 (a) 表面调节因子λ与表面接触角的函数关系, 插图为纳米孔隙的初始构型(不含水滴); (b) 浸润相图, 即纳米孔隙界面调节因子λA与壁面调节因子λB对水滴浸润纳米孔隙的影响, 插图Ⅰ和Ⅱ分别代表该区域的最终浸润状态

Fig. 7. (a) Surface tuning factor λ as a function of the intrinsic contact angle of the surface, the inset shows the initial configuration of the nanochannel (without water droplets); (b) the wetting phase diagram, the effect of interfacial tuning factor λA and wall tuning factor λB on the infiltration of water droplets into the nanochannel, insets I and II represent the final infiltration state of the region, respectively.

-

[1] Kavokine N, Netz R R, Bocquet L 2021 Annu. Rev. Fluid Mech. 53 377

Google Scholar

Google Scholar

[2] 张烨, 张冉, 常青, 李桦 2019 68 20190248

Google Scholar

Google Scholar

Zhang Y, Zhang R, Chang Q, Li H 2019 Acta Phys. Sin. 68 20190248

Google Scholar

Google Scholar

[3] 李文, 马骁婧, 徐进良, 王艳, 雷俊鹏 2021 70 126101

Google Scholar

Google Scholar

Li W, Ma X J, Xu J L, Wang Y, Lei J P 2021 Acta Phys. Sin. 70 126101

Google Scholar

Google Scholar

[4] Shen A, Liu Y, Ali S F 2020 Capillarity 3 1

Google Scholar

Google Scholar

[5] Zhang J, Xie Z, Hao S Q, Li Z, Yao J, Kou J L 2022 Energy Fuels 36 1507

Google Scholar

Google Scholar

[6] Lee C, Wei X D, Kysar J W, Hone J 2008 Science 321 385

Google Scholar

Google Scholar

[7] Balandin A A 2011 Nat. Mater. 10 569

Google Scholar

Google Scholar

[8] Li X, Tao L, Chen Z F, Fang H, Li X S, Wang X R, Xu J B, Zhu H W 2017 Appl. Phys. Rev. 4 021306

Google Scholar

Google Scholar

[9] Chen C X, Lin Y, Zhou W, Gong M, He Z Y, Shi F Y, Li X Y, Wu J Z, Lam K T, Wang J N 2021 Nat. Electron. 4 653

Google Scholar

Google Scholar

[10] Stoller M D, Park S J, Zhu Y W, An J H, Ruoff R S 2008 Nano Lett. 8 3498

Google Scholar

Google Scholar

[11] Hao S Q, Xie Z, Li Z, Kou J L, Wu F M 2021 Nanoscale 13 15963

Google Scholar

Google Scholar

[12] Xie Q, Alibakhshi M A, Jiao S, Xu Z, Hempel M, Kong J, Park H G, Duan C 2018 Nat. Nanotechnol. 13 238

Google Scholar

Google Scholar

[13] Su J Y, Zhao Y Z, Fang C 2018 Nanotechnology 29 225706

Google Scholar

Google Scholar

[14] Chen L, Shi G S, Shen J, Peng B Q, Zhang B W, Wang Y Z, Bian F G, Wang J J, Li D Y, Qian Z, Xu G, Liu G P, Zeng J R, Zhang L J, Yang Y Z, Zhou G Q, Wu M H, Jin W Q, Li J Y, Fang H P 2017 Nature 550 380

Google Scholar

Google Scholar

[15] Jiang J, Yan L, Fang H P 2021 Chin. Phys. Lett. 38 106801

Google Scholar

Google Scholar

[16] Qiu H, Zhou W Q, Guo W L 2021 ACS Nano 15 18848

Google Scholar

Google Scholar

[17] Min S K, Kim W Y, Cho Y, Kim K S 2011 Nat. Nanotechnol. 6 162

Google Scholar

Google Scholar

[18] Jin Y, Tao R, Li Z 2019 Electrophoresis 40 859

Google Scholar

Google Scholar

[19] Algara-Siller G, Lehtinen O, Wang F C, Nair R R, Kaiser U, Wu H A, Geim A K, Grigorieva I V 2015 Nature 519 443

Google Scholar

Google Scholar

[20] 王奉超, 朱银波, 吴恒安 2018 中国科学: 物理学 力学 天文学 48 094609

Google Scholar

Google Scholar

Wang F C, Zhu Y B, Wu H A 2018 Sci. Sin. Phys. Mech. Astron. 48 094609

Google Scholar

Google Scholar

[21] Celebi K, Buchheim J, Wyss R M, Droudian A, Gasser P, Shorubalko I, Kye J I, Lee C H, Park H G 2014 Science 344 289

Google Scholar

Google Scholar

[22] Radha B, Esfandiar A, Wang F C, Rooney A P, Gopinadhan K, Keerthi A, Mishchenko A, Janardanan A, Blake P, Fumagalli L, Lozada-Hidalgo M, Garaj S, Haigh S J, Grigorieva I V, Wu H A, Geim A K 2016 Nature 538 222

Google Scholar

Google Scholar

[23] Katagiri G, Ishida H, Ishitani A 1988 Carbon 26 565

Google Scholar

Google Scholar

[24] Choi G B, Hong S, Wee J H, Kim D W, Seo T H, Nomura K, Nishihara H, Kim Y A 2020 Nano Lett. 20 5885

Google Scholar

Google Scholar

[25] Wei Y, Jia C Q 2015 Carbon 87 10

Google Scholar

Google Scholar

[26] Włoch J, Terzyk A P, Kowalczyk P, Korczeniewski E D, Kaneko K 2017 Carbon 115 571

Google Scholar

Google Scholar

[27] Fujiwara K, Shibahara M 2013 Nanoscale Microscale Thermophys. Eng. 17 1

Google Scholar

Google Scholar

[28] Fujiwara K, Shibahara M 2015 J. Nanosci. Nanotechnol. 15 3143

Google Scholar

Google Scholar

[29] Wang S R, Zhang Y, Abidi N, Cabrales L 2009 Langmuir 25 11078

Google Scholar

Google Scholar

[30] Li G Z, Wang S S, Zeng J, Yu J 2021 Carbon 171 111

Google Scholar

Google Scholar

[31] Humphrey W, Dalke A, Schulten K 1996 J. Mol. Graphics 14 33

Google Scholar

Google Scholar

[32] Hess B, Kutzner C, Van D S D, Lindahl E 2008 J. Chem. Theory Comput. 4 435

Google Scholar

Google Scholar

[33] Bussi G, Donadio D, Parrinello M 2007 J. Chem. Phys. 126 014101

Google Scholar

Google Scholar

[34] Berendsen H J C, Grigera J R, Straatsma T P 1987 J. Phys. Chem. 91 6269

Google Scholar

Google Scholar

[35] Werder T, Walther J H, Jaffe R L, Halicioglu T, Koumoutsakos P 2003 J. Phys. Chem. B 107 1345

Google Scholar

Google Scholar

[36] Essmann U, Perera L, Berkowitz M L, Darden T, Lee H, Pedersen L G 1995 J. Chem. Phys. 103 8577

Google Scholar

Google Scholar

[37] Kaminski G A, Friesner R A, Tirado-Rives J, Jorgensen W L 2001 J. Phys. Chem. B 105 6474

Google Scholar

Google Scholar

[38] Kou J L, Zhou X Y, Lu H J, Xu Y S, Wu F M, Fan J T 2012 Soft Matter 8 12111

Google Scholar

Google Scholar

[39] Fan C F, Caǧin T 1995 J. Chem. Phys. 103 9053

Google Scholar

Google Scholar

[40] Lee J H, Kim C, Tokman M, Colvin M E 2021 J. Phys. Chem. C 125 6933

Google Scholar

Google Scholar

[41] Kou J L, Lu H J, Wu F M, Fan J T 2011 Europhys. Lett. 96 56008

Google Scholar

Google Scholar

[42] Liu Q C, Xu B X 2015 Langmuir 31 9070

Google Scholar

Google Scholar

[43] Zangi R, Zhou R, Berne B J 2009 J. Am. Chem. Soc. 131 1535

Google Scholar

Google Scholar

[44] Koishi T, Yasuoka K, Fujikawa S, Ebisuzaki T, Zeng X C 2009 Proc. Natl. Acad. Sci. U.S.A. 106 8435

Google Scholar

Google Scholar

[45] Koishi T, Yasuoka K, Fujikawa S, Zeng X C 2011 ACS Nano 5 6834

Google Scholar

Google Scholar

[46] Zhu C Q, Gao, Y R, Huang Y Y, Li H, Meng S, Francisco J S, Zeng X C 2017 Nanoscale 9 18240

Google Scholar

Google Scholar

[47] Khan S, Singh J K 2014 Mol. Simul. 40 458

Google Scholar

Google Scholar

计量

- 文章访问数: 6315

- PDF下载量: 108

- 被引次数: 0

下载:

下载: