-

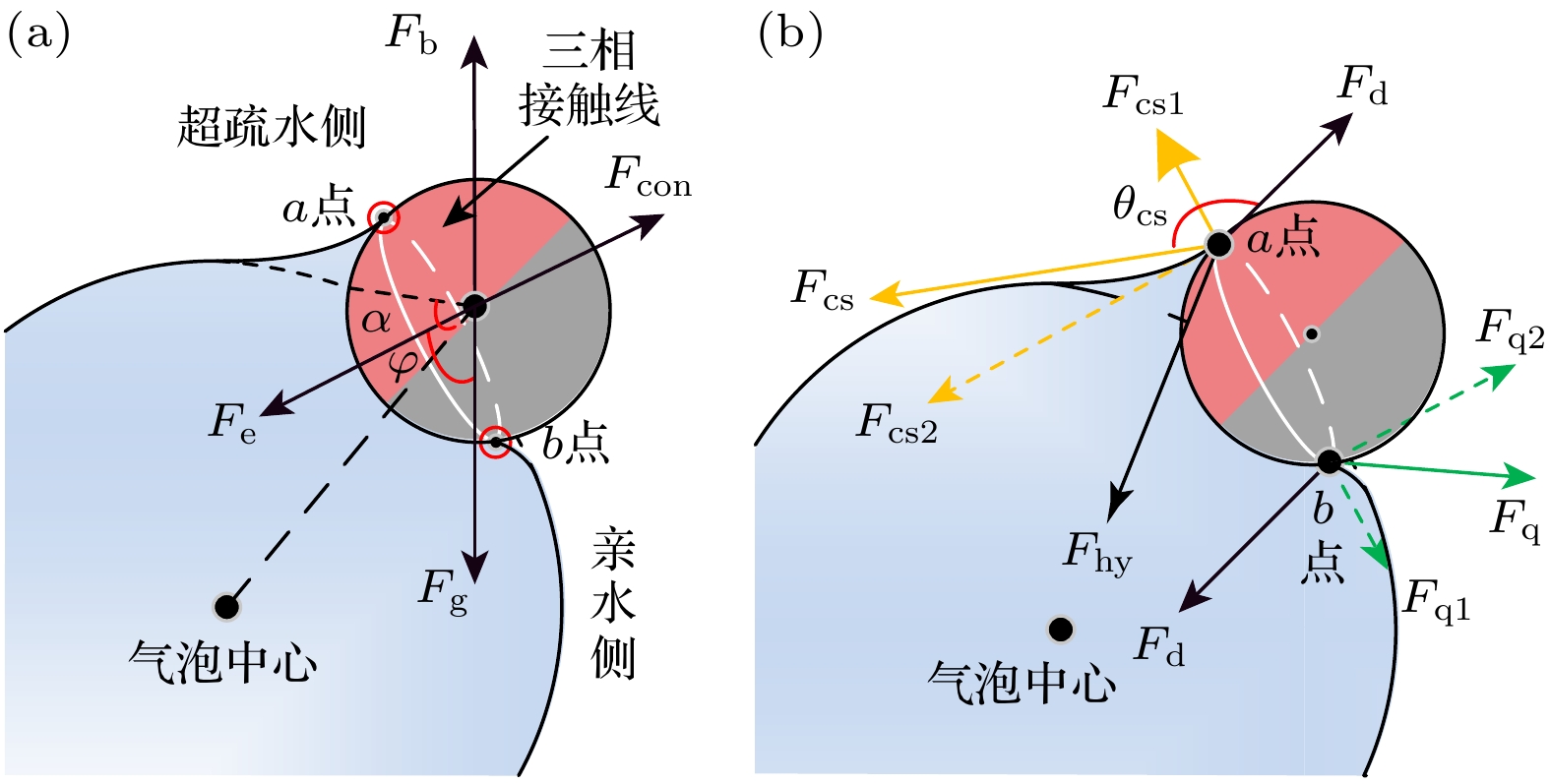

为更好地在相变传热中应用双亲性Janus颗粒, 用铜球制备了亲水-超疏水Janus颗粒, 其粒径为1.0 mm, 气泡直径为3.0 mm. 研究了不同高度下带小气泡的Janus颗粒撞击气泡的行为特征. 结果表明: Janus颗粒不同润湿性表面撞击气泡时的行为特征存在明显差异, 当超疏水侧接触气泡时, 会沿着气泡表面无旋转地滑到气泡底部; 当亲水侧接触气泡时, 会先沿着气泡表面滑行一段距离, 随后发生旋转, 对气泡造成强烈扰动; 而亲水-超疏水分界面接触气泡时, 颗粒会在接触的瞬间开始旋转. 当Janus颗粒具有一定的高度撞击气泡时, 一般以亲水面首先与气泡接触, 随高度的增加, Janus颗粒拉扯气泡变形的程度增加. 基于受力分析发现: Janus颗粒发生旋转的主要原因是不同润湿性表面所受毛细力作用点和方向的不同, 相应地产生旋转力矩.In order to better apply amphiphilic Janus particles to phase change heat transfer, the hydrophilic-superhydrophobic Janus particles are prepared with copper balls. The particle size is 1.0 mm and the bubble diameter is 3.0 mm. The behavior of Janus particle with small bubbles impinging on bubbles at different heights is studied. The falling heights are 0, 10.0, 20.0, 30.0 and 40.0 mm. The results show that there are obvious differences in behavior characteristic among Janus particles with different wettability surfaces when they hit the bubble. When the superhydrophobic side contacts the bubble, it will slide to the bottom of the bubble without rotation along the bubble surface; when the hydrophilic side contacts the bubble, it will first slide along the bubble surface for a certain distance, and then rotate, resulting in strong disturbance to the bubble. When the interface between hydrophilic and superhydrophobic contacts the bubble, the particle will start to rotate at the moment of contact. When Janus particle impacts the bubble at a certain height, the hydrophilic surface generally contacts bubble first. With the increase of height, the degree of deformation of Janus particles pulling bubbles increases. The force analysis shows that the main reason for the rotation of Janus particles is that the action points and directions of capillary force acting on different wettable surfaces are different, resulting in corresponding rotation torque.

-

Keywords:

- Janus particle /

- bubble /

- collision /

- behavioral characteristic

[1] 王永贵, 张国俊, 崔晓俊 2018 中兴通讯技术 24 48

Google Scholar

Google Scholar

Wang Y G, Zhang G J, Cui X J 2018 ZTE. Tech. J. 24 48

Google Scholar

Google Scholar

[2] 魏进家, 张永海 2016 化工学报 67 97

Google Scholar

Google Scholar

Wei J J, Zhang Y H 2016 J. Chem. Ind. Eng. 67 97

Google Scholar

Google Scholar

[3] 林石泉, 赵雅鑫, 吕中原, 赖展程, 胡海涛 2021 化工学报 72 295

Google Scholar

Google Scholar

Lin S Q, Zhao Y X, Lü Z Y, Lai Z C, Hu H T 2021 J. Chem. Ind. Eng. 72 295

Google Scholar

Google Scholar

[4] Nam Y, Aktinol E, Dhir V K, Ju Y S 2011 Int. J. Heat Mass Transfer 54 1572

Google Scholar

Google Scholar

[5] You S M, Kim J H, Kim K H 2003 Appl. Phys. Lett. 83 3374

Google Scholar

Google Scholar

[6] Vassallo P, Kumar R, D'Amico S 2004 Int. J. Heat Mass Transfer 47 407

Google Scholar

Google Scholar

[7] Bang I C, Chang S H 2005 Int. J. Heat Mass Transfer 48 2407

Google Scholar

Google Scholar

[8] 彭家略, 郭浩, 尤天涯, 纪献兵, 徐进良 2021 70 044701

Google Scholar

Google Scholar

Peng J L, Guo H, You T Y, Ji X B, Xu J L 2021 Acta Phys. Sin. 70 044701

Google Scholar

Google Scholar

[9] Sarrot V, Guiraud P, Legendre D 2005 Chem. Eng. Sci. 60 6107

Google Scholar

Google Scholar

[10] Legendre D, Sarrot V, Guiraud P 2009 Int. J. Multiphase Flow 35 163

Google Scholar

Google Scholar

[11] Moreno-Atanasio R, Gao Y, Neville F, Evans G M, Wanless E J 2016 Chem. Eng. Res. Des. 109 354

Google Scholar

Google Scholar

[12] Gao Y, Evans G M, Wanless E J, Moreno-Atanasio R 2014 Adv. Powder Technol. 25 1177

Google Scholar

Google Scholar

[13] Whelan P F, Brown D J 1956 Trans. Inst. Min. Metall. 65 181

[14] Nguyen A V, Evans G M 2004 J. Colloid Interface Sci. 273 271

Google Scholar

Google Scholar

[15] Wang W, Zhou Z, Nandakumar K, Xu Z, Masliyah J H 2003 J. Colloid Interface Sci. 259 81

Google Scholar

Google Scholar

[16] Scheludko W, Toshev B V, Bojadjiev D T 1976 J. Chem. Soc., Faraday Trans. 72 2815

Google Scholar

Google Scholar

[17] Paulsen F G, Pan R, Bousfield D W, Thompson E V 1996 J. Colloid Interface Sci. 178 400

Google Scholar

Google Scholar

[18] Wang W, Zhou Z, Nandakumar K, Xu Z, Masliyah J H 2003 Int. J. Miner. Process. 68 47

Google Scholar

Google Scholar

[19] Nguyen A V 2007 Int. J. Environment and Pollution 30 231

Google Scholar

Google Scholar

[20] Gao Y, Wang G, Evans G M, Wanless E J, Sathe M, Mitra S, Moreno-Atanasio R 2015 Procedia. Eng. 102 1346

Google Scholar

Google Scholar

[21] Gennes P 1992 Angew. Chem. Int. Ed. 31 842

Google Scholar

Google Scholar

[22] 肖轶, 孟东, 徐呈艺, 张瑞华, 姚燕生, 吴思竹, 姚成立 2020 中国激光 47 133

Xiao Y, Meng D, Xu C Y, Zhang R H, Yao Y S, Wu S Z, Yao C L 2020 Chin. J. Lasers 47 133

[23] 王雷磊, 崔海航, 张静, 郑旭, 王磊, 陈力 2016 65 220201

Google Scholar

Google Scholar

Wang L L, Cui H H, Zhang J, Zheng X, Wang L, Chen L 2016 Acta Phys. Sin. 65 220201

Google Scholar

Google Scholar

[24] Yuan Y, Gao C Y, Wang D L, Zhou C, Zhu B H, He Q 2019 J. Nanotechnol. 10 1324

Google Scholar

Google Scholar

[25] Dong X F, Gustafsson E, Price M, Dai Z F, Xu M Q, Pelton R 2017 Colloids Surf. A 533 159

Google Scholar

Google Scholar

[26] Khurana G, Sahoo N, Dhar P 2019 Phys. Fluids 31 072003

Google Scholar

Google Scholar

[27] Manica R, Klaseboer E, Chan D Y C 2015 Langmuir 31 6763

Google Scholar

Google Scholar

[28] Sun Z 2017 Ph. D. Dissertation (Harbin: Harbin Institute of Technology) (in Chinese)

[29] Sun Q, Klaseboer E, Khoo B C, Chan D Y C 2013 Phys. Rev. E 87 043009

Google Scholar

Google Scholar

[30] Safaei S, Archereau A, Hendy S C, Willmott G R 2019 Soft Matter 15 6742

Google Scholar

Google Scholar

[31] Safaei S, Hendy S C, Willmott G R 2020 Soft Matter 16 7116

Google Scholar

Google Scholar

[32] Drzymala J 1994 Int. J. Mine. Process. 42 153

Google Scholar

Google Scholar

[33] Zhang Y, Liu Q, Li W B, Lian X L, Li J L, Rao X X 2020 Can. J. Phys. 98 981

Google Scholar

Google Scholar

[34] Nguyen A V, Evans G M 2004 Exp. Therm. Fluid Sci. 28 381

Google Scholar

Google Scholar

[35] 胡岳华, 邱冠周, 王淀佐 1994 中南矿冶学院学报 25 310

Hu Y H, Qiu G Z, Wang D Z 1994 J. Cent. South Inst. Min. Metall. 25 310

[36] Ducker W A, Xu Z, Israelachvili J N 1994 Langmuir 10 3279

Google Scholar

Google Scholar

-

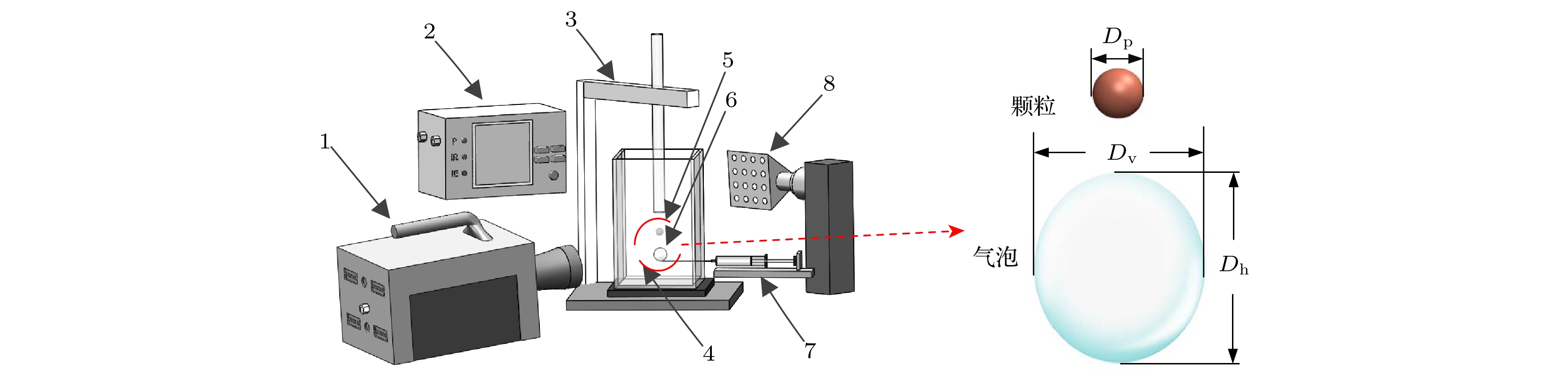

图 3 实验装置图(1, 高速摄影仪; 2, 数据采集仪; 3, xyz三轴微位移平台; 4, 亚克力玻璃池; 5, 实验样品; 6, 气泡; 7, 高精度注射器; 8, LED背光灯)

Fig. 3. Diagram of the experimental device. 1, high-speed camera; 2, data collector; 3, xyz three-axes micro-displacement platform; 4, acrylic glass cell; 5, experimental sample; 6, bubble; 7, high-precision syringe; 8, LED backlight.

图 7 Janus颗粒旋转过程中的受力分析 (a) Janus颗粒中心受力图; (b) 三相接触线上超疏水侧与亲水侧的受力图 (包括重力

${F_{\text{g}}}$ , 浮力$ {F_{\text{b}}} $ , 接触力${F_{{\text{con}}}}$ , 流体阻力${F_{\text{d}}}$ , 过余力${F_{\text{e}}}$ , 疏水力${F_{{\text{hy}}}}$ , 亲水侧毛细力${F_{\text{q}}}$ 和超疏水侧毛细力${F_{{\text{cs}}}}$ )Fig. 7. Force analysis on Janus particle during rotation: (a) Force diagram of Janus particle’s central; (b) the forcediagram of superhydrophobic side and hydrophilic side on three phase contact line (Including gravity

${F_{\text{g}}}$ , buoyancy$ {F_{\text{b}}} $ , contact force${F_{{\text{con}}}}$ , drag force${F_{\text{d}}}$ , excess force${F_{\text{e}}}$ , hydrophobic force${F_{{\text{hy}}}}$ , hydrophilic side capillary force${F_{\text{q}}}$ , andsuperhydrophobic side capillary force${F_{{\text{cs}}}}$ ). -

[1] 王永贵, 张国俊, 崔晓俊 2018 中兴通讯技术 24 48

Google Scholar

Google Scholar

Wang Y G, Zhang G J, Cui X J 2018 ZTE. Tech. J. 24 48

Google Scholar

Google Scholar

[2] 魏进家, 张永海 2016 化工学报 67 97

Google Scholar

Google Scholar

Wei J J, Zhang Y H 2016 J. Chem. Ind. Eng. 67 97

Google Scholar

Google Scholar

[3] 林石泉, 赵雅鑫, 吕中原, 赖展程, 胡海涛 2021 化工学报 72 295

Google Scholar

Google Scholar

Lin S Q, Zhao Y X, Lü Z Y, Lai Z C, Hu H T 2021 J. Chem. Ind. Eng. 72 295

Google Scholar

Google Scholar

[4] Nam Y, Aktinol E, Dhir V K, Ju Y S 2011 Int. J. Heat Mass Transfer 54 1572

Google Scholar

Google Scholar

[5] You S M, Kim J H, Kim K H 2003 Appl. Phys. Lett. 83 3374

Google Scholar

Google Scholar

[6] Vassallo P, Kumar R, D'Amico S 2004 Int. J. Heat Mass Transfer 47 407

Google Scholar

Google Scholar

[7] Bang I C, Chang S H 2005 Int. J. Heat Mass Transfer 48 2407

Google Scholar

Google Scholar

[8] 彭家略, 郭浩, 尤天涯, 纪献兵, 徐进良 2021 70 044701

Google Scholar

Google Scholar

Peng J L, Guo H, You T Y, Ji X B, Xu J L 2021 Acta Phys. Sin. 70 044701

Google Scholar

Google Scholar

[9] Sarrot V, Guiraud P, Legendre D 2005 Chem. Eng. Sci. 60 6107

Google Scholar

Google Scholar

[10] Legendre D, Sarrot V, Guiraud P 2009 Int. J. Multiphase Flow 35 163

Google Scholar

Google Scholar

[11] Moreno-Atanasio R, Gao Y, Neville F, Evans G M, Wanless E J 2016 Chem. Eng. Res. Des. 109 354

Google Scholar

Google Scholar

[12] Gao Y, Evans G M, Wanless E J, Moreno-Atanasio R 2014 Adv. Powder Technol. 25 1177

Google Scholar

Google Scholar

[13] Whelan P F, Brown D J 1956 Trans. Inst. Min. Metall. 65 181

[14] Nguyen A V, Evans G M 2004 J. Colloid Interface Sci. 273 271

Google Scholar

Google Scholar

[15] Wang W, Zhou Z, Nandakumar K, Xu Z, Masliyah J H 2003 J. Colloid Interface Sci. 259 81

Google Scholar

Google Scholar

[16] Scheludko W, Toshev B V, Bojadjiev D T 1976 J. Chem. Soc., Faraday Trans. 72 2815

Google Scholar

Google Scholar

[17] Paulsen F G, Pan R, Bousfield D W, Thompson E V 1996 J. Colloid Interface Sci. 178 400

Google Scholar

Google Scholar

[18] Wang W, Zhou Z, Nandakumar K, Xu Z, Masliyah J H 2003 Int. J. Miner. Process. 68 47

Google Scholar

Google Scholar

[19] Nguyen A V 2007 Int. J. Environment and Pollution 30 231

Google Scholar

Google Scholar

[20] Gao Y, Wang G, Evans G M, Wanless E J, Sathe M, Mitra S, Moreno-Atanasio R 2015 Procedia. Eng. 102 1346

Google Scholar

Google Scholar

[21] Gennes P 1992 Angew. Chem. Int. Ed. 31 842

Google Scholar

Google Scholar

[22] 肖轶, 孟东, 徐呈艺, 张瑞华, 姚燕生, 吴思竹, 姚成立 2020 中国激光 47 133

Xiao Y, Meng D, Xu C Y, Zhang R H, Yao Y S, Wu S Z, Yao C L 2020 Chin. J. Lasers 47 133

[23] 王雷磊, 崔海航, 张静, 郑旭, 王磊, 陈力 2016 65 220201

Google Scholar

Google Scholar

Wang L L, Cui H H, Zhang J, Zheng X, Wang L, Chen L 2016 Acta Phys. Sin. 65 220201

Google Scholar

Google Scholar

[24] Yuan Y, Gao C Y, Wang D L, Zhou C, Zhu B H, He Q 2019 J. Nanotechnol. 10 1324

Google Scholar

Google Scholar

[25] Dong X F, Gustafsson E, Price M, Dai Z F, Xu M Q, Pelton R 2017 Colloids Surf. A 533 159

Google Scholar

Google Scholar

[26] Khurana G, Sahoo N, Dhar P 2019 Phys. Fluids 31 072003

Google Scholar

Google Scholar

[27] Manica R, Klaseboer E, Chan D Y C 2015 Langmuir 31 6763

Google Scholar

Google Scholar

[28] Sun Z 2017 Ph. D. Dissertation (Harbin: Harbin Institute of Technology) (in Chinese)

[29] Sun Q, Klaseboer E, Khoo B C, Chan D Y C 2013 Phys. Rev. E 87 043009

Google Scholar

Google Scholar

[30] Safaei S, Archereau A, Hendy S C, Willmott G R 2019 Soft Matter 15 6742

Google Scholar

Google Scholar

[31] Safaei S, Hendy S C, Willmott G R 2020 Soft Matter 16 7116

Google Scholar

Google Scholar

[32] Drzymala J 1994 Int. J. Mine. Process. 42 153

Google Scholar

Google Scholar

[33] Zhang Y, Liu Q, Li W B, Lian X L, Li J L, Rao X X 2020 Can. J. Phys. 98 981

Google Scholar

Google Scholar

[34] Nguyen A V, Evans G M 2004 Exp. Therm. Fluid Sci. 28 381

Google Scholar

Google Scholar

[35] 胡岳华, 邱冠周, 王淀佐 1994 中南矿冶学院学报 25 310

Hu Y H, Qiu G Z, Wang D Z 1994 J. Cent. South Inst. Min. Metall. 25 310

[36] Ducker W A, Xu Z, Israelachvili J N 1994 Langmuir 10 3279

Google Scholar

Google Scholar

计量

- 文章访问数: 7739

- PDF下载量: 69

- 被引次数: 0

下载:

下载: