-

根据建立的变掺杂变组分反射式AlxGa1–xAs/GaAs光电阴极的分辨力模型以及调制传递函数(MTF)理论模型, 仿真了材料中掺杂浓度线性变化、Al组分线性变化, 掺杂浓度均匀不变、Al组分线性变化, 掺杂浓度线性变化、Al组分均匀不变, 掺杂浓度均匀不变、Al组分均匀不变这4种不同结构反射式光电阴极的分辨力特性. 分析了Al组分、掺杂浓度、AlxGa1–xAs层厚度、GaAs层厚度和入射光波长对阴极分辨力的影响. 仿真结果表明, 阴极材料中掺杂浓度梯度变化以及Al组分梯度变化都可以提高反射式AlxGa1–xAs/GaAs光电阴极的分辨力, 其中掺杂浓度线性变化的同时, Al组分线性变化对AlxGa1–xAs/GaAs光电阴极分辨力的影响最为明显. 仿真结果还表明: Al组分从0.45线性变化至0时, 阴极分辨力最好; 掺杂浓度从1019—1018 cm–3线性变化比保持1019 cm–3不变, 阴极分辨力更好; 而阴极中AlxGa1–xAs、GaAs层厚度以及入射光波长对4种阴极分辨力的影响则有着不同的变化规律.According to the established resolution model and modulation transfer function (MTF) of varying doping and varing composition reflection-mode (r-mode) AlxGa1–xAs/GaAs photocathode, the resolutions of four types of r-mode photocathodes, i.e. linearly varying doping and linearly varying Al composition, uniform doping and linearly varying Al composition, linearly varying doping and uniform Al composition, uniform doping and uniform Al composition structures, are simulated, and the effects of Al composition, the types of doping, AlxGa1–xAs layer thickness, GaAs layer thickness, and incident light wavelength on the resolution of cathodes are analyzed. The simulation results indicate that the varying doping and varying band-gap structures can also upgrade the resolution for r-mode AlxGa1–xAs/GaAs photocathodes, and the effect of linearly varying doping and linearly varying composition structure are more pronounced. The simulation results also show that the MTFs of the cathodes with the Al composition varying from 0.45 to 0 linearly declining are highest. The MTFs of the cathodes with the linearly varying doping from 1019−1018 cm–3 are higher than that with uniform 1019 cm–3 doping. With the increase of AlxGa1–xAs thickness, GaAs thickness and incident light wavelength, the MTFs of four types photocathode have different regularities.

-

Keywords:

- varying doping and varying composition /

- modulation transfer function /

- built-in electric field /

- resolution

[1] Chanlek N, Herbert J D, Jones R M, Jones L B, Middleman K J 2015 J. Phys. D: Appl. Phys. 48 375102

Google Scholar

Google Scholar

[2] Kim J, Kim J, Oh H, Meyyappan M, Han J W, Lee J S 2016 J. Vac. Sci. Technol. B 34 042201

Google Scholar

Google Scholar

[3] Liu Z, Sun Y, Peterson S, Pianetta P 2008 Appl. Phys. Lett. 92 3042

Google Scholar

Google Scholar

[4] Zou J J, Chang B K, Yang Z, Qian J L, Zeng Y P 2008 Appl. Phys. Lett. 92 1721021

Google Scholar

Google Scholar

[5] Karkare S, Dimitrov D, Schaff W, Cultrera L, Bartnik A 2013 J. Appl. Phys. 113 104904

Google Scholar

Google Scholar

[6] Orlov D A, Krantz C, Wolf A, Jaroshevich A S, Kosolobov S N, Scheibler H E, Terekhov A S 2009 J. Appl. Phys. 106 054907

Google Scholar

Google Scholar

[7] Yang Y, Yang W Z, Sun C D 2015 Sol. Energ. Mat. Sol. C. 132 410

Google Scholar

Google Scholar

[8] 郝光辉, 韩攀阳, 李兴辉, 李泽鹏, 高玉娟 2020 69 108501

Google Scholar

Google Scholar

Hao G H, Han P Y, Li X H, Li Z P, Gao Y J 2020 Acta Phys. Sin. 69 108501

Google Scholar

Google Scholar

[9] Wang H G, Qian Y S, Du Y J, Xu Y, Lu L B, Chang B K 2014 Appl. Opt. 53 335

Google Scholar

Google Scholar

[10] Zou J J, Zhang Y J, Peng X C, Deng W J, Feng L, Chang B K 2012 Appl. Opt. 51 7662

Google Scholar

Google Scholar

[11] Zhang Y J, Chang B K, Niu J, Zhao J, Zou J J, Shi F, Cheng H C 2011 Appl. Phys. Lett. 99 101104

Google Scholar

Google Scholar

[12] Wang H G, Fu X Q, Ji X H, Du Y J, Liu J, Qian Y S, Chang B K 2014 Appl. Opt. 53 6230

Google Scholar

Google Scholar

[13] 邹继军, 常本康, 杨智 2007 56 2992

Google Scholar

Google Scholar

Zou J J, Chang B K, Yang Z 2007 Acta Phys. Sin. 56 2992

Google Scholar

Google Scholar

[14] Zou J J, Zhang Y J, Deng W J, Peng X C, Jiang S T Chang B K 2015 Appl. Opt. 54 8521

Google Scholar

Google Scholar

[15] 牛军, 杨智, 常本康, 乔建良, 张益军 2009 58 5002

Google Scholar

Google Scholar

Niu J, Yang Z, Chang B K, Qiao J L, Zhang Y J 2009 Acta Phys. Sin. 58 5002

Google Scholar

Google Scholar

[16] Deng W J, Zou J J, Peng X C, Feng L, Zhu Z F, Wang W L, Zhang Y J, Chang B K 2015 Appl. Opt. 54 1414

Google Scholar

Google Scholar

[17] Deng W J, Zhang D L, Zou J J, Peng X C, Wang W L, Zhang Y J, Chang B K 2015 Proceddings of the 2th Photoelectronic Technology Committee Conferences Changchun, China, July 22–24, 2015 p97951X

[18] Goldberg Y A 1999 Handbook Series on Semiconductor Parameters (Vol. 2) (London: World Scientific) pp1–36

[19] Zarem H A, Lebens J A, Nordstrom K B, Sercel P C, Sanders S, Eng L E, Yariv A, Vahala K J 1989 Appl. Phys. Lett. 55 2622

Google Scholar

Google Scholar

[20] Timmons M L, Colpitts T S, Venkatasubramanian, Keyes B M, Dunlavy D J, Ahrenkiel R K 1990 Appl. Phys. Lett. 56 1850

Google Scholar

Google Scholar

[21] Aspnes D E, Kelso S M, Logan R A, Bhat R 1986 J. Appl. Phys. 60 754

Google Scholar

Google Scholar

-

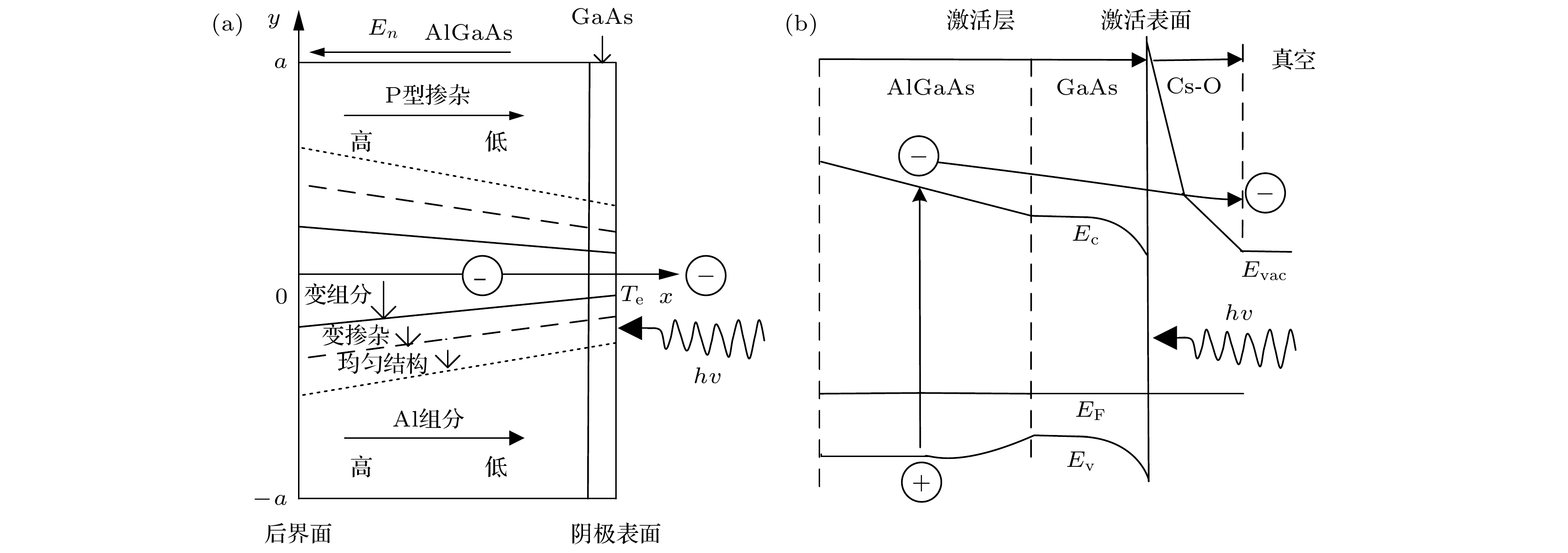

图 1 变掺杂变组分AlxGa1–xAs/GaAs反射式光电阴极结构示意图 (a) 结构及电场影响图; (b) 能带图(Ec为导带底, Ev为价带顶, Evac为真空能级, EF为费米能级, Te为激活层厚度)

Fig. 1. Structure diagram of varying doping and varying composition reflection-mode AlxGa1–xAs/GaAs photocathodes: (a) Structure and electric field effect diagram; (b) band structure (Ec is the conduction band minimum, Ev is the valence band peak level, Evac is the vacumm level, EF is the Fermi level, Te is the thickness of active layer).

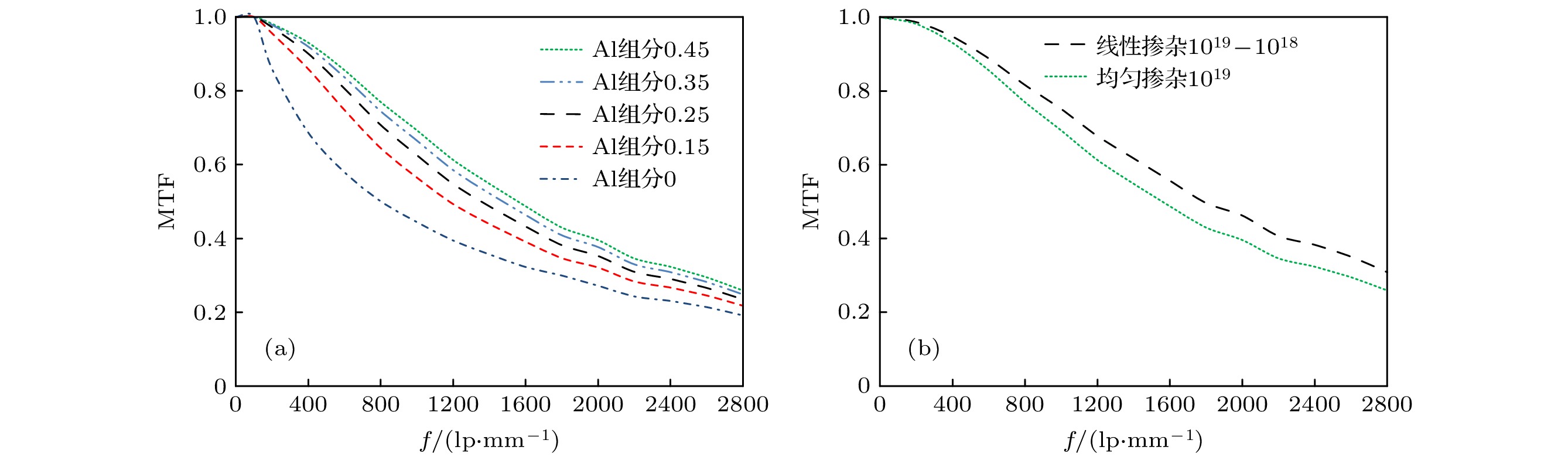

图 2 (a)变组分及(b)变掺杂反射式AlxGa1–xAs/GaAs光电阴极的MTF值 (a) 均匀掺杂(掺杂浓度1019 cm–3), 不同Al组分变化; (b) 变掺杂, 组分从0.45—0线性变化(结构中AlxGa1–xAs厚度为1 μm, GaAs厚度为10 nm, 入射光波长λ为600 nm)

Fig. 2. MTFs of (a) varying composition and (b) varying doping reflection-mode AlxGa1–xAs/GaAs photocathodes: (a) Uniform doping (doping concentration of 1019 cm–3), varying Al composition; (b) different doping styles, Al linearly changed from 0.45 to 0 (The thickness of AlxGa1–xAs is 1 μm, the thickness of GaAs is 10 nm, and the incident light wavelength λ is 600 nm).

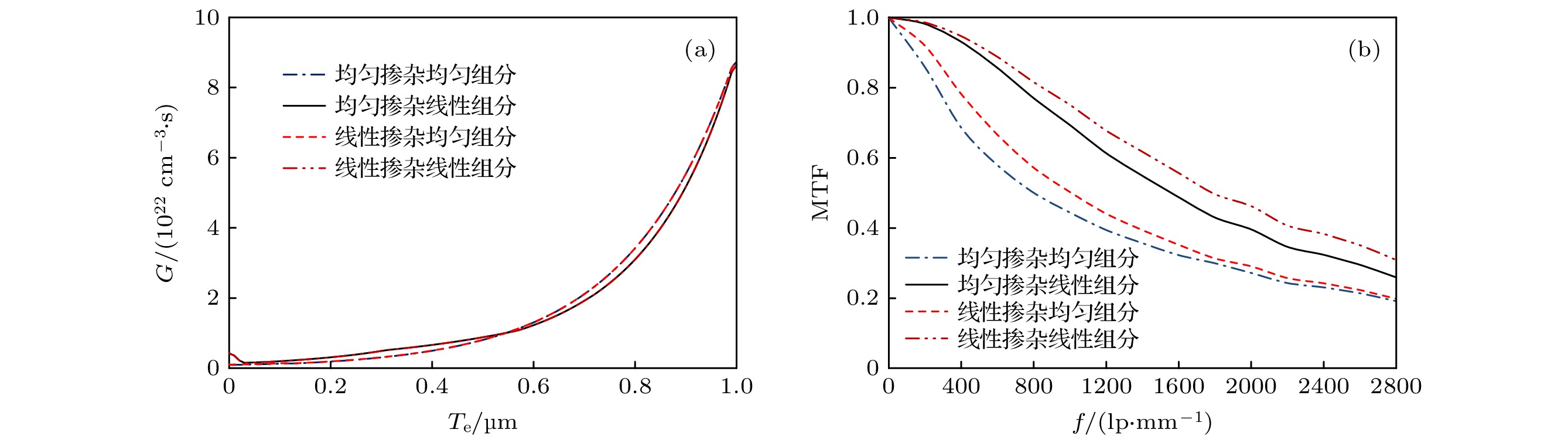

图 3 四种不同结构反射式AlxGa1–xAs/GaAs光电阴极 (a) 光子产生 (f = 400 lp/mm); (b) 不同空间频率下的MTF值(结构中AlxGa1–xAs厚度为1 μm, GaAs厚度为10 nm, λ = 600 nm)

Fig. 3. Four types reflection-mode AlxGa1–xAs/GaAs photocathodes: (a) Photons generation (f = 400 lp/mm); (b) MTFs with the different special frequency (The thickness of AlxGa1–xAs is 1 μm, the thickness of GaAs is 10 nm, and λ = 600 nm).

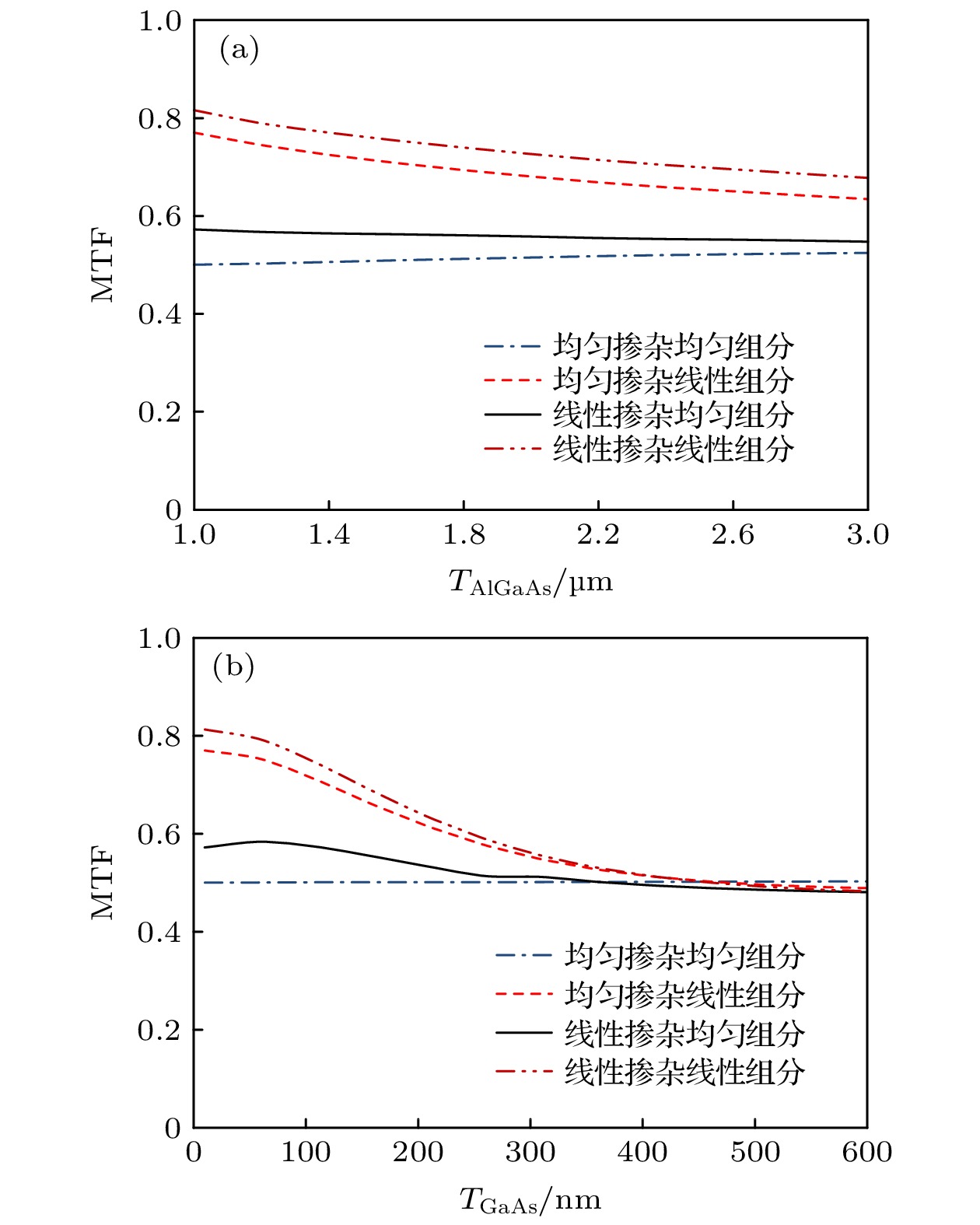

图 4 变掺杂变组分反射式AlxGa1–xAs/GaAs光电阴极的MTF值 (a) 将GaAs层厚度固定为10 nm, 改变AlxGa1–xAs厚度; (b) 将AlxGa1–xAs厚度固定为1 μm, 改变GaAs层厚度 (λ = 600 nm, f = 800 lp/mm)

Fig. 4. MTFs of varying doping and varying composition reflection-mode AlxGa1–xAs/GaAs photocathodes: (a) GaAs layer thickness is fixed at 10 nm, changing AlxGa1–xAs thickness; (b) AlxGa1–xAs layer thickness is fixed at 1 µm, changing GaAs thickness (λ = 600 nm, f = 800 lp/mm).

图 5 不同波长入射时, 变掺杂变组分反射式AlxGa1–xAs/GaAs光电阴极MTF值 (AlxGa1–xAs层厚度为1 μm, GaAs层厚度为10 nm, f = 800 lp/mm)

Fig. 5. MTFs of varying doping and varying composition reflection-mode AlxGa1–xAs/GaAs photocathodes with different incident light wavelength (The thickness of AlxGa1–xAs is 1 μm, the thickness of GaAs is 10 nm, f = 800 lp/mm).

表 1 四种不同结构反射式AlxGa1–xAs/GaAs光电阴极参数

Table 1. Parameters of four different reflection-mode AlxGa1–xAs/GaAs photocathodes.

阴极结构 Al组分 掺杂浓度/cm–3 均匀掺杂均匀组分 0 保持1019 不变 均匀掺杂线性组分 从0.45—0线性变化 保持1019 不变 线性掺杂均匀组分 0 从1019—1018 线性变化 线性掺杂线性组分 从0.45—0线性变化 从1019—1018 线性变化 表 2 四种不同结构反射式AlxGa1–xAs/GaAs光电阴极内建电场

Table 2. Built-in field of four types reflection-mode AlxGa1–xAs/GaAs photocathodes.

阴极结构类型 E/(V·cm–1) 均匀掺杂均匀组分 0 均匀掺杂线性组分 2099 线性掺杂均匀组分 600 线性掺杂线性组分 2106 -

[1] Chanlek N, Herbert J D, Jones R M, Jones L B, Middleman K J 2015 J. Phys. D: Appl. Phys. 48 375102

Google Scholar

Google Scholar

[2] Kim J, Kim J, Oh H, Meyyappan M, Han J W, Lee J S 2016 J. Vac. Sci. Technol. B 34 042201

Google Scholar

Google Scholar

[3] Liu Z, Sun Y, Peterson S, Pianetta P 2008 Appl. Phys. Lett. 92 3042

Google Scholar

Google Scholar

[4] Zou J J, Chang B K, Yang Z, Qian J L, Zeng Y P 2008 Appl. Phys. Lett. 92 1721021

Google Scholar

Google Scholar

[5] Karkare S, Dimitrov D, Schaff W, Cultrera L, Bartnik A 2013 J. Appl. Phys. 113 104904

Google Scholar

Google Scholar

[6] Orlov D A, Krantz C, Wolf A, Jaroshevich A S, Kosolobov S N, Scheibler H E, Terekhov A S 2009 J. Appl. Phys. 106 054907

Google Scholar

Google Scholar

[7] Yang Y, Yang W Z, Sun C D 2015 Sol. Energ. Mat. Sol. C. 132 410

Google Scholar

Google Scholar

[8] 郝光辉, 韩攀阳, 李兴辉, 李泽鹏, 高玉娟 2020 69 108501

Google Scholar

Google Scholar

Hao G H, Han P Y, Li X H, Li Z P, Gao Y J 2020 Acta Phys. Sin. 69 108501

Google Scholar

Google Scholar

[9] Wang H G, Qian Y S, Du Y J, Xu Y, Lu L B, Chang B K 2014 Appl. Opt. 53 335

Google Scholar

Google Scholar

[10] Zou J J, Zhang Y J, Peng X C, Deng W J, Feng L, Chang B K 2012 Appl. Opt. 51 7662

Google Scholar

Google Scholar

[11] Zhang Y J, Chang B K, Niu J, Zhao J, Zou J J, Shi F, Cheng H C 2011 Appl. Phys. Lett. 99 101104

Google Scholar

Google Scholar

[12] Wang H G, Fu X Q, Ji X H, Du Y J, Liu J, Qian Y S, Chang B K 2014 Appl. Opt. 53 6230

Google Scholar

Google Scholar

[13] 邹继军, 常本康, 杨智 2007 56 2992

Google Scholar

Google Scholar

Zou J J, Chang B K, Yang Z 2007 Acta Phys. Sin. 56 2992

Google Scholar

Google Scholar

[14] Zou J J, Zhang Y J, Deng W J, Peng X C, Jiang S T Chang B K 2015 Appl. Opt. 54 8521

Google Scholar

Google Scholar

[15] 牛军, 杨智, 常本康, 乔建良, 张益军 2009 58 5002

Google Scholar

Google Scholar

Niu J, Yang Z, Chang B K, Qiao J L, Zhang Y J 2009 Acta Phys. Sin. 58 5002

Google Scholar

Google Scholar

[16] Deng W J, Zou J J, Peng X C, Feng L, Zhu Z F, Wang W L, Zhang Y J, Chang B K 2015 Appl. Opt. 54 1414

Google Scholar

Google Scholar

[17] Deng W J, Zhang D L, Zou J J, Peng X C, Wang W L, Zhang Y J, Chang B K 2015 Proceddings of the 2th Photoelectronic Technology Committee Conferences Changchun, China, July 22–24, 2015 p97951X

[18] Goldberg Y A 1999 Handbook Series on Semiconductor Parameters (Vol. 2) (London: World Scientific) pp1–36

[19] Zarem H A, Lebens J A, Nordstrom K B, Sercel P C, Sanders S, Eng L E, Yariv A, Vahala K J 1989 Appl. Phys. Lett. 55 2622

Google Scholar

Google Scholar

[20] Timmons M L, Colpitts T S, Venkatasubramanian, Keyes B M, Dunlavy D J, Ahrenkiel R K 1990 Appl. Phys. Lett. 56 1850

Google Scholar

Google Scholar

[21] Aspnes D E, Kelso S M, Logan R A, Bhat R 1986 J. Appl. Phys. 60 754

Google Scholar

Google Scholar

计量

- 文章访问数: 5687

- PDF下载量: 98

- 被引次数: 0

下载:

下载: