-

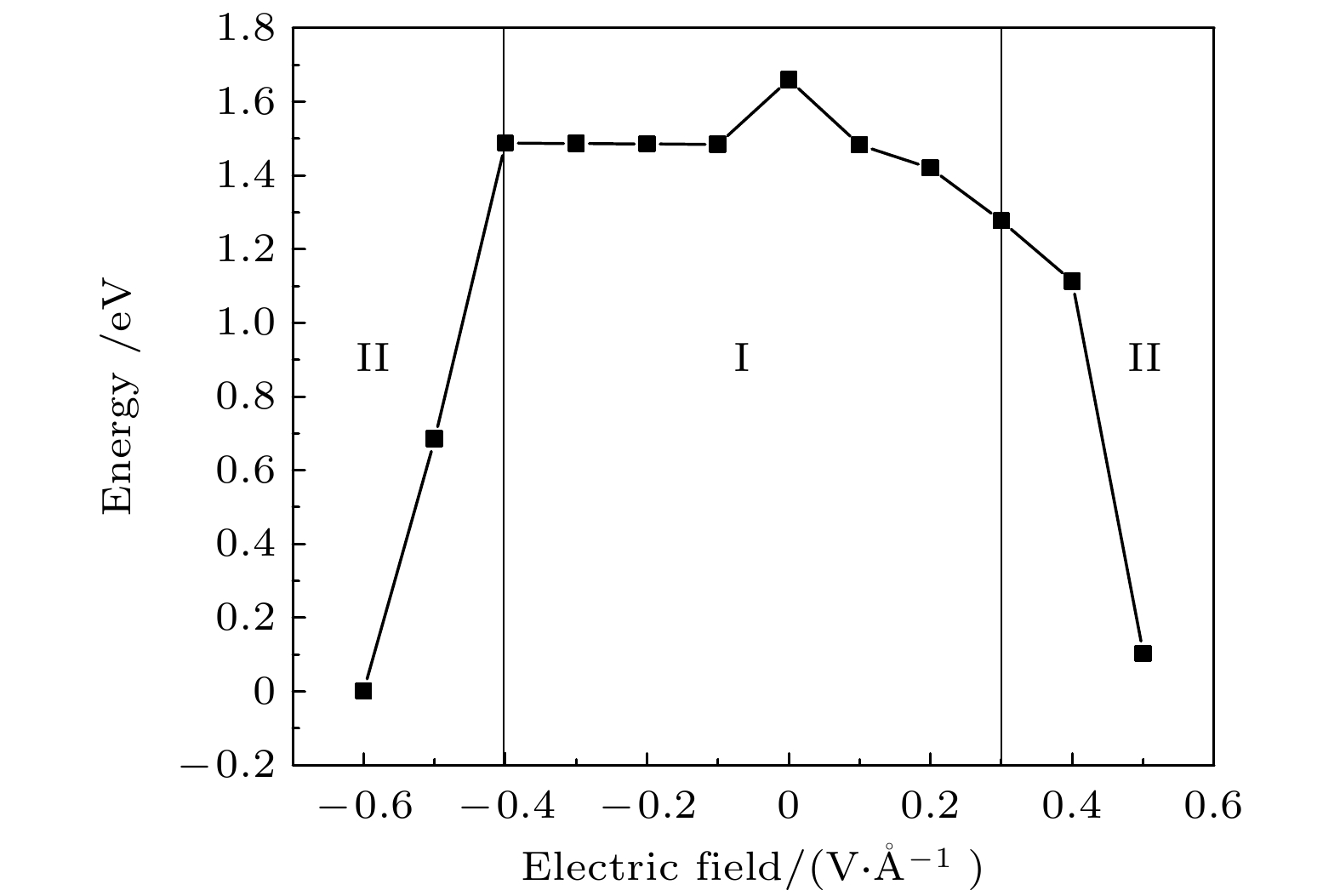

采用基于密度泛函理论的第一性原理平面波超软赝势方法研究了GaN/g-C3N4异质结的稳定性、电子结构、光学性质及功函数, 同时考虑了电场效应. 结果表明: GaN/g-C3N4范德瓦耳斯异质结的晶格失配率(0.9%)和晶格失配能极低(–1.230 meV/Å2, 1 Å = 0.1 nm), 说明该异质结稳定性很好, 且该异质结在很大程度上保留了GaN和g-C3N4的基本电子性质, 可作为直接带隙半导体材料. 同时, GaN/g-C3N4异质结在界面处形成了从GaN指向g-C3N4的内建电场, 使得光生电子-空穴对可以有效分离, 这有利于提高体系的光催化能力. 进一步分析可知, 外加电场使GaN/g-C3N4异质结的禁带宽度有着不同程度的减小, 使得电子从价带跃迁至导带更加容易, 有利于提高体系的光催化活性; 此外, 当外加电场高于0.3 V/Å以及低于–0.4 V/Å时, 异质结的能带排列由I型向II型过渡, 更好地实现光生电子-空穴对的分离, 进一步提高了体系的光催化活性. 因此, 本文提出的构建异质结及施加外电场是提高体系光催化活性的有效手段.In this paper, the stability, electronic structure, optical properties, and work function of GaN/g-C3N4 heterojunction are studied by using the first-principles plane wave ultra-soft pseudopotential method based on density functional theory. The electric field effect is also considered. The results show that the total energy for each of the three stacking modes changes little for using the two different dispersion correction methods, i.e. Tkatchenko-Scheffler and Grimme, and the total energy of mode II is the lowest, indicating that the structure of mode II is the most stable. The lattice mismatch ratio and lattice mismatch energy of GaN/g-C3N4 van der Waals heterojunction are very low, indicating that the heterojunction has good stability. The heterojunction retains the basic electronic properties of GaN and g-C3N4 to a great extent and can be used as a direct bandgap semiconductor material. It can be known from the work function and differential charge diagram that the charge on the heterojunction interface is transferred from GaN to g-C3N4, and a built-in electric field orientating g-C3N4 from GaN is formed at the interface. The built-in electric field of the heterojunction can effectively separate the photogenerated electron-hole pairs, which is conducive to improving the photocatalytic capability of the system. Further analysis shows that the applied electric field reduces the bandgap of GaN/g-C3N4 heterostructure to varying degrees. It makes it easier for electrons to transit from valence band to conduction band, which is conducive to improving the photocatalytic activity of the system. In addition, when the applied electric field is –0.6 V/Å and 0.5 V/Å separately, the semiconductor metal phase transition occurs in the heterojunction. When the applied electric field is higher than 0.3 V/Å and lower than –0.4 V/Å, in the energy band arrangement of the heterojunction there occurs the transition from type I to type II. This can better realize the separation of photogenerated electron-hole pairs and further improve the photocatalytic capactivity of the system. Therefore, the construction of heterojunction and application of external electric field proposed in this work constitute an effective means to improve the photocatalytic activity of the system.

-

Keywords:

- electronic structure /

- optical properties /

- work function /

- external electric field

[1] Cao S W, Yu J G 2014 Phys. Chem. Lett. 5 2101

Google Scholar

Google Scholar

[2] Mao N, Gao X M, Zhang C, Shu C, Ma W Y, Wang F, Jiang J X 2019 Dalton. T. 48 14864

Google Scholar

Google Scholar

[3] Antil B, Kumar L, Ranjan R, Shenoy S, Tarafder K, Gopinath C S, Deka S 2021 ACS Appl. Energ. Mater. 4 3118

Google Scholar

Google Scholar

[4] Fu J W, Xu Q L, Low J X, Jiang C J, Yu J G 2019 A Appl. Catal. B-Environ. 243 556

Google Scholar

Google Scholar

[5] Song Y H, She X J, Yi J J, Mo Z, Liu L, Xu H, Li H M 2017 Phys. Status. Solidi. A 214 1600704

Google Scholar

Google Scholar

[6] Na S, Seo S, Lee H 2020 Catalysts 10 679

Google Scholar

Google Scholar

[7] Ali S M, Khan M A M, ALKhuraiji T S 2020 J. Mater. Sci-Mater. El. 31 14901

Google Scholar

Google Scholar

[8] Eisa M H 2019 Results Phys. 13 102330

Google Scholar

Google Scholar

[9] Tong T, Zhu B C, Jiang C J, Cheng B, Yu J G 2018 Appl. Surf. Sci. 433 1175

Google Scholar

Google Scholar

[10] Zhu B C, Zhang L Y, Cheng B, Yu Y, Yu J G 2021 Chin. J. Catal. 42 115

Google Scholar

Google Scholar

[11] Li H H, Wu Y, Li L, Gong Y Y, Niu L Y, Liu X J, Wang T, Sun C Q, Li C 2018 Appl. Surf. Sci. 457 735

Google Scholar

Google Scholar

[12] Liu X L, Ma R, Zhuang L, Hu B W, Chen J R, Liu X Y, Wang X K 2021 Crit. Rev. Env. Sci. Tec. 51 751

Google Scholar

Google Scholar

[13] Li S J, Li Y Y, Shao L X, Wang C D 2021 ChemistrySelect 6 181

Google Scholar

Google Scholar

[14] Ariyanti D, Mukhtar S, Ahmed N, Liu Z, Dong J, Gao W 2020 Int. J. Mod. Phys. B 34 2040067

Google Scholar

Google Scholar

[15] Li J Y, Liu B K, Han X L, Liu B B, Jiang J X, Liu S R, Zhang J T, Shi H Z 2021 Sep. Purif. Technol. 261 118306

Google Scholar

Google Scholar

[16] Wang G R, Jin Z L 2019 Chemistry Select 4 3602

Google Scholar

Google Scholar

[17] Xu Q L, Zhu B C, Jiang C J, Cheng B, Yu J G 2018 Solar RRL 2 1800006

Google Scholar

Google Scholar

[18] Zhang M, Liu X Z, Zeng X, Wang M F, Shen J Y, Liu R Y 2020 Chem. Phy. Lett. X 7 100049

Google Scholar

Google Scholar

[19] Ye C Y, Wang R, Wang H Y, Jiang F B 2020 BMC Chemistry 14 65

Google Scholar

Google Scholar

[20] Al-Zaqri N, Ahmed M A, Alsalme A, Alharthi F, Alsyahi A, Elmahgary M G, Galal A H 2021 J. Mater. Sci-Mater. El. 32 2601

Google Scholar

Google Scholar

[21] Ai C Z, Li J, Yang L, Wang Z P, Wang Z, Zeng Y M, Deng R, Lin S W, Wang C Z 2020 Chem. Sus. Chem. 13 4985

Google Scholar

Google Scholar

[22] Ma X G, Chen C, Hu J S, Zheng M K, Wang H H, Dong S J, Huang C Y, Chen X B 2019 J. Alloy. Compd. 788 1

Google Scholar

Google Scholar

[23] Xue Z, Zhang X Y, Qin J Q, Liu R P 2020 Appl. Surf. Sci. 510 145489

Google Scholar

Google Scholar

[24] Wu F, Zhang Z B, Cheng Z P, Zhou R Z, Lin Y L, Liu Y H, Wang Y Q, Cao X H, Liu M G, Liu Y H 2021 J. Radioanal. Nucl. Ch. 329 1125

Google Scholar

Google Scholar

[25] Lou P, Lee J Y 2020 ACS Appl. Mater. Inter. 12 14289

Google Scholar

Google Scholar

[26] Shu H B 2020 Mat. Sci. Eng. B-Adv. 261 114672

Google Scholar

Google Scholar

[27] Sivasamy R, Paredes-Gil K, Quero F 2022 Physica. E 135 114994

Google Scholar

Google Scholar

[28] Wang J, Shu H B, Liang P, Wang N, Cao D, Chen X S 2019 J. Phys. Chem. C 123 3861

Google Scholar

Google Scholar

[29] Li X R, Dai Y, Ma Y D, Han S H, Huang B B 2014 Phys. Chem. Chem. Phys. 16 4230

Google Scholar

Google Scholar

[30] Ye J X, Liu J W, An Y K 2020 Appl. Surf. Sci. 501 144262

Google Scholar

Google Scholar

[31] Bai K F, Cui Z, Li E L, Ding Y C, Zheng J S, Liu C, Zheng Y P 2020 Vacuum 180 109562

Google Scholar

Google Scholar

[32] Clark S J, Segall M D, Pickard C J, Hasnip P J, Probert M I J, Refson K, Payne M C 2005 Z. Krist. Cryst. Mater. 220 567

Google Scholar

Google Scholar

[33] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[34] Tkatchenko A, Scheffler M 2009 Phys. Rev. Lett. 102 73005

Google Scholar

Google Scholar

[35] Chadi D J 1977 Phys. Rev. B 16 1746

Google Scholar

Google Scholar

[36] 危阳, 马新国, 祝林, 贺华, 黄楚云 2017 66 087101

Google Scholar

Google Scholar

Wei Y, Ma X G, Zhu L, He H, Huang C Y 2017 Acta. Phys. Sin. 66 087101

Google Scholar

Google Scholar

[37] Ma X G, Hu J S, He H, Dong S J, Huang C Y, Chen X B 2018 ACS Appl. Nano Mater. 1 5507

Google Scholar

Google Scholar

[38] Liu J J 2015 J. Phys. Chem. C 119 28417

Google Scholar

Google Scholar

[39] 郭丽娟, 胡吉松, 马新国, 项炬 2019 68 097101

Google Scholar

Google Scholar

Guo L J, Hu J S, Ma X G, Xiang J 2019 Acta. Phys. Sin. 68 097101

Google Scholar

Google Scholar

[40] Liao J M, Sa B S, Zhou J, Ahuja R, Sun Z 2014 J. Phys. Chem. C 118 17594

Google Scholar

Google Scholar

[41] Ivanov A S, Miller E, Boldyrev A I, Kameoka Y, Sato T, Tanaka K 2015 J. Phys. Chem. C 119 12008

Google Scholar

Google Scholar

[42] Yeoh K H, Yoon T L, Lim T L, Rusi, Ong D S 2019 Superlattice. Microst. 130 428

Google Scholar

Google Scholar

[43] 张丽丽, 夏桐, 刘桂安, 雷博程, 赵旭才, 王少霞, 黄以能 2019 68 017401

Google Scholar

Google Scholar

Zhang L L, Xia T, Liu G A, Lei B C, Zhao X C, Wang S X, Huang Y N 2019 Acta. Phys. Sin. 68 017401

Google Scholar

Google Scholar

[44] Pham T A, Ping Y, Galli G 2017 Nat. Mater. 16 401

Google Scholar

Google Scholar

[45] Liu Z R, Yu X, Li L L 2020 Chinese J. Catal. 41 534

Google Scholar

Google Scholar

-

图 1 (a) GaN单胞俯视图; (b) g-C3N4单胞俯视图; (c) 3 × 3的单层GaN俯视图; (d) 2 × 2的单层g-C3N4俯视图; (e) GaN/g-C3N4异质结侧视图

Fig. 1. Top views of primitive cells of monolayer GaN (a) and g-C3N4 (b); top views of (c) monolayer GaN with 3 × 3 lateral periodicity and (d) monolayer g-C3N4 with 2 × 2 lateral periodicity; (e) side view of GaN/g-C3N4 heterojunction.

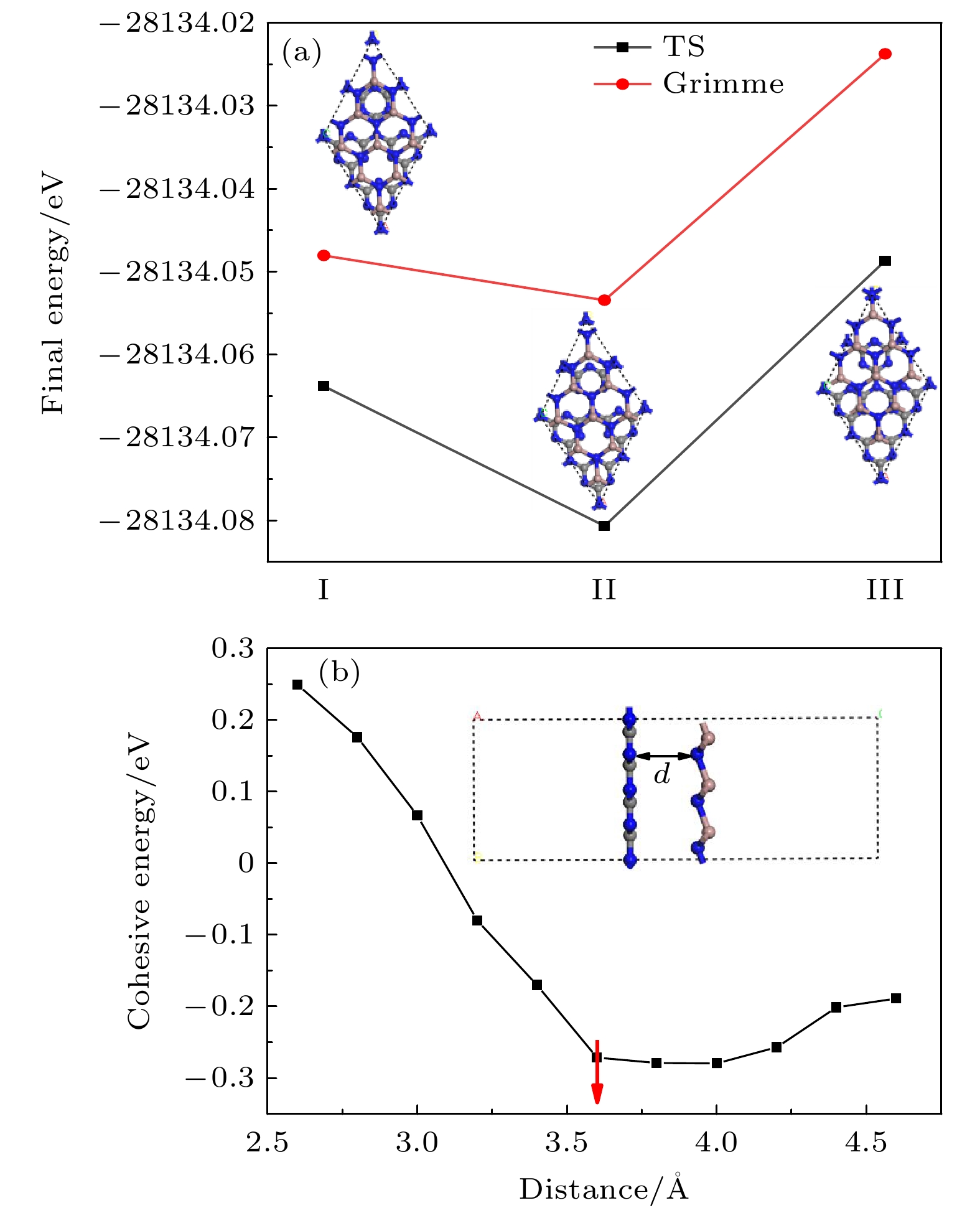

图 2 (a) GaN/g-C3N4异质结的3种堆垛模式俯视图以及采用TS和Grimme色散修正方法获得的总能量; (b)几何优化后模式II的结合能与层间距的关系

Fig. 2. (a) Top view of three stacking modes of GaN/g-C3N4 heterojunction and total energy obtained by TS and Grimme dispersion correction method; (b) the relation between the cohesive energies and interlayer spacing distance for stacking pattern II after geometric optimization.

图 3 (a) 单层GaN能带图; (b) 单层g-C3N4能带图; (c) GaN/g-C3N4异质结能带图; (d) GaN/g-C3N4异质结的总态密度及分态密度图; (e) 单层GaN、单层g-C3N4及异质结的吸收光谱图

Fig. 3. Energy band diagram of (a) monolayer GaN, (b) monolayer g-C3N4 and (c) GaN/g-C3N4 heterojunction; (d) total density of states and partial density of states of GaN/g-C3N4 heterojunction; (e) absorption spectra of monolayer GaN, g-C3N4 and GaN/g-C3N4 heterojunction.

图 4 (a) 单层g-C3N4功函数; (b) 单层GaN功函数; (c) GaN/g-C3N4异质结功函数; (d) GaN/g-C3N4异质结的三维差分电荷密度图(绿色和紫色分别表示电荷耗尽和电荷积累)

Fig. 4. Work function of (a) monolayer g-C3N4, (b) monolayer GaN and (c) GaN/g-C3N4 heterojunction; (d) three-dimensional differential charge density diagram of GaN/g-C3N4 heterojunction (green and purple represent charge depletion and charge accumulation, respectively).

图 5 在不同外加电场(–0.6—0.5 V/Å)下GaN/g-C3N4异质结的能带结构图, 能量零点设置为费米能级 (a) –0.6 V/Å; (b) –0.5 V/Å; (c) –0.4 V/Å; (d) –0.3 V/Å; (e) –0.2 V/Å; (f) –0.1 V/Å; (g) 0 V/Å; (h) 0.1 V/Å; (i) 0.2 V/Å; (j) 0.3 V/Å; (k) 0.4 V/Å; (l) 0.5 V/Å

Fig. 5. Energy band structure of GaN/g-C3N4 heterojunction under different applied electric fields, with the energy zero set as the Fermi level: (a) –0.6 V/Å; (b) –0.5 V/Å; (c) –0.4 V/Å; (d) –0.3 V/Å; (e) –0.2 V/Å; (f) –0.1 V/Å; (g) 0 V/Å; (h) 0.1 V/Å; (i) 0.2 V/Å; (j) 0.3 V/Å; (k) 0.4 V/Å; (l) 0.5 V/Å.

-

[1] Cao S W, Yu J G 2014 Phys. Chem. Lett. 5 2101

Google Scholar

Google Scholar

[2] Mao N, Gao X M, Zhang C, Shu C, Ma W Y, Wang F, Jiang J X 2019 Dalton. T. 48 14864

Google Scholar

Google Scholar

[3] Antil B, Kumar L, Ranjan R, Shenoy S, Tarafder K, Gopinath C S, Deka S 2021 ACS Appl. Energ. Mater. 4 3118

Google Scholar

Google Scholar

[4] Fu J W, Xu Q L, Low J X, Jiang C J, Yu J G 2019 A Appl. Catal. B-Environ. 243 556

Google Scholar

Google Scholar

[5] Song Y H, She X J, Yi J J, Mo Z, Liu L, Xu H, Li H M 2017 Phys. Status. Solidi. A 214 1600704

Google Scholar

Google Scholar

[6] Na S, Seo S, Lee H 2020 Catalysts 10 679

Google Scholar

Google Scholar

[7] Ali S M, Khan M A M, ALKhuraiji T S 2020 J. Mater. Sci-Mater. El. 31 14901

Google Scholar

Google Scholar

[8] Eisa M H 2019 Results Phys. 13 102330

Google Scholar

Google Scholar

[9] Tong T, Zhu B C, Jiang C J, Cheng B, Yu J G 2018 Appl. Surf. Sci. 433 1175

Google Scholar

Google Scholar

[10] Zhu B C, Zhang L Y, Cheng B, Yu Y, Yu J G 2021 Chin. J. Catal. 42 115

Google Scholar

Google Scholar

[11] Li H H, Wu Y, Li L, Gong Y Y, Niu L Y, Liu X J, Wang T, Sun C Q, Li C 2018 Appl. Surf. Sci. 457 735

Google Scholar

Google Scholar

[12] Liu X L, Ma R, Zhuang L, Hu B W, Chen J R, Liu X Y, Wang X K 2021 Crit. Rev. Env. Sci. Tec. 51 751

Google Scholar

Google Scholar

[13] Li S J, Li Y Y, Shao L X, Wang C D 2021 ChemistrySelect 6 181

Google Scholar

Google Scholar

[14] Ariyanti D, Mukhtar S, Ahmed N, Liu Z, Dong J, Gao W 2020 Int. J. Mod. Phys. B 34 2040067

Google Scholar

Google Scholar

[15] Li J Y, Liu B K, Han X L, Liu B B, Jiang J X, Liu S R, Zhang J T, Shi H Z 2021 Sep. Purif. Technol. 261 118306

Google Scholar

Google Scholar

[16] Wang G R, Jin Z L 2019 Chemistry Select 4 3602

Google Scholar

Google Scholar

[17] Xu Q L, Zhu B C, Jiang C J, Cheng B, Yu J G 2018 Solar RRL 2 1800006

Google Scholar

Google Scholar

[18] Zhang M, Liu X Z, Zeng X, Wang M F, Shen J Y, Liu R Y 2020 Chem. Phy. Lett. X 7 100049

Google Scholar

Google Scholar

[19] Ye C Y, Wang R, Wang H Y, Jiang F B 2020 BMC Chemistry 14 65

Google Scholar

Google Scholar

[20] Al-Zaqri N, Ahmed M A, Alsalme A, Alharthi F, Alsyahi A, Elmahgary M G, Galal A H 2021 J. Mater. Sci-Mater. El. 32 2601

Google Scholar

Google Scholar

[21] Ai C Z, Li J, Yang L, Wang Z P, Wang Z, Zeng Y M, Deng R, Lin S W, Wang C Z 2020 Chem. Sus. Chem. 13 4985

Google Scholar

Google Scholar

[22] Ma X G, Chen C, Hu J S, Zheng M K, Wang H H, Dong S J, Huang C Y, Chen X B 2019 J. Alloy. Compd. 788 1

Google Scholar

Google Scholar

[23] Xue Z, Zhang X Y, Qin J Q, Liu R P 2020 Appl. Surf. Sci. 510 145489

Google Scholar

Google Scholar

[24] Wu F, Zhang Z B, Cheng Z P, Zhou R Z, Lin Y L, Liu Y H, Wang Y Q, Cao X H, Liu M G, Liu Y H 2021 J. Radioanal. Nucl. Ch. 329 1125

Google Scholar

Google Scholar

[25] Lou P, Lee J Y 2020 ACS Appl. Mater. Inter. 12 14289

Google Scholar

Google Scholar

[26] Shu H B 2020 Mat. Sci. Eng. B-Adv. 261 114672

Google Scholar

Google Scholar

[27] Sivasamy R, Paredes-Gil K, Quero F 2022 Physica. E 135 114994

Google Scholar

Google Scholar

[28] Wang J, Shu H B, Liang P, Wang N, Cao D, Chen X S 2019 J. Phys. Chem. C 123 3861

Google Scholar

Google Scholar

[29] Li X R, Dai Y, Ma Y D, Han S H, Huang B B 2014 Phys. Chem. Chem. Phys. 16 4230

Google Scholar

Google Scholar

[30] Ye J X, Liu J W, An Y K 2020 Appl. Surf. Sci. 501 144262

Google Scholar

Google Scholar

[31] Bai K F, Cui Z, Li E L, Ding Y C, Zheng J S, Liu C, Zheng Y P 2020 Vacuum 180 109562

Google Scholar

Google Scholar

[32] Clark S J, Segall M D, Pickard C J, Hasnip P J, Probert M I J, Refson K, Payne M C 2005 Z. Krist. Cryst. Mater. 220 567

Google Scholar

Google Scholar

[33] Perdew J P, Burke K, Ernzerhof M 1996 Phys. Rev. Lett. 77 3865

Google Scholar

Google Scholar

[34] Tkatchenko A, Scheffler M 2009 Phys. Rev. Lett. 102 73005

Google Scholar

Google Scholar

[35] Chadi D J 1977 Phys. Rev. B 16 1746

Google Scholar

Google Scholar

[36] 危阳, 马新国, 祝林, 贺华, 黄楚云 2017 66 087101

Google Scholar

Google Scholar

Wei Y, Ma X G, Zhu L, He H, Huang C Y 2017 Acta. Phys. Sin. 66 087101

Google Scholar

Google Scholar

[37] Ma X G, Hu J S, He H, Dong S J, Huang C Y, Chen X B 2018 ACS Appl. Nano Mater. 1 5507

Google Scholar

Google Scholar

[38] Liu J J 2015 J. Phys. Chem. C 119 28417

Google Scholar

Google Scholar

[39] 郭丽娟, 胡吉松, 马新国, 项炬 2019 68 097101

Google Scholar

Google Scholar

Guo L J, Hu J S, Ma X G, Xiang J 2019 Acta. Phys. Sin. 68 097101

Google Scholar

Google Scholar

[40] Liao J M, Sa B S, Zhou J, Ahuja R, Sun Z 2014 J. Phys. Chem. C 118 17594

Google Scholar

Google Scholar

[41] Ivanov A S, Miller E, Boldyrev A I, Kameoka Y, Sato T, Tanaka K 2015 J. Phys. Chem. C 119 12008

Google Scholar

Google Scholar

[42] Yeoh K H, Yoon T L, Lim T L, Rusi, Ong D S 2019 Superlattice. Microst. 130 428

Google Scholar

Google Scholar

[43] 张丽丽, 夏桐, 刘桂安, 雷博程, 赵旭才, 王少霞, 黄以能 2019 68 017401

Google Scholar

Google Scholar

Zhang L L, Xia T, Liu G A, Lei B C, Zhao X C, Wang S X, Huang Y N 2019 Acta. Phys. Sin. 68 017401

Google Scholar

Google Scholar

[44] Pham T A, Ping Y, Galli G 2017 Nat. Mater. 16 401

Google Scholar

Google Scholar

[45] Liu Z R, Yu X, Li L L 2020 Chinese J. Catal. 41 534

Google Scholar

Google Scholar

计量

- 文章访问数: 11420

- PDF下载量: 271

- 被引次数: 0

下载:

下载: