-

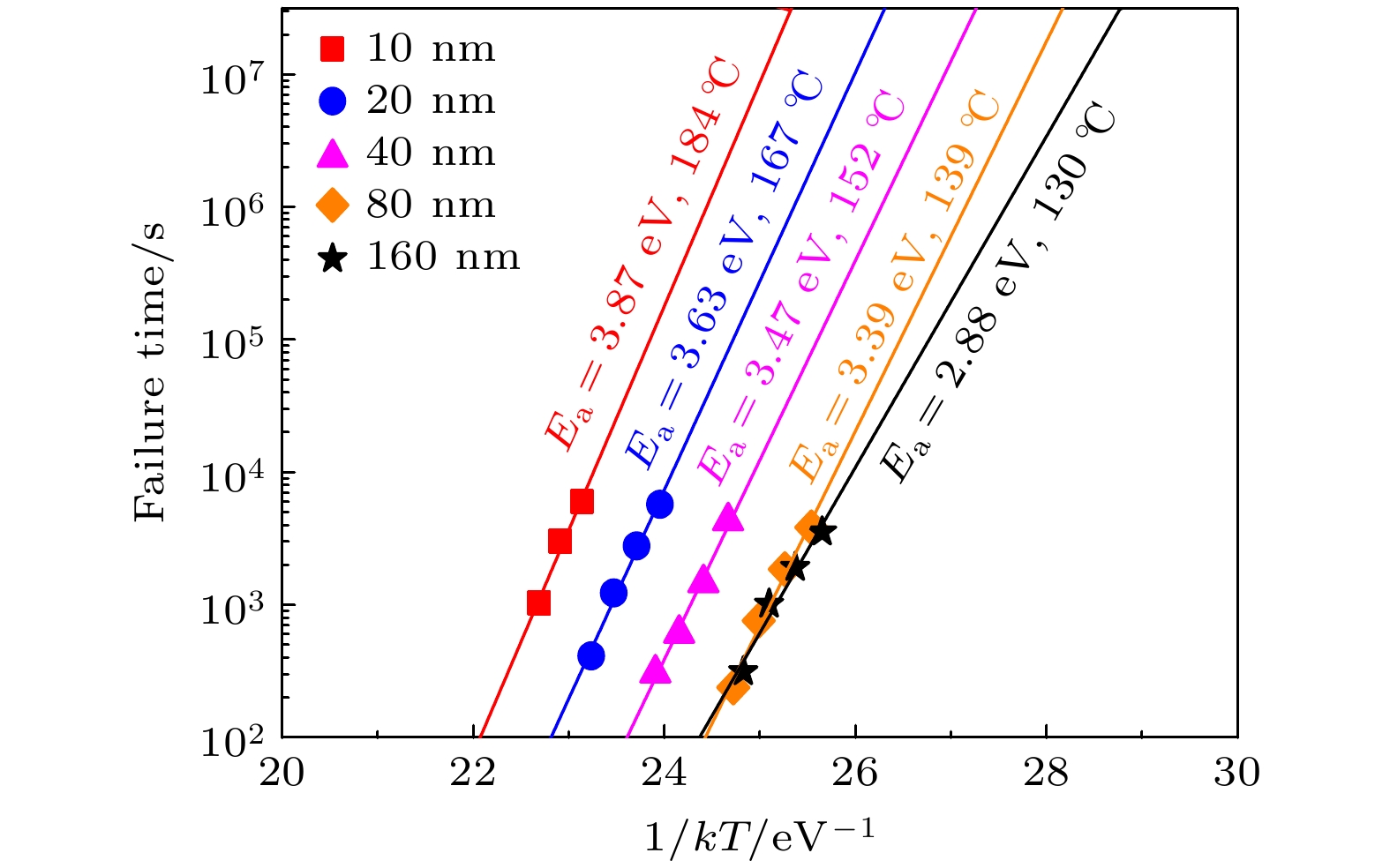

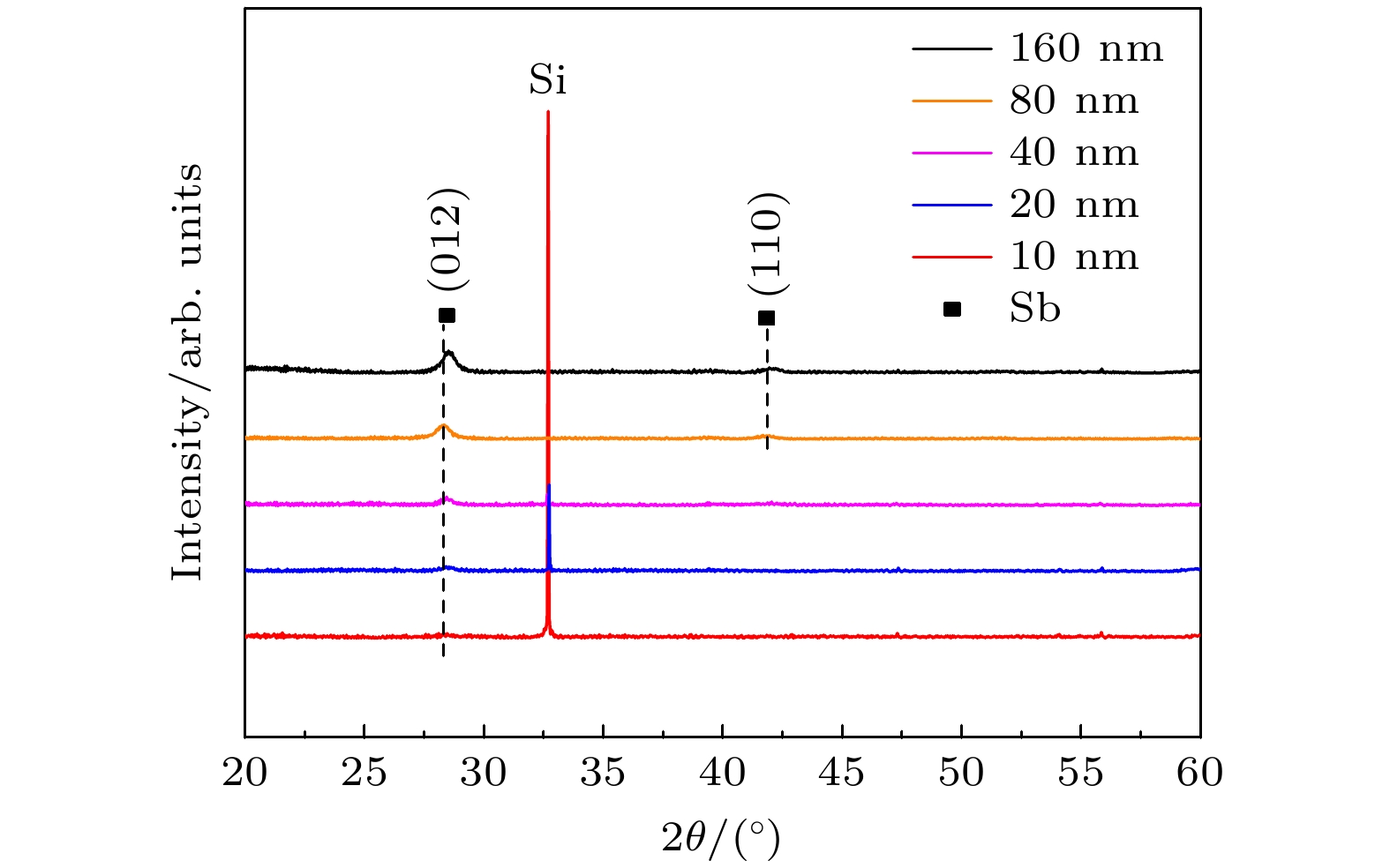

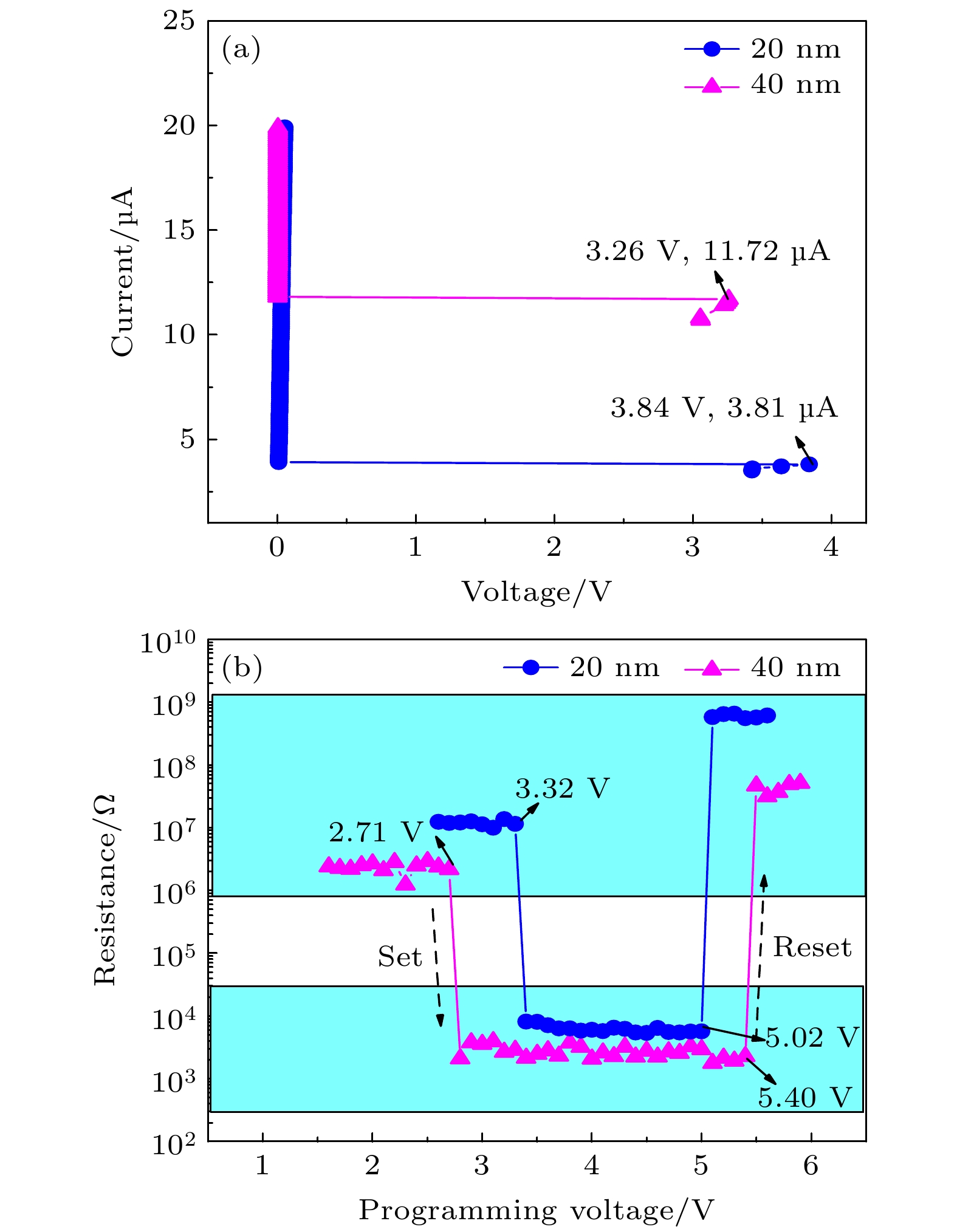

采用磁控溅射法制备了不同厚度的Sn15Sb85薄膜, 使用电阻-温度-时间测试系统研究了Sn15Sb85薄膜在热致作用下从非晶态到晶态的相变动力学过程. 应用近红外分光光度计获得了非晶Sn15Sb85薄膜的反射率光谱, 拟合计算得到薄膜的光学带隙. 通过原子力显微镜观察了Sn15Sb85薄膜晶化后的表面形貌, 研究了膜厚对薄膜粗糙度的影响. 通过X射线衍射仪(XRD)分析了晶态Sn15Sb85薄膜的相结构及晶粒尺寸变化. 采用互补金属氧化物半导体(CMOS)工艺制备了基于不同厚度Sn15Sb85薄膜的T型相变存储器单元, 并通过半导体器件测试系统分析了其阈值转换能力及功耗. 研究结果表明, 随着薄膜厚度的减小, Sn15Sb85相变材料的非晶态和晶态电阻、相变温度、十年非晶态数据保持力、结晶激活能、光学带隙均显著提升. 基于20 nm厚度Sn15Sb85薄膜相变存储单元在纳秒级电脉冲作用下能够实现可逆SET/RESET操作, 且厚度较小的薄膜具有较高的SET电压和较低的RESET电压, 体现了超薄Sn15Sb85薄膜的高热稳定性和低操作功耗特征, 有利于实现相变存储器的高密度集成.

-

关键词:

- Sn15Sb85薄膜 /

- 厚度效应 /

- 热稳定性 /

- 功耗

Sn15Sb85 thin films with different thickness are prepared by magnetron sputtering. The evolution of Sn15Sb85 thin film from the amorphous state to the crystalline state is studied by an in-situ resistance temperature measurement system. The crystallization temperature, electrical resistance, crystallization activation energy, and data retention capacity of Sn15Sb85 thin film increase significantly with film thickness decreasing. The near infrared spectrophotometer is used to record the diffuse reflectance spectra of amorphous Sn15Sb85 film. The results show that the band gap energy increases with film thickness decreasing. The surface morphology of Sn15Sb85 film after being crystalized is observed by atomic force microscope, which shows that the thinner film has lower roughness. The analysis of X-ray diffraction indicates that the grain size becomes smaller and the crystallization may be inhibited by reducing the film thickness. T-type phase change memory cells based on Sn15Sb85 thin films with different thickness are fabricated by the CMOS technology. The electrical performances of phase change memory show that the thinner Sn15Sb85 film has a larger threshold switching voltage and smaller RESET operation voltage, which means the better thermal stability and lower power consumption. The outcomes of this work provide the guidance for designing the high-density phase change memory by reducing the size of Sn15Sb85 thin film.-

Keywords:

- Sn15Sb85 thin film /

- thickness effect /

- thermal stability /

- power consumption

[1] Jiao F Y, Chen B, Ding K Y, Li K L, Wang L, Zeng X R, Rao F 2020 Appl. Mater. Today 20 100641

Google Scholar

Google Scholar

[2] Zhang W, Ma E 2020 Mater. Today 41 156

Google Scholar

Google Scholar

[3] 杜玲玲, 周细应, 李晓 2020 人工晶体学报 49 2398

[4] Durai S, Raj S, Manivannan A 2020 Semicond. Sci. Tech. 35 015022

Google Scholar

Google Scholar

[5] Ding K Y, Chen B, Chen Y M, Wang J Q, Shen X, Rao F 2020 NPG Asia Mater. 12 63

Google Scholar

Google Scholar

[6] Zhu X Q, Zhang R, Hu Y F, Lai T S, Zhang J H, Zou H, Song Z T 2018 Chin. Phys. Lett. 35 056803

Google Scholar

Google Scholar

[7] Hu Y F, Lai T S, Zou H, Zhu X Q 2019 Mater. Res. Expr. 6 025907

[8] 宋志昊, 张昆华, 闻明, 郭俊梅, 陈家林, 谭志龙 2020 材料导报 34 21099

[9] Guo X, Hu Y F, Chou Q Q, Lai T S, Zhang R, Zhu X Q 2018 ECS J. Solid State Sci. Techn. 7 647

Google Scholar

Google Scholar

[10] Hu Y F, Guo X, Chou Q Q, Lai T S 2018 Chinese Phys Lett. 35 096801

Google Scholar

Google Scholar

[11] Mao Y N, Chen Y M, Zhang Q, Wang R P, Shen X 2020 J Non-cryst. Solids 549 120338

Google Scholar

Google Scholar

[12] Pandey S K, Manivannan A 2021 Scripta. Mater. 192 73

Google Scholar

Google Scholar

[13] Liu R R, W P Z, He Z F, Zhai J W, Liu X Y, Lai T S 2017 Thin Solid Films 625 11

Google Scholar

Google Scholar

[14] Putero M, Coulet M V, Muller C, Baehtz C, Raoux S, Cheng H Y 2016 Appl. Phys. Lett. 108 101909

[15] Kim J H, Park J H, Ko D H 2018 Thin Solid Films. 653 173

Google Scholar

Google Scholar

[16] Zou H, Zhai L J, Hu Y F, Zhang J H, Zhu X Q, Sun Y M, Song Z T 2018 Appl. Phys. A 124 717

[17] Wu W H, Chen S Y, Zhai J W, Liu X Y, Lai T S, Song S N, Song Z T 2017 Appl. Phys. Lett. 110 181906

Google Scholar

Google Scholar

[18] Rao F, Song Z T, Ren K, Li X L, Wu L C, Xi W, Liu B 2009 Appl. Phys. Lett. 95 032105

Google Scholar

Google Scholar

[19] Wu W H, Zhao Z H, Shen B, Zhai J W, Song S N, Song Z T 2018 Nanoscale 10 7228

Google Scholar

Google Scholar

[20] You H P, Hu Y F, Zhu X Q, Zou H, Song S N, Song Z T 2018 Appl. Phys. A 124 168

Google Scholar

Google Scholar

[21] 朱小芹, 胡益丰 2020 69 146101

Google Scholar

Google Scholar

Zhu X Q, Hu Y F 2020 Acta Phys. Sin. 69 146101

Google Scholar

Google Scholar

[22] Hu Y F, Zhu X Q, Zou H, Zheng L, Song S N, Song Z T 2017 J. Alloy Compd. 696 150

Google Scholar

Google Scholar

[23] Hu Y F, Zhai J W, Zeng H R, Song S N, Song Z T 2015 J. Appl. Phys. 117 175704

Google Scholar

Google Scholar

[24] Zou H, Hu Y F, Zhu X Q, Sun Y M, Zheng L, Sui Y X, Wu S C, Song Z T 2017 J. Mater. Sci. 52 5216

Google Scholar

Google Scholar

[25] Zhang W, Wu D Y, Hu Y F, Jiang A, Xu J J, Liu H, Bu S P, Shi R H 2016 J. Mater. Sci. -Mater. Electron. 27 13148

Google Scholar

Google Scholar

[26] Shen X, Li J J, Wang G X, Wang Z S, Lu Y G, Dai S X 2015 Vacuum 112 33

Google Scholar

Google Scholar

-

-

[1] Jiao F Y, Chen B, Ding K Y, Li K L, Wang L, Zeng X R, Rao F 2020 Appl. Mater. Today 20 100641

Google Scholar

Google Scholar

[2] Zhang W, Ma E 2020 Mater. Today 41 156

Google Scholar

Google Scholar

[3] 杜玲玲, 周细应, 李晓 2020 人工晶体学报 49 2398

[4] Durai S, Raj S, Manivannan A 2020 Semicond. Sci. Tech. 35 015022

Google Scholar

Google Scholar

[5] Ding K Y, Chen B, Chen Y M, Wang J Q, Shen X, Rao F 2020 NPG Asia Mater. 12 63

Google Scholar

Google Scholar

[6] Zhu X Q, Zhang R, Hu Y F, Lai T S, Zhang J H, Zou H, Song Z T 2018 Chin. Phys. Lett. 35 056803

Google Scholar

Google Scholar

[7] Hu Y F, Lai T S, Zou H, Zhu X Q 2019 Mater. Res. Expr. 6 025907

[8] 宋志昊, 张昆华, 闻明, 郭俊梅, 陈家林, 谭志龙 2020 材料导报 34 21099

[9] Guo X, Hu Y F, Chou Q Q, Lai T S, Zhang R, Zhu X Q 2018 ECS J. Solid State Sci. Techn. 7 647

Google Scholar

Google Scholar

[10] Hu Y F, Guo X, Chou Q Q, Lai T S 2018 Chinese Phys Lett. 35 096801

Google Scholar

Google Scholar

[11] Mao Y N, Chen Y M, Zhang Q, Wang R P, Shen X 2020 J Non-cryst. Solids 549 120338

Google Scholar

Google Scholar

[12] Pandey S K, Manivannan A 2021 Scripta. Mater. 192 73

Google Scholar

Google Scholar

[13] Liu R R, W P Z, He Z F, Zhai J W, Liu X Y, Lai T S 2017 Thin Solid Films 625 11

Google Scholar

Google Scholar

[14] Putero M, Coulet M V, Muller C, Baehtz C, Raoux S, Cheng H Y 2016 Appl. Phys. Lett. 108 101909

[15] Kim J H, Park J H, Ko D H 2018 Thin Solid Films. 653 173

Google Scholar

Google Scholar

[16] Zou H, Zhai L J, Hu Y F, Zhang J H, Zhu X Q, Sun Y M, Song Z T 2018 Appl. Phys. A 124 717

[17] Wu W H, Chen S Y, Zhai J W, Liu X Y, Lai T S, Song S N, Song Z T 2017 Appl. Phys. Lett. 110 181906

Google Scholar

Google Scholar

[18] Rao F, Song Z T, Ren K, Li X L, Wu L C, Xi W, Liu B 2009 Appl. Phys. Lett. 95 032105

Google Scholar

Google Scholar

[19] Wu W H, Zhao Z H, Shen B, Zhai J W, Song S N, Song Z T 2018 Nanoscale 10 7228

Google Scholar

Google Scholar

[20] You H P, Hu Y F, Zhu X Q, Zou H, Song S N, Song Z T 2018 Appl. Phys. A 124 168

Google Scholar

Google Scholar

[21] 朱小芹, 胡益丰 2020 69 146101

Google Scholar

Google Scholar

Zhu X Q, Hu Y F 2020 Acta Phys. Sin. 69 146101

Google Scholar

Google Scholar

[22] Hu Y F, Zhu X Q, Zou H, Zheng L, Song S N, Song Z T 2017 J. Alloy Compd. 696 150

Google Scholar

Google Scholar

[23] Hu Y F, Zhai J W, Zeng H R, Song S N, Song Z T 2015 J. Appl. Phys. 117 175704

Google Scholar

Google Scholar

[24] Zou H, Hu Y F, Zhu X Q, Sun Y M, Zheng L, Sui Y X, Wu S C, Song Z T 2017 J. Mater. Sci. 52 5216

Google Scholar

Google Scholar

[25] Zhang W, Wu D Y, Hu Y F, Jiang A, Xu J J, Liu H, Bu S P, Shi R H 2016 J. Mater. Sci. -Mater. Electron. 27 13148

Google Scholar

Google Scholar

[26] Shen X, Li J J, Wang G X, Wang Z S, Lu Y G, Dai S X 2015 Vacuum 112 33

Google Scholar

Google Scholar

计量

- 文章访问数: 6587

- PDF下载量: 85

- 被引次数: 0

下载:

下载: