-

通过低温等离子体聚合交联作用, 制备了基于PDMS@ZnO纳米颗粒复合涂层的超耐久、自修复超疏水涤纶纤维. 研究了制备工艺对超疏水性、自修复性以及涂层的耐久性和稳定性的影响. 结果显示, PET-g-PDMS@ZnO织物表面的水接触角(WCA)可达162.7°, 滚动角(SA)为7.5°, 经过300次水洗循环和1300次摩擦循环后仍然保持超疏水特性, WCA和SA分别为150.0°和35.0°. 分别采用等离子体和加热方法对磨损破坏的涂层进行自修复处理, 结果表明等离子体修复效果明显, 而热修复只在小载荷下效果明显, 并利用扫描电子显微镜、纳米压痕以及X射线光电子能谱测量结果探讨了自修复机理. 该研究为等离子体技术在超疏水织物制备中的开发和应用提供理论和技术支撑.The ultra-durable, self-healing superhydrophobic polyester fabric based on ZnO@PDMS nanoparticle composite coating (PET-g-PDMS@ZnO fiber) is prepared by low-temperature plasma polymerization. The influences of the preparation process on the superhydrophobicity, self-healing property, durability and stability of the coating are studied. The results show that the water contact angle on the surface of PET-g-PDMS@ZnO fabric can reach 162.7°, and the sliding angle is 7.5°. After 300 washing cycles and 1300 rubbing cycles, the superhydrophobic property is still maintained. Both plasma method and heating method are used to repair the worn coating, and it is found that the repair effect of plasma is obvious, while the heating repair is effective only in the case of small loads. Moreover, scanning electron microscope, nanoindentation and X-ray photoelectron spectroscopy measurement are used to explore the self-healing mechanism. This research provides the theoretical and technical support for the development and application of plasma technology in the preparation of superhydrophobic fabrics.

-

Keywords:

- plasma /

- polyester /

- superhydrophobic /

- durability /

- self-healing

[1] Dimitrakellis P, Gogolides E 2018 Adv. Colloid Interface Sci. 254 1

Google Scholar

Google Scholar

[2] Tsougeni K, Vourdas N, Tserepi A, Gogolides E, Cardinaud C 2009 Langmuir 25 11748

Google Scholar

Google Scholar

[3] 王奔, 念敬妍, 铁璐, 张来斌, 郭志光 2013 62 146801

Google Scholar

Google Scholar

Wang B, Nian J Y, Tie L, Zhang Y B, Guo Z G 2013 Acta Phys. Sin. 62 146801

Google Scholar

Google Scholar

[4] Liu H, Huang J Y, Chen Z, Chen G Q, Zhang K Q, Al-Deyab S S, Lai Y K 2017 Chem. Eng. J. 330 26

Google Scholar

Google Scholar

[5] Zimmermann J, Reifler F A, Fortunato G, Gerhardt L C, Seeger S 2008 Adv. Funct. Mater. 18 3662

Google Scholar

Google Scholar

[6] Deng B, Cai R, Yu Y, Jiang H Q, Wang C L, Li J A, Li L F, Yu M, Li J Y, Xie L D, Huang Q, Fan C H 2010 Adv. Mater. 22 5473

Google Scholar

Google Scholar

[7] Xue C H, Li X, Jia S T, Guo X J, Li M 2016 RSC Adv. 6 84887

Google Scholar

Google Scholar

[8] Liu S, Zhou H, Wang H X, Yang W D, Shao H, Fu S D, Zhao Y, Liu D Q, Feng Z H, Lin T 2017 Small 13 1701891

Google Scholar

Google Scholar

[9] Kong L Z, Tu K K, Guan H, Wang X Q 2017 Appl. Surf. Sci. 407 479

Google Scholar

Google Scholar

[10] Fu S D, Zhou H, Wang H X, Ding J, Liu S, Zhao Y, Niu H T, Rutledge G C, Lin T 2018 RSC Adv. 8 717

Google Scholar

Google Scholar

[11] Abbas R, Khereby M A, Sadik W A, El Demerdash A G M 2015 Cellulose 22 887

Google Scholar

Google Scholar

[12] Zhao Q, Wu L, Huang H, Liu Y C 2016 Mater. Des. 92 541

Google Scholar

Google Scholar

[13] Oh J H, Ko T J, Moon M W, Park C H 2017 RSC Adv. 7 25597

Google Scholar

Google Scholar

[14] Su X J, Li H Q, Lai X J, Zhang L, Wang J, Liao X F, Zeng X R 2017 ACS Appl. Mater. Interfaces 9 28089

Google Scholar

Google Scholar

[15] Li Y, Li L, Sun J Q 2010 Angew. Chem.Int. Ed. 49 6129

Google Scholar

Google Scholar

[16] Zhang H, Hou C P, Song L X, Ma Y, Ali Z, Gu J W, Zhang B L, Zhang H P, Zhang Q Y 2018 Chem. Eng. J. 334 598

Google Scholar

Google Scholar

[17] Xu L Y, Yang L L, Yang S, Xu Z, Lin G J, Shi J J, Zhang R Y, Yu J Y, Ge D T, Guo Y 2021 ACS Appl. Mater. Interfaces 13 6758

Google Scholar

Google Scholar

[18] Lee J, Hwang S, Cho D H, Hong J, Shin J H, Byun D 2017 Appl. Surf. Sci. 394 543

Google Scholar

Google Scholar

[19] Jiang C, Liu W Q, Yang M P, Liu C H, He S, Xie Y K, Wang Z F 2019 Appl. Surf. Sci. 463 34

Google Scholar

Google Scholar

[20] Zhao N, Xie Q D, Weng L H, Wang S Q, Zhang X Y, Xu J 2005 Macromolecules 38 8996

Google Scholar

Google Scholar

[21] Qian Z Y, Risan J, Stadnick B, McKenna G B 2018 J. Polym. Sci., Part B: Polym. Phys. 56 414

Google Scholar

Google Scholar

-

图 1 (a) 超疏水织物的制备流程; (b) 不同液滴在超疏水织物表面的铺展图; 不同纤维表面的SEM图像, 其中图(c)—(e)分别对应(c) 涤纶纤维原样, (d) PET-g-PDMS, (e) PET-g-PDMS@ZnO; 不同纤维表面的AFM图像, 其中图(f)—(h)分别对应(f) 涤纶纤维原样, (g) PET-g-PDMS, (h) PET-g-PDMS@ZnO

Fig. 1. (a) Preparation process of superhydrophobic fabric. (b) Spreading image of different droplets on the surface of superhydrophobic fabric. SEM images of different fiber surfaces: (c) Untreated; (d) PET-g-PDMS; (e) PET-g-PDMS@ZnO. AFM images of different fiber surfaces: (f) Untreated; (g) PET-g-PDMS; (h) PET-g-PDMS@ZnO.

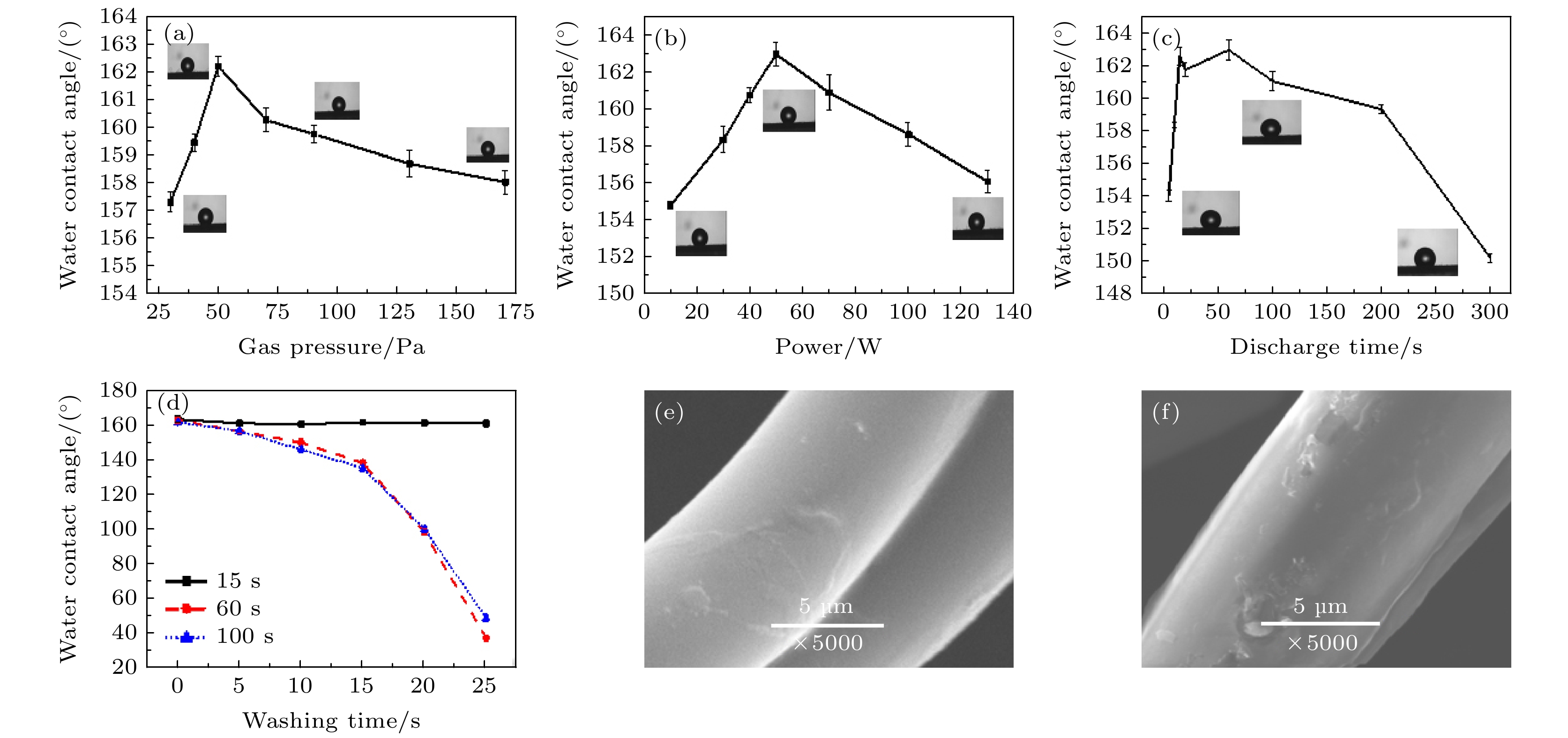

图 2 (a)气体压强、(b)功率、(c)放电时间和(d)循环次数对PET-g-PDMS@ZnO织物水接触角的影响; 不同放电时间处理的纤维表面的SEM图像, 其中图(e), (f)对应的放电时间分别为(e) 15 s; (f) 100 s

Fig. 2. Effects of (a) gas pressure, (b) power, (c) discharge time, and (d) washing times on the WCA of PET-g-PDMS@ZnO fabric; SEM images of fiber surface treated with different discharge time: (e) 15 s; (f) 100 s.

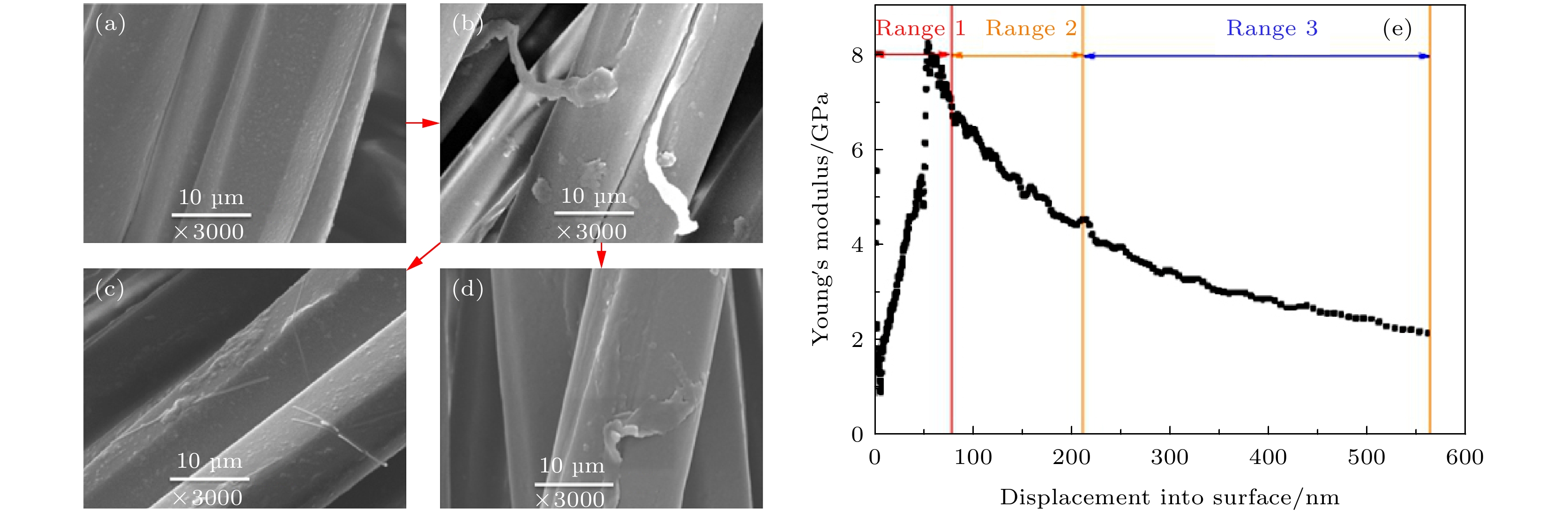

图 4 PET-g-PDMS@ZnO纤维自修复前后SEM图像, 其中图(a)—(d)分别对应(a) PET-g-PDMS@ZnO纤维原样, (b) 磨擦400次后, (c) 等离子体处理修复后, (d) 加热(80 ℃, 30 min)修复后; (e) PDMS膜的纳米压痕

Fig. 4. SEM images of PET-g-PDMS@ZnO fiber before and after self-healing: (a) PET-g-PDMS@ZnO fiber; (b) 400 rubs; (c) plasma treatment; (d) heating (80 ℃, 30 min). (e) Nanoindentation of PDMS film on the surface of PET-g-PDMS fiber.

表 1 不同样品表面元素含量

Table 1. Surface element content of different samples.

结合能/eV 化学键 原样 PET-g-PDMS@ZnO织物 摩擦400次 等离子体法修复 加热法修复 289.3 O—C=O 8.94 — 5.67 — 3.23 286.8 C=O 18.56 6.75 10.29 7.51 9.54 284.8 C—C 72.51 93.25 84.04 92.49 89.23 -

[1] Dimitrakellis P, Gogolides E 2018 Adv. Colloid Interface Sci. 254 1

Google Scholar

Google Scholar

[2] Tsougeni K, Vourdas N, Tserepi A, Gogolides E, Cardinaud C 2009 Langmuir 25 11748

Google Scholar

Google Scholar

[3] 王奔, 念敬妍, 铁璐, 张来斌, 郭志光 2013 62 146801

Google Scholar

Google Scholar

Wang B, Nian J Y, Tie L, Zhang Y B, Guo Z G 2013 Acta Phys. Sin. 62 146801

Google Scholar

Google Scholar

[4] Liu H, Huang J Y, Chen Z, Chen G Q, Zhang K Q, Al-Deyab S S, Lai Y K 2017 Chem. Eng. J. 330 26

Google Scholar

Google Scholar

[5] Zimmermann J, Reifler F A, Fortunato G, Gerhardt L C, Seeger S 2008 Adv. Funct. Mater. 18 3662

Google Scholar

Google Scholar

[6] Deng B, Cai R, Yu Y, Jiang H Q, Wang C L, Li J A, Li L F, Yu M, Li J Y, Xie L D, Huang Q, Fan C H 2010 Adv. Mater. 22 5473

Google Scholar

Google Scholar

[7] Xue C H, Li X, Jia S T, Guo X J, Li M 2016 RSC Adv. 6 84887

Google Scholar

Google Scholar

[8] Liu S, Zhou H, Wang H X, Yang W D, Shao H, Fu S D, Zhao Y, Liu D Q, Feng Z H, Lin T 2017 Small 13 1701891

Google Scholar

Google Scholar

[9] Kong L Z, Tu K K, Guan H, Wang X Q 2017 Appl. Surf. Sci. 407 479

Google Scholar

Google Scholar

[10] Fu S D, Zhou H, Wang H X, Ding J, Liu S, Zhao Y, Niu H T, Rutledge G C, Lin T 2018 RSC Adv. 8 717

Google Scholar

Google Scholar

[11] Abbas R, Khereby M A, Sadik W A, El Demerdash A G M 2015 Cellulose 22 887

Google Scholar

Google Scholar

[12] Zhao Q, Wu L, Huang H, Liu Y C 2016 Mater. Des. 92 541

Google Scholar

Google Scholar

[13] Oh J H, Ko T J, Moon M W, Park C H 2017 RSC Adv. 7 25597

Google Scholar

Google Scholar

[14] Su X J, Li H Q, Lai X J, Zhang L, Wang J, Liao X F, Zeng X R 2017 ACS Appl. Mater. Interfaces 9 28089

Google Scholar

Google Scholar

[15] Li Y, Li L, Sun J Q 2010 Angew. Chem.Int. Ed. 49 6129

Google Scholar

Google Scholar

[16] Zhang H, Hou C P, Song L X, Ma Y, Ali Z, Gu J W, Zhang B L, Zhang H P, Zhang Q Y 2018 Chem. Eng. J. 334 598

Google Scholar

Google Scholar

[17] Xu L Y, Yang L L, Yang S, Xu Z, Lin G J, Shi J J, Zhang R Y, Yu J Y, Ge D T, Guo Y 2021 ACS Appl. Mater. Interfaces 13 6758

Google Scholar

Google Scholar

[18] Lee J, Hwang S, Cho D H, Hong J, Shin J H, Byun D 2017 Appl. Surf. Sci. 394 543

Google Scholar

Google Scholar

[19] Jiang C, Liu W Q, Yang M P, Liu C H, He S, Xie Y K, Wang Z F 2019 Appl. Surf. Sci. 463 34

Google Scholar

Google Scholar

[20] Zhao N, Xie Q D, Weng L H, Wang S Q, Zhang X Y, Xu J 2005 Macromolecules 38 8996

Google Scholar

Google Scholar

[21] Qian Z Y, Risan J, Stadnick B, McKenna G B 2018 J. Polym. Sci., Part B: Polym. Phys. 56 414

Google Scholar

Google Scholar

计量

- 文章访问数: 9978

- PDF下载量: 287

- 被引次数: 0

下载:

下载: