-

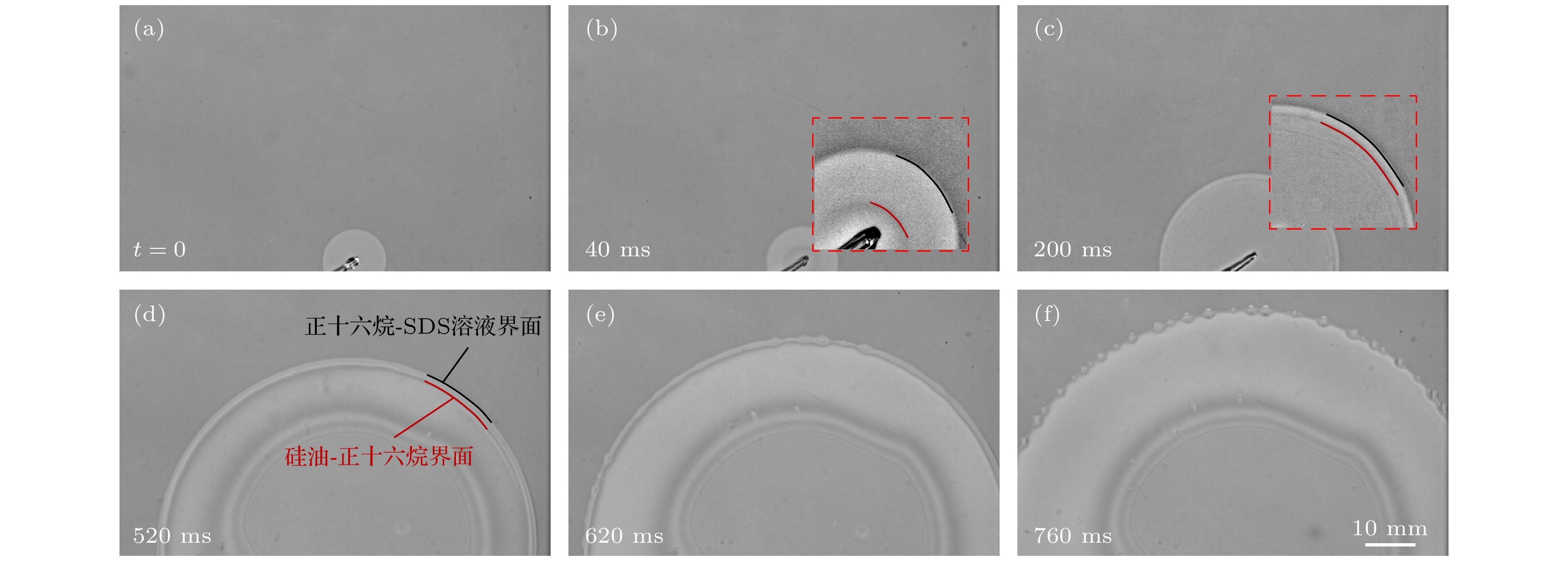

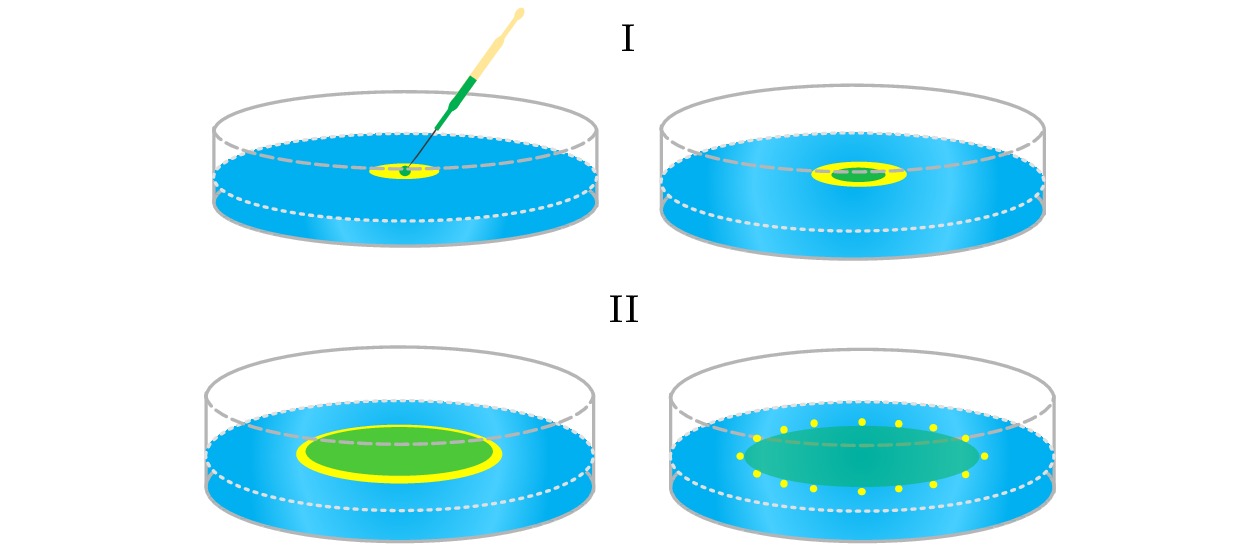

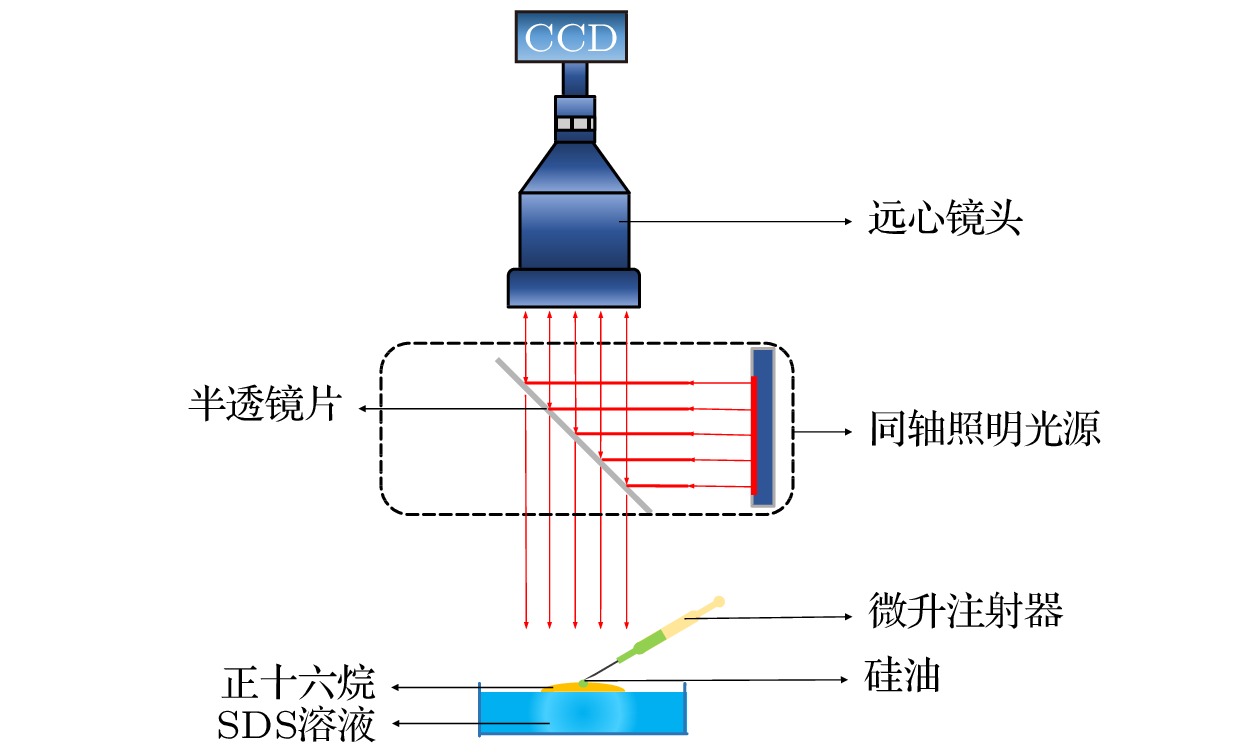

液体表面的液滴运动在微流体和许多生物过程中具有广泛的应用前景. 本文通过研究在液体基底上一种低表面张力液体对另一液体的驱动来理解Marangoni效应在自发驱动体系中的作用. 为了研究液体驱动的液滴铺展过程, 建立了以不易挥发性硅油作为驱动溶剂、正十六烷作为受驱动液滴, 以及不同浓度的十二烷基硫酸钠溶液作为基底溶液的实验体系. 通过对正十六烷液滴受驱动铺展动态过程的观察和研究, 发现界面张力梯度对液体驱动的铺展起主导作用. 实验结果表明: 基底溶液浓度主要对正十六烷液滴的最大铺展半径存在影响. 此外, 用经典稳定性分析模型解释了正十六烷在受驱动铺展过程中由液柱破碎成小液滴的原因, 同时得到了失稳特征参数最快不稳定波长与正十六烷液柱半径之间的关系.Drop dynamics at liquid surfaces is existent in nature and industry, which is of great value in studying droplet self-propulsion, surface coating, and drug delivery, and possesses great potential applications in microfluidics and biological process. Here, we analyze the role of Marangoni effect in the spontaneously driving system by studying the driving effect of a low surface tension liquid at the liquid substrate on another liquid. A three-phase liquid system is established to explore the liquid-driven spreading process, including non-volatile silicone oil as driving solvent, n-hexadecane as driven solvent, and sodium dodecyl sulfate (SDS) solution with different concentrations as aqueous substrates. The spreading process of n-hexadecane driven by silicone oil can be divided into two stages. N-hexadecane is first driven to form a thin rim, and then the rim breaks up into small liquid beads. Afterwards, the driving mechanism, spreading scaling laws and instability characteristic parameters of the liquid-driven spreading process are analyzed theoretically. The analysis of driving mechanism indicates that the differences in surface tension among silicone oil, n-hexadecane and SDS solution cause surface tension gradient at the liquid-liquid interface, which plays a crucial role in spreading the n-hexadecane. The results also demonstrate that the maximum spreading radius of n-hexadecane is affected by the concentration of the aqueous substrate. When the concentration of SDS solution is lower than the critical micelle concentration, the maximum spreading radius of n-hexadecane is proportional to the concentration of SDS solution. Meanwhile, the scaling law between the spreading radius R and time t driven by silicone oil conforms to the classical theoretical

$ \mathrm{r}\mathrm{e}\mathrm{l}\mathrm{a}\mathrm{t}\mathrm{i}\mathrm{o}\mathrm{n}\;R\left(t\right)\propto {t}^{3/4} $ . In addition, the classical analysis model is used to explain the instability pattern of n-hexadecane breaking into small beads from rim in the liquid-driven spreading process, which is called Rayleigh-Plateau instability. The fastest instability wavelength$ {\lambda }_{\mathrm{s}} $ and the constant radius$ {r}_{\mathrm{c}} $ of the n-hexadecane liquid rim are related by$ {\lambda }_{\mathrm{s}}\approx 9{r}_{\mathrm{c}} $ . Our results prove the applicability of the spreading scaling law to the liquid-driven spreading process, and also help to understand in depth the mechanism of the liquid-driven spreading and the instability pattern in the spreading process.-

Keywords:

- driven spreading /

- drop dynamics /

- interface instability /

- surface tension

[1] 袁泉子, 沈文豪, 赵亚溥 2016 力学进展 46 343

Google Scholar

Google Scholar

Yuan Q Z, Shen W H, Zhao Y B 2016 Adv. Mech. 46 343

Google Scholar

Google Scholar

[2] Yeo Y, Chen A, Basaran O, Park K 2004 Pharm. Res. 21 1419

Google Scholar

Google Scholar

[3] Charve J, Reineccius G 2009 J. Agric. Food Chem. 57 2486

Google Scholar

Google Scholar

[4] Blanco-Pascual N, Koldeweij R, Stevens R, Montero P, Gomez-Guillen M, Ten Cate A T 2014 Food Bioprocess Technol. 7 2472

Google Scholar

Google Scholar

[5] Zhao X, Kim J, Cezar C, Huebsch N, Lee K, Bouhadir K, Mooney D 2011 Proc. Natl. Acad. Sci. U. S. A. 108 67

Google Scholar

Google Scholar

[6] Seemann R, Fleury J B, Maass C C 2016 Eur. Phys. J.-Spec. Top. 225 2227

Google Scholar

Google Scholar

[7] Kang D, Nadim A, Chugunova M 2017 Phys. Fluids 29 495

Google Scholar

Google Scholar

[8] Roman B, Bico J 2010 J. Phys. Condens. Matter 22 493101

Google Scholar

Google Scholar

[9] Elfring G, Goyal G 2015 J. Non-Newtonian Fluid Mech. 234 8

Google Scholar

Google Scholar

[10] Tanner L H 1979 J. Phys. D; Appl. Phys. 12 13

Google Scholar

Google Scholar

[11] Milchev A, Binder K 2002 J. Chem. Phys. 116 7691

Google Scholar

Google Scholar

[12] Franklin B, Brownrigg W, Farish A 1774 Philos. Trans. R. Soc. Lond 64 445

Google Scholar

Google Scholar

[13] Hoult D P 1972 Annu. Rev. Fluid Mech. 4 341

Google Scholar

Google Scholar

[14] Fraaije J G E M, Cazabat A 1989 J. Colloid Interface Sci. 133 452

Google Scholar

Google Scholar

[15] Berg S 2009 Phys. Fluids 21 398

Google Scholar

Google Scholar

[16] Wodlei F, Sebilleau J, Magnaudet J, Pimienta V 2018 Nat. Commun. 9 820

Google Scholar

Google Scholar

[17] Afsar-Siddiqui A, Luckham P, Matar O 2004 Adv. Colloid Interface Sci. 106 183

Google Scholar

Google Scholar

[18] Lee K S, Starov V 2009 J. Colloid Interface Sci. 329 361

Google Scholar

Google Scholar

[19] Afsar-Siddiqui A, Luckham P, Matar O 2003 Langmuir 19 703

Google Scholar

Google Scholar

[20] Lee K S, Starov V 2007 J. Colloid Interface Sci. 314 631

Google Scholar

Google Scholar

[21] Koldeweij R, Capelleveen B, Lohse D, Visser C W 2019 Soft Matter 15 8525

Google Scholar

Google Scholar

[22] Chengara A, Nikolov A D, Wasan D T 2007 Ind. Eng. Chem. Res. 46 2987

Google Scholar

Google Scholar

[23] Wilkinson K, Bain C, Matsubara H, Aratono M 2005 ChemPhysChem 6 547

Google Scholar

Google Scholar

[24] Bonn D, Ross D 2001 Rep. Prog. Phys. 64 1085

Google Scholar

Google Scholar

[25] Bergeron V, Langevin D 1996 Phys. Rev. Lett. 76 3152

Google Scholar

Google Scholar

[26] Brochardwyart F, Dimeglio J M, Quere D, Degennes P G 1991 Langmuir 7 335

Google Scholar

Google Scholar

[27] Rayleigh J 1878 Proc. London Math. Soc. 10 4

Google Scholar

Google Scholar

[28] Eggers J, Dupont T 2001 J. Fluid Mech. 262 205

Google Scholar

Google Scholar

[29] Frankel I, Weihs D 1987 J. Fluid Mech. 185 361

Google Scholar

Google Scholar

-

图 4 硅油的驱动作用示意图. 1, 2和3分别为驱动溶剂硅油、受驱动溶剂正十六烷和基底SDS溶液,

$ {\sigma }_{23} $ 和$ {\sigma }_{12} $ 分别表示正十六烷与SDS基底溶液之间和硅油与正十六烷之间的界面张力,$ \nabla \sigma $ 表示界面张力梯度,${\Delta }P$ 表示压力梯度Fig. 4. Schematic diagram of the driving effect of silicone oil. 1, 2 and 3 are driving solvent (silicone oil), driven solvent (n-hexadecane) and aqueous substrate (SDS solution),

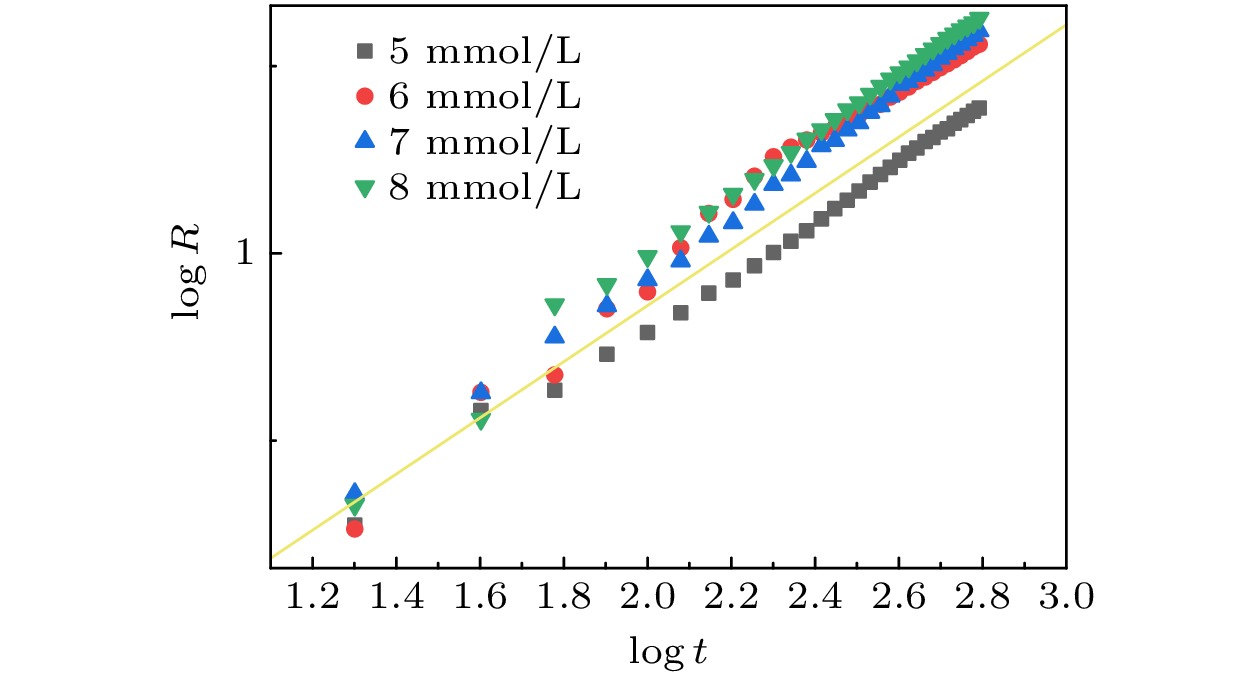

$ {\sigma }_{23} $ and$ {\sigma }_{12} $ represent the interfacial tension between n-hexadecane and SDS solution and between silicone oil and n-hexadecane, respectively.$ \nabla \sigma $ represents the interfacial tension gradient, and$ {\Delta }P $ represents the pressure gradient.图 6 失稳前不同浓度的SDS溶液表面正十六烷铺展半径R随时间的变化(在5, 6, 7和8 mmol/L的SDS溶液表面, 正十六烷受驱动铺展的标度率分别为0.73, 0.80, 0.82, 0.83, 黄线为理论值0.75)

Fig. 6. Variations of the spreading radius R of n-hexadecane on the surface of SDS solutions with different concentrations before instability occurs. The driven-spreading scale rate of n-hexadecane is 0.73, 0.80, 0.82, and 0.83 on the surface of 5, 6, 7 and 8 mmol/L SDS solution, respectively. The yellow line is the theoretical rate of 0.75.

表 1 表/界面张力

$ \sigma $ (单位: mN·m–1)Table 1. Surface/Interfacial tension

$ \sigma $ (in mN·m–1)SDS溶液浓度/(mmol·L–1) 5 6 7 8 表面张力 33.19 32.82 32.62 34.53 与正十六烷界面张力 6.52 6.29 6.56 6.60 表 2 铺展系数S

Table 2. Spreading coefficient S.

SDS溶液浓度/(mmol·L–1) 5 6 7 8 S –0.13 –0.27 –0.74 1.12 表 3 增长最快波长

$ {\lambda }_{\mathrm{s}} $ 、半径$ {r}_{\mathrm{c}} $ 和$ {\lambda }_{\mathrm{s}}/{r}_{\mathrm{c}} $ 的实验值Table 3. Experimental values of the fastest growing wavelength

$ {\lambda }_{\mathrm{s}} $ , the radius$ {r}_{\mathrm{c}} $ and$ {\lambda }_{\mathrm{s}}/{r}_{\mathrm{c}} $ .SDS溶液浓度/(mmol·L–1) 5 6 7 8 $ {\lambda }_{\mathrm{s}} $/mm 3.38 3.12 3.04 3.79 $ {r}_{\mathrm{c}} $/mm 0.36 0.32 0.31 0.41 $ {\lambda }_{\mathrm{s}}/{r}_{\mathrm{c}} $ 9.39 9.75 9.81 9.24 -

[1] 袁泉子, 沈文豪, 赵亚溥 2016 力学进展 46 343

Google Scholar

Google Scholar

Yuan Q Z, Shen W H, Zhao Y B 2016 Adv. Mech. 46 343

Google Scholar

Google Scholar

[2] Yeo Y, Chen A, Basaran O, Park K 2004 Pharm. Res. 21 1419

Google Scholar

Google Scholar

[3] Charve J, Reineccius G 2009 J. Agric. Food Chem. 57 2486

Google Scholar

Google Scholar

[4] Blanco-Pascual N, Koldeweij R, Stevens R, Montero P, Gomez-Guillen M, Ten Cate A T 2014 Food Bioprocess Technol. 7 2472

Google Scholar

Google Scholar

[5] Zhao X, Kim J, Cezar C, Huebsch N, Lee K, Bouhadir K, Mooney D 2011 Proc. Natl. Acad. Sci. U. S. A. 108 67

Google Scholar

Google Scholar

[6] Seemann R, Fleury J B, Maass C C 2016 Eur. Phys. J.-Spec. Top. 225 2227

Google Scholar

Google Scholar

[7] Kang D, Nadim A, Chugunova M 2017 Phys. Fluids 29 495

Google Scholar

Google Scholar

[8] Roman B, Bico J 2010 J. Phys. Condens. Matter 22 493101

Google Scholar

Google Scholar

[9] Elfring G, Goyal G 2015 J. Non-Newtonian Fluid Mech. 234 8

Google Scholar

Google Scholar

[10] Tanner L H 1979 J. Phys. D; Appl. Phys. 12 13

Google Scholar

Google Scholar

[11] Milchev A, Binder K 2002 J. Chem. Phys. 116 7691

Google Scholar

Google Scholar

[12] Franklin B, Brownrigg W, Farish A 1774 Philos. Trans. R. Soc. Lond 64 445

Google Scholar

Google Scholar

[13] Hoult D P 1972 Annu. Rev. Fluid Mech. 4 341

Google Scholar

Google Scholar

[14] Fraaije J G E M, Cazabat A 1989 J. Colloid Interface Sci. 133 452

Google Scholar

Google Scholar

[15] Berg S 2009 Phys. Fluids 21 398

Google Scholar

Google Scholar

[16] Wodlei F, Sebilleau J, Magnaudet J, Pimienta V 2018 Nat. Commun. 9 820

Google Scholar

Google Scholar

[17] Afsar-Siddiqui A, Luckham P, Matar O 2004 Adv. Colloid Interface Sci. 106 183

Google Scholar

Google Scholar

[18] Lee K S, Starov V 2009 J. Colloid Interface Sci. 329 361

Google Scholar

Google Scholar

[19] Afsar-Siddiqui A, Luckham P, Matar O 2003 Langmuir 19 703

Google Scholar

Google Scholar

[20] Lee K S, Starov V 2007 J. Colloid Interface Sci. 314 631

Google Scholar

Google Scholar

[21] Koldeweij R, Capelleveen B, Lohse D, Visser C W 2019 Soft Matter 15 8525

Google Scholar

Google Scholar

[22] Chengara A, Nikolov A D, Wasan D T 2007 Ind. Eng. Chem. Res. 46 2987

Google Scholar

Google Scholar

[23] Wilkinson K, Bain C, Matsubara H, Aratono M 2005 ChemPhysChem 6 547

Google Scholar

Google Scholar

[24] Bonn D, Ross D 2001 Rep. Prog. Phys. 64 1085

Google Scholar

Google Scholar

[25] Bergeron V, Langevin D 1996 Phys. Rev. Lett. 76 3152

Google Scholar

Google Scholar

[26] Brochardwyart F, Dimeglio J M, Quere D, Degennes P G 1991 Langmuir 7 335

Google Scholar

Google Scholar

[27] Rayleigh J 1878 Proc. London Math. Soc. 10 4

Google Scholar

Google Scholar

[28] Eggers J, Dupont T 2001 J. Fluid Mech. 262 205

Google Scholar

Google Scholar

[29] Frankel I, Weihs D 1987 J. Fluid Mech. 185 361

Google Scholar

Google Scholar

计量

- 文章访问数: 9023

- PDF下载量: 226

- 被引次数: 0

下载:

下载: