-

六方氮化硼(hexagonal boron nitride, h-BN)因其良好的润滑性和绝缘性, 在微纳机电系统中有巨大的应用潜力. 本文通过基底刻蚀的工艺, 在SiO2/Si基底上制备了微孔阵列, 然后将h-BN转移到微孔基底上形成悬浮结构, 利用原子力显微镜研究电场对悬浮h-BN摩擦特性的影响. 结果表明: 悬浮状态的h-BN的表面摩擦力小于有基底支撑的h-BN的表面摩擦力, 原因是更大的面内拉伸削弱了褶皱效应. 电场作用下, 针尖与h-BN之间的静电相互作用增强, 悬浮h-BN表面的摩擦力随偏压的增大而增大, 且正偏压的影响大于负偏压的影响. 同时, 在电场下针尖在悬浮h-BN表面的黏滑行为出现单步黏滑向多步黏滑的转变. 此外, 与有基底支撑的h-BN相比, 悬浮状态的h-BN受电场的影响更大, 这是由于针尖与基底界面距离的缩小以及基底氧化层的缺失导致静电力增强. 本文提出了通过施加外电场来调节悬浮h-BN表面摩擦的方法, 对研究二维材料摩擦特性提供了一定的理论指导.Hexagonal boron nitride (h-BN) has huge potential applications in micro-nano electromechanical system due to its good lubricity and insulation. In this paper, a microporous array is prepared on a SiO2/Si substrate by the substrate etching process, and then the h-BN is transferred to the microporous substrate to form a suspension structure. The effect of electric field on tribological properties of suspended h-BN is studied by atomic force microscopy. The results show that the friction of the suspended h-BN is smaller than the friction on the h-BN supported by the substrate, because the greater in-plane stretch weakens the puckering effect. The electric field increases the friction of the suspended h-BN, and the influence of positive bias is greater than that of negative bias. The application of the electric field increases the electrostatic force on the tip, thereby increasing the additional load and the interface barrier in the friction process. The electric field causes the stick-slip behavior to change from single-slip to multi-slip. Compared with the h-BN supported by the substrate, h-BN in the suspended state is strongly affected by the electric field. The reduction of the interface distance and the absence of the substrate oxide layer lead the electrostatic force to increase. This paper proposes a method to adjust h-BN’s friction by electric field, which provides theoretical guidance for studying the friction characteristics of two-dimensional materials.

-

Keywords:

- friction force /

- suspended hexagonal boron nitride /

- atomic force microscope /

- electrostatic force

[1] 郑泉水, 欧阳稳根, 马明, 张首沫, 赵治华, 董华来, 林立 2016 科技导报 34 12

Zheng Q S, Ouyang W G, Ma M, Zhang S M, Zhao Z H, Dong H L, Lin L 2016 Sci. Technol. Rev. 34 12

[2] Zhang S, Ma T B, Erdemir A, Li Q Y 2019 Mater. Today 26 67

Google Scholar

Google Scholar

[3] Spear J C, Ewers B W, Batteas J D 2015 Nano Today 10 301

Google Scholar

Google Scholar

[4] Dean C R, Young A F, Meric I, Lee C, Wang L, Sorgenfrei S, Watanabe K, Taniguchi T, Kim P, Shepard K L 2010 Nat. Nanotechnol. 5 722

Google Scholar

Google Scholar

[5] Liu X C, Hwang E H, Yoo W J, Lee S, Cheong B K 2015 Solid State Commun. 209 1

[6] Mirkarimi P B, McCarty K F, Medlin D L 1997 Mater. Sci. Eng. R Rep. 21 47

Google Scholar

Google Scholar

[7] Martin J M, Mogne T L, Chassagnette C, Gardos M N 1992 Tribol. Trans. 35 462

Google Scholar

Google Scholar

[8] Watanabe K, Taniguchi T, Kanda H 2004 Nat. Mater. 3 404

Google Scholar

Google Scholar

[9] Lee C G, Li Q Y, Kalb W, Liu X Z, Berger H, Carpick R W, Hone J 2010 Science 328 76

Google Scholar

Google Scholar

[10] Zeng X Z, Peng Y T, Yu M C, Lang H J, Cao X A, Zou K 2018 ACS Appl. Mater. Interfaces 10 8214

Google Scholar

Google Scholar

[11] Jiang Y, Yue L L, Yan B S, Liu X, Yang X F, Tai G A, Song J 2015 Nano 10 1550038

Google Scholar

Google Scholar

[12] Lang H J, Peng Y T, Shao G W, Zou K, Tao G M 2019 J. Mater. Chem. C 7 6041

Google Scholar

Google Scholar

[13] Wagner K, Cheng P, Vezenov D 2011 Langmuir 27 4635

Google Scholar

Google Scholar

[14] Nemes-Incze P, Osváth Z, Kamarás K, Biró L P 2008 Carbon 46 1435

Google Scholar

Google Scholar

[15] Elinski M B, Menard B D, Liu Z, Batteas J D 2017 J. Phys. Chem. C 121 5635

[16] Fang L, Liu D M, Guo Y Z, Liao Z M, Luo J B, Wen S Z 2017 Nanotechnology 28 245703

Google Scholar

Google Scholar

[17] Smolyanitsky A, Killgore J P, Tewary V K 2012 Phys. Rev. B 85 035412

Google Scholar

Google Scholar

[18] Li H, Zeng X C 2012 ACS Nano 6 2401

Google Scholar

Google Scholar

[19] Kostoglou N, Polychronopoulou K, Rebholz C 2015 Vacuum 112 42

Google Scholar

Google Scholar

[20] Jean M S, Hudlet S, Guthmann C, Berger J 1999 Eur. Phys. J. B. 12 471

Google Scholar

Google Scholar

[21] Qi Y B, Park J Y, Hendriksen B L M, Ogletree D F, Salmeron M 2008 Phys. Rev. B 77 184105

Google Scholar

Google Scholar

[22] Law B M, Rieutord F 2002 Phys. Rev. B 66 035402

Google Scholar

Google Scholar

[23] Lang H J, Peng Y T, Cao X A, Zou K 2020 ACS Appl. Mater. Interfaces 12 25503

Google Scholar

Google Scholar

[24] Medyanik S N, Liu W K, Sung I H, Carpick R W 2006 Phys. Rev. Lett. 97 136106

Google Scholar

Google Scholar

-

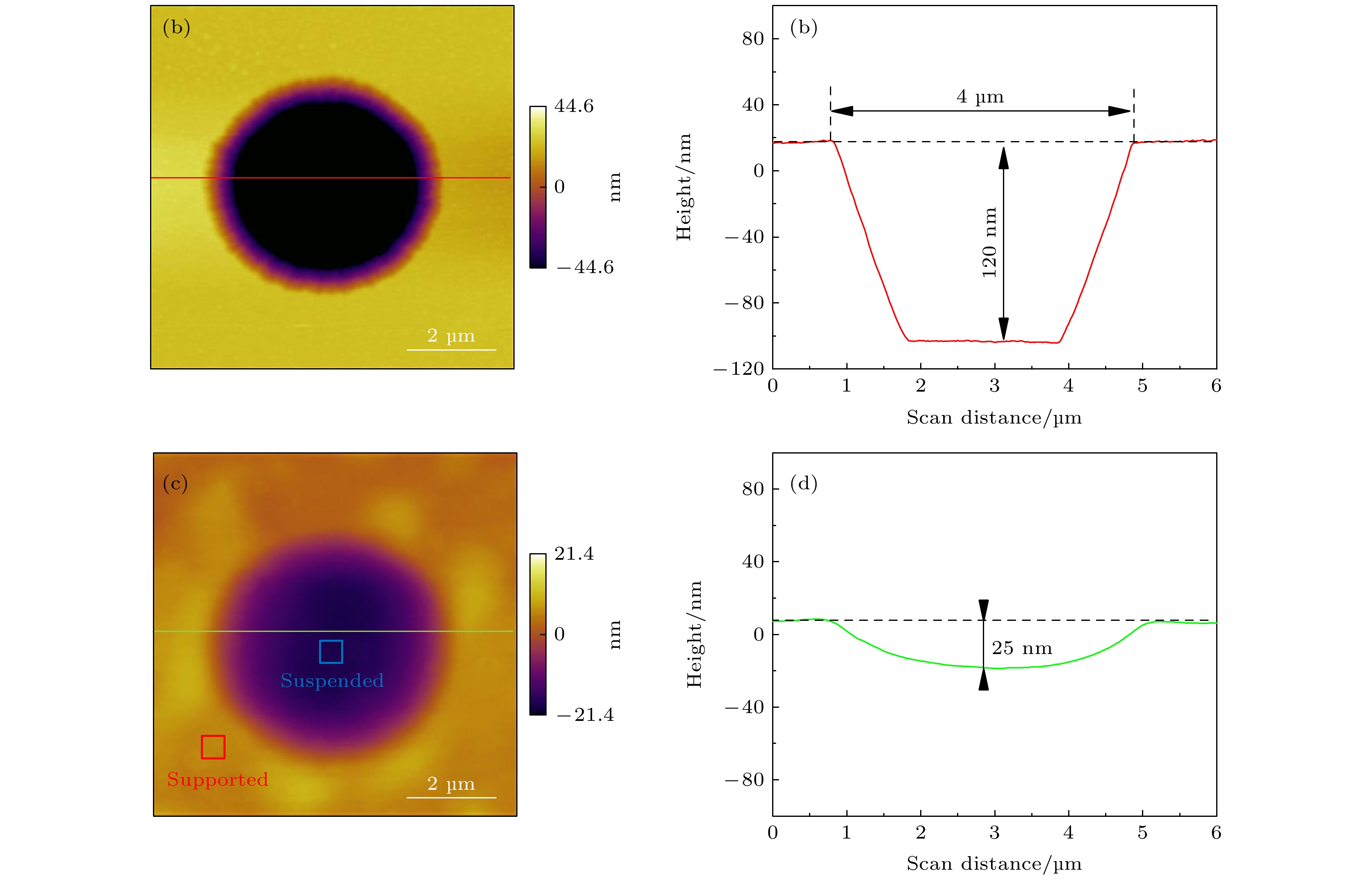

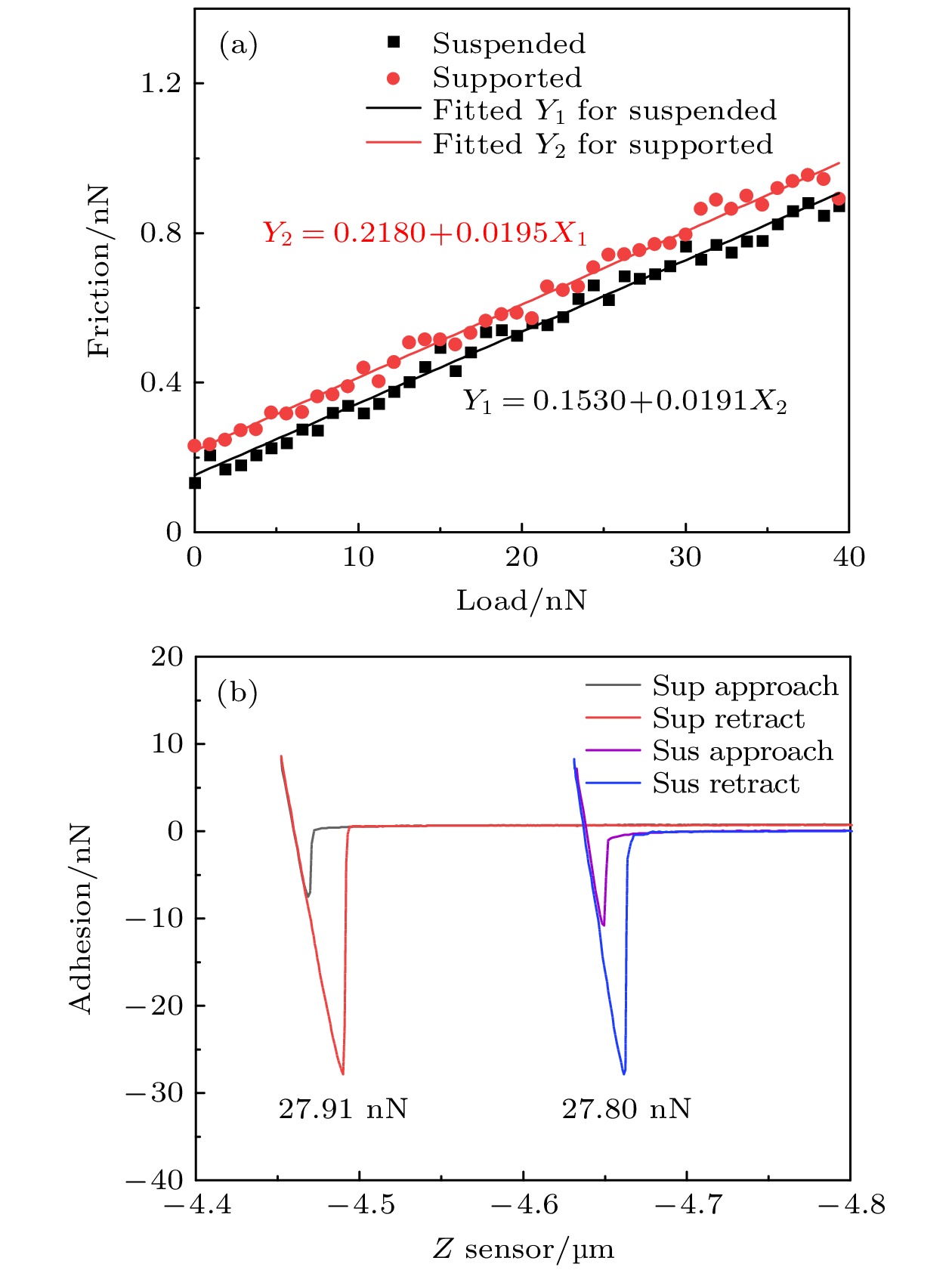

图 3 微孔和悬浮h-BN的形貌及高度轮廓图 (a) 微孔的AFM形貌图; (b) 微孔的高度轮廓图; (c) 悬浮h-BN的AFM形貌图; (d) 悬浮h-BN的高度轮廓图

Fig. 3. Topography and height profile of microporous and suspended h-BN: (a) AFM topography of micropores; (b) height profile of micropores; (c) AFM topography of suspended h-BN; (d) height profile of suspended h-BN.

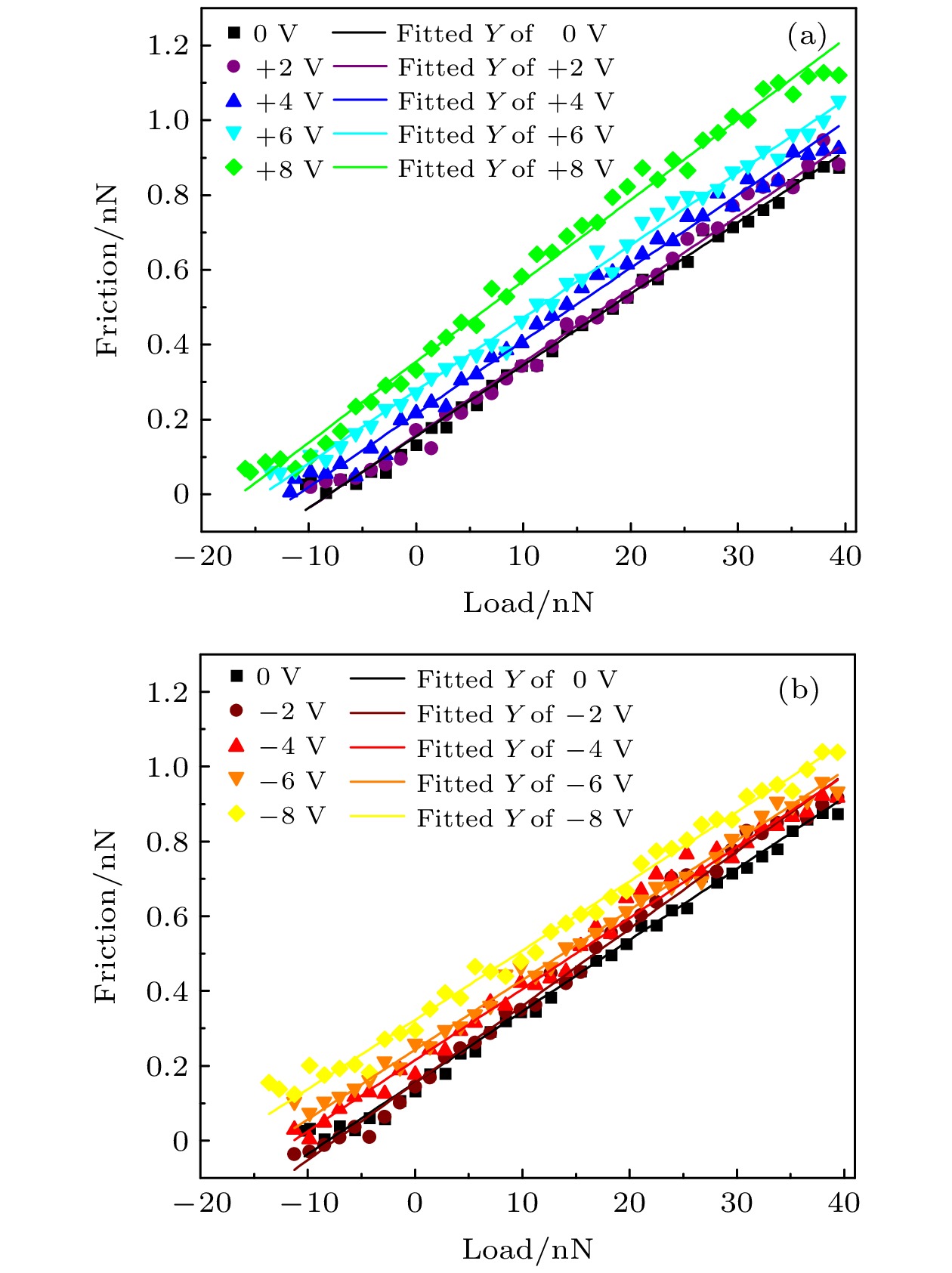

图 5 不同电场下悬浮h-BN的摩擦力-载荷关系的对比 (a) 不同正偏压下悬浮h-BN的摩擦力-载荷关系; (b) 不同负偏压下悬浮h-BN的摩擦力-载荷关系

Fig. 5. Comparison of friction-load relationship of suspended h-BN under different electric fields: (a) Friction-load relationship of suspended h-BN under different positive biases; (b) friction-load relationship of suspended h-BN under different negative biases.

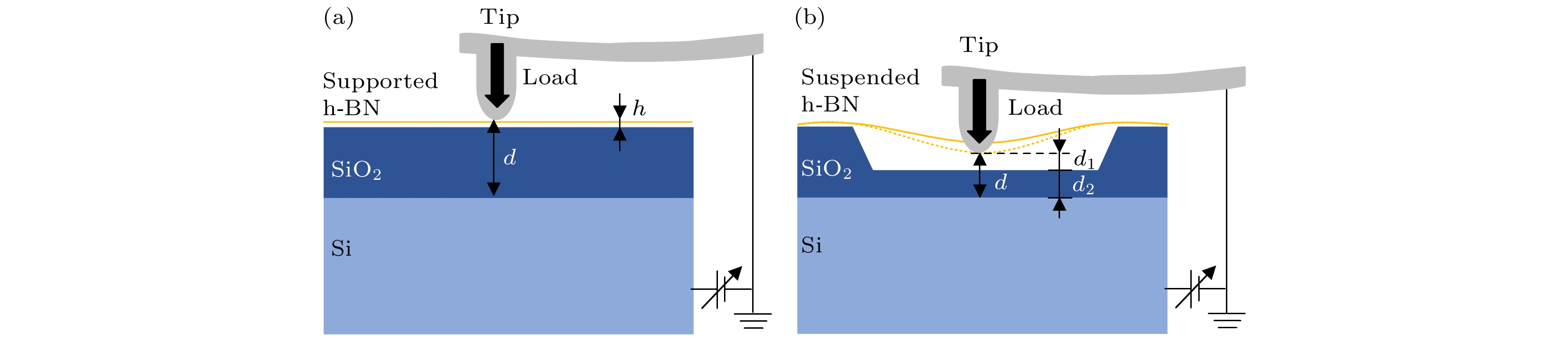

图 8 电场下支撑与悬浮状态的h-BN的摩擦力对比 (a) 电场下有基底支撑的h-BN的摩擦力图; (b) 不同偏压下有基底支撑的h-BN的摩擦力柱状图; (c) 电场下悬浮h-BN的摩擦力图; (d) 不同偏压下悬浮h-BN的摩擦力柱状图

Fig. 8. Comparison of the friction on the supported and suspended h-BN under electric fields: (a) Friction on supported h-BN under biases; (b) histogram of the friction on supported h-BN under different biases; (c) friction on suspended h-BN under biases; (d) histogram of the friction on suspended h-BN under different biases.

-

[1] 郑泉水, 欧阳稳根, 马明, 张首沫, 赵治华, 董华来, 林立 2016 科技导报 34 12

Zheng Q S, Ouyang W G, Ma M, Zhang S M, Zhao Z H, Dong H L, Lin L 2016 Sci. Technol. Rev. 34 12

[2] Zhang S, Ma T B, Erdemir A, Li Q Y 2019 Mater. Today 26 67

Google Scholar

Google Scholar

[3] Spear J C, Ewers B W, Batteas J D 2015 Nano Today 10 301

Google Scholar

Google Scholar

[4] Dean C R, Young A F, Meric I, Lee C, Wang L, Sorgenfrei S, Watanabe K, Taniguchi T, Kim P, Shepard K L 2010 Nat. Nanotechnol. 5 722

Google Scholar

Google Scholar

[5] Liu X C, Hwang E H, Yoo W J, Lee S, Cheong B K 2015 Solid State Commun. 209 1

[6] Mirkarimi P B, McCarty K F, Medlin D L 1997 Mater. Sci. Eng. R Rep. 21 47

Google Scholar

Google Scholar

[7] Martin J M, Mogne T L, Chassagnette C, Gardos M N 1992 Tribol. Trans. 35 462

Google Scholar

Google Scholar

[8] Watanabe K, Taniguchi T, Kanda H 2004 Nat. Mater. 3 404

Google Scholar

Google Scholar

[9] Lee C G, Li Q Y, Kalb W, Liu X Z, Berger H, Carpick R W, Hone J 2010 Science 328 76

Google Scholar

Google Scholar

[10] Zeng X Z, Peng Y T, Yu M C, Lang H J, Cao X A, Zou K 2018 ACS Appl. Mater. Interfaces 10 8214

Google Scholar

Google Scholar

[11] Jiang Y, Yue L L, Yan B S, Liu X, Yang X F, Tai G A, Song J 2015 Nano 10 1550038

Google Scholar

Google Scholar

[12] Lang H J, Peng Y T, Shao G W, Zou K, Tao G M 2019 J. Mater. Chem. C 7 6041

Google Scholar

Google Scholar

[13] Wagner K, Cheng P, Vezenov D 2011 Langmuir 27 4635

Google Scholar

Google Scholar

[14] Nemes-Incze P, Osváth Z, Kamarás K, Biró L P 2008 Carbon 46 1435

Google Scholar

Google Scholar

[15] Elinski M B, Menard B D, Liu Z, Batteas J D 2017 J. Phys. Chem. C 121 5635

[16] Fang L, Liu D M, Guo Y Z, Liao Z M, Luo J B, Wen S Z 2017 Nanotechnology 28 245703

Google Scholar

Google Scholar

[17] Smolyanitsky A, Killgore J P, Tewary V K 2012 Phys. Rev. B 85 035412

Google Scholar

Google Scholar

[18] Li H, Zeng X C 2012 ACS Nano 6 2401

Google Scholar

Google Scholar

[19] Kostoglou N, Polychronopoulou K, Rebholz C 2015 Vacuum 112 42

Google Scholar

Google Scholar

[20] Jean M S, Hudlet S, Guthmann C, Berger J 1999 Eur. Phys. J. B. 12 471

Google Scholar

Google Scholar

[21] Qi Y B, Park J Y, Hendriksen B L M, Ogletree D F, Salmeron M 2008 Phys. Rev. B 77 184105

Google Scholar

Google Scholar

[22] Law B M, Rieutord F 2002 Phys. Rev. B 66 035402

Google Scholar

Google Scholar

[23] Lang H J, Peng Y T, Cao X A, Zou K 2020 ACS Appl. Mater. Interfaces 12 25503

Google Scholar

Google Scholar

[24] Medyanik S N, Liu W K, Sung I H, Carpick R W 2006 Phys. Rev. Lett. 97 136106

Google Scholar

Google Scholar

计量

- 文章访问数: 7687

- PDF下载量: 97

- 被引次数: 0

下载:

下载: