-

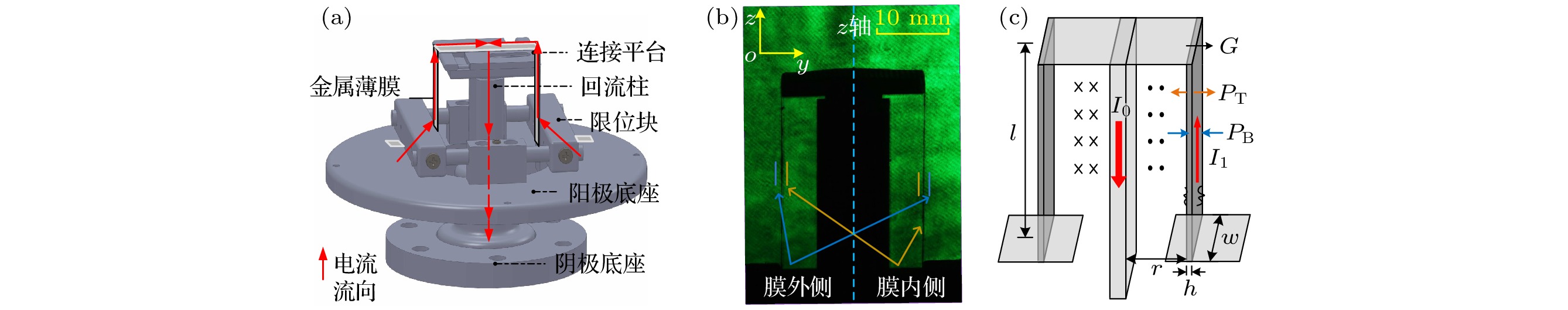

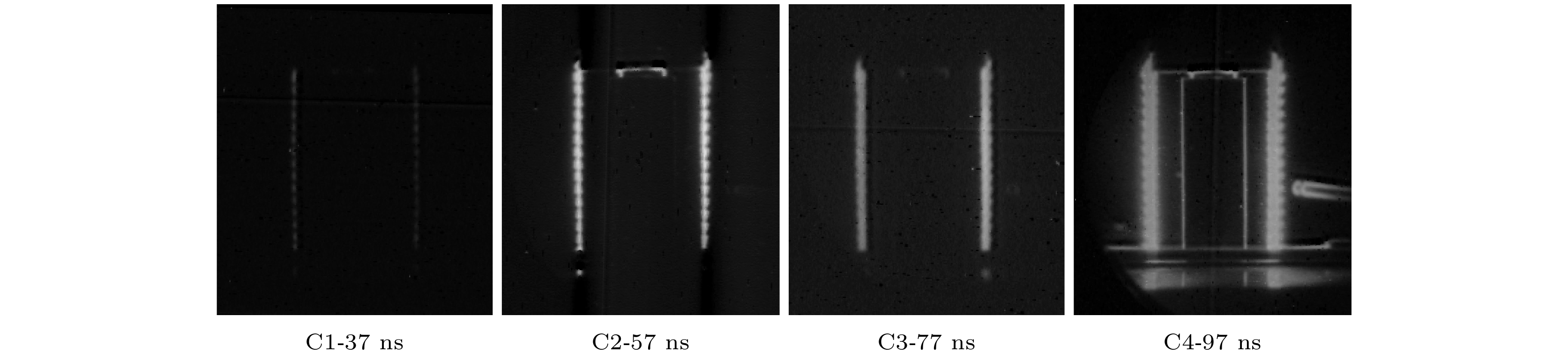

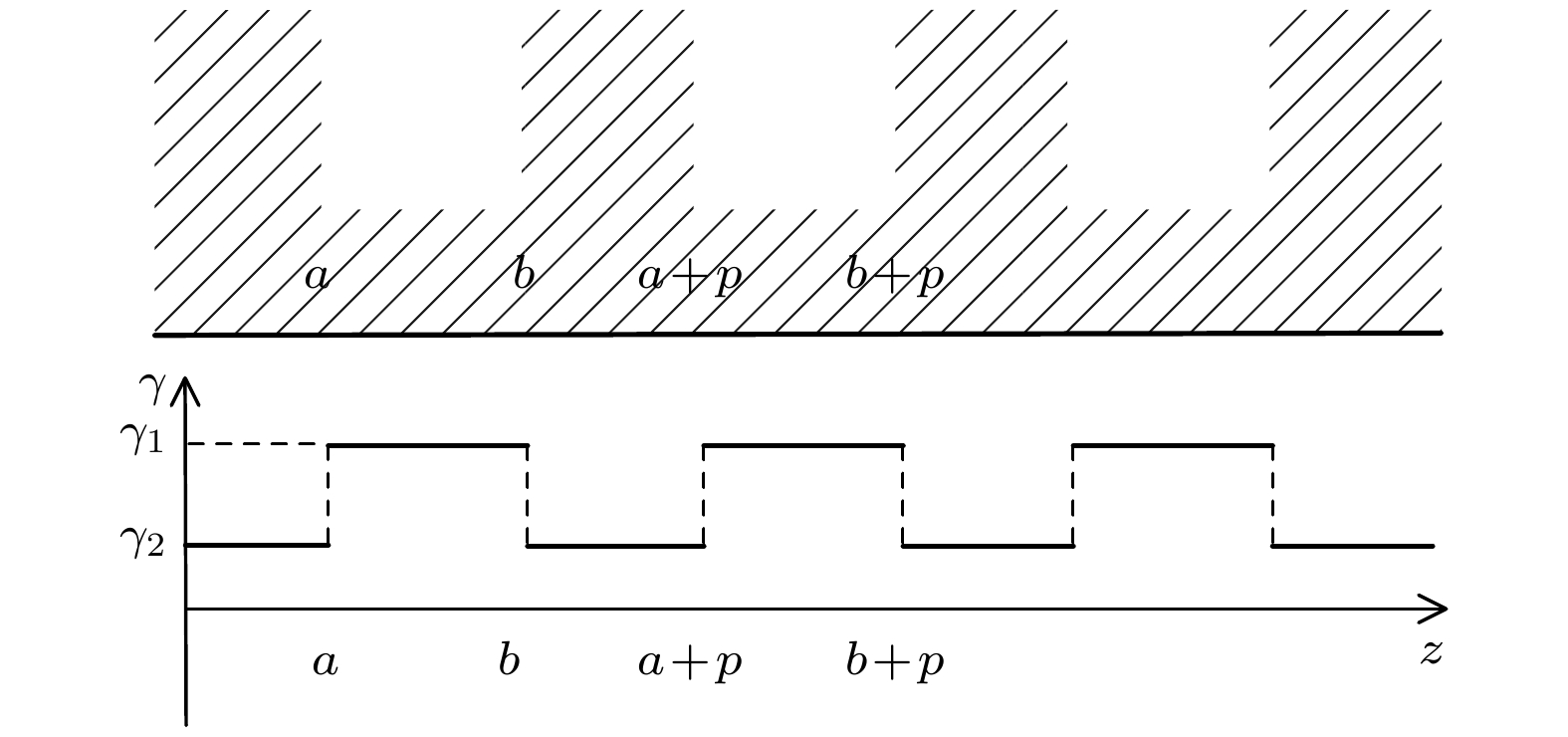

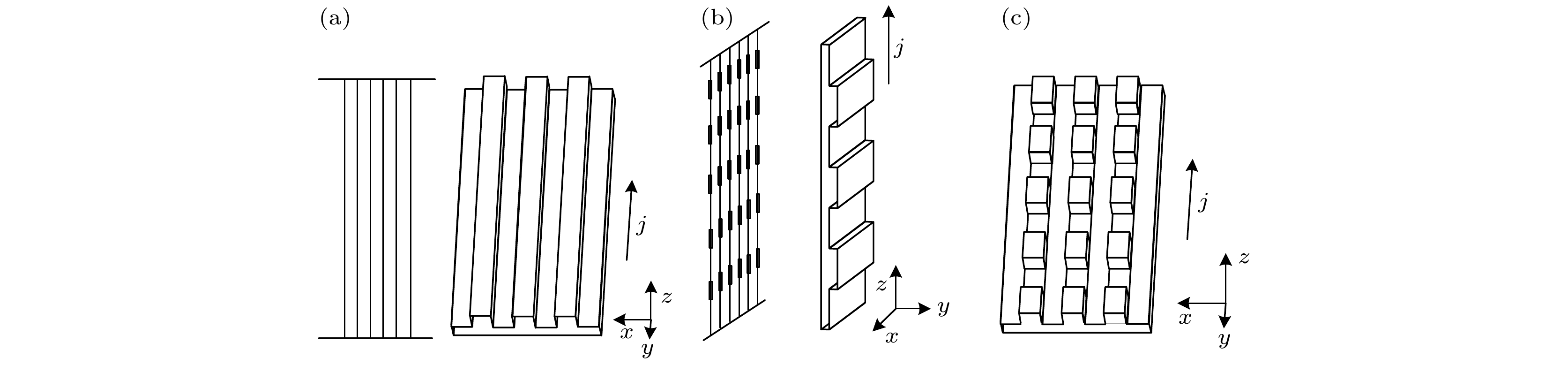

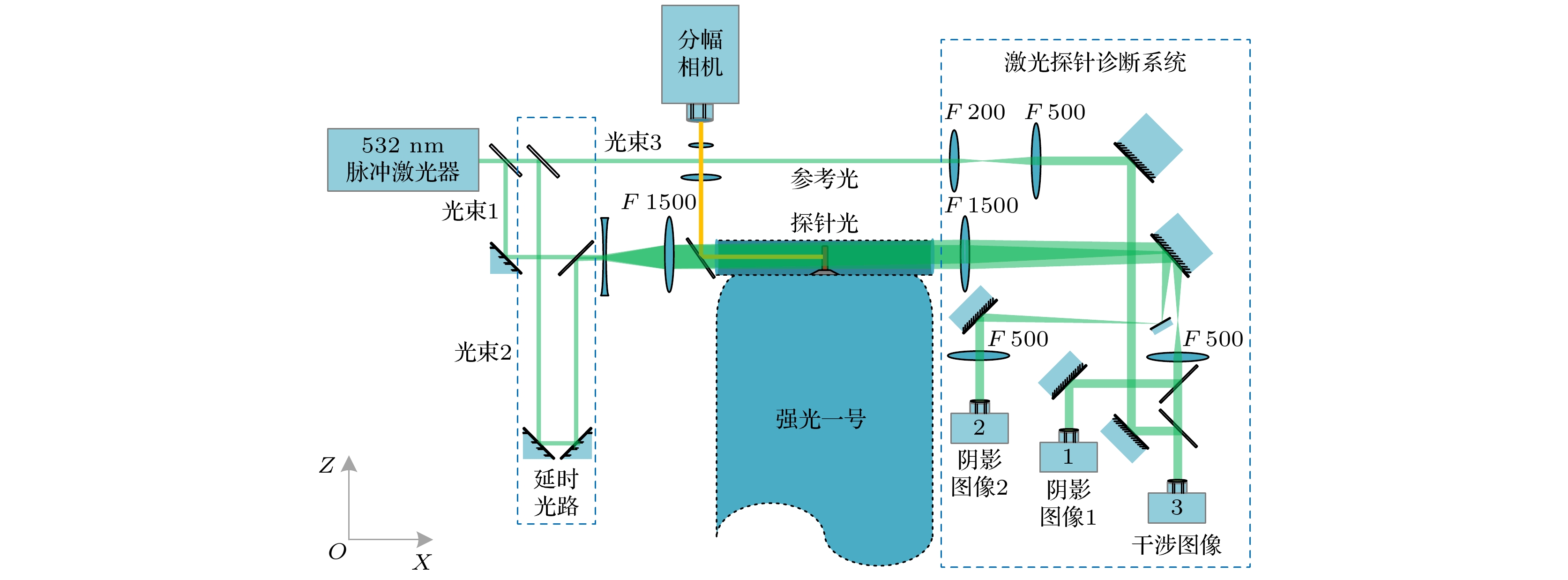

在金属层表面引入微结构以实现对Z箍缩等离子体形成和发展过程中不稳定性的调控具有重要研究价值. 在“强光一号”装置上(峰值电流~1.4 MA, 上升时间~100 ns), 开展了针对具有一维周期性凹槽调制结构的金属薄膜的电爆炸实验研究. 实验负载采用外推型平面结构, 基底为30 μm厚铝膜, 刻蚀周期为2 mm, 刻蚀深度约为10 μm. 通过激光阴影成像、激光干涉成像和可见光自辐射成像等系统进行联合诊断. 实验结果表明刻蚀结构对等离子体发展过程的不稳定性特征产生了明显调制作用, 原本征波长也受到抑制, 微结构周期对不稳定结构波长产生趋同效应; 未刻蚀一侧边界层同样受刻蚀层结构的影响, 在不稳定结构上表现出相似形貌, 且内外侧不稳定性特征的耦合关联性增强; 刻蚀凹槽处在爆炸过程中膨胀更为迅速, 形成的表面等离子体结构与初始结构反相; 在刻蚀结构的几何突变处会形成细长的等离子体喷流, 在二分之一刻蚀波长处出现波谱特征峰. 理论分析表明电流密度调制造成电热不稳定性分布改变是调控作用产生的重要原因.The fast Z-pinch plasma formation, exploding dynamics, and the evolution of the instability can be controlled experimentally by making special structures on metal surface layer to change the initial state of material, which is valuable for studying the Z-pinch physics. Experiments on the explosion of thin flat foils which have been etched into a periodical structure on surface are performed on the QG-1 facility (~1.4 MA peak current, ~100 ns rise time) in order to study the effects of different surface conditions on explosion and control the evolution of the instability in fast Z-pinch plasma. A kind of inverse load configuration is used in experiment in which the return current post is set at the central axial-position and two modified flat foils are strained outside symmetrically as the main load. So the corresponding J × B force directs outward from the return current post orthogonal to the foil plane, creating an acceleration and pushing the foil plasma away from the center in this configuration. Different surfaces of the foil are also investigated in different conditions because of the asymmetric magnetic field distribution which is useful to study the different evolutions of instability. The foils used in the experiment mainly are the 30-μm-thick aluminum foil. The wavelength of groove perturbations seeded on the surface is 2 mm wide and ~10 μm deep. The plasma explosion dynamic behaviors around conditioned area are diagnosed by laser shadowgraphy, laser interferometry, multiframe optical self-emission imaging and B-dot. It is found that the initially etched periodical structure on surface can control the plasma structure in exploding process which can be concluded as follows. Developing plasma structure shows a periodic character similar to the initial surface structure and the eigenwavelength of the Al is suppressed. In the meantime, the surface without etched perturbations is also influenced by the etched side, showing a similar instability structure but with a lower amplitude. The correlation between two surfaces turns stronger than the case of normal foils. A faster expanding rate occurs in the deep region of the initial periodical groove structure which causes a reverse structure to form. In the discontinuous area of the conditoned structure, a narrow stream of plasma jets perpendicularly from the metal surface which causes a half-wavelength to occur in spectrum analysis. The magneto-hydro-dynamic theory analysis shows that the change of electrothermal instabilities is caused dominantly by the modulation of current density flowing around the periodical structure.

-

Keywords:

- exploding foils /

- planar configuration /

- periodical modified structure /

- electrothermal instability

[1] Jones B, Deeney C, McKenney J L, Garasi C J, Mehlhorn T A, Robinson A C, Wunsch S E, Bland S N, Lebedev S V, Chittenden J P, Bott S C, Ampleford D J, Palmer J B A, Rapley J, Hall G N, Oliver B V 2005 Phys. Rev. Lett. 95 225001

Google Scholar

Google Scholar

[2] Hall G N 2007 Ph. D. Dissertation (London: Science of the University of London)

[3] Hall G N, Chittenden J P, Bland S N, Lebedev S V, Bott S C, Jennings C, Palmer J B A, Suzuki-Vidal F 2008 Phys. Rev. Lett. 100 065003

Google Scholar

Google Scholar

[4] 盛亮, 李阳, 吴坚, 袁媛, 赵吉祯, 张美, 彭博栋, 黑东炜 2014 63 205203

Google Scholar

Google Scholar

Sheng L, Li Y, Wu J, Yuan Y, Zhao J Z, Zhang M, Peng B D, Hei D W 2014 Acta Phys. Sin. 63 205203

Google Scholar

Google Scholar

[5] 盛亮, 李阳, 袁媛, 彭博栋, 李沫, 张美, 赵吉祯, 魏福利, 王亮平, 黑东炜, 邱爱慈 2014 63 055201

Google Scholar

Google Scholar

Sheng L, Li Y, Yuan Y, Peng B D, Li M, Zhang M, Zhao J Z, Wei F L, Wang L P, Hei D W, Qiu A C 2014 Acta Phys. Sin. 63 055201

Google Scholar

Google Scholar

[6] Slutz S A, Herrmann M C, Vesey R A, Sefkow A B, Sinars D B, Rovang D C, Peterson K J, Cuneo M E 2010 Phys. Plasmas 17 056303

Google Scholar

Google Scholar

[7] Slutz S A, Vesey R A 2012 Phys. Rev. Lett. 108 025003

Google Scholar

Google Scholar

[8] Sinars D B, Slutz S A, Herrmann M C, McBride R D, Cuneo M E, Peterson K J, Vesey R A, Nakhleh C, Blue B E, Killebrew K, Schroen D, Tomlinson K, Edens A D, Lopez M R, Smith I C, Shores J, Bigman V, Bennett G R, Atherton B W, Savage M, Stygar W A, Leifeste G T, Porter J L 2010 Phys. Rev. Lett. 105 185001

Google Scholar

Google Scholar

[9] Sinars D B, Slutz S A, Herrmann M C, McBride R D, Cuneo M E, Jennings C A, Chittenden J P, Velikovich A L, Peterson K J, Vesey R A, Nakhleh C, Waisman E M, Blue B E, Killebrew K, Schroen D, Tomlinson K, Edens A D, Lopez M R, Smith I C, Shores J, Bigman V, Bennett G R, Atherton B W, Savage M, Stygar W A, Leifeste G T, Porter J L 2011 Phys. Plasmas 18 056301

Google Scholar

Google Scholar

[10] Awe T J, Jennings C A, McBride R D, Cuneo M E, Lamppa D C, Martin M R, Rovang D C, Sinars D B, Slutz S A, Owen A C, Tomlinson K, Gomez M R, Hansen S B, Herrmann M C, Jones M C, McKenney J L, Robertson G K, Rochau G A, Savage M E, Schroen D G, Stygar W A 2014 Phys. Plasmas 21 056303

Google Scholar

Google Scholar

[11] Awe T J, Peterson K J, Yu E P, McBride R D, Sinars D B, Gomez M R, Jennings C A, Martin M R, Rosenthal S E, Schroen D G, Sefkow A B, Slutz S A, Tomlinson K, Vesey R A 2016 Phys. Rev. Lett. 116 065001

Google Scholar

Google Scholar

[12] Kantsyrev V L, Chuvatin A S, Safronova A S, Rudakov L I, Esaulov A A, Velikovich A L, Shrestha I, Astanovitsky A, Osborne G C, Shlyaptseva V V, Weller M E, Keim S, Stafford A, Cooper M 2014 Phys. Plasmas 21 031204

Google Scholar

Google Scholar

[13] Lau Y Y, Zier J C, Rittersdorf I M, Weis M R, Gilgenbach R M 2011 Phys. Rev. E 83 066405

Google Scholar

Google Scholar

[14] Zier J C, Gilgenbach R M, Chalenski D A, Lau Y Y, French D M, Gomez M R, Patel S G, Rittersdorf I M, Steiner A M, Weis M, Zhang P, Mazarakis M, Cuneo M E, Lopez M 2012 Phys. Plasmas 19 032701

Google Scholar

Google Scholar

[15] Shelkovenko T A, Pikuz S A, Tilikin I N, Romanova V M, Mishin S N, Atoyan L, Hammer D A 2018 IEEE Trans. Plasma Sci. 46 3741

Google Scholar

Google Scholar

[16] Shelkovenko T A, Pikuz S A, Tilikin I N, Mingaleev A R, Atoyan L, Hammer D A 2018 Plasma Phys. Rep. 44 236

Google Scholar

Google Scholar

[17] Shelkovenko T A, Pikuz S A, Hammer D A 2016 Plasma Phy. Rep. 42 226

Google Scholar

Google Scholar

[18] Rousskikh A G, Zhigalin A S, Oreshkin V I, Baksht R B 2020 Phys. Plasmas 27 033505

Google Scholar

Google Scholar

[19] Clayson T, Lebedev S V, Suzuki-Vidal F, Burdiak G C, Halliday J W D, Hare J D, Ma J, Suttle L G, Tubman E R 2018 IEEE Trans. Plasma Sci. 46 3734

Google Scholar

Google Scholar

[20] Hu Min, Kusse B R 2005 Phys. Plasmas 12 102701

Google Scholar

Google Scholar

[21] Bland S N, Lebedev S V, Chittenden J P, Ampleford D J, Tang G 2004 Phys. Plasmas 11 4911

Google Scholar

Google Scholar

[22] Swadling G F, Lebedev S V, Hall G N, Patankar S, Stewart N H, Smith R A, Harvey-Thompson A J, Burdiak G C, de Grouchy P, Skidmore J, Suttle L, Suzuki-Vidal F, Bland S N, Kwek K H, Pickworth L, Bennett M, Hare J D, Rozmus W, Yuan J 2014 Rev. Sci. Instrum. 85 11E502

Google Scholar

Google Scholar

[23] Peterson K J, Awe T J, Yu E P, Sinars D B, Field E S, Cuneo M E, Herrmann M C, Savage M, Schroen D, Tomlinson K, Nakhleh C 2014 Phys. Rev. Lett. 112 135002

Google Scholar

Google Scholar

[24] Oreshkin V I 2008 Phys. Plasmas 15 092103

Google Scholar

Google Scholar

-

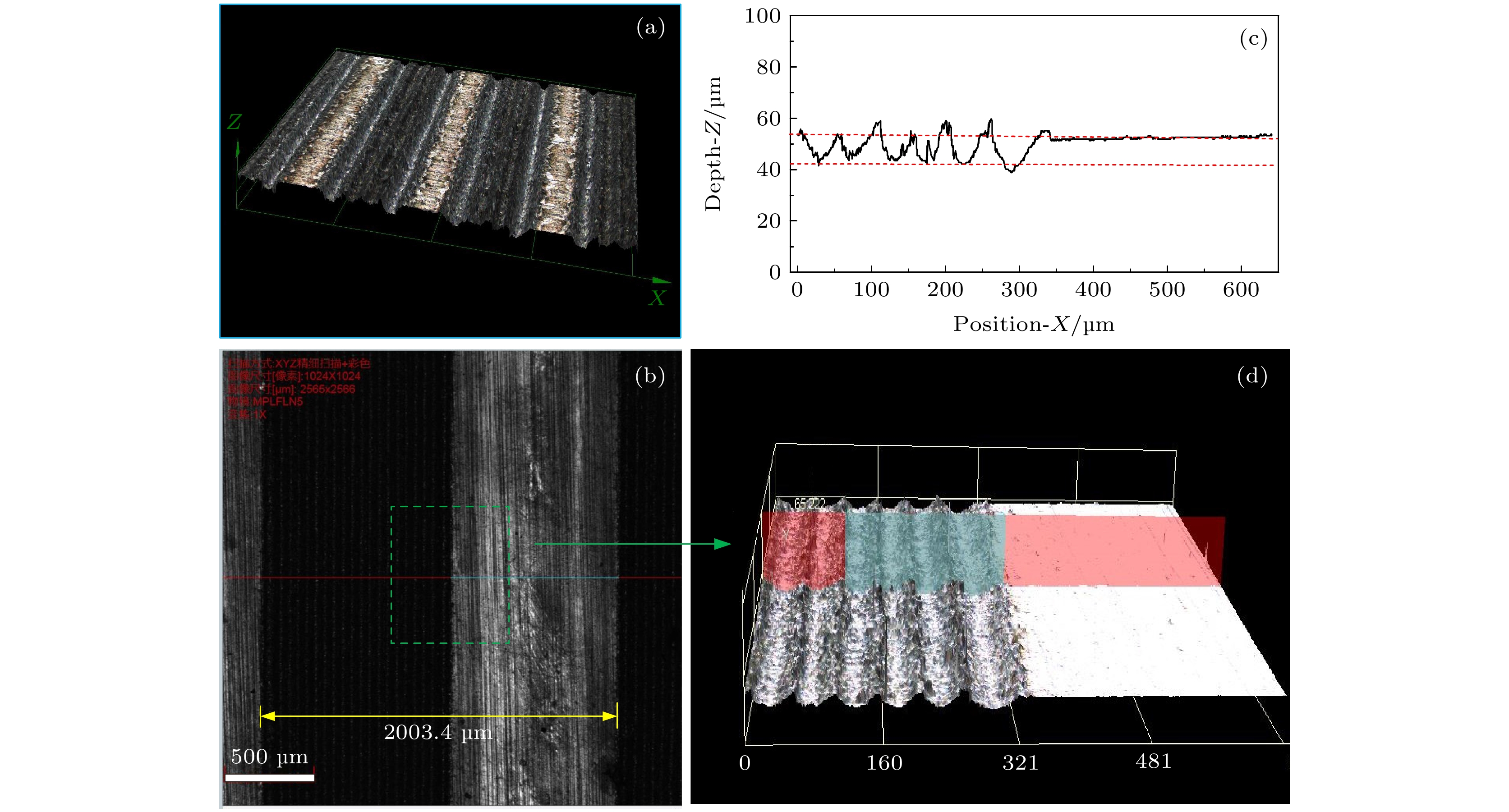

图 3 铝膜表面凹槽型周期刻蚀结构共聚焦显微镜扫描图 (a) 刻蚀结构三维形貌图; (b) 二维平面扫描图, 其单个刻蚀周期长度测量值为2003.4 μm; (c) 方框区域深度扫描曲线, 红线间距为10.2 μm; (d) 方框对应区域放大形貌

Fig. 3. Scanning graph of the periodical groove structure exploited on Al foil surface which was measured by confocal imaging microscope: (a) Three-dimensional scanning image; (b) surface scanning image which shows that the measured period of structure is 2003.4 μm; (c) the depth curve in which the etched depth between the red lines is 10.2 μm; (d) the enlarged image corresponding to the region of green box in (b).

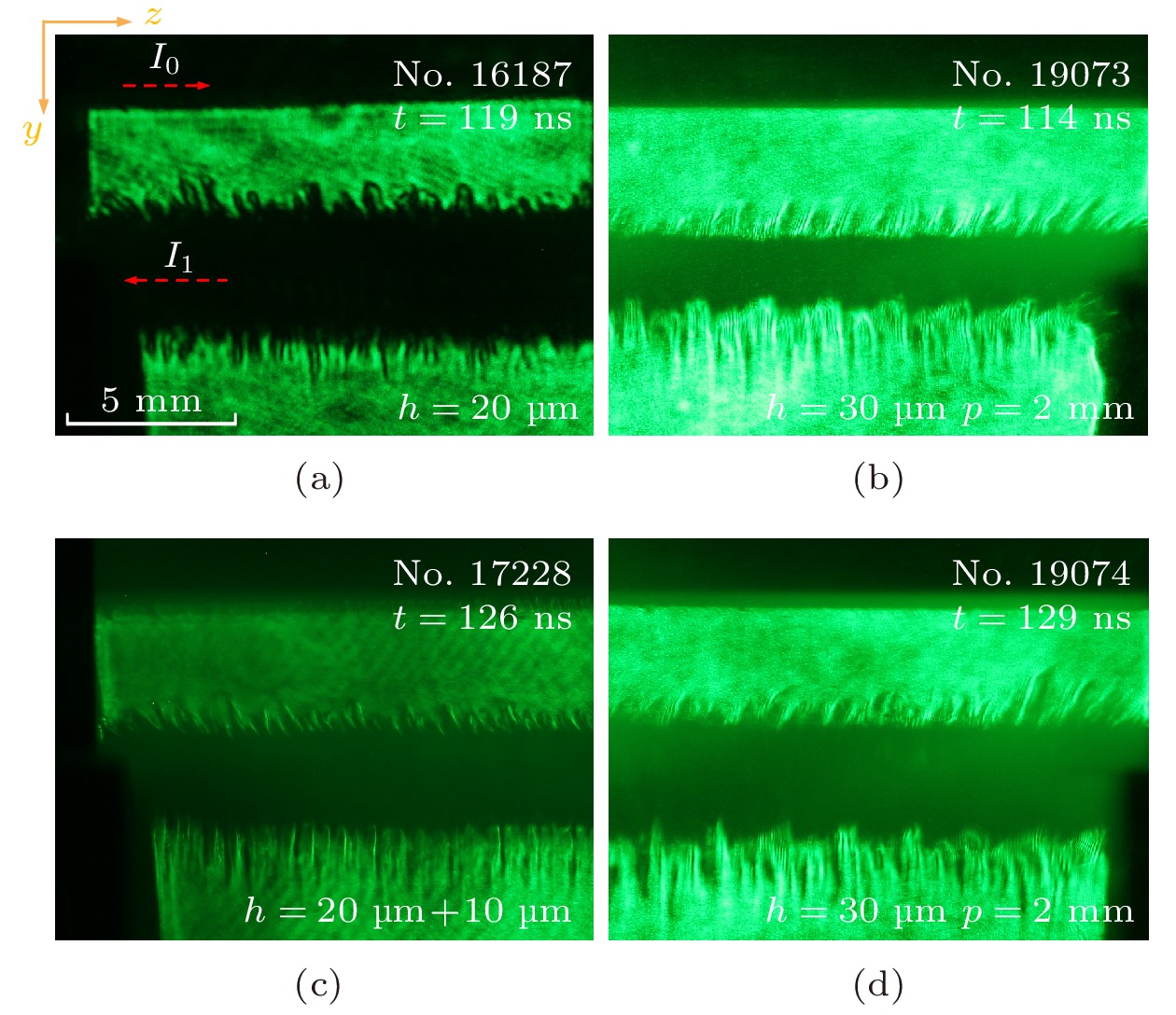

图 5 不同调制铝膜实验过程激光阴影图对比 (a) 标准铝膜119 ns时刻图(No. 16187); (b) 2 mm刻蚀周期结构铝膜114 ns时刻图(No. 19073); (c) 镀膜铝膜126 ns时刻图(No. 17228); (d) 2 mm刻蚀周期铝膜129 ns时刻图(No. 19074)

Fig. 5. Laser shadow graphy images for different Al foils in experiments: (a) Normal Al foil at 119 ns of No. 16187; (b) Al foil with 2 mm etched periodical structure at 114 ns of No. 19073; (c) coated Al foil at 126 ns of No. 17228; (d) Al foil with 2 mm etched periodical structure at 129 ns of No. 19074.

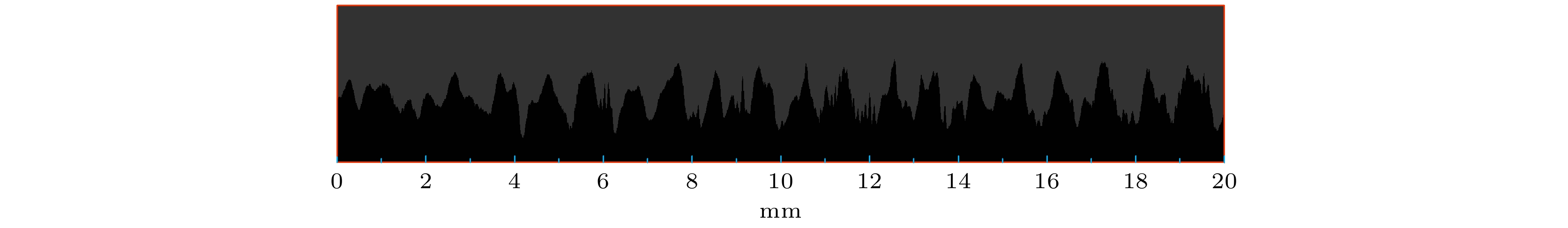

图 6 边界不稳定结构波谱分析 (a) 标准铝膜, No. 16187; (b) 2 mm刻蚀周期结构铝膜, No. 19073; (c) 镀膜铝膜, No. 17228; (d) 2 mm刻蚀周期结构铝膜, No. 19074

Fig. 6. Wavelength spectra analysis of the instability structure in experiments: (a) No. 16187 for normal case; (b) No. 19073 for 2 mm periodical structure sample; (c) No. 17228 for coated sample; (d) No. 19074 for 2 mm periodical structure sample.

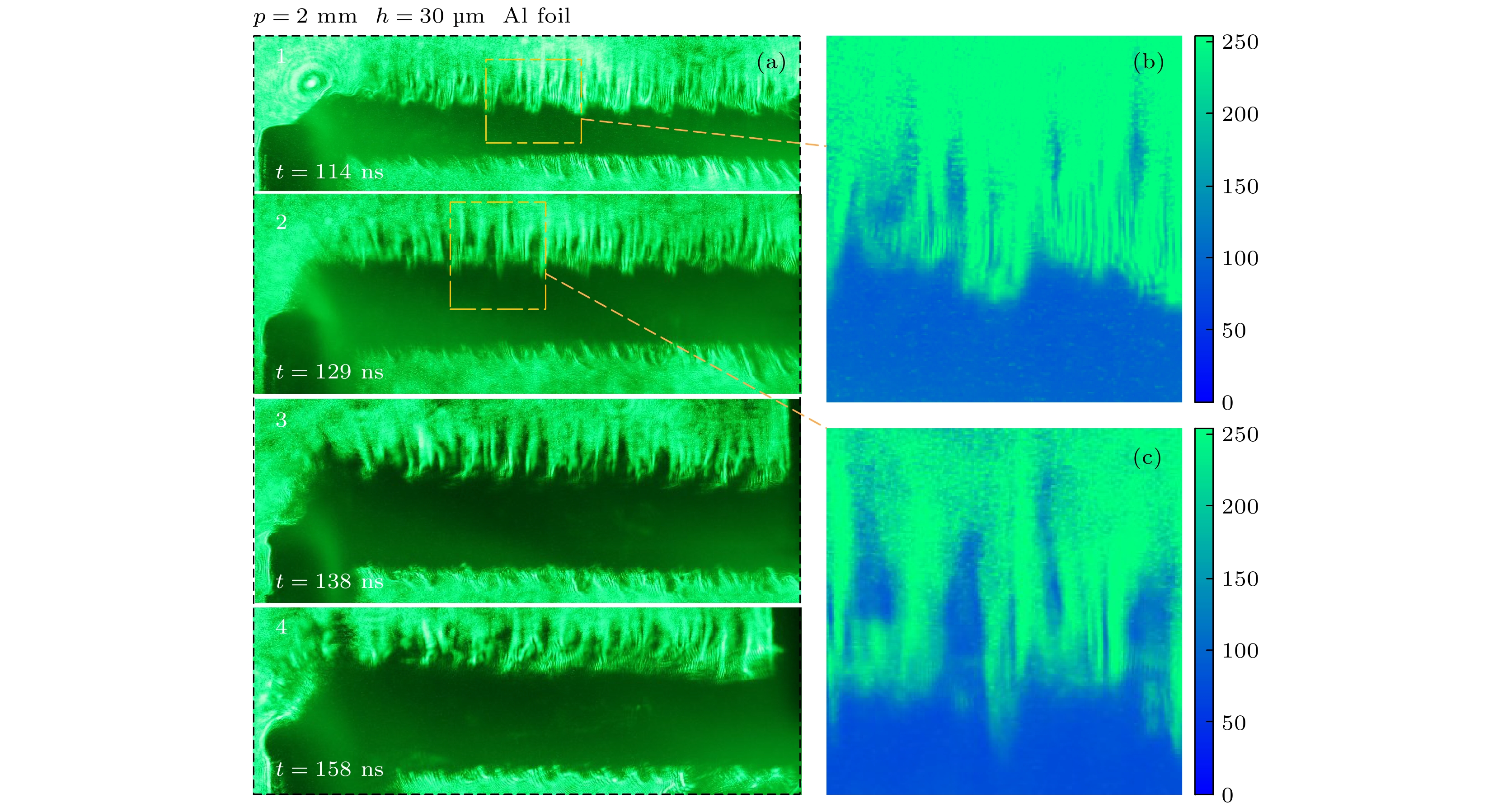

图 9 2 mm刻蚀周期铝膜激光阴影图序列 (a) 实验发次与对应时刻, No. 19073-114 ns, No. 19074-129 ns, No. 19072-138 ns, No. 19060-158 ns; (b) 114 ns时刻下局部结构放大伪色图; (c) 129 ns时刻下局部结构放大伪色图; (b), (c)中右侧标尺代表颜色域与灰度值的对应关系

Fig. 9. Laser shadow graphy image sequence for the Al foils with 2 mm periodical structure: (a) Corresponding shot numbers are No. 19073-114 ns, No. 19074-129 ns, No. 19072-138 ns, No. 19060-158 ns; (b) enlarged image of the box at 114 ns; (c) enlarged image of the box at 129 ns. Flase color has been added in (b) and (c) where the corresponding relationship between color and gray-scale value is shown in the label on the right.

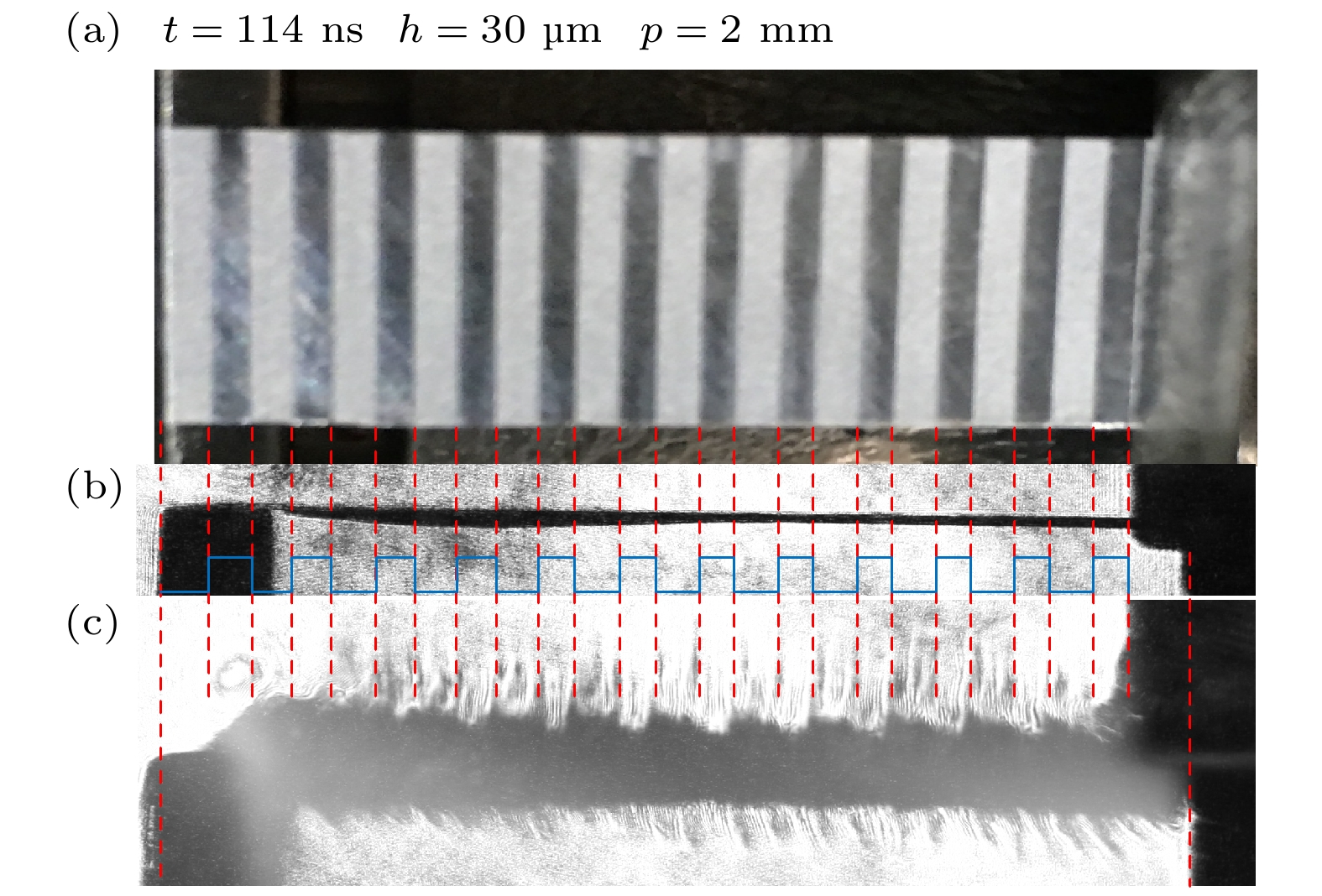

图 10 初始薄膜刻蚀结构与实验发展过程结构对照 (a) 初始薄膜实物放置图; (b)初始状态侧向激光阴影成像图; (c) 实验激光阴影成像图

Fig. 10. Initial structure of foil surface comparing with developing plasma structure in experiments: (a) The photograph of actual etched foil; (b) the side-on laser shadow graphy image of Al foil before experiment; (c) corresponding shadow graphy image in experiment.

表 1 金属薄膜参数

Table 1. Parameters of the foils used in the exploding experiments.

材料M 厚度 h/μm 刻蚀槽深d/μm 刻蚀周期p/mm 宽度w/mm 长度l/mm 中心距r/mm 铝(刻蚀) 30 10 2 1 2 10 铝(镀膜) 20 + 10 (PI) # # 1 2 10 铝(标准) 20 # # 1 2 10 注: PI表示聚酰亚胺有机膜, #表示无刻蚀结构. -

[1] Jones B, Deeney C, McKenney J L, Garasi C J, Mehlhorn T A, Robinson A C, Wunsch S E, Bland S N, Lebedev S V, Chittenden J P, Bott S C, Ampleford D J, Palmer J B A, Rapley J, Hall G N, Oliver B V 2005 Phys. Rev. Lett. 95 225001

Google Scholar

Google Scholar

[2] Hall G N 2007 Ph. D. Dissertation (London: Science of the University of London)

[3] Hall G N, Chittenden J P, Bland S N, Lebedev S V, Bott S C, Jennings C, Palmer J B A, Suzuki-Vidal F 2008 Phys. Rev. Lett. 100 065003

Google Scholar

Google Scholar

[4] 盛亮, 李阳, 吴坚, 袁媛, 赵吉祯, 张美, 彭博栋, 黑东炜 2014 63 205203

Google Scholar

Google Scholar

Sheng L, Li Y, Wu J, Yuan Y, Zhao J Z, Zhang M, Peng B D, Hei D W 2014 Acta Phys. Sin. 63 205203

Google Scholar

Google Scholar

[5] 盛亮, 李阳, 袁媛, 彭博栋, 李沫, 张美, 赵吉祯, 魏福利, 王亮平, 黑东炜, 邱爱慈 2014 63 055201

Google Scholar

Google Scholar

Sheng L, Li Y, Yuan Y, Peng B D, Li M, Zhang M, Zhao J Z, Wei F L, Wang L P, Hei D W, Qiu A C 2014 Acta Phys. Sin. 63 055201

Google Scholar

Google Scholar

[6] Slutz S A, Herrmann M C, Vesey R A, Sefkow A B, Sinars D B, Rovang D C, Peterson K J, Cuneo M E 2010 Phys. Plasmas 17 056303

Google Scholar

Google Scholar

[7] Slutz S A, Vesey R A 2012 Phys. Rev. Lett. 108 025003

Google Scholar

Google Scholar

[8] Sinars D B, Slutz S A, Herrmann M C, McBride R D, Cuneo M E, Peterson K J, Vesey R A, Nakhleh C, Blue B E, Killebrew K, Schroen D, Tomlinson K, Edens A D, Lopez M R, Smith I C, Shores J, Bigman V, Bennett G R, Atherton B W, Savage M, Stygar W A, Leifeste G T, Porter J L 2010 Phys. Rev. Lett. 105 185001

Google Scholar

Google Scholar

[9] Sinars D B, Slutz S A, Herrmann M C, McBride R D, Cuneo M E, Jennings C A, Chittenden J P, Velikovich A L, Peterson K J, Vesey R A, Nakhleh C, Waisman E M, Blue B E, Killebrew K, Schroen D, Tomlinson K, Edens A D, Lopez M R, Smith I C, Shores J, Bigman V, Bennett G R, Atherton B W, Savage M, Stygar W A, Leifeste G T, Porter J L 2011 Phys. Plasmas 18 056301

Google Scholar

Google Scholar

[10] Awe T J, Jennings C A, McBride R D, Cuneo M E, Lamppa D C, Martin M R, Rovang D C, Sinars D B, Slutz S A, Owen A C, Tomlinson K, Gomez M R, Hansen S B, Herrmann M C, Jones M C, McKenney J L, Robertson G K, Rochau G A, Savage M E, Schroen D G, Stygar W A 2014 Phys. Plasmas 21 056303

Google Scholar

Google Scholar

[11] Awe T J, Peterson K J, Yu E P, McBride R D, Sinars D B, Gomez M R, Jennings C A, Martin M R, Rosenthal S E, Schroen D G, Sefkow A B, Slutz S A, Tomlinson K, Vesey R A 2016 Phys. Rev. Lett. 116 065001

Google Scholar

Google Scholar

[12] Kantsyrev V L, Chuvatin A S, Safronova A S, Rudakov L I, Esaulov A A, Velikovich A L, Shrestha I, Astanovitsky A, Osborne G C, Shlyaptseva V V, Weller M E, Keim S, Stafford A, Cooper M 2014 Phys. Plasmas 21 031204

Google Scholar

Google Scholar

[13] Lau Y Y, Zier J C, Rittersdorf I M, Weis M R, Gilgenbach R M 2011 Phys. Rev. E 83 066405

Google Scholar

Google Scholar

[14] Zier J C, Gilgenbach R M, Chalenski D A, Lau Y Y, French D M, Gomez M R, Patel S G, Rittersdorf I M, Steiner A M, Weis M, Zhang P, Mazarakis M, Cuneo M E, Lopez M 2012 Phys. Plasmas 19 032701

Google Scholar

Google Scholar

[15] Shelkovenko T A, Pikuz S A, Tilikin I N, Romanova V M, Mishin S N, Atoyan L, Hammer D A 2018 IEEE Trans. Plasma Sci. 46 3741

Google Scholar

Google Scholar

[16] Shelkovenko T A, Pikuz S A, Tilikin I N, Mingaleev A R, Atoyan L, Hammer D A 2018 Plasma Phys. Rep. 44 236

Google Scholar

Google Scholar

[17] Shelkovenko T A, Pikuz S A, Hammer D A 2016 Plasma Phy. Rep. 42 226

Google Scholar

Google Scholar

[18] Rousskikh A G, Zhigalin A S, Oreshkin V I, Baksht R B 2020 Phys. Plasmas 27 033505

Google Scholar

Google Scholar

[19] Clayson T, Lebedev S V, Suzuki-Vidal F, Burdiak G C, Halliday J W D, Hare J D, Ma J, Suttle L G, Tubman E R 2018 IEEE Trans. Plasma Sci. 46 3734

Google Scholar

Google Scholar

[20] Hu Min, Kusse B R 2005 Phys. Plasmas 12 102701

Google Scholar

Google Scholar

[21] Bland S N, Lebedev S V, Chittenden J P, Ampleford D J, Tang G 2004 Phys. Plasmas 11 4911

Google Scholar

Google Scholar

[22] Swadling G F, Lebedev S V, Hall G N, Patankar S, Stewart N H, Smith R A, Harvey-Thompson A J, Burdiak G C, de Grouchy P, Skidmore J, Suttle L, Suzuki-Vidal F, Bland S N, Kwek K H, Pickworth L, Bennett M, Hare J D, Rozmus W, Yuan J 2014 Rev. Sci. Instrum. 85 11E502

Google Scholar

Google Scholar

[23] Peterson K J, Awe T J, Yu E P, Sinars D B, Field E S, Cuneo M E, Herrmann M C, Savage M, Schroen D, Tomlinson K, Nakhleh C 2014 Phys. Rev. Lett. 112 135002

Google Scholar

Google Scholar

[24] Oreshkin V I 2008 Phys. Plasmas 15 092103

Google Scholar

Google Scholar

计量

- 文章访问数: 7391

- PDF下载量: 65

- 被引次数: 0

下载:

下载: