-

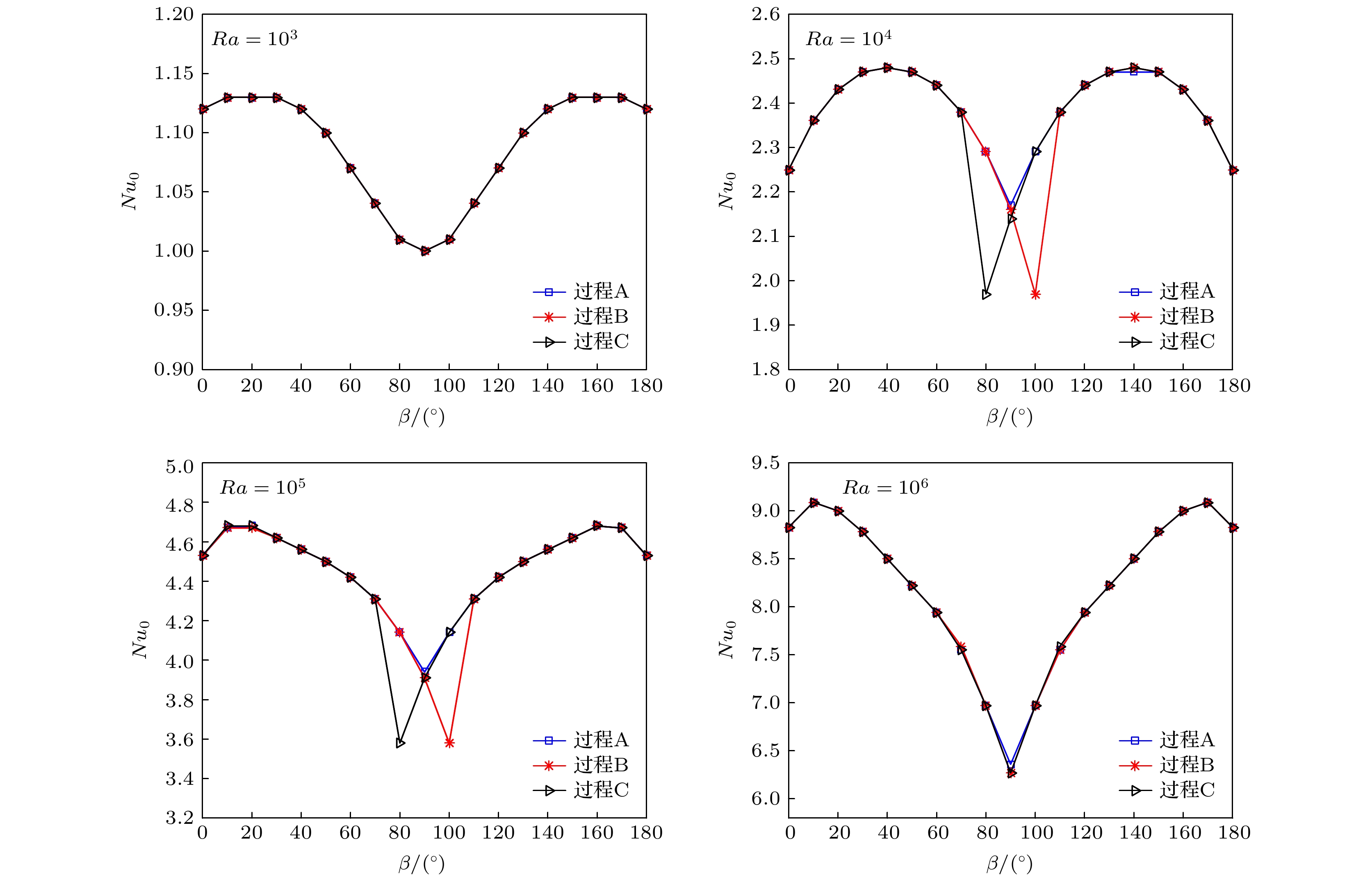

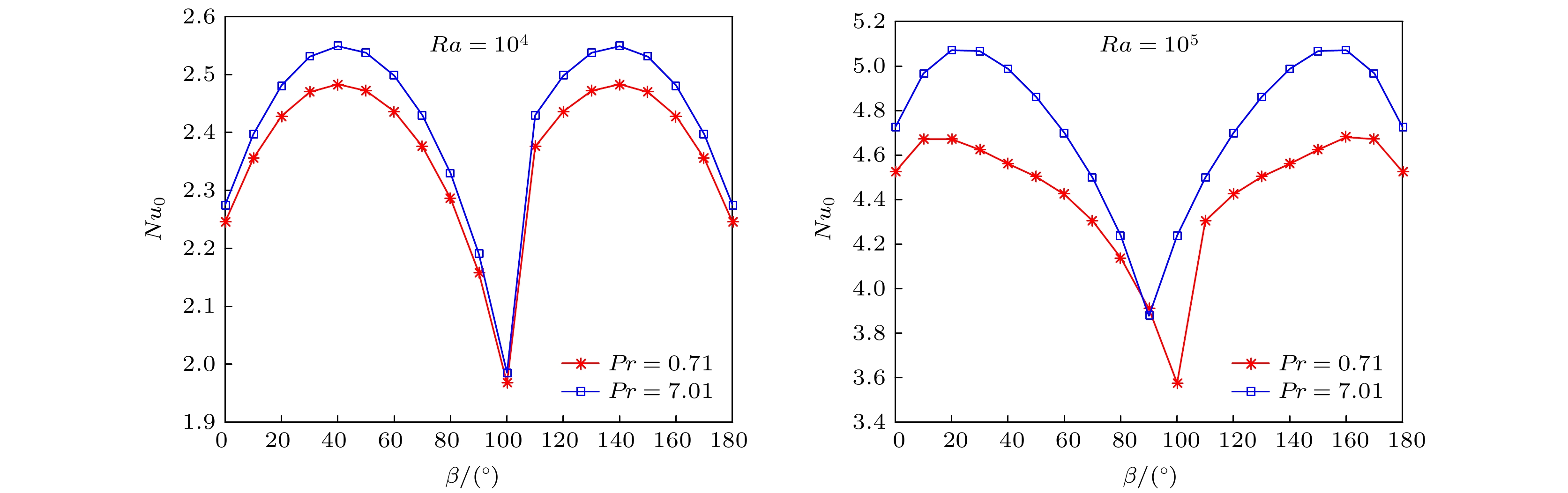

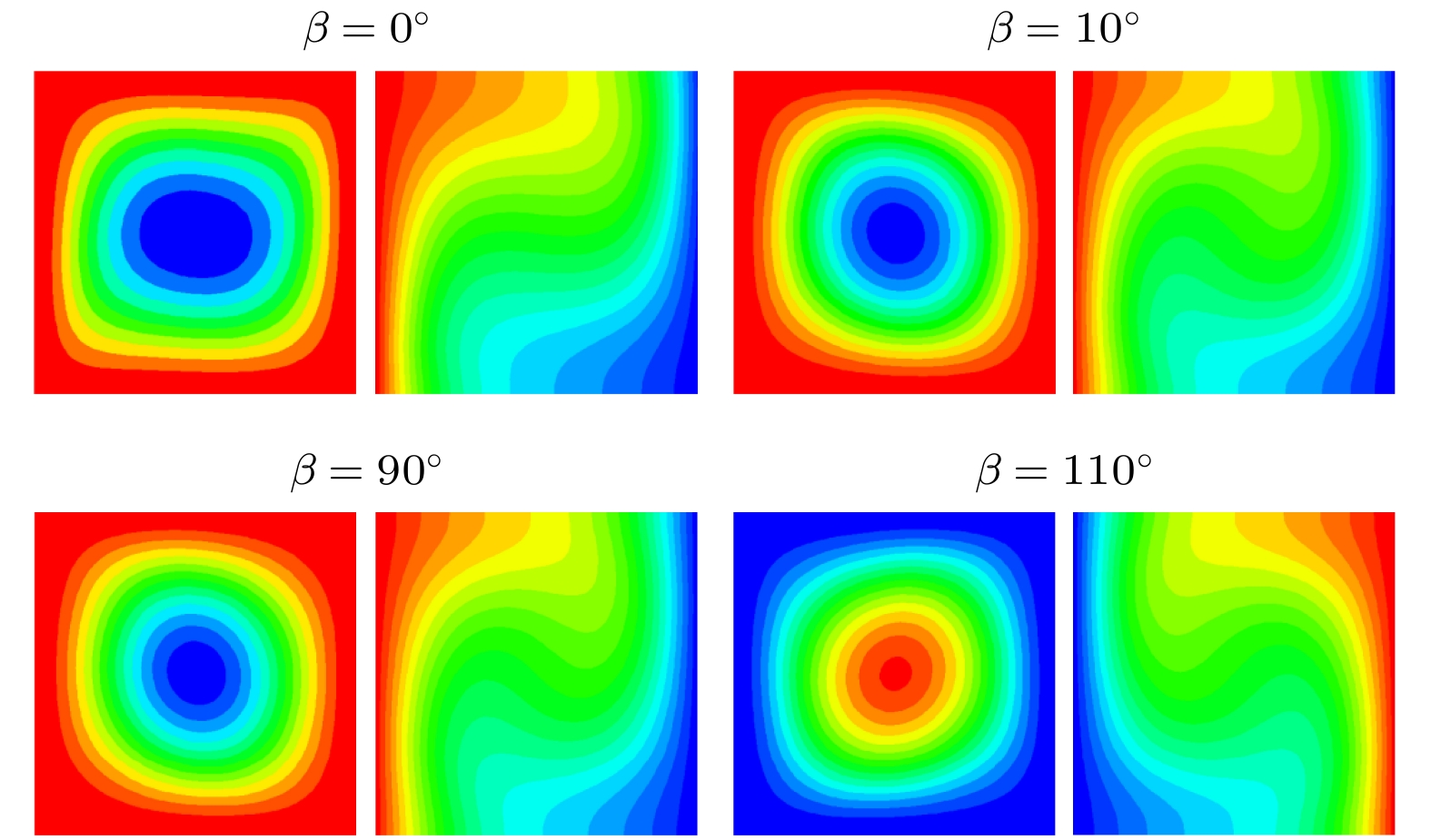

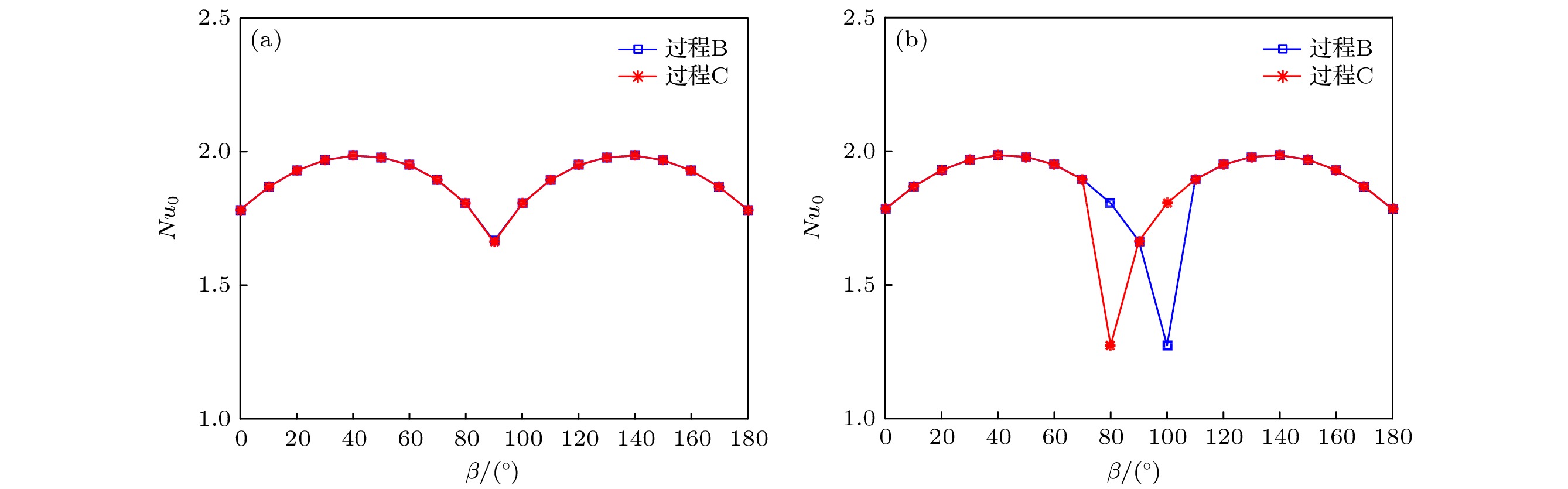

倾斜封闭腔内对流换热问题是非线性非平衡系统中研究的热点问题之一. 本文采用高精度数值方法对倾斜方腔内流体热对流进行了直接数值模拟, 研究了腔体倾角在

$0^\circ— 180^\circ$ 之间变化时, 倾角的不同变化过程对流场非线性演化、传热效率以及流动分岔的影响. 所考虑的Rayleigh数范围为$10^3— 10^6$ . 结果表明: 表征传热效率的Nusselt 数对Rayleigh数、Prandtl数及倾斜角度均具有较强依赖性, 在较高Rayleigh数时, Nusselt数会在80°和100°附近产生较大幅度的变化; 高Rayleigh 数下流场及温度场的演变更为复杂, 腔体内存在1—3个对流强度不等的涡卷; 低Rayleigh数下腔体倾角接近90°时流动状态为热传导状态. 当腔体倾角介于$70^\circ— 110^\circ$ 之间时, 在Rayleigh数$Ra\in(4949,314721)$ 内存在解的两条稳定分支.Heat transfer of natural convection in inclined cavities is one of the hot research topics in nonlinear non-equilibrium systems. In this paper, direct numerical simulations of natural convection in an inclined square cavity are carried out by using a high-accuracy numerical method. The effects of the different trends of inclination angle in a range of 0°–180° on the nonlinear evolution of flow field, heat transfer efficiency, and bifurcation are investigated. The Rayleigh number varies in a range from 103 to 106. The results show that the heat transfer efficiency characterized by Nusselt number is highly dependent on the Rayleigh number, Prandtl number, and the inclination angle. When the Rayleigh number is high, the Nusselt number will have a small jump near the inclination angle in a range of 80°–100°. The evolution of the flow field and temperature field are more complicated at high Rayleigh number. There are one to three vortices of different intensities in the cavity. At low Rayleigh number and inclination angle of the cavity being close to 90°, the flow state is composed mainly of heat conduction state. In addition, it is found that there exist two stable branches of solutions in a range of Rayleigh number (4949, 314721) when the inclination angle is in the interval of (70°, 110°).-

Keywords:

- thermal convection /

- direct numerical simulation /

- bifurcation /

- inclination angle /

- high-accuracy

[1] Batchelor G K 1954 Q. Appl. Math. 12 209

Google Scholar

Google Scholar

[2] Eckert E R G, Carlson W O 1961 Int. J. Heat Mass Transfer 2 106

Google Scholar

Google Scholar

[3] Patterson J C, Armfield S W 1990 J. Fluid Mech. 219 469

Google Scholar

Google Scholar

[4] Xin S, Quéré P L 1995 J. Fluid Mech. 304 87

Google Scholar

Google Scholar

[5] Das D, Roy M, Basak T 2017 Int. J. Heat Mass Transfer 106 356

Google Scholar

Google Scholar

[6] Arnold J N, Catton I, Edwards D K 1976 J. Heat Transfer 98 67

Google Scholar

Google Scholar

[7] John P, Jorg I 1980 J. Fluid Mech. 100 65

Google Scholar

Google Scholar

[8] Khezzar L, Siginer D, Vinogradov I 2012 Heat Mass Transfer 48 227

Google Scholar

Google Scholar

[9] Dider S, Abdelmadjid B, François P 2012 Exp. Therm Fluid Sci. 38 74

Google Scholar

Google Scholar

[10] Torres J F, Henry D, Komiya A, Maruyama S 2014 J. Fluid Mech. 756 650

Google Scholar

Google Scholar

[11] Torres J F, Henry D, Komiya A, Maruyama S 2015 Phys. Rev. E 92 023031

Google Scholar

Google Scholar

[12] Miroshnichenko I V, Sheremet M A 2018 Renewable Sustainable Energy Rev. 82 40

Google Scholar

Google Scholar

[13] 徐丰, 崔会敏 2014 力学进展 44 201403

Xu F, Cui H M 2014 Adv. Mech. 44 201403

[14] Hamady F J, Lloyd J R, Yang H Q, Yang K T 1989 Int. J. Heat Mass Transfer 32 1697

Google Scholar

Google Scholar

[15] Kuyper R A, Meer T H V D, Hoogendoorn C J 1994 Chem. Eng. Sci. 49 851

Google Scholar

Google Scholar

[16] Rasoul J, Prinos P 1997 Int. J. Numer. Methods Heat Fluid Flow 7 438

Google Scholar

Google Scholar

[17] Janssen R J A, Armfield S 1996 Int. J. Heat Fluid Flow 17 547

Google Scholar

Google Scholar

[18] Varol Y, Oztop H F 2008 Build. Environ. 43 1535

Google Scholar

Google Scholar

[19] Corcione M 2003 Int. J. Therm. Sci. 42 199

Google Scholar

Google Scholar

[20] Wang H, Hamed M S 2006 Int. J. Therm. Sci. 45 782

Google Scholar

Google Scholar

[21] Armfield S W, Janssen R 1996 Int. J. Heat Fluid Flow 17 539

Google Scholar

Google Scholar

[22] Zhao B X, Tian Z F 2016 Int. J. Heat Mass Transfer 98 313

Google Scholar

Google Scholar

[23] Sheremet M A, Pop I, Mahian O 2018 Int. J. Heat Mass Transfer 116 751

Google Scholar

Google Scholar

[24] Boudjeniba B, Laouer A, Laouar S, Mezaache E H 2019 Int. J. Heat Technol. 37 413

Google Scholar

Google Scholar

[25] Wang Q, Xia S N, Wang B F, Sun D J, Zhou Q, Wan Z H 2018 J. Fluid Mech. 849 355

Google Scholar

Google Scholar

[26] Wang Q, Wan Z H, Yan R, Sun D J 2018 Phys. Rev. Fluids 3 113503

Google Scholar

Google Scholar

[27] Wang Q, Chong K L, Stevens R J A M, Verzicco R, Lohse D 2020 J. Fluid Mech. 905 A21

Google Scholar

Google Scholar

[28] Wang Q, Wan Z H, Yan R, Sun D J 2019 Phys. Fluids 31 025102

Google Scholar

Google Scholar

[29] Wang Q, Verzicco R, Lohse D, Shishkina O 2020 Phys. Rev. Lett. 125 074501

Google Scholar

Google Scholar

[30] Sugiyama K, Ni R, Stevens R J A M, Chan T S, Zhou S Q, Xi H D, Sun C, Grossmann S, Xia K Q, Lohse D 2010 Phys. Rev. Lett. 105 034503

Google Scholar

Google Scholar

[31] Tian Z F, Liang X, Yu P X 2011 Int. J. Numer. Methods Eng. 88 511

Google Scholar

Google Scholar

[32] Davis G D V 1983 Int. J. Numer. Methods Fluids 3 249

Google Scholar

Google Scholar

[33] Kalita J C, Dalal D C, Dass A K 2001 Phys. Rev. E 64 066703

Google Scholar

Google Scholar

[34] Tian Z F, Ge Y B 2003 Int. J. Numer. Methods Fluids 41 495

Google Scholar

Google Scholar

[35] Yu P X, Tian Z F 2012 Phys. Rev. E 85 036703

Google Scholar

Google Scholar

-

表 1 与其他文献结果的对比(

$ Pr = 0.71 $ ,$ \beta = {\rm{0}}^\circ $ )Table 1. Comparison of the results by different numerical methods for

$ Pr = 0.71 $ and$ \beta = {\rm{0}}^\circ $ .文献 $ \left| \psi \right|_{\rm {max}} $ $ \left| {\psi _{\rm {mid}} } \right| $ $ Nu_{0} $ $ \overline{Nu} $ 文献 $ \left| \psi \right|_{\rm {max}} $ $ \left| {\psi _{\rm {mid}} } \right| $ $ Nu_{0} $ $ \overline{Nu} $ $ Ra=10^{5} $ $ Ra=10^{6} $ 本文 9.615 9.115 4.520 4.522 本文 16.807 16.383 8.815 8.827 [32] 9.612 9.111 4.509 4.519 [32] 16.750 16.320 8.817 8.800 [33] — 9.123 4.512 4.522 [33] — 16.420 8.763 8.829 [34] 9.6173 9.1161 4.5195 — [34] 16.8107 16.3863 8.8216 — [35] 9.6202 9.1194 4.5214 — [35] 16.8411 16.4183 8.8091 — 表 2

$ Pr = 0.71 $ ,$ \beta = {\rm{0}}^\circ $ ,$ Ra = 10^{6} $ 下的网格检验结果Table 2. Grid test results for

$ Pr = 0.71 $ ,$ \beta = {\rm{0}}^\circ $ and$ Ra = 10^{6} $ .网格尺寸 $\left| \psi \right|_{\rm {max}}$ 误差/% $\left| {\psi _{\rm {mid}} } \right|$ 误差/% $ Nu_0 $ 误差/% $ 31\times31 $ 16.460 2.086 16.118 1.631 9.293 5.301 $ 61\times61 $ 16.830 0.119 16.410 0.148 8.798 0.315 $ 91\times91 $ 16.802 0.051 16.385 0.002 8.786 0.445 $ 121\times121 $ 16.807 0.017 16.383 0.014 8.815 0.119 $ 241\times241 $ 16.810 — 16.386 — 8.825 — 表 3

$ Pr = 0.71 $ ,$ \beta = {\rm{45}}^\circ $ ,$ Ra = 10^{6} $ 下的网格检验结果Table 3. Grid test results for

$ Pr = 0.71 $ ,$ \beta = {\rm{45}}^\circ $ and$ Ra = 10^{6} $ .网格尺寸 $\left| \psi \right|_{\rm {max}}$ 误差/% $\left| {\psi _{\rm {mid}} } \right|$ 误差/% $ Nu_0 $ 误差/% $ 31\times31 $ 32.400 3.276 27.974 3.306 9.077 9.345 $ 61\times61 $ 33.252 0.734 28.707 0.771 8.332 0.381 $ 91\times91 $ 33.438 0.176 28.874 0.195 8.301 0.001 $ 121\times121 $ 33.477 0.062 28.911 0.068 8.304 0.039 $ 241\times241 $ 33.498 — 28.931 — 8.301 — 表 4

$ Pr = 7.01 $ ,$ \beta = {\rm{0}}^\circ $ ,$ Ra = 10^{6} $ 下的网格检验结果Table 4. Grid test results for

$ Pr = 7.01 $ ,$ \beta = {\rm{0}}^\circ $ and$ Ra = 10^{6} $ .网格尺寸 $\left| \psi \right|_{\rm {max}}$ 误差/% $\left| {\psi _{\rm {mid}} } \right|$ 误差/% $ Nu_0 $ 误差/% $ 31\times31 $ 18.625 5.075 17.873 5.021 9.548 3.514 $ 61\times61 $ 19.634 0.067 18.838 0.110 9.195 0.310 $ 91\times91 $ 19.609 0.059 18.814 0.020 9.206 0.193 $ 121\times121 $ 19.612 0.044 18.812 0.029 9.221 0.037 $ 241\times241 $ 19.621 — 18.818 — 9.224 — 表 5

$ Pr = 7.01 $ ,$ \beta = 45^\circ $ ,$ Ra = 10^{6} $ 下的网格检验结果Table 5. The grid test results for

$ Pr = 7.01 $ ,$ \beta = {\rm{45}}^\circ $ and$ Ra = 10^{6} $ .网格尺寸 $\left| \psi \right|_{\rm {max}}$ 误差 $\left| {\psi _{\rm {mid}} } \right|$ 误差 $ Nu_0 $ 误差 $ {\rm{31}} \times {\rm{31}} $ 38.233 6.689% 34.649 6.739% 9.791 7.723% $ {\rm{61}} \times {\rm{61}} $ 40.665 0.752% 36.858 0.793% 9.114 0.271% $ {\rm{91}} \times {\rm{91}} $ 40.902 0.174% 37.090 0.167% 9.089 0.001% $ {\rm{121}} \times {\rm{121}} $ 40.950 0.057% 37.131 0.058% 9.092 0.025% $ {\rm{241}} \times {\rm{241}} $ 40.973 — 37.152 — 9.089 — -

[1] Batchelor G K 1954 Q. Appl. Math. 12 209

Google Scholar

Google Scholar

[2] Eckert E R G, Carlson W O 1961 Int. J. Heat Mass Transfer 2 106

Google Scholar

Google Scholar

[3] Patterson J C, Armfield S W 1990 J. Fluid Mech. 219 469

Google Scholar

Google Scholar

[4] Xin S, Quéré P L 1995 J. Fluid Mech. 304 87

Google Scholar

Google Scholar

[5] Das D, Roy M, Basak T 2017 Int. J. Heat Mass Transfer 106 356

Google Scholar

Google Scholar

[6] Arnold J N, Catton I, Edwards D K 1976 J. Heat Transfer 98 67

Google Scholar

Google Scholar

[7] John P, Jorg I 1980 J. Fluid Mech. 100 65

Google Scholar

Google Scholar

[8] Khezzar L, Siginer D, Vinogradov I 2012 Heat Mass Transfer 48 227

Google Scholar

Google Scholar

[9] Dider S, Abdelmadjid B, François P 2012 Exp. Therm Fluid Sci. 38 74

Google Scholar

Google Scholar

[10] Torres J F, Henry D, Komiya A, Maruyama S 2014 J. Fluid Mech. 756 650

Google Scholar

Google Scholar

[11] Torres J F, Henry D, Komiya A, Maruyama S 2015 Phys. Rev. E 92 023031

Google Scholar

Google Scholar

[12] Miroshnichenko I V, Sheremet M A 2018 Renewable Sustainable Energy Rev. 82 40

Google Scholar

Google Scholar

[13] 徐丰, 崔会敏 2014 力学进展 44 201403

Xu F, Cui H M 2014 Adv. Mech. 44 201403

[14] Hamady F J, Lloyd J R, Yang H Q, Yang K T 1989 Int. J. Heat Mass Transfer 32 1697

Google Scholar

Google Scholar

[15] Kuyper R A, Meer T H V D, Hoogendoorn C J 1994 Chem. Eng. Sci. 49 851

Google Scholar

Google Scholar

[16] Rasoul J, Prinos P 1997 Int. J. Numer. Methods Heat Fluid Flow 7 438

Google Scholar

Google Scholar

[17] Janssen R J A, Armfield S 1996 Int. J. Heat Fluid Flow 17 547

Google Scholar

Google Scholar

[18] Varol Y, Oztop H F 2008 Build. Environ. 43 1535

Google Scholar

Google Scholar

[19] Corcione M 2003 Int. J. Therm. Sci. 42 199

Google Scholar

Google Scholar

[20] Wang H, Hamed M S 2006 Int. J. Therm. Sci. 45 782

Google Scholar

Google Scholar

[21] Armfield S W, Janssen R 1996 Int. J. Heat Fluid Flow 17 539

Google Scholar

Google Scholar

[22] Zhao B X, Tian Z F 2016 Int. J. Heat Mass Transfer 98 313

Google Scholar

Google Scholar

[23] Sheremet M A, Pop I, Mahian O 2018 Int. J. Heat Mass Transfer 116 751

Google Scholar

Google Scholar

[24] Boudjeniba B, Laouer A, Laouar S, Mezaache E H 2019 Int. J. Heat Technol. 37 413

Google Scholar

Google Scholar

[25] Wang Q, Xia S N, Wang B F, Sun D J, Zhou Q, Wan Z H 2018 J. Fluid Mech. 849 355

Google Scholar

Google Scholar

[26] Wang Q, Wan Z H, Yan R, Sun D J 2018 Phys. Rev. Fluids 3 113503

Google Scholar

Google Scholar

[27] Wang Q, Chong K L, Stevens R J A M, Verzicco R, Lohse D 2020 J. Fluid Mech. 905 A21

Google Scholar

Google Scholar

[28] Wang Q, Wan Z H, Yan R, Sun D J 2019 Phys. Fluids 31 025102

Google Scholar

Google Scholar

[29] Wang Q, Verzicco R, Lohse D, Shishkina O 2020 Phys. Rev. Lett. 125 074501

Google Scholar

Google Scholar

[30] Sugiyama K, Ni R, Stevens R J A M, Chan T S, Zhou S Q, Xi H D, Sun C, Grossmann S, Xia K Q, Lohse D 2010 Phys. Rev. Lett. 105 034503

Google Scholar

Google Scholar

[31] Tian Z F, Liang X, Yu P X 2011 Int. J. Numer. Methods Eng. 88 511

Google Scholar

Google Scholar

[32] Davis G D V 1983 Int. J. Numer. Methods Fluids 3 249

Google Scholar

Google Scholar

[33] Kalita J C, Dalal D C, Dass A K 2001 Phys. Rev. E 64 066703

Google Scholar

Google Scholar

[34] Tian Z F, Ge Y B 2003 Int. J. Numer. Methods Fluids 41 495

Google Scholar

Google Scholar

[35] Yu P X, Tian Z F 2012 Phys. Rev. E 85 036703

Google Scholar

Google Scholar

计量

- 文章访问数: 5751

- PDF下载量: 59

- 被引次数: 0

下载:

下载: