-

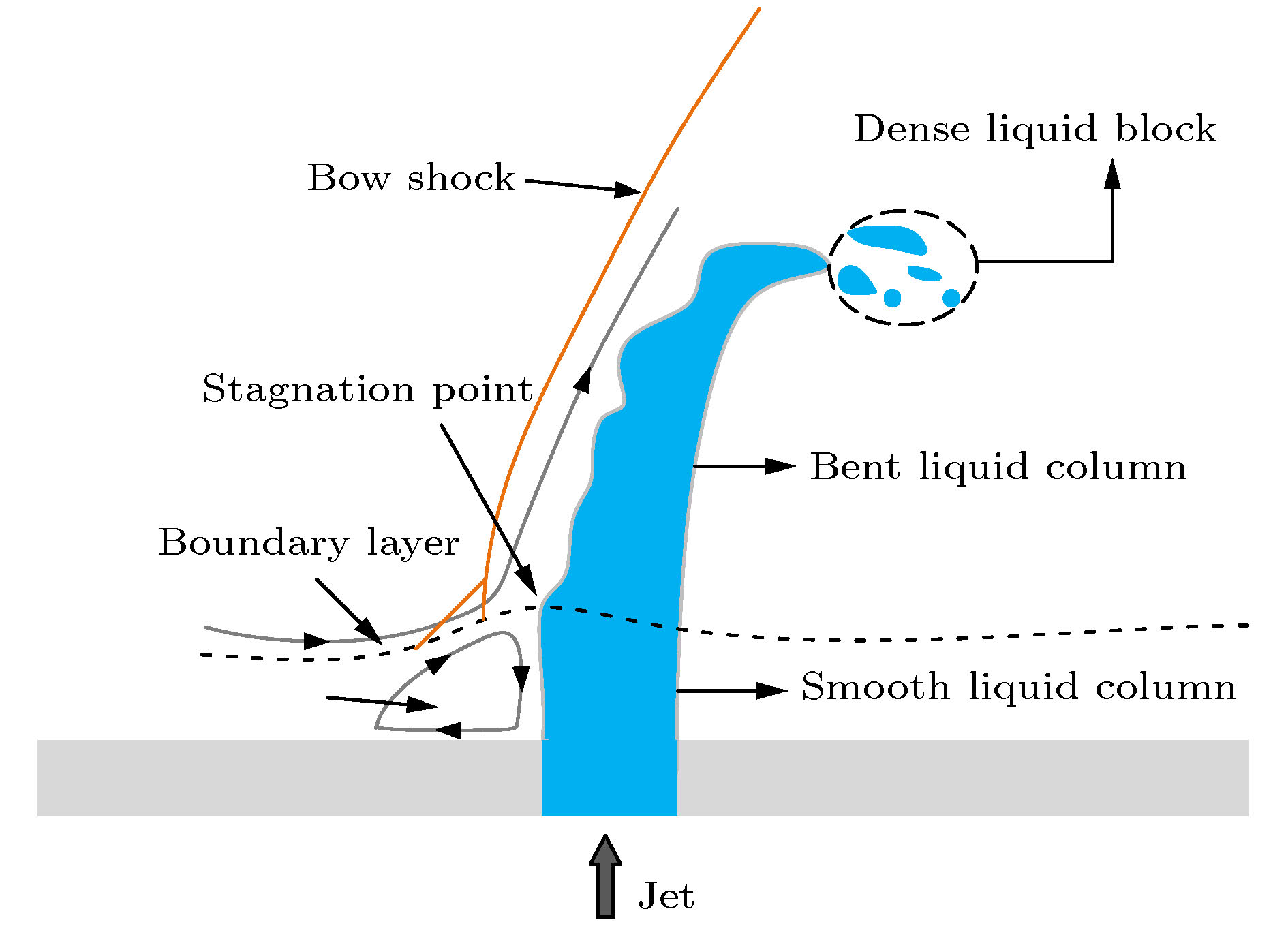

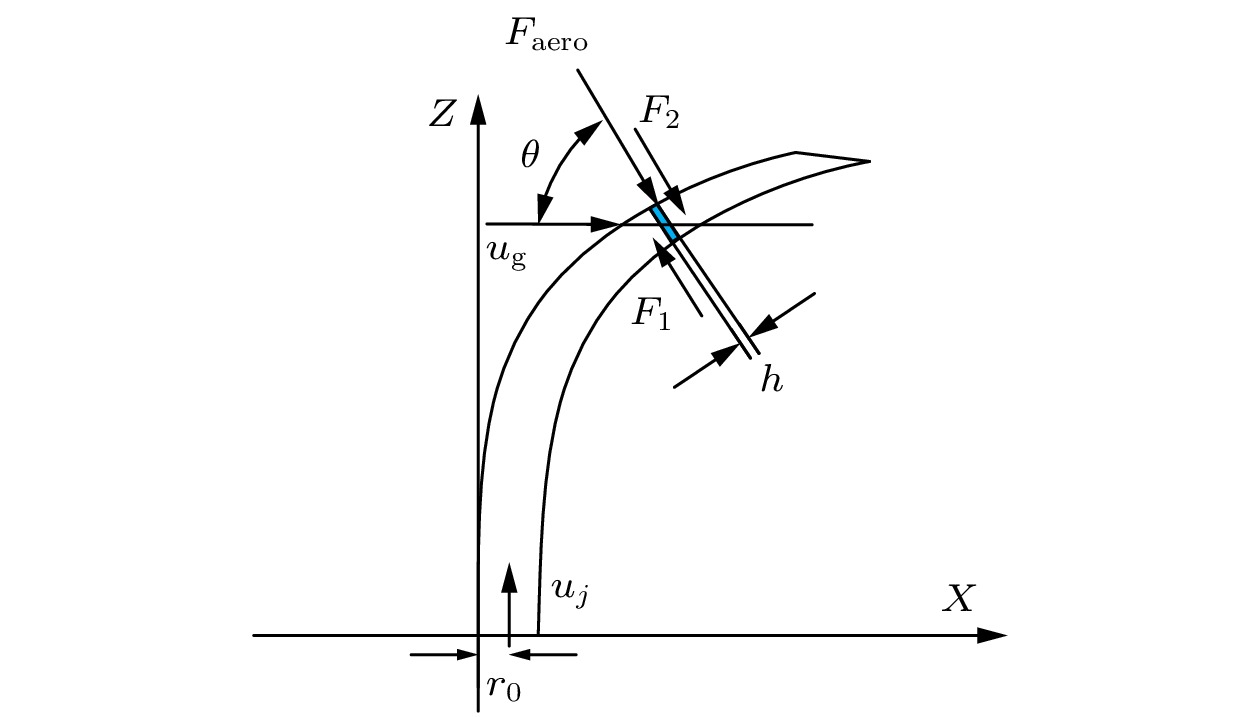

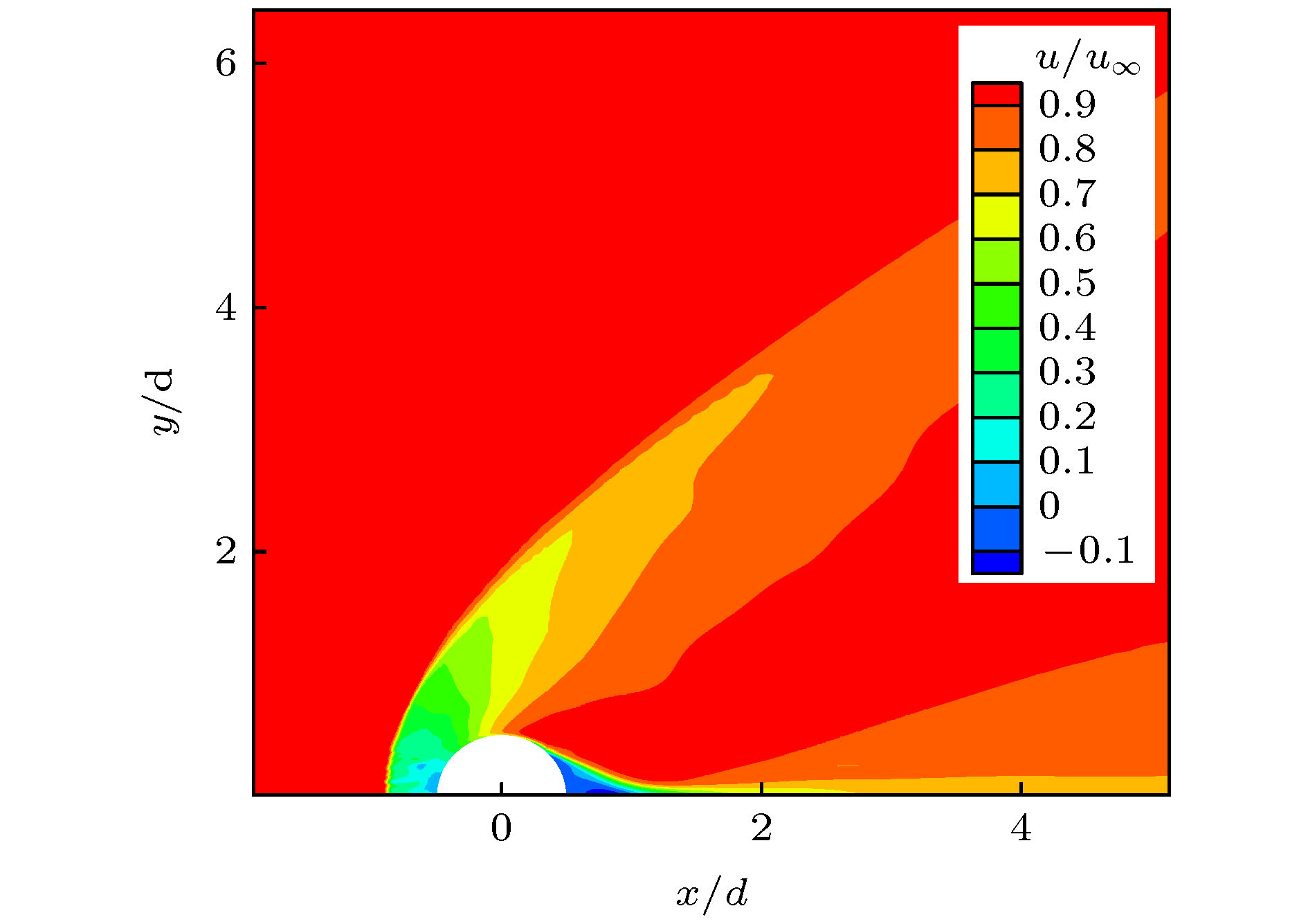

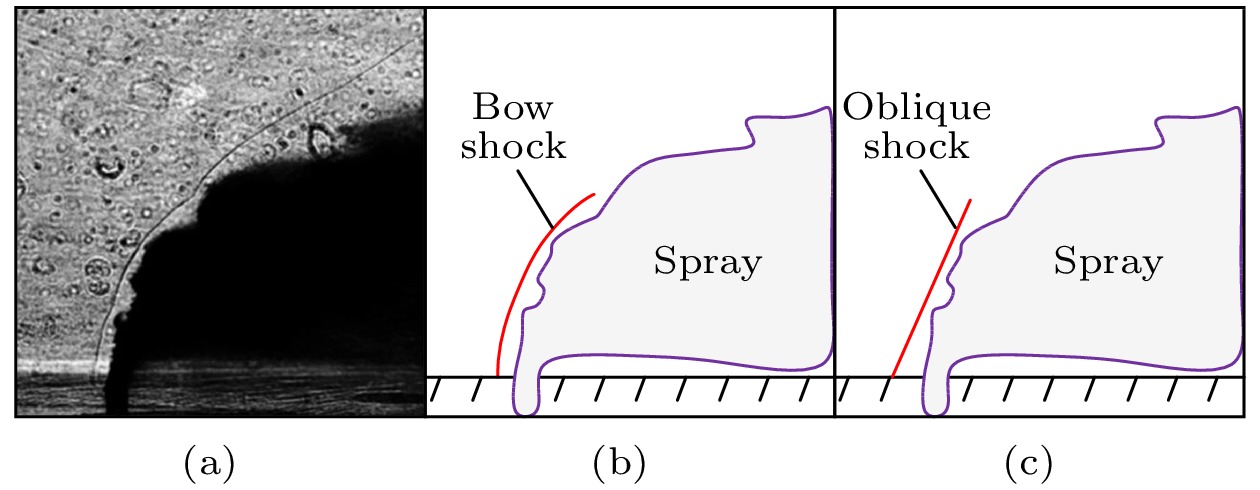

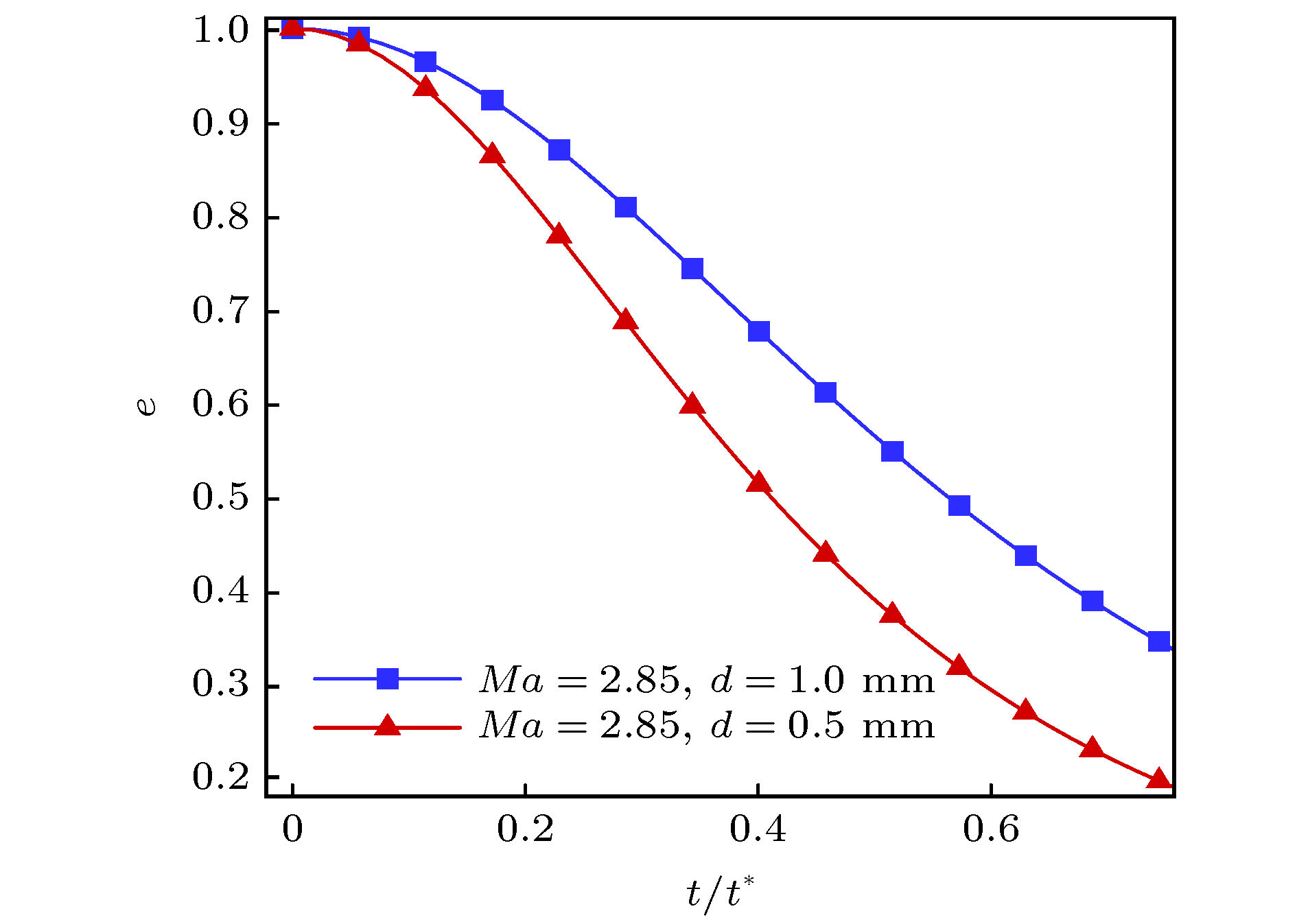

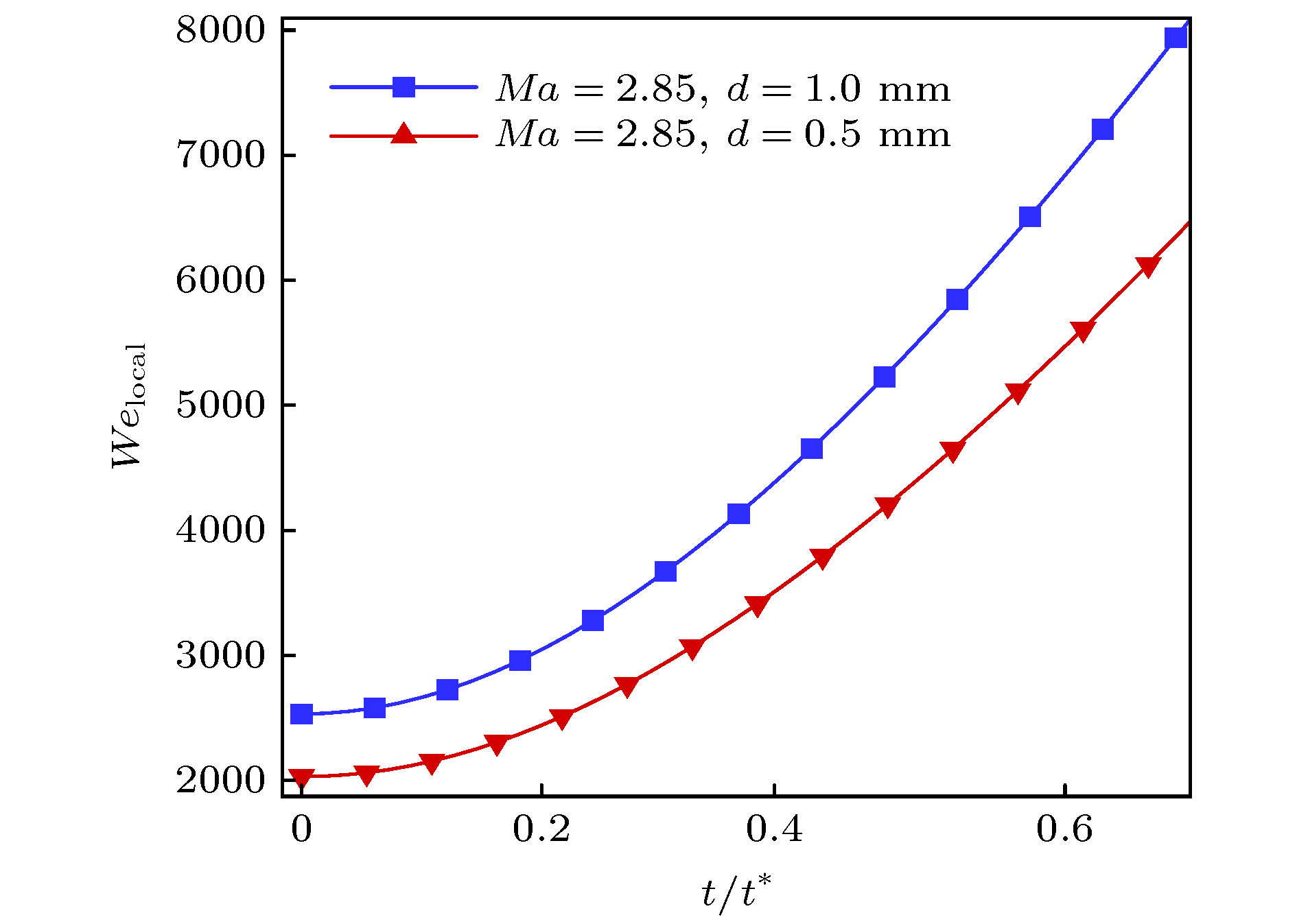

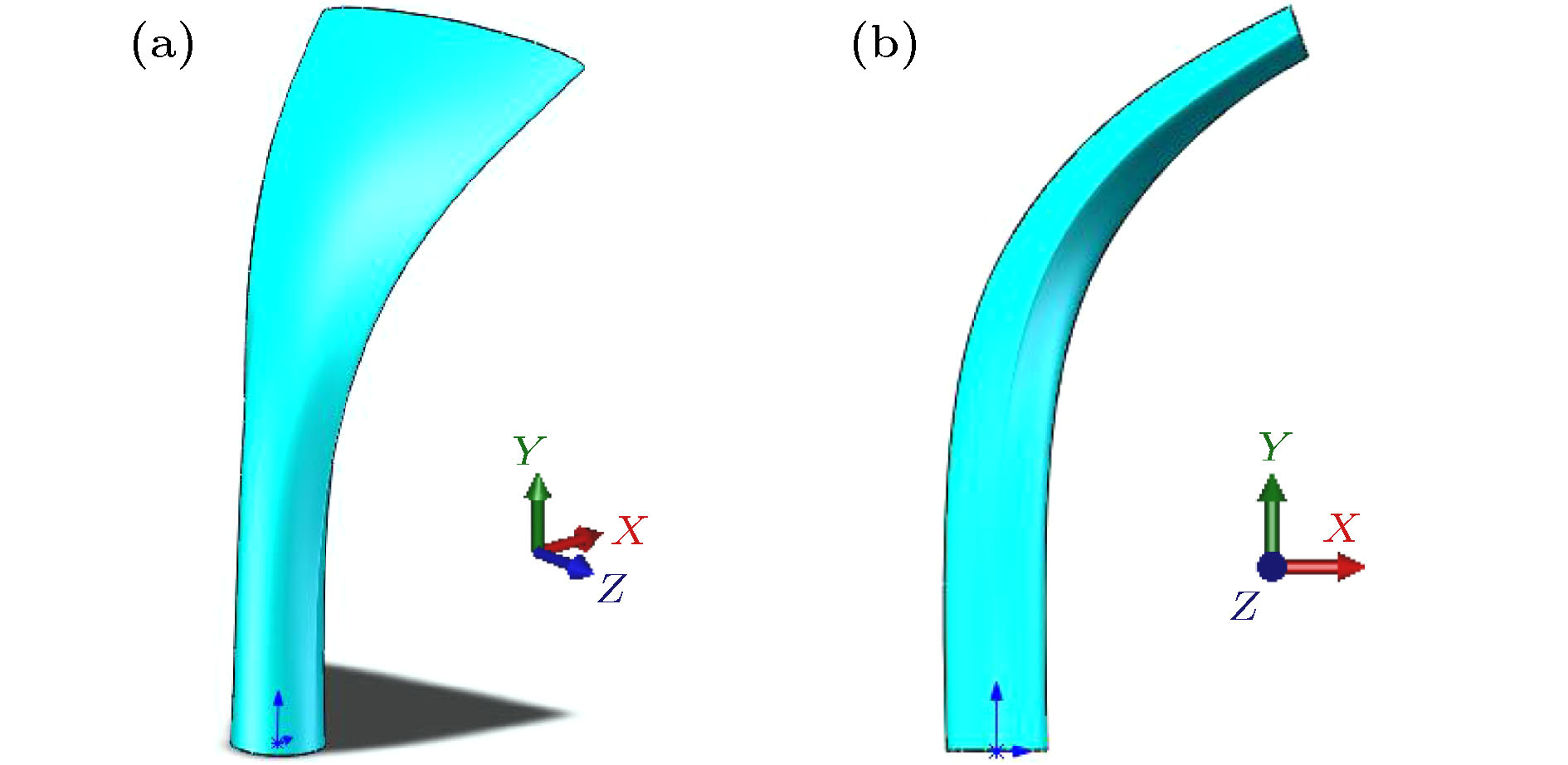

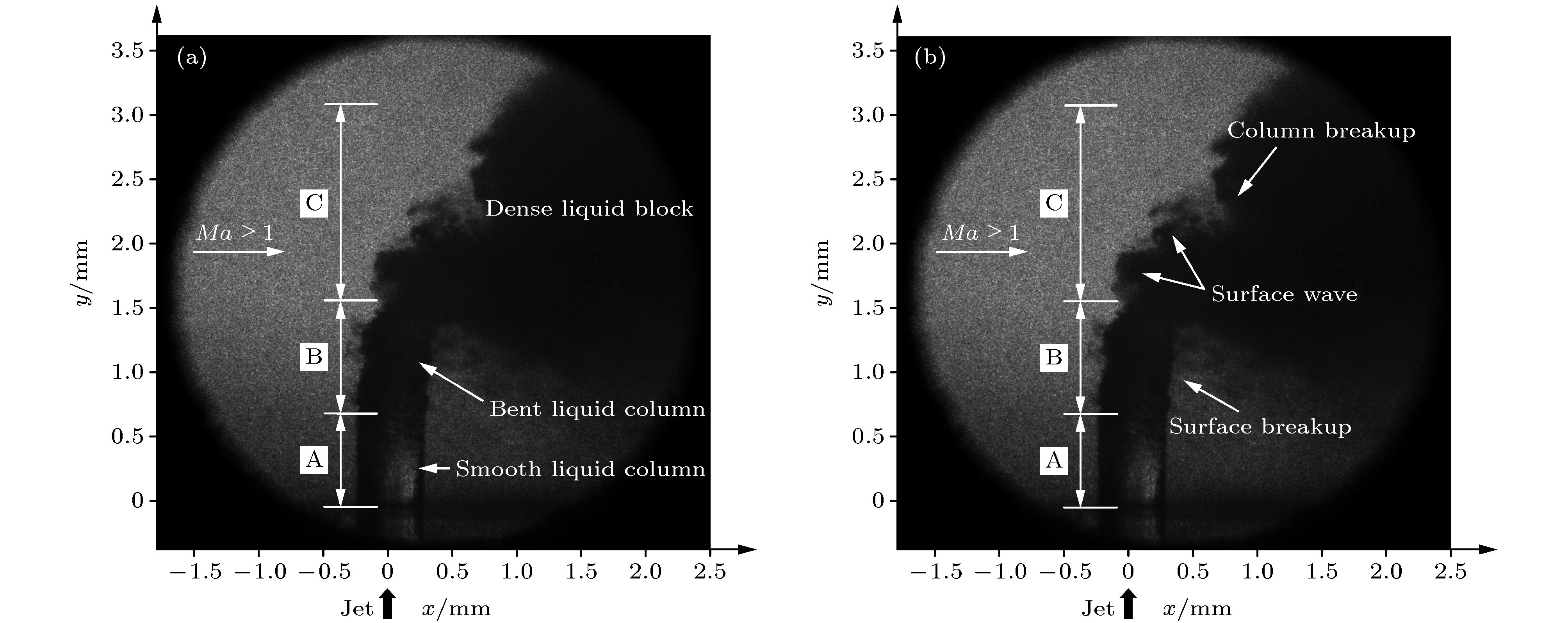

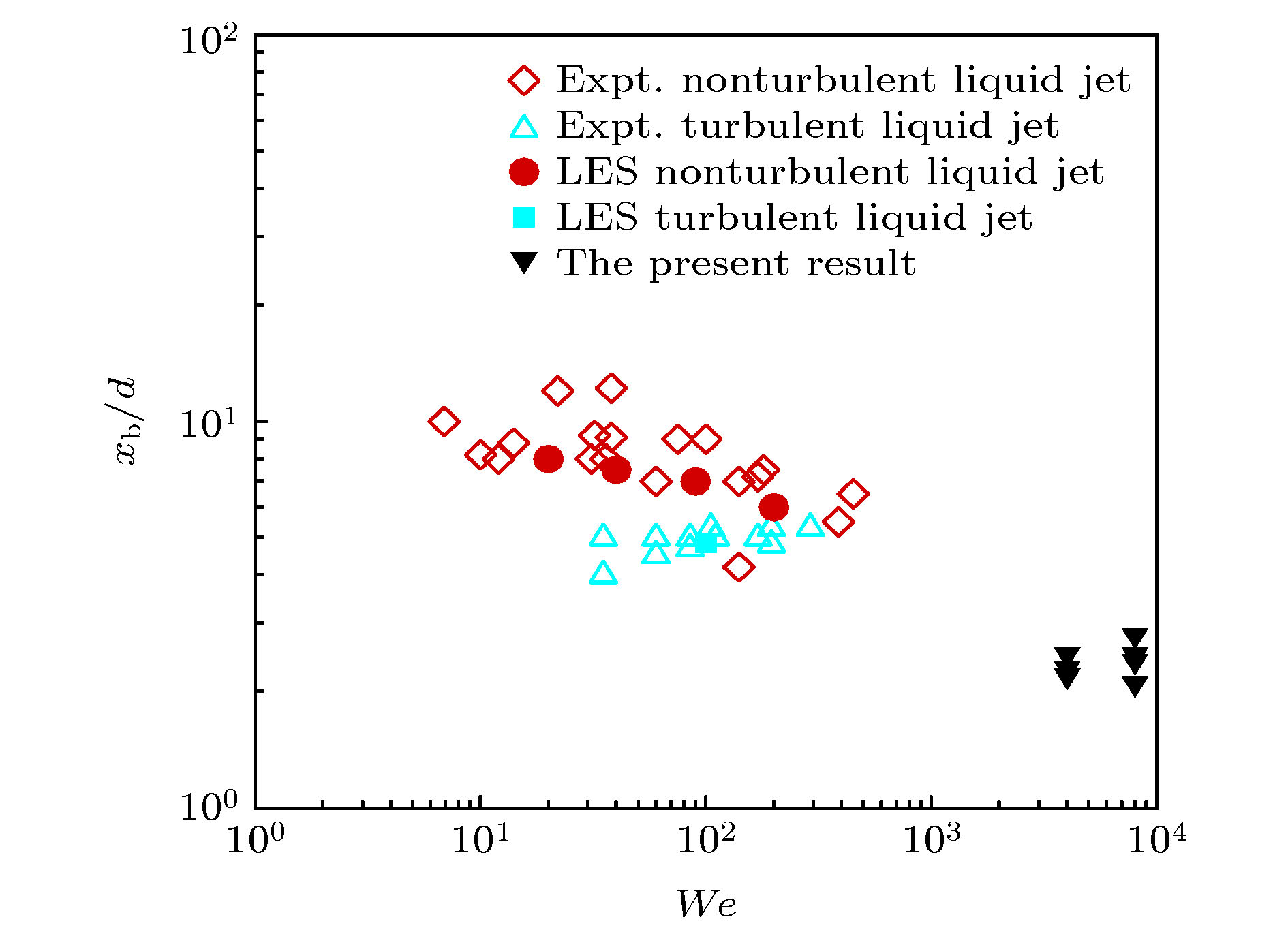

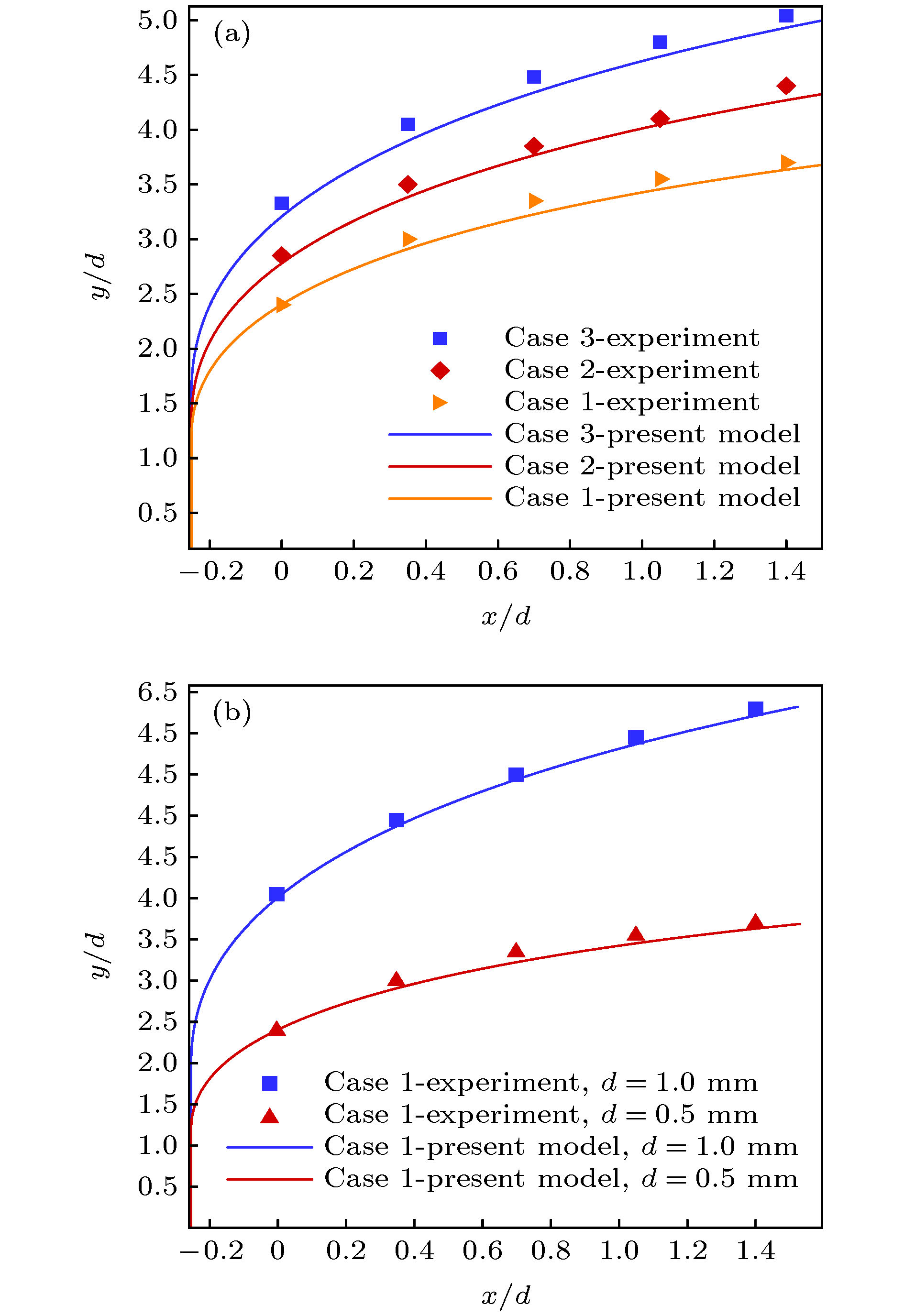

对于液体射流沿壁面法向喷注进入超声速横向气流中的射流轨迹开展了理论与实验研究, 建立了连续液柱三维实体模型. 基于液体微元受力分析建立了连续液柱沿喷注方向横截面的截面变形控制方程, 计算了液体射流轨迹与横截面变形, 合理考虑了液体射流因发生表面破碎所引起的质量损失, 提出适用于超声速横向气流的连续液柱模型. 利用高时空分辨率的显微成像方法拍摄超声速横向气流中连续液柱的瞬时图像, 研究的参数变量包括液体喷注压降(1—2 MPa)、液体喷嘴直径(0.5 mm/1.0 mm)及液气动量比(3.32—7.27). 研究结果表明, 采用连续液柱模型可以较好地预测中心面上的射流轨迹和三维空间上的液柱形态, 并可较为真实地反映实际流场特征, 预测结果与实验结果吻合良好.The trajectory of the spray is studied theoretically and experimentally when a round liquid jet is injected into a supersonic crossflow vertically. A solid model of continuous liquid column is established in three-dimensional space. The cross-section deformation equation of the continuous liquid column along the injection direction is established using a method of micro-element analysis. The stress analysis of cross section is simplified into a two-dimensional droplet. The shape of the cross section is considered to continuously change from circular to elliptical shape. And the bow shock wave in front of the jet column is simplified into an oblique shock wave with a known shock angle. Based on this, the calculation of aerodynamic force is greatly simplified. A dimensionless parameter named effective deformation time of liquid column (the logogram is

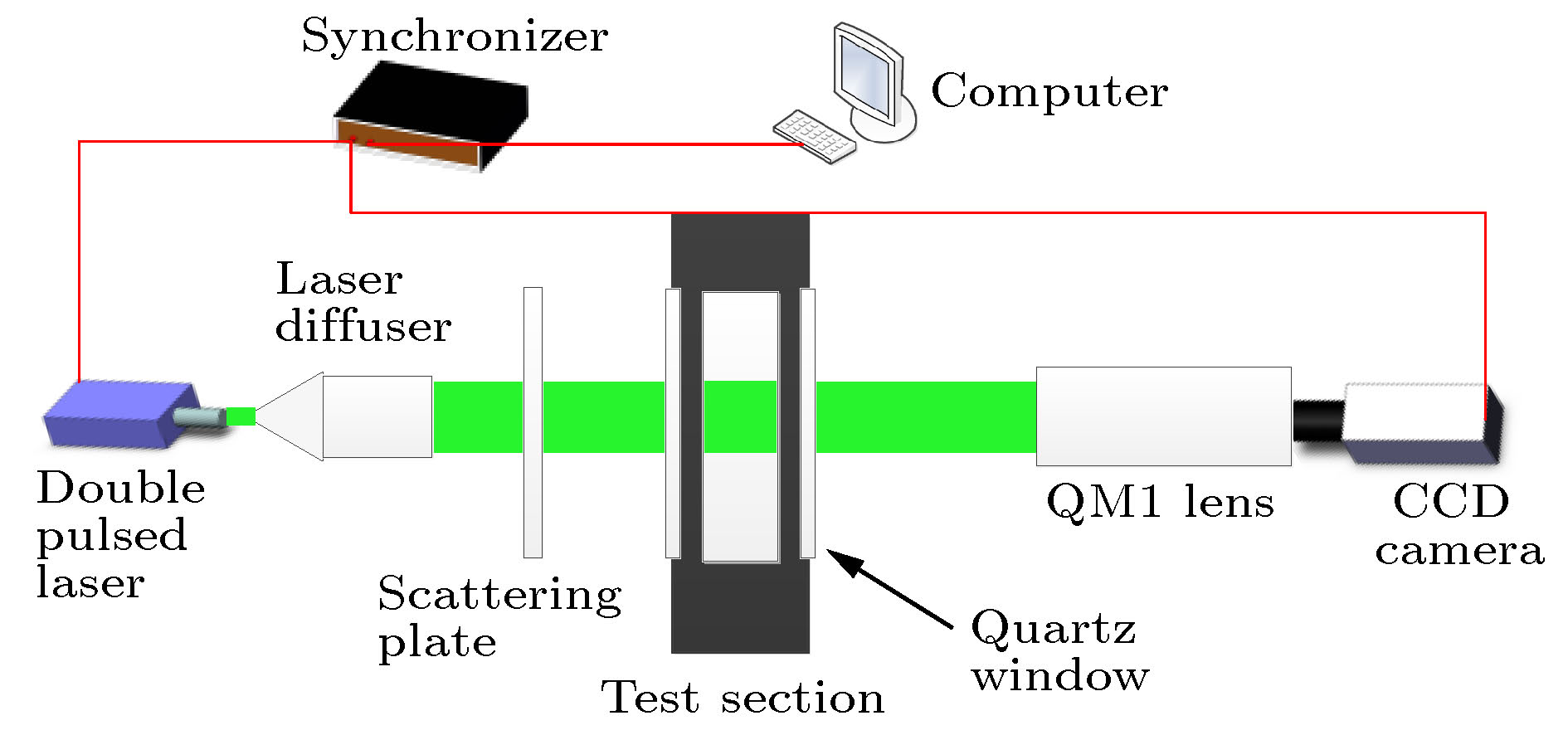

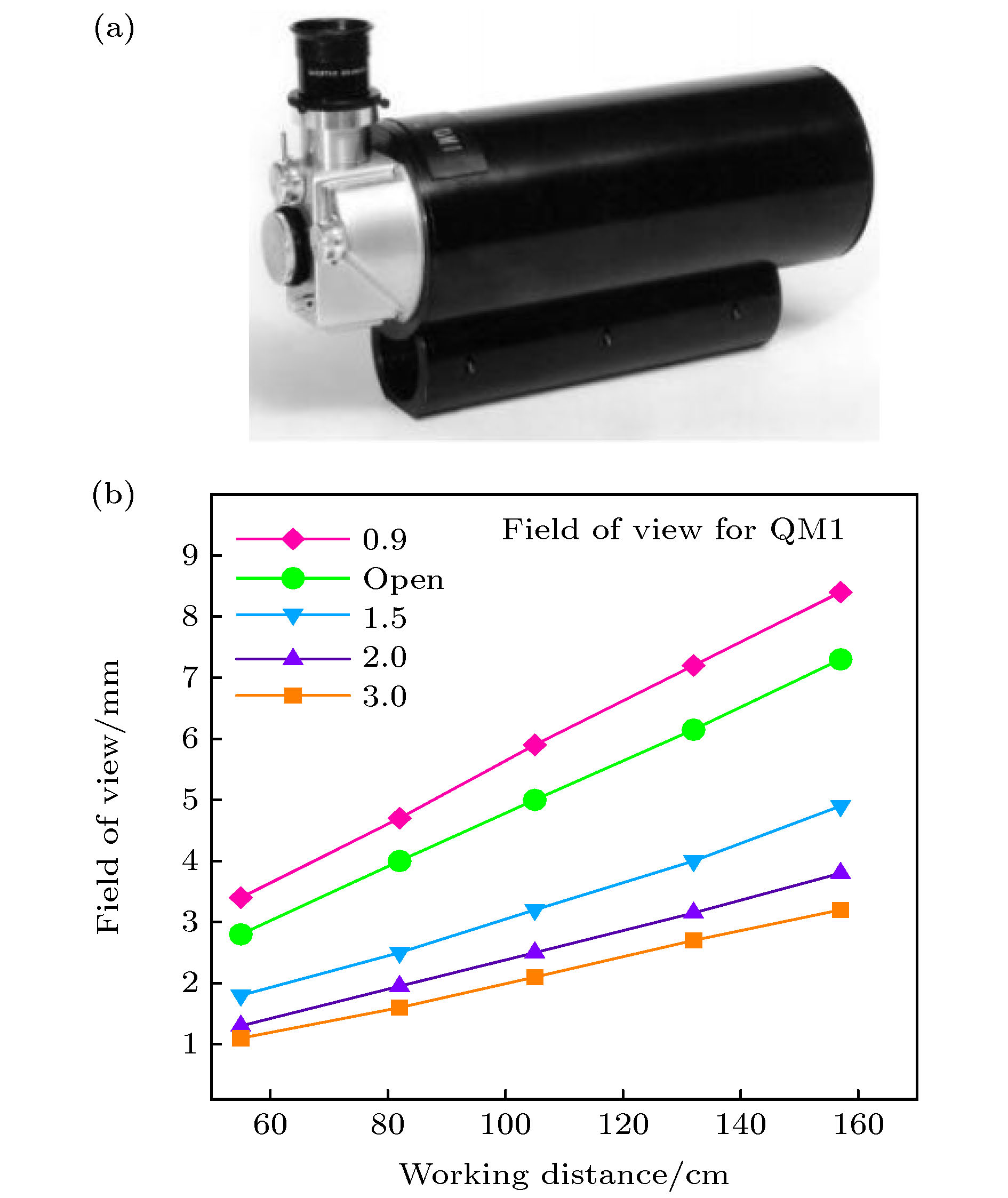

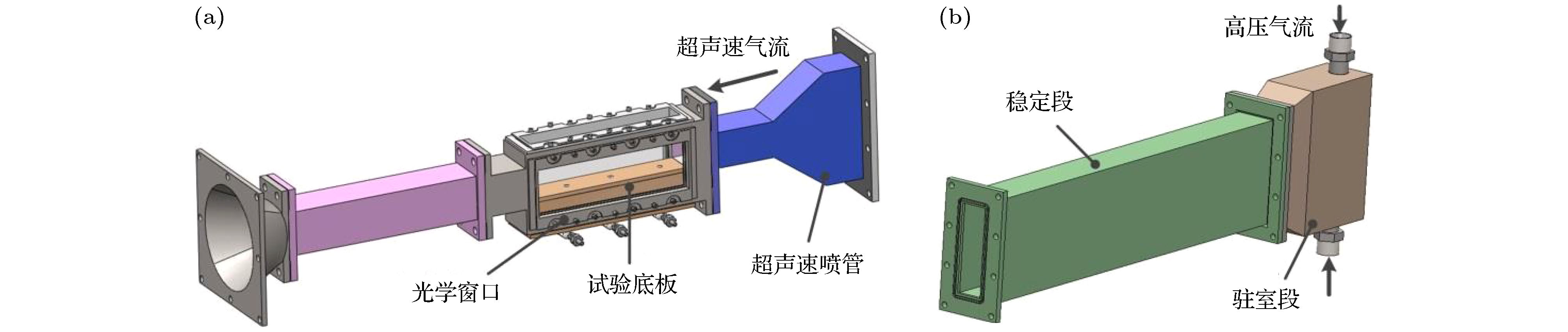

${t_{\rm valid}}$ ) is defined and used to judge the end point of the liquid column quantitatively. The liquid jet trajectory and cross-section deformation can be calculated using MATLAB software. The instantaneous images of continuous liquid columns in supersonic crossflow are captured using high-spatial-resolution microscopic imaging methods. The microscopic imaging system is composed of a double pulse solid-state laser, computer, CCD camera, synchronous controller, microscope lens and laser diffuser. After passing through the laser diffuser, a plane background light with uniform distribution is formed on the scattering plate. The mean filtering method is used to filter the original image. After filtering, the range of gray distribution in the background area is obviously reduced. The distribution of gray value is more concentrated, and the background of the image is more uniform. Then the image edge detection function is used to obtain the near-field jet trajectory. The parameter variables studied include liquid injection pressure drop (1–2 MPa), liquid nozzle diameter (0.5 mm/1.0 mm), and liquid gas momentum ratio (3.32–7.27). The results show that the continuous liquid column model can better predict the jet trajectory on the center plane and the shape of the liquid column in three-dimensional space. It is indicated that the predictive result matches well with the experimental result. This study is of great significance for establishing the solid-particle coupling model of liquid jet in supersonic crossflows.[1] Xiao F, Dianat M, Mcguirk J J 2013 AIAA J. 51 2878

Google Scholar

Google Scholar

[2] 夏同军, 董永强, 曹义刚 2013 62 214702

Google Scholar

Google Scholar

Xia T J, Dong Y Q, Cao Y G 2013 Acta Phys. Sin. 62 214702

Google Scholar

Google Scholar

[3] Heister S D 2011 Handbook of Atomization and Sprays: Theory and Applications (New York: Springer) pp65−660

[4] Li C Y, Li C, Xiao F, Li Q L, Zhu Y H 2019 Aerosp. Sci. Technol. 95 105426

Google Scholar

Google Scholar

[5] Dixon D R, Gruber M R, Jackson T A, Lin K C 2005 43th AIAA Aerospace Sciences Meeting & Exhibit Reno, America, January 10−13, 2005 p733

[6] Wu L Y, Wang Z G, Li Q L, Li C 2016 J. Visualization 3 337

Google Scholar

Google Scholar

[7] Hu R S, Li Q, Li C Y, Li C 2019 Acta Astronaut. 159 440

Google Scholar

Google Scholar

[8] Lin K C, Kennedy P J 2002 40 th AIAA Aerospace Sciences Meeting & Exhibit Reno, America, January 14−17, 2002 p873

[9] Lin K C, Kennedy P J, Kennedy P J, Jackson T A 2004 42th AIAA Aerospace Sciences Meeting & Exhibit Reno, America, January 5−8, 2004 p971

[10] 刘静, 王辽, 张佳, 韦宝禧, 徐旭 2008 航空动力学报 4 146

Google Scholar

Google Scholar

Liu J, Wang L, Zhang J, Wei B X, Xu X 2008 J. Aerosp. Power 4 146

Google Scholar

Google Scholar

[11] 仝毅恒, 李清廉, 吴里银 2012 国防科技大学学报 2 73

Google Scholar

Google Scholar

Tong Y H, Li Q L, Wu L Y 2012 J. Natl. Univ. Def. Technol. 2 73

Google Scholar

Google Scholar

[12] 李春 2014 硕士学位论文 (长沙: 国防科学技术大学)

Li C 2012 M. S. Thesis (Changsha: National University of Defense Technology) (in Chinese)

[13] 吴里银, 王振国, 李清廉, 李春 中国专利 zl201410800056.5 [2018-2-2]

Wu L Y, Wang Z G, Li Q L, Li C Chinese Patent zl201410800056.5 [20218-2-2] (in Chinese)

[14] 胡润生, 朱元昊, 张翔宇, 李清廉 2019 工程热 7 1659

Google Scholar

Google Scholar

Hu R S, Zhu Y H, Zhang X Y, Li Q L 2019 J. Eng. Therm. 7 1659

Google Scholar

Google Scholar

[15] 吴里银, 王振国, 李清廉, 李春 2016 68 094701

Google Scholar

Google Scholar

Wu L Y, Wang Z G, Li Q L, Li C 2016 Acta Phys. Sin. 68 094701

Google Scholar

Google Scholar

[16] 周曜智, 李清廉, 李晨阳 2020 推进技术 41 7

Google Scholar

Google Scholar

Zhou Y Z, Li Q L, Li C Y 2020 J. Propul. Technol. 41 7

Google Scholar

Google Scholar

[17] Mashayek A, Behzad M, Ashgriz N 2011 AIAA J. 49 2407

Google Scholar

Google Scholar

[18] 李春 2020 博士学位论文 (长沙: 国防科技大学)

Li C 2020 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[19] Xiao F, Wang Z G, Sun M B, Liang J H, Liu N 2016 Int. J. Multiphase Flow 87 229

Google Scholar

Google Scholar

[20] 李佩波, 王振国, 孙明波, 汪洪波 2016 宇航学报 37 79

Google Scholar

Google Scholar

Li P B, Wang Z G, Sun M B, Wang H B 2016 J. Astronautics 37 79

Google Scholar

Google Scholar

[21] Zhu Y X, Xiao F, Li Q L, Li C Y, Lin S 2018 Acta Astronaut. 154 119

Google Scholar

Google Scholar

[22] Liu N, Wang Z G, Sun M B, Deiterding R, Wang H B 20191 Aerosp. Sci. Technol. 91 456

Google Scholar

Google Scholar

[23] Douglas H F, Vitor V, Lucas S M, Francisco J S 2019 Int. J. Multiphase Flow 114 98

Google Scholar

Google Scholar

[24] Li P B, Li C Y, Wang H B, Sun M B, Liu C Y, Wang Z G, Huang Y H 2019 Aerosp. Sci. Technol. 94 105401

Google Scholar

Google Scholar

[25] Nguyen T, Karagozian A R 1992 J. Propul. Power 8 21

Google Scholar

Google Scholar

[26] Clark M M 1988 Chem. Eng. Sci. 43 671

Google Scholar

Google Scholar

[27] Inamura T 2000 J. Propul. Power 16 155

Google Scholar

Google Scholar

[28] Sallam K A, Aalburg C, Faeth G M 2004 AIAA J. 42 2529

Google Scholar

Google Scholar

[29] Wu P K, Kirkendall K A, Fuller R P, Nejad A S 1997 J. Propul. Power 13 64

Google Scholar

Google Scholar

[30] 吴里银 2016 博士学位论文 (长沙: 国防科学技术大学

Wu L Y 2016 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[31] Lee K, Aalburg C, Diez F J, Faeth G M, Sallam K A 2007 AIAA J. 45 1907

Google Scholar

Google Scholar

[32] Ranger A A, Nicholls J A 1969 AIAA J. 7 285

Google Scholar

Google Scholar

[33] Chryssakis C A, Assanis, D N 2005 18th Annual Conference on Liquid and Atomization and Spray Systems, Irvine, America, May 15−18, 2005 p283

-

表 1 超声速横流参数

Table 1. Supersonic cross flow parameters

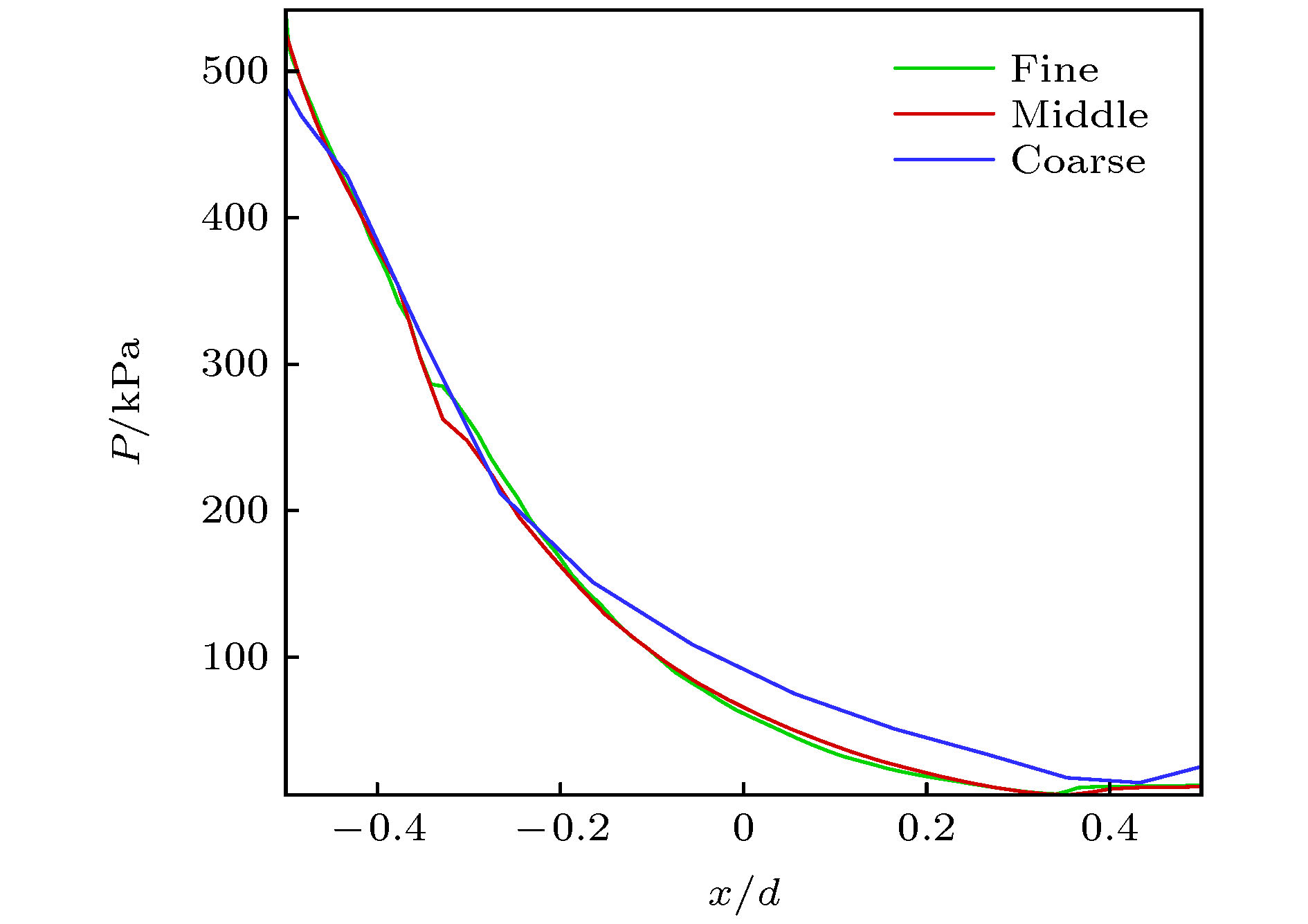

Ma = 2.1 Ma = 2.85 总温T0/K 300 300 总压P0/kPa 891 1410 静温T/K 159.4 114.3 静压P/kPa 97.7 48.1 密度/kg·m–3 2.13 1.47 声速/m·s–1 253 214 速度/m·s–1 531 611 表 2 不同网格计算得到的气动阻力系数

Table 2. Aerodynamic drag coefficients calculated from different grids.

类别 最小网格尺寸/d 网格量 气动阻力系数 Coarse 0.020 50840 1.372 Middle 0.010 225448 1.350 Fine 0.005 488752 1.349 表 3 理论计算参数

Table 3. Theoretical calculation parameters.

编号 横向气流 (T0 = 300 K) 水射流 (密度: 998 kg·m–3) Ma P0/kPa ρg/kg·m–3 uj/m·s–1 d/mm $\Delta P$/MPa q Case 1 2.85 1410 1.47 44.7 0.5/1.0 1.0 3.323 Case 2 2.85 1410 1.47 54.8 0.5/1.0 1.5 4.985 Case 3 2.85 1410 1.47 63.2 0.5/1.0 2.0 6.647 Case 4 2.1 891 2.13 44.7 0.5/1.0 1.0 3.637 Case 5 2.1 891 2.13 54.8 0.5/1.0 1.5 5.456 Case 6 2.1 891 2.13 63.2 0.5/1.0 2.0 7.274 表 4 三维连续液柱模型参数

Table 4. 3D continuous liquid column model parameters.

类别 $x{\rm{/}}d$ $y{\rm{/}}d$ $z/d$ 考虑质量损失 0—1.92 0—4.17 –1.03—1.03 -

[1] Xiao F, Dianat M, Mcguirk J J 2013 AIAA J. 51 2878

Google Scholar

Google Scholar

[2] 夏同军, 董永强, 曹义刚 2013 62 214702

Google Scholar

Google Scholar

Xia T J, Dong Y Q, Cao Y G 2013 Acta Phys. Sin. 62 214702

Google Scholar

Google Scholar

[3] Heister S D 2011 Handbook of Atomization and Sprays: Theory and Applications (New York: Springer) pp65−660

[4] Li C Y, Li C, Xiao F, Li Q L, Zhu Y H 2019 Aerosp. Sci. Technol. 95 105426

Google Scholar

Google Scholar

[5] Dixon D R, Gruber M R, Jackson T A, Lin K C 2005 43th AIAA Aerospace Sciences Meeting & Exhibit Reno, America, January 10−13, 2005 p733

[6] Wu L Y, Wang Z G, Li Q L, Li C 2016 J. Visualization 3 337

Google Scholar

Google Scholar

[7] Hu R S, Li Q, Li C Y, Li C 2019 Acta Astronaut. 159 440

Google Scholar

Google Scholar

[8] Lin K C, Kennedy P J 2002 40 th AIAA Aerospace Sciences Meeting & Exhibit Reno, America, January 14−17, 2002 p873

[9] Lin K C, Kennedy P J, Kennedy P J, Jackson T A 2004 42th AIAA Aerospace Sciences Meeting & Exhibit Reno, America, January 5−8, 2004 p971

[10] 刘静, 王辽, 张佳, 韦宝禧, 徐旭 2008 航空动力学报 4 146

Google Scholar

Google Scholar

Liu J, Wang L, Zhang J, Wei B X, Xu X 2008 J. Aerosp. Power 4 146

Google Scholar

Google Scholar

[11] 仝毅恒, 李清廉, 吴里银 2012 国防科技大学学报 2 73

Google Scholar

Google Scholar

Tong Y H, Li Q L, Wu L Y 2012 J. Natl. Univ. Def. Technol. 2 73

Google Scholar

Google Scholar

[12] 李春 2014 硕士学位论文 (长沙: 国防科学技术大学)

Li C 2012 M. S. Thesis (Changsha: National University of Defense Technology) (in Chinese)

[13] 吴里银, 王振国, 李清廉, 李春 中国专利 zl201410800056.5 [2018-2-2]

Wu L Y, Wang Z G, Li Q L, Li C Chinese Patent zl201410800056.5 [20218-2-2] (in Chinese)

[14] 胡润生, 朱元昊, 张翔宇, 李清廉 2019 工程热 7 1659

Google Scholar

Google Scholar

Hu R S, Zhu Y H, Zhang X Y, Li Q L 2019 J. Eng. Therm. 7 1659

Google Scholar

Google Scholar

[15] 吴里银, 王振国, 李清廉, 李春 2016 68 094701

Google Scholar

Google Scholar

Wu L Y, Wang Z G, Li Q L, Li C 2016 Acta Phys. Sin. 68 094701

Google Scholar

Google Scholar

[16] 周曜智, 李清廉, 李晨阳 2020 推进技术 41 7

Google Scholar

Google Scholar

Zhou Y Z, Li Q L, Li C Y 2020 J. Propul. Technol. 41 7

Google Scholar

Google Scholar

[17] Mashayek A, Behzad M, Ashgriz N 2011 AIAA J. 49 2407

Google Scholar

Google Scholar

[18] 李春 2020 博士学位论文 (长沙: 国防科技大学)

Li C 2020 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[19] Xiao F, Wang Z G, Sun M B, Liang J H, Liu N 2016 Int. J. Multiphase Flow 87 229

Google Scholar

Google Scholar

[20] 李佩波, 王振国, 孙明波, 汪洪波 2016 宇航学报 37 79

Google Scholar

Google Scholar

Li P B, Wang Z G, Sun M B, Wang H B 2016 J. Astronautics 37 79

Google Scholar

Google Scholar

[21] Zhu Y X, Xiao F, Li Q L, Li C Y, Lin S 2018 Acta Astronaut. 154 119

Google Scholar

Google Scholar

[22] Liu N, Wang Z G, Sun M B, Deiterding R, Wang H B 20191 Aerosp. Sci. Technol. 91 456

Google Scholar

Google Scholar

[23] Douglas H F, Vitor V, Lucas S M, Francisco J S 2019 Int. J. Multiphase Flow 114 98

Google Scholar

Google Scholar

[24] Li P B, Li C Y, Wang H B, Sun M B, Liu C Y, Wang Z G, Huang Y H 2019 Aerosp. Sci. Technol. 94 105401

Google Scholar

Google Scholar

[25] Nguyen T, Karagozian A R 1992 J. Propul. Power 8 21

Google Scholar

Google Scholar

[26] Clark M M 1988 Chem. Eng. Sci. 43 671

Google Scholar

Google Scholar

[27] Inamura T 2000 J. Propul. Power 16 155

Google Scholar

Google Scholar

[28] Sallam K A, Aalburg C, Faeth G M 2004 AIAA J. 42 2529

Google Scholar

Google Scholar

[29] Wu P K, Kirkendall K A, Fuller R P, Nejad A S 1997 J. Propul. Power 13 64

Google Scholar

Google Scholar

[30] 吴里银 2016 博士学位论文 (长沙: 国防科学技术大学

Wu L Y 2016 Ph. D. Dissertation (Changsha: National University of Defense Technology) (in Chinese)

[31] Lee K, Aalburg C, Diez F J, Faeth G M, Sallam K A 2007 AIAA J. 45 1907

Google Scholar

Google Scholar

[32] Ranger A A, Nicholls J A 1969 AIAA J. 7 285

Google Scholar

Google Scholar

[33] Chryssakis C A, Assanis, D N 2005 18th Annual Conference on Liquid and Atomization and Spray Systems, Irvine, America, May 15−18, 2005 p283

计量

- 文章访问数: 10656

- PDF下载量: 153

- 被引次数: 0

下载:

下载: