-

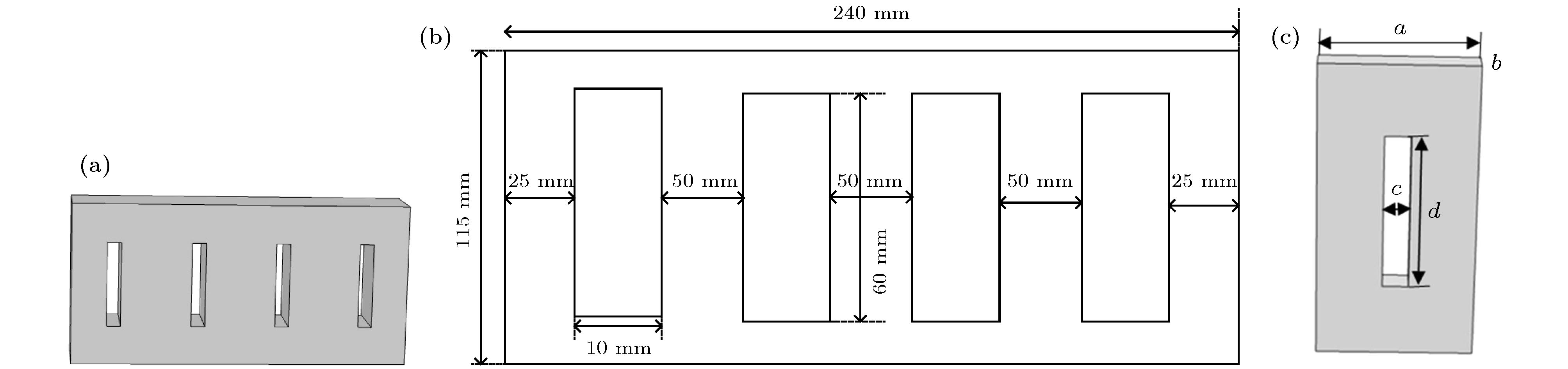

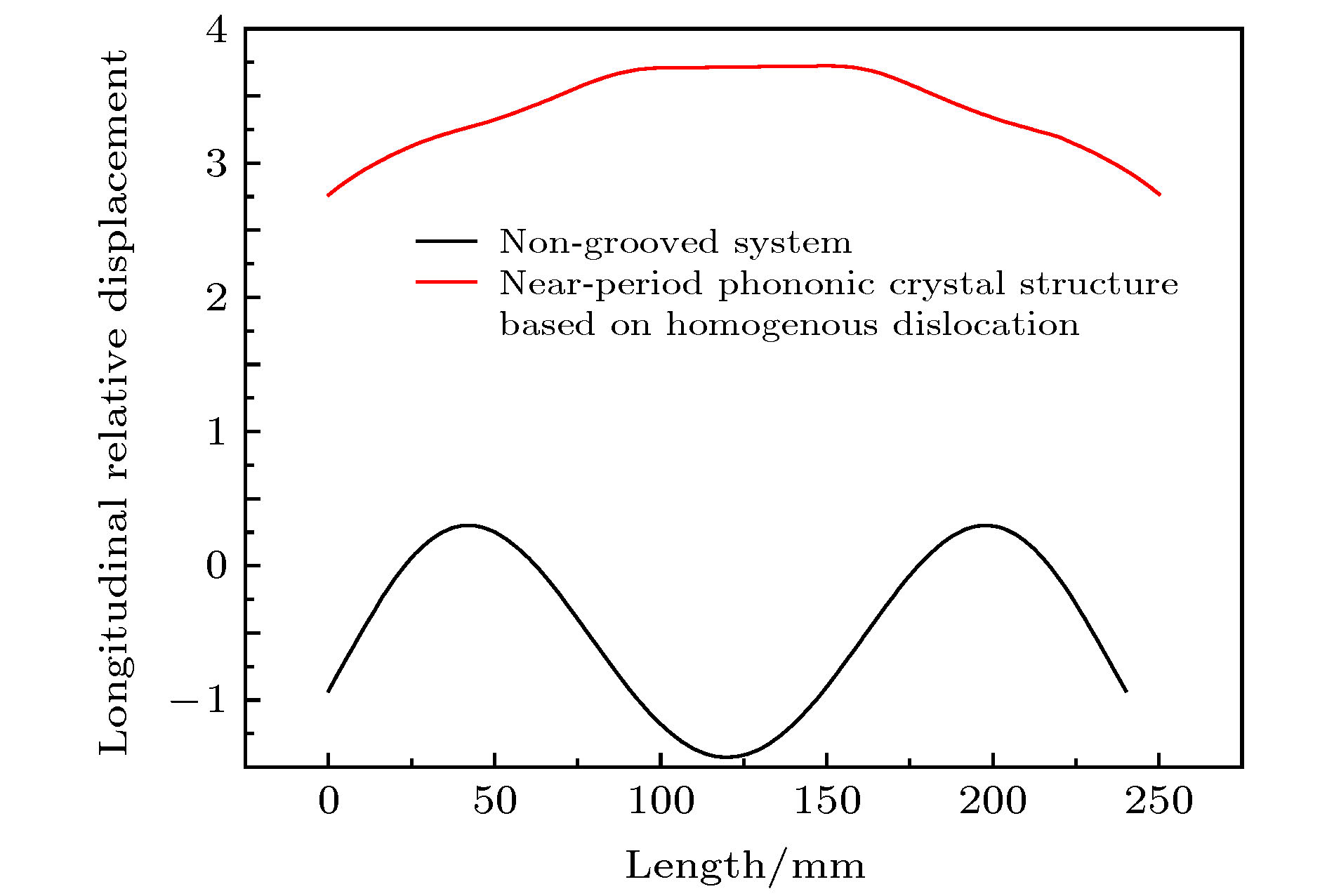

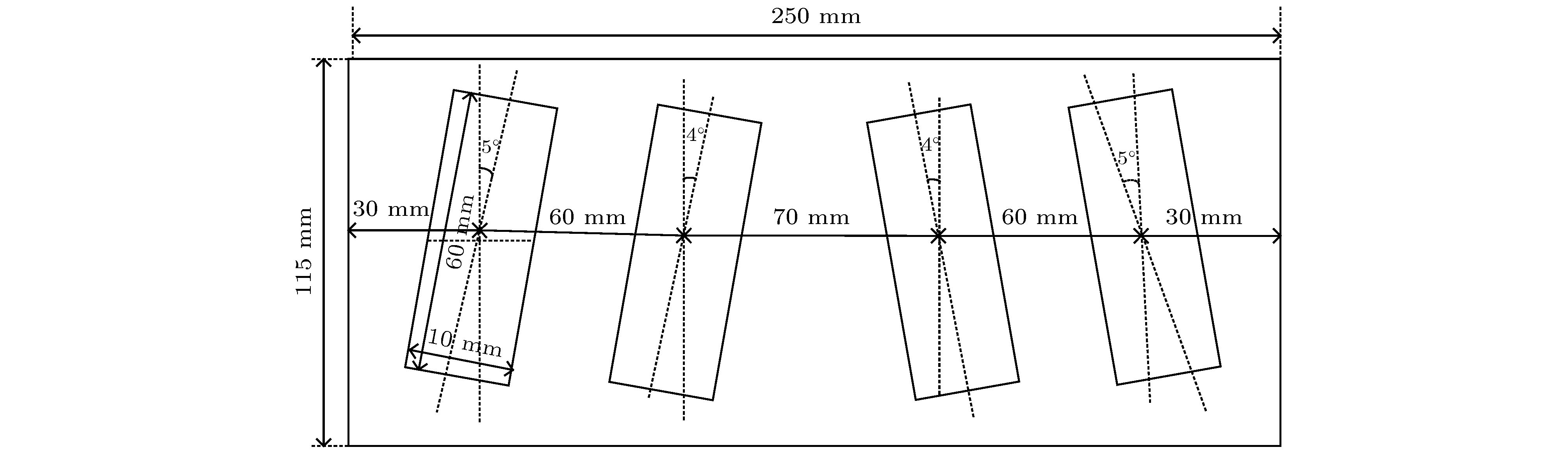

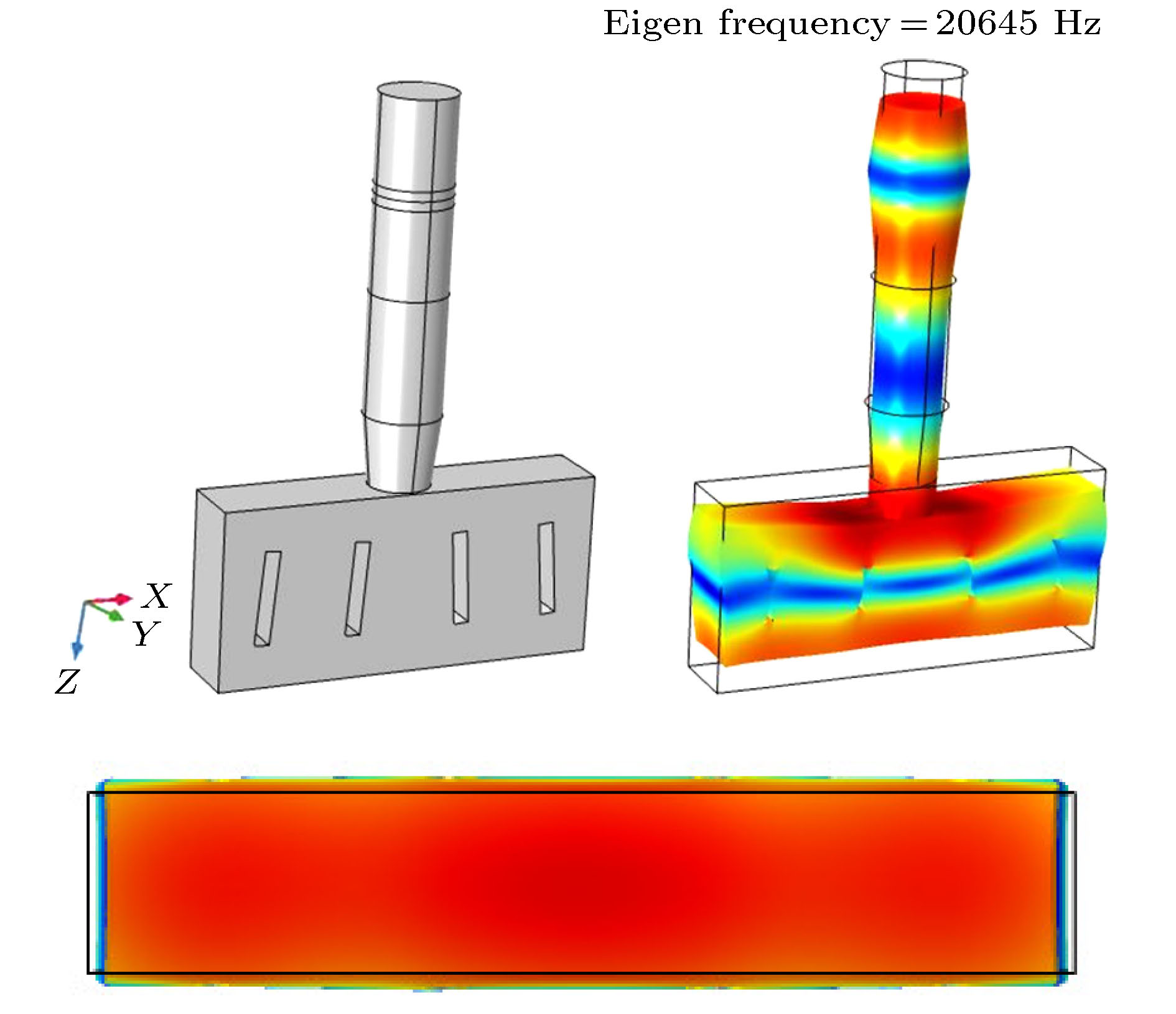

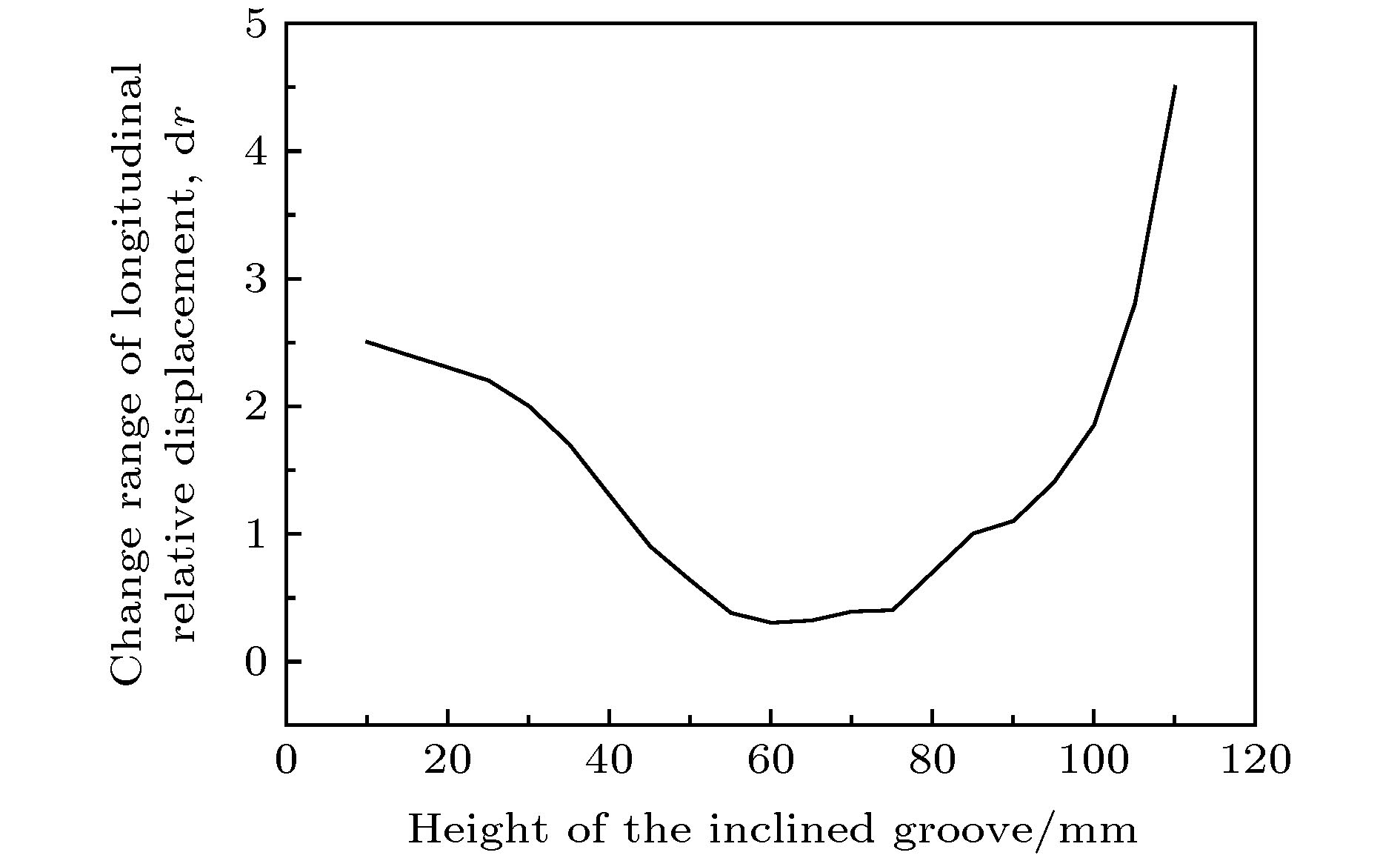

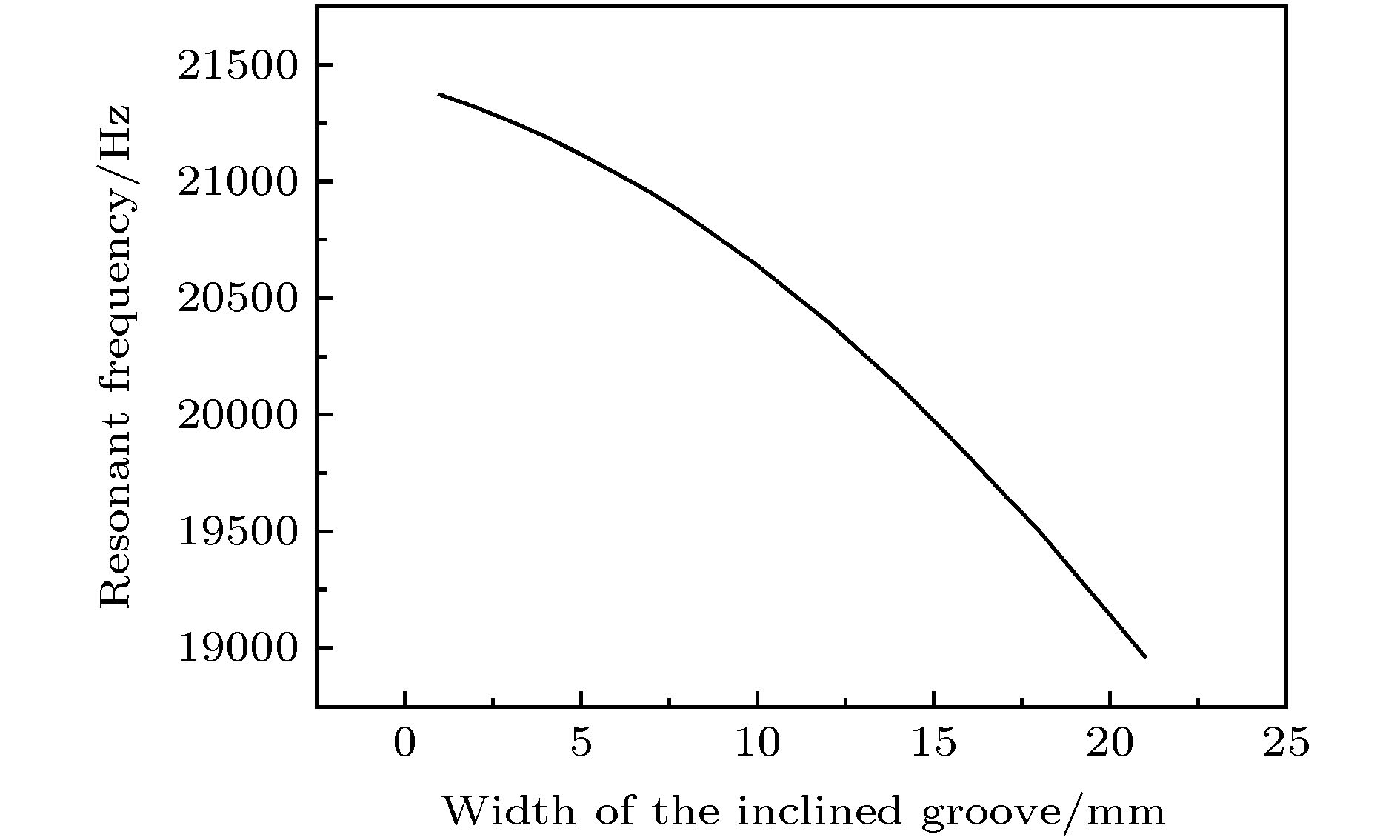

为了有效改善二维工具头辐射面振幅分布不均匀的问题, 对二维超声塑料焊接系统进行了优化设计研究: 首先, 利用横向位错在大尺寸长条形工具头上构造近周期声子晶体同质位错结, 调节带隙的宽度和位置, 使得二维超声塑料焊接系统的工作频率位于工具头的横向振动的带隙内, 进而有效地控制工具头X方向的横向振动; 其次, 利用近周期声子晶体斜槽结构进一步优化辐射面的振幅分布均匀度, 并分析了斜槽结构参数对超声塑料焊接系统纵向共振频率和振幅分布均匀度的影响规律. 模拟仿真结果表明, 近周期声子晶体同质位错结和斜槽结构能够实现对二维超声塑料焊接系统的优化, 为横向振动抑制理论的进一步研究提供了基础.When the lateral dimension of the tool head is close to or greater than a quarter of the longitudinal wave length, the tool head will produce severe lateral vibration. The coupling of the lateral vibration and the longitudinal vibration makes the amplitude distribution of the tool head’s radiation surface uneven, which seriously affects the welding quality. To solve the problem of uneven amplitude distribution of the two-dimensional tool head’s radiating surface, in the paper we conduct an optimized design study on a two-dimensional ultrasonic plastic welding system. First, using the theory of phononic crystal dislocations, we construct a nearly periodic phononic crystal homogenous dislocation junction on a large-sized long strip tool head, and use the homogenous dislocation junction to change the regular lattice arrangement of the phononic crystal structure to adjust the position of the band gap and increase the width of the band gap, so that the operating frequency of the two-dimensional ultrasonic plastic welding system can be located in the band gap of the lateral vibration of the tool head, and the effective control of the lateral coupling vibration of the tool head can be achieved, thus optimizing the amplitude uniformity of the radiating surface of the tool head and increasing the amplitude gain. Although the homogenous dislocation junction structure improves the amplitude uniformity of the radiating surface of the tool head, the lateral dislocation effect of the homogenous dislocation junction causes the sound waves in the band gap frequency range to propagate along the dislocation channel, while the dislocation line channel is located in the middle of the tool head, which results in a larger displacement of the middle part of the tool head’s radiating surface, and a smaller displacement on both sides. Therefore, the further optimizing of the two-dimensional tool head is required. In this study, the nearly periodic phononic crystal inclined groove structure is used to better optimize the amplitude distribution uniformity of the radiating surface, and the influence of the inclined groove structure parameters on the longitudinal resonance frequency and amplitude distribution uniformity of the ultrasonic plastic welding system are analyzed, that is, the inclined groove can better improve the uniformity of the amplitude distribution than the straight groove, but the angle of inclination of neither the inner nor outer inclined grooves should be too large: the optimal range is 3°-6°. In addition, the difference in inclination angle between the inner inclined groove and the outer inclined groove should not be too large, and the angle difference from 0° to 2° is best. The simulation results show that the nearly periodic phononic crystal homogenous dislocation junction and inclined groove structure can optimize the two-dimensional ultrasonic plastic welding system, which provides a basis for further research on the theory of lateral vibration suppression.

-

Keywords:

- near-period phononic crystal /

- homogeneous dislocation junction /

- inclined groove structure /

- amplitude distribution uniformity

[1] Rani M R, Rudramoorthy R 2012 Ultrasonics 53 763772

Google Scholar

Google Scholar

[2] Wells, Peter J 1991 Asse. Auto. 11 1014

Google Scholar

Google Scholar

[3] Shu-Chu R 1982 Chin.Jour. Acous. 1 138151

Google Scholar

Google Scholar

[4] Shu-Chu R 1983 Acta Acus. 1 152161

Google Scholar

Google Scholar

[5] Shu K M, Wang Y J, Chi C W 2014 Appl. Mecha. & Mater. 28 329332

Google Scholar

Google Scholar

[6] Hung J C, Tsai Y P, Hung C H 2012 Appl. Mecha. & Mater. 14 98

Google Scholar

Google Scholar

[7] Cardoni A, Lucas M 2002 Ultrasonics 40 365369

Google Scholar

Google Scholar

[8] Adachi K, Ueha S 1990 Jour. Acous. Soci. Ame. 87 208214

Google Scholar

Google Scholar

[9] Mori E, Itoh K, Imamura A 1995 Jour. acou. Soci. Japan 51 455462

Google Scholar

Google Scholar

[10] Lucas M, Smith A C 1997 Jour. Vibr. Acous. 119 410413

Google Scholar

Google Scholar

[11] Lee Y J, Shahid M B, Park D S 2019 MATEC Web Conf 257 02009

Google Scholar

Google Scholar

[12] Nguyen T H, Quang Q T, Tran C L, Nguyen H L 2017 5th Asia Conference on Mechanical and Materials Engineering Tokyo, Japan, June 9–11, 2017 p012023

[13] Kumar R D, Rani M R, Elangovan S 2014 Appl. Mecha. & Mater. 592 859863

Google Scholar

Google Scholar

[14] Rani M R, Prakasan K, Rudramoorthy R 2014 Int. J. Desi. Engi. 5 344357

Google Scholar

Google Scholar

[15] 林书玉, 张福成 1992 声学技术 4 2428

Google Scholar

Google Scholar

Lin S Y, Zhang F C 1992 Acou. Tech. 4 2428

Google Scholar

Google Scholar

[16] 梁召峰, 周光平, 莫喜平, 李正中 2009 工程设计学报 16 200204

Google Scholar

Google Scholar

Liang Z F, Zhou G P, Mo X P, Li Z Z 2009 Engi. Desi. Jour. Acc. 16 200204

Google Scholar

Google Scholar

[17] 赵甜甜, 林书玉, 段祎林 2018 67 224207

Google Scholar

Google Scholar

Zhao T T, Lin S Y, Duan Y L 2018 Acta Phys. Sin. 67 224207

Google Scholar

Google Scholar

[18] Lin J Y, Lin S Y 2020 Crystals 10 116

Google Scholar

Google Scholar

[19] Guo D F 2015 Ph. D. Dissertation (Beijing: Beijing Jiaotong University) (in Chinese)

[20] Wang G, Wen X S, Wen J H, Liu Y Z 2006 Jour. Appl. Mech. Tran. ASME 73 167170

Google Scholar

Google Scholar

[21] Chen A, Wang Y, Yu G, et al. 2008 Acta Mech. Soli.Sini. 21 4051

Google Scholar

Google Scholar

[22] Steurer W, Sutter-Widmer D 2007 Jour. Phy. D Appl. Phys. 40 R229

Google Scholar

Google Scholar

[23] 赵芳, 苑立波 2006 55 517

Google Scholar

Google Scholar

Zhao F, Yuan L B 2006 Acta Phys. Sin. 55 517

Google Scholar

Google Scholar

[24] 赵言诚, 赵芳, 苑立波 2006 哈尔滨工程大学学报 4 145148

Google Scholar

Google Scholar

Zhao Y C, Zhao F, Yuan L B 2006 Jour. Harbin Engi.Uni. 4 145148

Google Scholar

Google Scholar

[25] Khelif A, Choujaa A, Djafari-Rouhani B, et al. 2003 Phys. Rev. B 68 214301

Google Scholar

Google Scholar

[26] Vasseur J, Deymier P, Djafari-Rouhani B, et al. 2008 Phys. Rev. B 77 85415

Google Scholar

Google Scholar

[27] Soliman Y M, Su M F, Leseman Z C, et al. 2010 Appl. Phys. Lett. 97 081907

Google Scholar

Google Scholar

[28] Liu Y, Su J Y, Xu Y L, et al. 2009 Ultrasonics 49 276280

Google Scholar

Google Scholar

-

图 11 基于近周期声子晶体同质位错结系统的工具头辐射面位移分布图及与不开槽系统的位移分布对比图

Fig. 11. Displacement distribution diagram of tool head radiating surface of system based on near-period phononic crystal homogenous dislocation junction and its comparison with radiation surface displacement distribution with non-grooved system and system.

图 14 基于近周期声子晶体斜槽结构的工具头辐射面位移分布及其同近周期声子晶体同质位错工具头辐射面位移分布对比图

Fig. 14. Displacement distribution diagram of tool head radiating surface of system based on near-period phononic crystal inclined groove structure and its comparison with the displacement distribution of radiating surface of tool head with homogenous dislocation in near-period phononic crystal

-

[1] Rani M R, Rudramoorthy R 2012 Ultrasonics 53 763772

Google Scholar

Google Scholar

[2] Wells, Peter J 1991 Asse. Auto. 11 1014

Google Scholar

Google Scholar

[3] Shu-Chu R 1982 Chin.Jour. Acous. 1 138151

Google Scholar

Google Scholar

[4] Shu-Chu R 1983 Acta Acus. 1 152161

Google Scholar

Google Scholar

[5] Shu K M, Wang Y J, Chi C W 2014 Appl. Mecha. & Mater. 28 329332

Google Scholar

Google Scholar

[6] Hung J C, Tsai Y P, Hung C H 2012 Appl. Mecha. & Mater. 14 98

Google Scholar

Google Scholar

[7] Cardoni A, Lucas M 2002 Ultrasonics 40 365369

Google Scholar

Google Scholar

[8] Adachi K, Ueha S 1990 Jour. Acous. Soci. Ame. 87 208214

Google Scholar

Google Scholar

[9] Mori E, Itoh K, Imamura A 1995 Jour. acou. Soci. Japan 51 455462

Google Scholar

Google Scholar

[10] Lucas M, Smith A C 1997 Jour. Vibr. Acous. 119 410413

Google Scholar

Google Scholar

[11] Lee Y J, Shahid M B, Park D S 2019 MATEC Web Conf 257 02009

Google Scholar

Google Scholar

[12] Nguyen T H, Quang Q T, Tran C L, Nguyen H L 2017 5th Asia Conference on Mechanical and Materials Engineering Tokyo, Japan, June 9–11, 2017 p012023

[13] Kumar R D, Rani M R, Elangovan S 2014 Appl. Mecha. & Mater. 592 859863

Google Scholar

Google Scholar

[14] Rani M R, Prakasan K, Rudramoorthy R 2014 Int. J. Desi. Engi. 5 344357

Google Scholar

Google Scholar

[15] 林书玉, 张福成 1992 声学技术 4 2428

Google Scholar

Google Scholar

Lin S Y, Zhang F C 1992 Acou. Tech. 4 2428

Google Scholar

Google Scholar

[16] 梁召峰, 周光平, 莫喜平, 李正中 2009 工程设计学报 16 200204

Google Scholar

Google Scholar

Liang Z F, Zhou G P, Mo X P, Li Z Z 2009 Engi. Desi. Jour. Acc. 16 200204

Google Scholar

Google Scholar

[17] 赵甜甜, 林书玉, 段祎林 2018 67 224207

Google Scholar

Google Scholar

Zhao T T, Lin S Y, Duan Y L 2018 Acta Phys. Sin. 67 224207

Google Scholar

Google Scholar

[18] Lin J Y, Lin S Y 2020 Crystals 10 116

Google Scholar

Google Scholar

[19] Guo D F 2015 Ph. D. Dissertation (Beijing: Beijing Jiaotong University) (in Chinese)

[20] Wang G, Wen X S, Wen J H, Liu Y Z 2006 Jour. Appl. Mech. Tran. ASME 73 167170

Google Scholar

Google Scholar

[21] Chen A, Wang Y, Yu G, et al. 2008 Acta Mech. Soli.Sini. 21 4051

Google Scholar

Google Scholar

[22] Steurer W, Sutter-Widmer D 2007 Jour. Phy. D Appl. Phys. 40 R229

Google Scholar

Google Scholar

[23] 赵芳, 苑立波 2006 55 517

Google Scholar

Google Scholar

Zhao F, Yuan L B 2006 Acta Phys. Sin. 55 517

Google Scholar

Google Scholar

[24] 赵言诚, 赵芳, 苑立波 2006 哈尔滨工程大学学报 4 145148

Google Scholar

Google Scholar

Zhao Y C, Zhao F, Yuan L B 2006 Jour. Harbin Engi.Uni. 4 145148

Google Scholar

Google Scholar

[25] Khelif A, Choujaa A, Djafari-Rouhani B, et al. 2003 Phys. Rev. B 68 214301

Google Scholar

Google Scholar

[26] Vasseur J, Deymier P, Djafari-Rouhani B, et al. 2008 Phys. Rev. B 77 85415

Google Scholar

Google Scholar

[27] Soliman Y M, Su M F, Leseman Z C, et al. 2010 Appl. Phys. Lett. 97 081907

Google Scholar

Google Scholar

[28] Liu Y, Su J Y, Xu Y L, et al. 2009 Ultrasonics 49 276280

Google Scholar

Google Scholar

计量

- 文章访问数: 8257

- PDF下载量: 110

- 被引次数: 0

下载:

下载: