-

在钙钛矿电池中, ZnO纳米棒的垂直性是影响器件效率的关键因素. AZO(ZnO:Al)玻璃作为一种廉价的透明导电衬底, 由于与ZnO纳米棒无晶格失配, 有望获得最佳垂直性. 然而目前在大气环境下, 以AZO为衬底、ZnO纳米棒为电子传输层的钙钛矿太阳能电池还鲜有报道. 本文通过水热法制备ZnO纳米棒作为电子传输层, 系统研究不同条件对ZnO纳米棒的形貌及结晶性能的调控规律, 分析其微观生长机理. 并在此基础上于大气环境下制备太阳能电池, 将以AZO为衬底在大气条件下制备的钙钛矿光伏器件的最佳效率从目前文献报道的7.0%提高到9.63%. 这对丰富钙钛矿电池的设计思路及进一步降低成本具有重要意义.

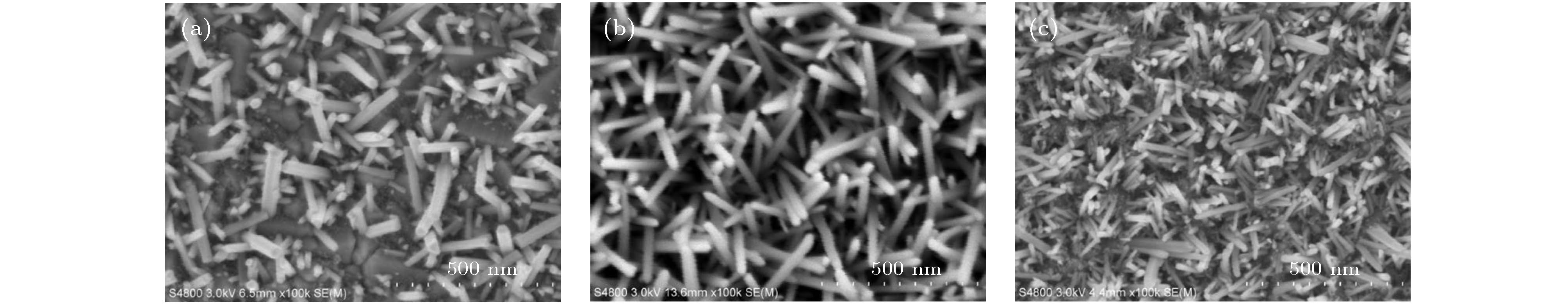

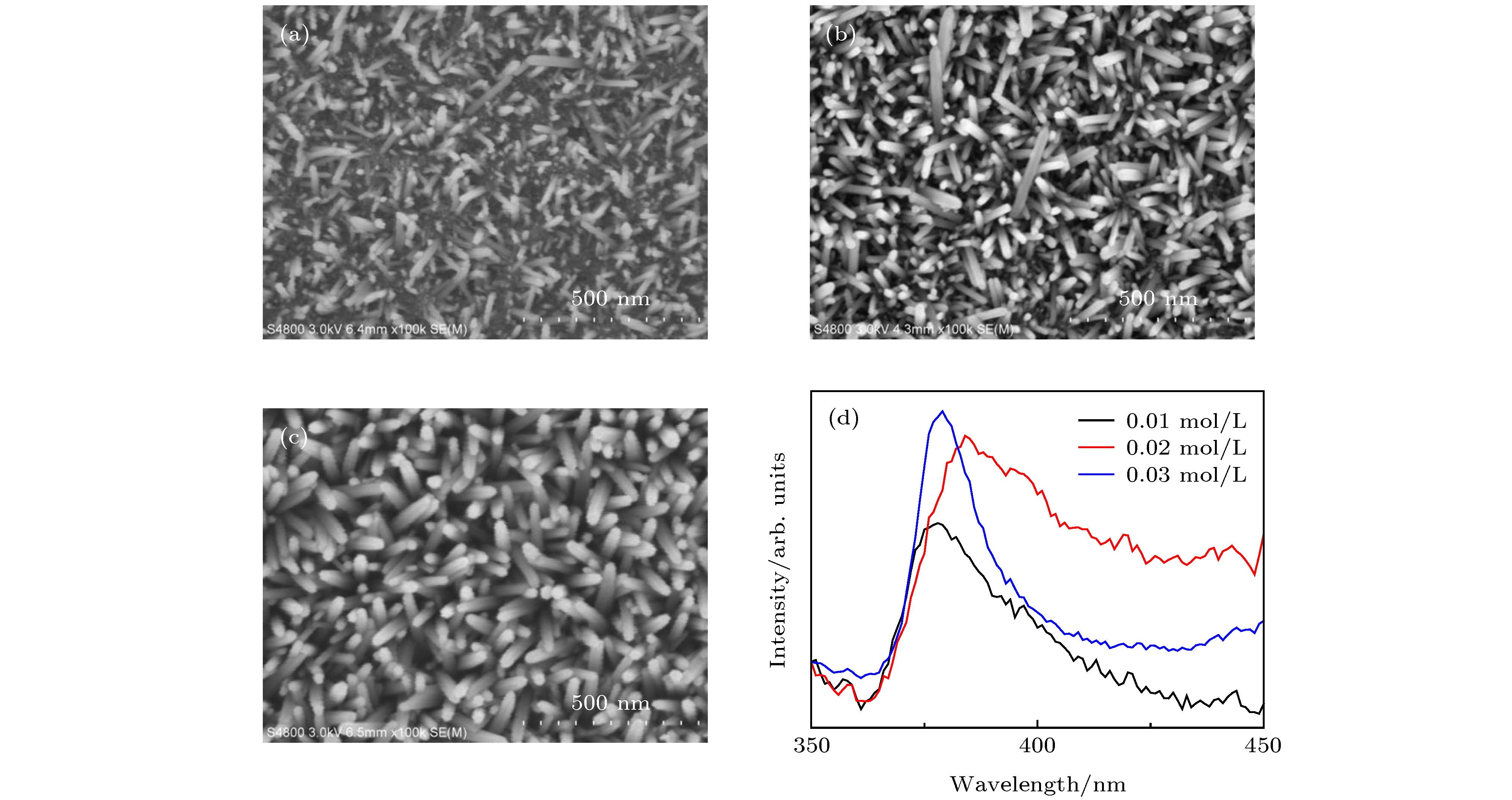

ZnO is a promising electron transport material. It has not only similar energy level position and physical properties to traditional TiO2, but also excellent light transmittance, conductivity, stability, low cost and low temperature preparation. Studies have shown that the one-dimensional nanostructured electron transport layer has a higher electron transport rate, provides a direct electron transport channel and avoids its being recombined at the grain boundaries, thereby improving carrier collection efficiency. It has also been reported that the electron transport rate of ZnO nanorods is significantly better than that of TiO2, showing their great potential applications. In perovskite solar cells, the verticality of ZnO nanorods is a key factor affecting device efficiency. The AZO (ZnO∶Al) glass, as an inexpensive transparent conductive substrate, is expected to obtain the best verticality because it has no lattice mismatch with ZnO nanorods. And in the field of perovskite solar cells, the light absorbing layer is usually prepared in a glove box and it has obviously not been industralized. However, there are few reports about perovskite solar cells prepared in atmospheric environment with AZO as substrate and ZnO nanorods as electron transport layer. And it is still much less efficient than the current perovskite solar cells with TiO2 as the electronic transport layer. It can be seen that further improving the efficiency of the structural battery prepared in the atmospheric environment is an urgent problem to be solved. In this paper, ZnO nanorods are prepared as an electron transport layer by the hydrothermal method. The effects of hydrothermal temperature, the number of seed layer, the precursor concentration, the substrate type, the hydrothermal time, and the other process parameters on the morphology and crystalline properties of ZnO nanorods are systematically studied, and the growth mechanism is analyzed. The results show that the length of the nanorods is mainly controlled by the hydrothermal time and hydrothermal temperature, and that the radial size is mainly determined by the number of seed layers and the concentration of the precursor solution. And the results also indicate that the verticality of ZnO nanorods’ growth is closely related to the substrate, and that the ZnO nanorods on the AZO substrate have the best growth verticality. On this basis, the perovskite solar cell is prepared in the atmospheric environment, and the optimal efficiency of the photovoltaic device prepared with AZO substrate increases from 7.0% reported in the literature to 9.63%. This is of great significance for enriching the design ideas of perovskite solar cells and further reducing costs. -

Keywords:

- zinc oxide nanorods /

- aluminum-doped zinc oxide substrate /

- atmospheric environment /

- perovskite solar cells

[1] Zhao Y Q, Ma Q, Liu B, Yu Z L, Yang J, Cai M Q 2018 Nanoscale 10 8677

Google Scholar

Google Scholar

[2] Yu Z L, Zhao Y Q, He P B, Liu B, Cai M 2019 J. Phys. Condens. Matter. 32

[3] Zhang J Y, Su J, Lin Z H, Liu M Y, Chang J J 2019 Appl. Phys. Lett. 114 181902

Google Scholar

Google Scholar

[4] Ding Y F, Zhao Q Q, Yu Z L, Zhao Y Q, Liu B, He P B 2019 J. Mater. Chem. C 7 7433

Google Scholar

Google Scholar

[5] Green M A, Ho-baillie A, Snaith H J 2014 Nat. Photonics. 8 506

Google Scholar

Google Scholar

[6] Dong Q, Fang Y, Shao Y, Mulligan P, Qiu J, Cao L 2015 Science 347 967

Google Scholar

Google Scholar

[7] Kojima A, Teshima K, Shirai Y 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[8] Ma L, Hao F, Stoumpos C C, Phelan B T, Wasielewski M R, Kanatzidis M G 2016 J. Am. Chem. Soc. 138 14750

Google Scholar

Google Scholar

[9] Ogomi Y, Morita A, Tsukamoto S, Saitho T, Hayase S 2014 J. Phys. Chem. Lett. 6 1004

[10] Jung H S, Park N G 2015 Small 16 1613

[11] Zhang P, Wu J, Zhang T, Wang Y, Liu D, Chen H 2018 Adv. Mater. 30 3

[12] Tseng Z L, Chiang C H, Chang S H, Wu C G 2016 Nano. Energy. 28 2211

[13] Zhang Q, Dandeneau C S, Zhou X, Cao G 2009 Adv. Mater. 21 4087

Google Scholar

Google Scholar

[14] Wang Z L 2004 J. Phys. Condens. Matter. 16 R829

Google Scholar

Google Scholar

[15] Liu H, Huang Z, Wei S, Zheng L, Gong Q 2016 Nanoscale 8 6209

Google Scholar

Google Scholar

[16] Law M, Greene L E, Johnson J C 2005 Nat. Mater. 4 455

Google Scholar

Google Scholar

[17] Kumar M H, Yantara N, Dharani S, Graetzel M, Mhaisalkar S, Boix P P 2013 Chem. Commun. 49 11089

Google Scholar

Google Scholar

[18] Wang H, Yan L, Liu J, Li J 2016 J. Mater. SCI-Mater. EL 27 6872

Google Scholar

Google Scholar

[19] Ferrara V L, Maria A D, Rametta G, Noce M D, Veneri P D 2017 Mater. Res. Express. 4 355

[20] 郎集会, 李雪, 刘晓艳, 杨景海 2009 吉林师范大学学报(自然科学版) 30 35

Lang J H, Li X, Liu X Y, Yang J H 2009 J. Jilin. Normal. Univ (Natural Science Edition) 30 35

-

图 1 (a) 应用ZnO纳米棒作为ETL的钙钛矿型太阳能电池的结构示意图; (b) ZnO和TiO2电性能的比较; (c) ZnO, TiO2与其他材料在PSCs中的能级

Fig. 1. (a) Structural schematic diagram of perovskite solar cells using ZnO nanorods as ETL; (b) comparison of the electrical proper-ties of ZnO, TiO2; (c) the energy level of ZnO, TiO2, and other usually used materials in PSCs.

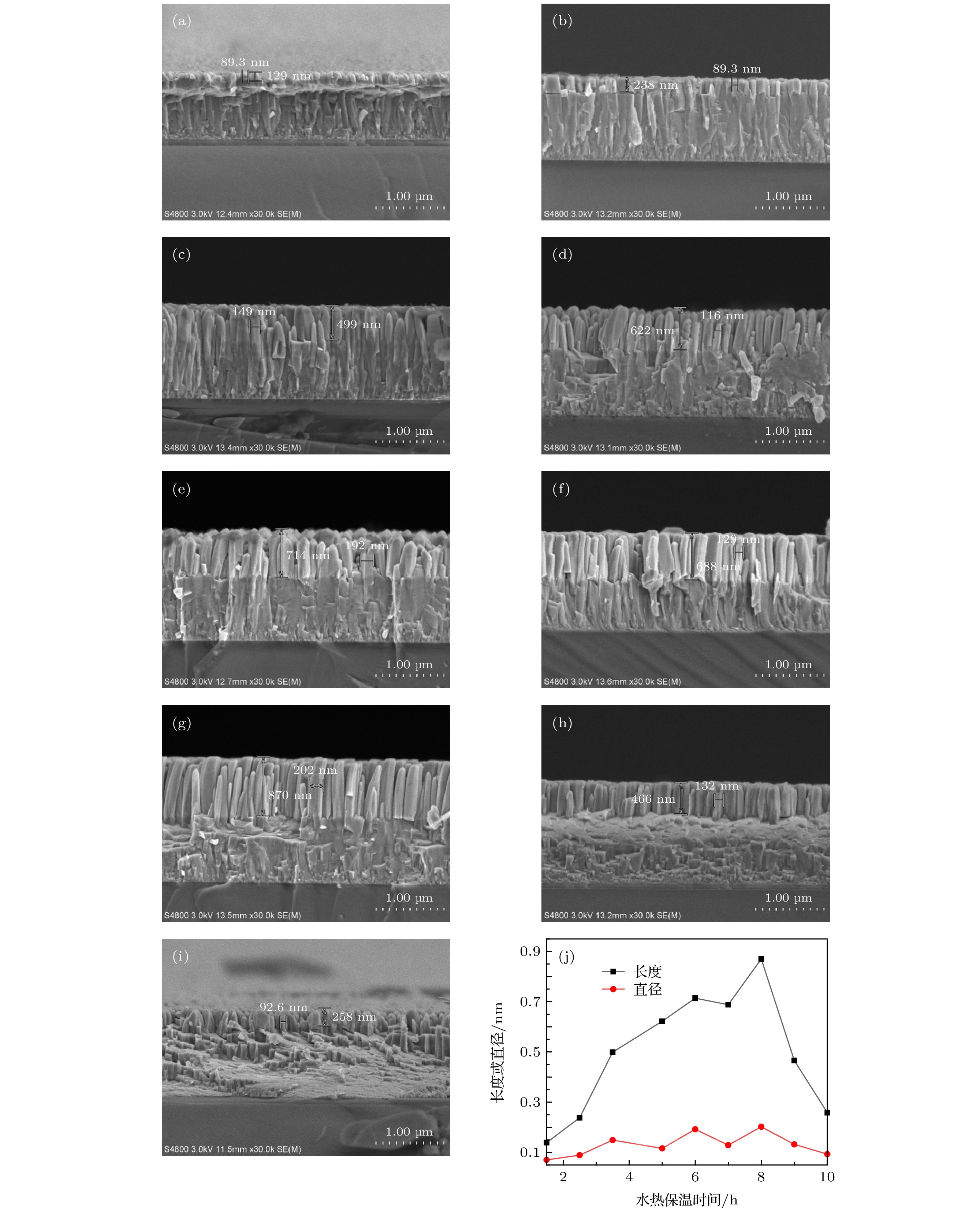

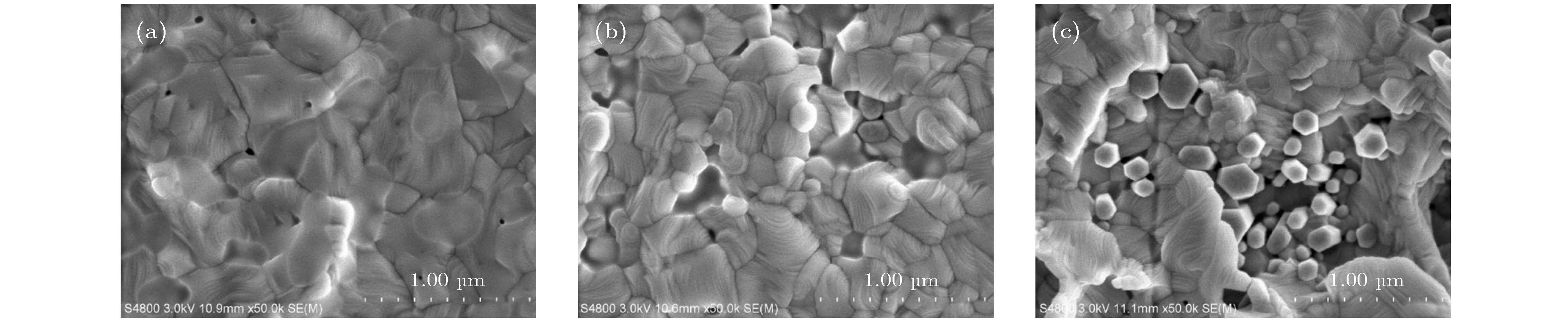

图 6 氧化锌纳米棒长度和直径随水热时间的变化SEM与折线图 (a) 1.5 h; (b) 2.5 h; (c) 3.5 h; (d) 5.0 h; (e) 6.0 h; (f) 7.0 h; (g) 8.0 h; (h) 9.0 h; (i) 10.0 h; (j) 折线图

Fig. 6. Changes of the length and diameter SEM of ZnO nanorods with water heat time: (a) 1.5 h; (b) 2.5 h; (c) 3.5 h; (d) 5.0 h; (e) 6.0 h; (f) 7.0 h; (g) 8.0 h; (h) 9.0 h; (i) 10.0 h; (j) line chart.

表 1 不同水热温度条件下制备的氧化锌纳米棒的平均长度和直径

Table 1. Average length and diameter of ZnO nanobars prepared under different water temperature conditions.

条件 温度/℃ 平均直径/nm 平均长度/nm 1 50 28 47 2 60 33 245 3 70 30 550 4 80 31 740 5 90 34 948 6 100 32 871 表 2 不同水热时间条件下所制备的氧化锌纳米棒的平均长度和直径

Table 2. Average length and diameter of zinc oxide nanorods prepared under different water heat time.

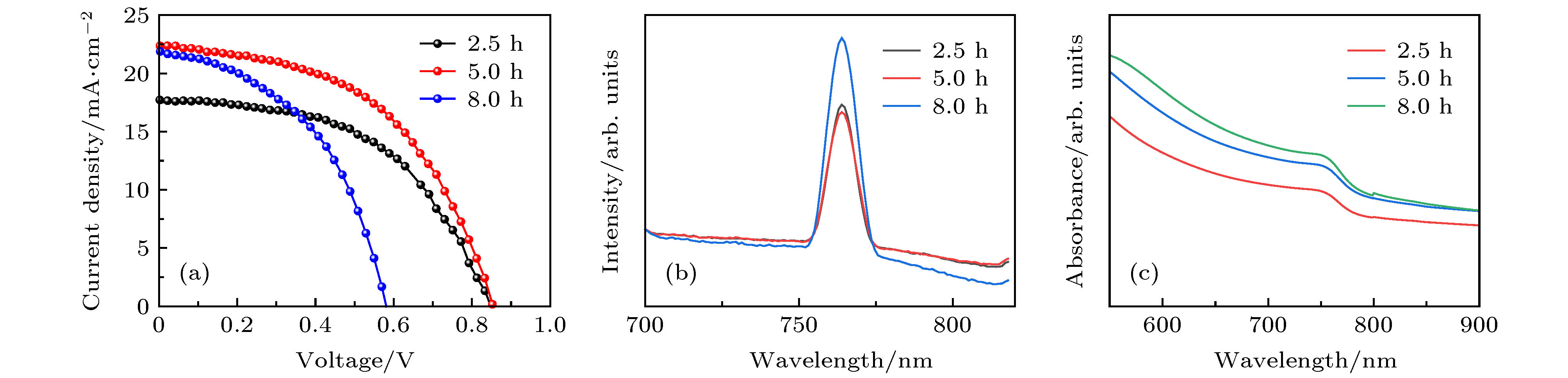

条件 衬底 保温时间/h 平均长度/nm 平均直径/nm 1 AZO 1.5 132 76 2 AZO 2.5 244 92 3 AZO 3.5 503 139 4 AZO 5.0 620 121 5 AZO 6.0 722 189 6 AZO 7.0 701 136 7 AZO 8.0 866 204 8 AZO 9.0 470 135 9 AZO 10.0 255 94 表 3 不同氧化锌纳米棒水热时间所制备PSCs平均性能参数及最佳PCE

Table 3. Average performance parameters and champion PCE of PSCs from different water heat time of ZnO nanorods.

水热条件/h Scan directions Voc/V Jsc/mA·cm–2 FF 平均PCE/% 最佳PCE/% 2.5 Reverse 0.77 18.51 0.47 6.71 7.96 5.0 Reverse 0.84 20.99 0.48 8.47 9.63 8.0 Reverse 0.52 17.15 0.43 3.85 6.00 -

[1] Zhao Y Q, Ma Q, Liu B, Yu Z L, Yang J, Cai M Q 2018 Nanoscale 10 8677

Google Scholar

Google Scholar

[2] Yu Z L, Zhao Y Q, He P B, Liu B, Cai M 2019 J. Phys. Condens. Matter. 32

[3] Zhang J Y, Su J, Lin Z H, Liu M Y, Chang J J 2019 Appl. Phys. Lett. 114 181902

Google Scholar

Google Scholar

[4] Ding Y F, Zhao Q Q, Yu Z L, Zhao Y Q, Liu B, He P B 2019 J. Mater. Chem. C 7 7433

Google Scholar

Google Scholar

[5] Green M A, Ho-baillie A, Snaith H J 2014 Nat. Photonics. 8 506

Google Scholar

Google Scholar

[6] Dong Q, Fang Y, Shao Y, Mulligan P, Qiu J, Cao L 2015 Science 347 967

Google Scholar

Google Scholar

[7] Kojima A, Teshima K, Shirai Y 2009 J. Am. Chem. Soc. 131 6050

Google Scholar

Google Scholar

[8] Ma L, Hao F, Stoumpos C C, Phelan B T, Wasielewski M R, Kanatzidis M G 2016 J. Am. Chem. Soc. 138 14750

Google Scholar

Google Scholar

[9] Ogomi Y, Morita A, Tsukamoto S, Saitho T, Hayase S 2014 J. Phys. Chem. Lett. 6 1004

[10] Jung H S, Park N G 2015 Small 16 1613

[11] Zhang P, Wu J, Zhang T, Wang Y, Liu D, Chen H 2018 Adv. Mater. 30 3

[12] Tseng Z L, Chiang C H, Chang S H, Wu C G 2016 Nano. Energy. 28 2211

[13] Zhang Q, Dandeneau C S, Zhou X, Cao G 2009 Adv. Mater. 21 4087

Google Scholar

Google Scholar

[14] Wang Z L 2004 J. Phys. Condens. Matter. 16 R829

Google Scholar

Google Scholar

[15] Liu H, Huang Z, Wei S, Zheng L, Gong Q 2016 Nanoscale 8 6209

Google Scholar

Google Scholar

[16] Law M, Greene L E, Johnson J C 2005 Nat. Mater. 4 455

Google Scholar

Google Scholar

[17] Kumar M H, Yantara N, Dharani S, Graetzel M, Mhaisalkar S, Boix P P 2013 Chem. Commun. 49 11089

Google Scholar

Google Scholar

[18] Wang H, Yan L, Liu J, Li J 2016 J. Mater. SCI-Mater. EL 27 6872

Google Scholar

Google Scholar

[19] Ferrara V L, Maria A D, Rametta G, Noce M D, Veneri P D 2017 Mater. Res. Express. 4 355

[20] 郎集会, 李雪, 刘晓艳, 杨景海 2009 吉林师范大学学报(自然科学版) 30 35

Lang J H, Li X, Liu X Y, Yang J H 2009 J. Jilin. Normal. Univ (Natural Science Edition) 30 35

计量

- 文章访问数: 12276

- PDF下载量: 167

- 被引次数: 0

下载:

下载: