-

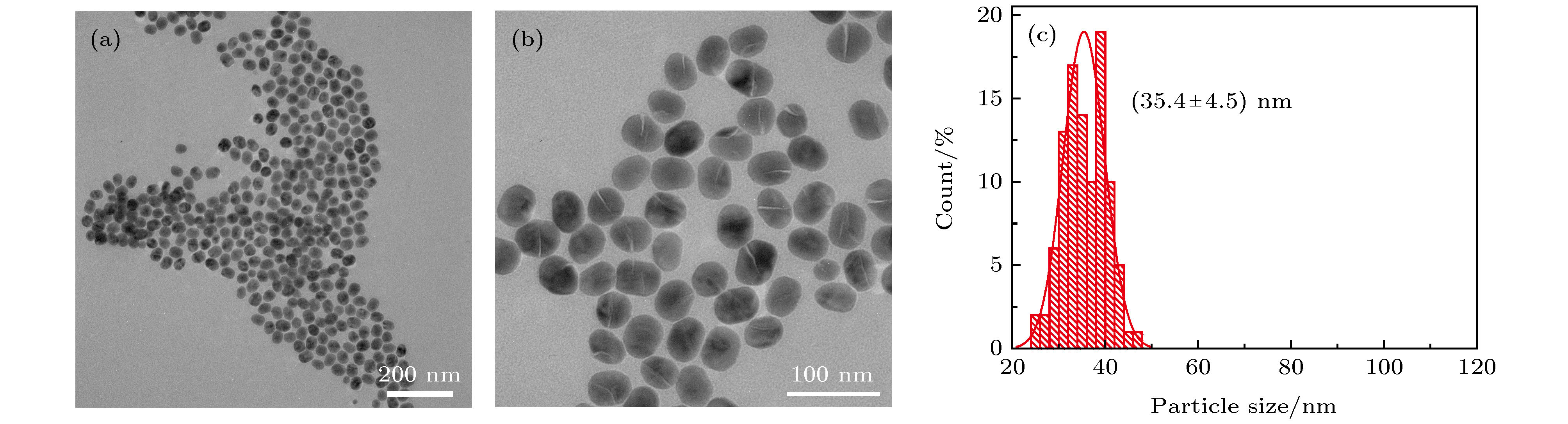

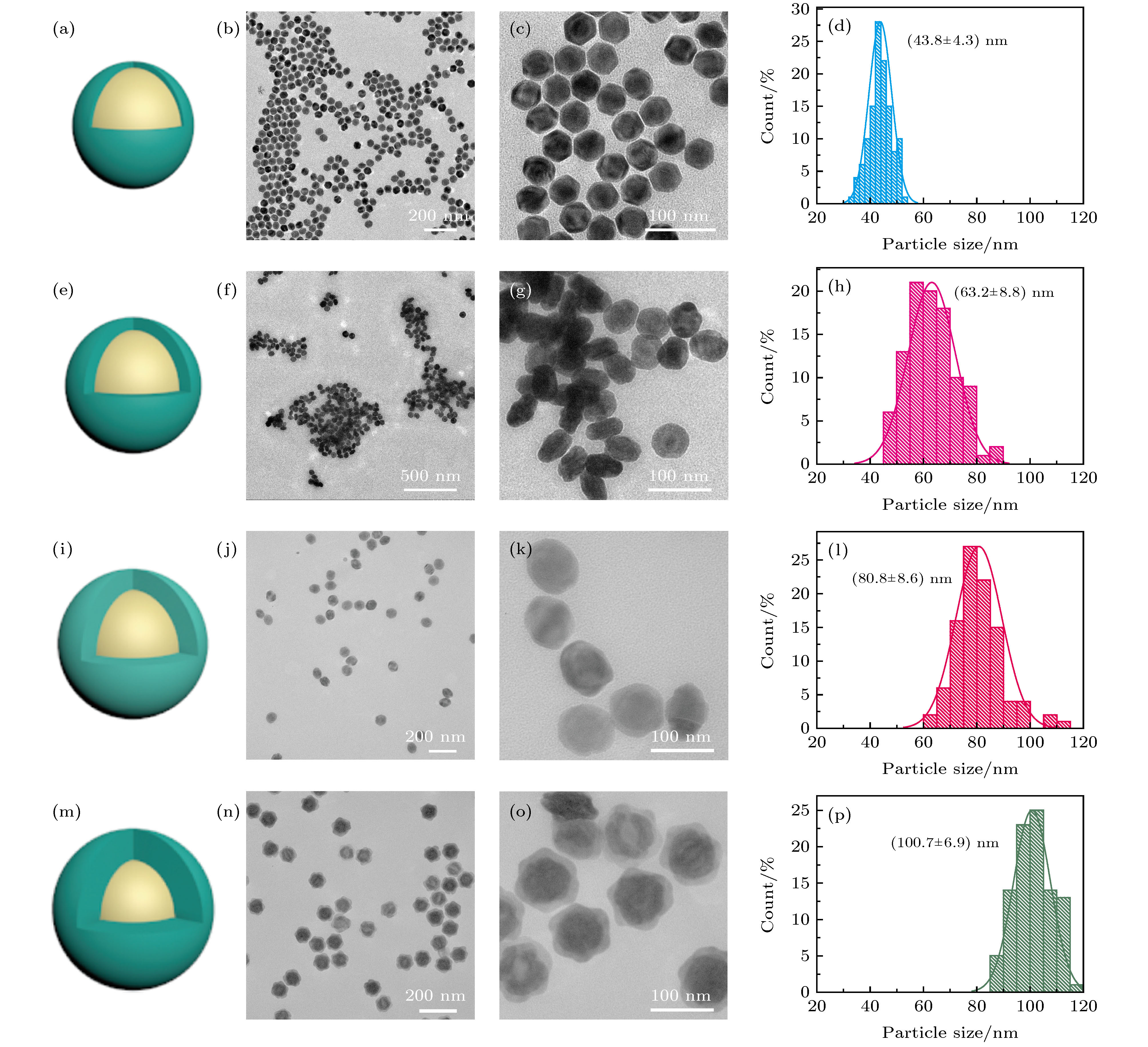

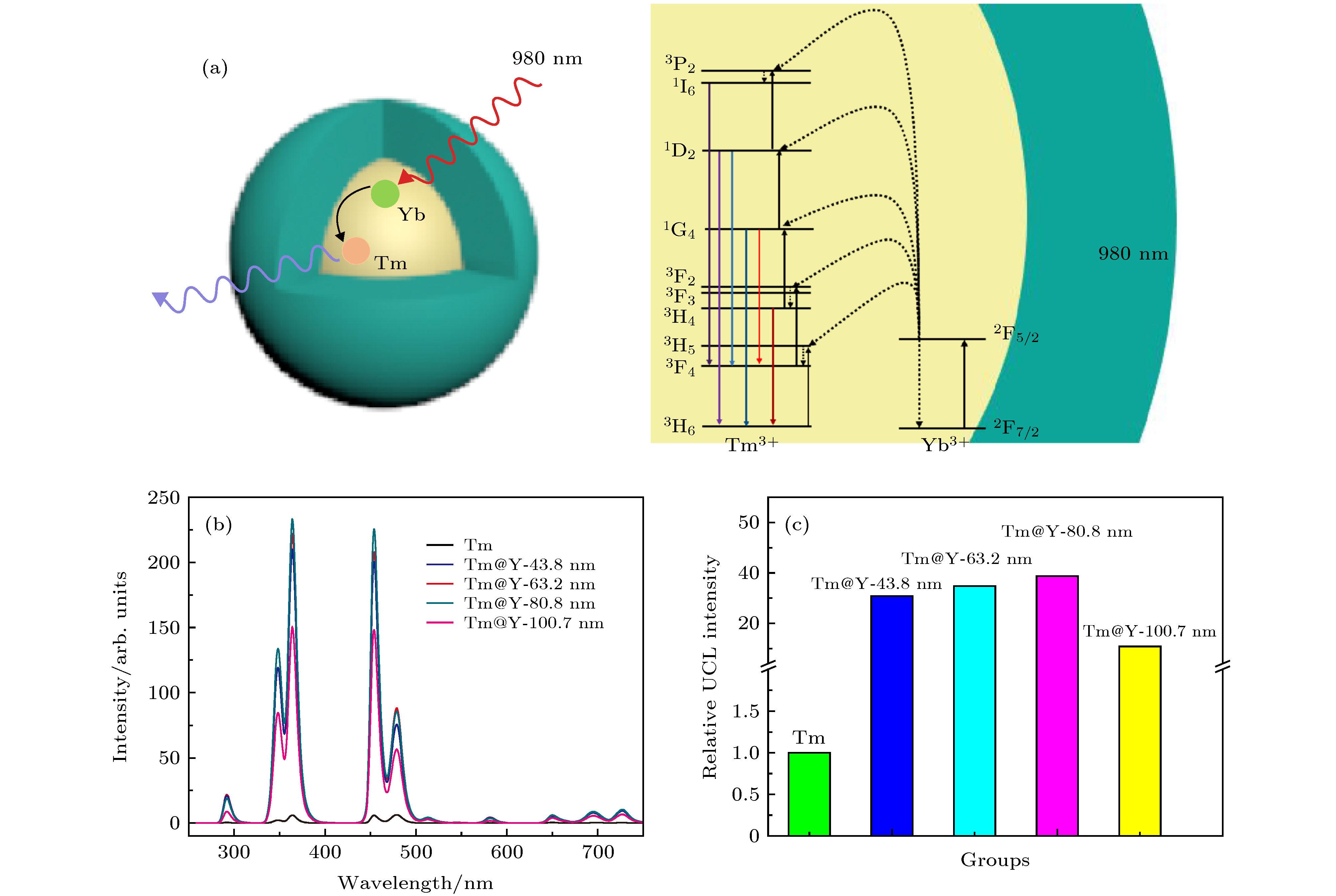

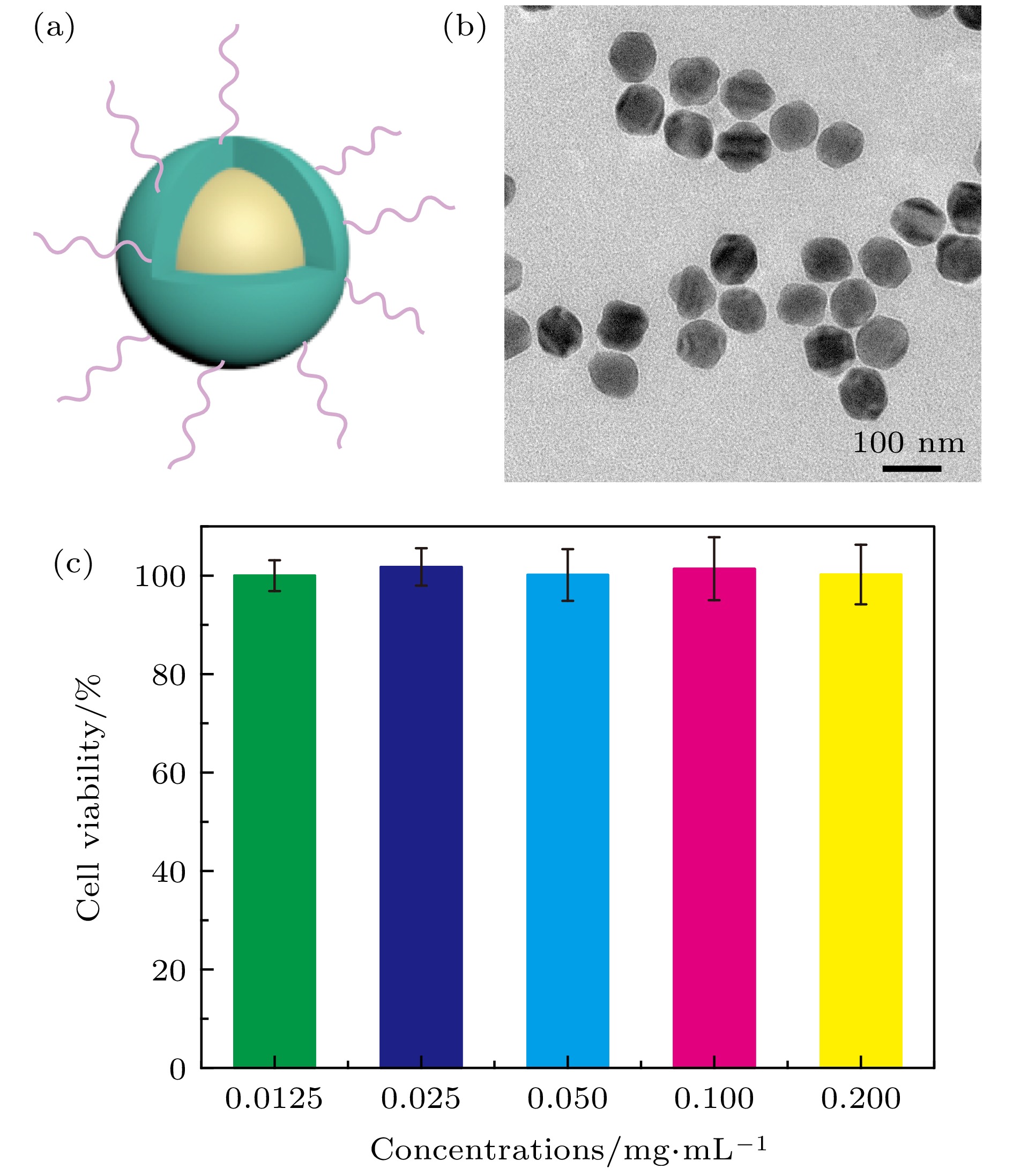

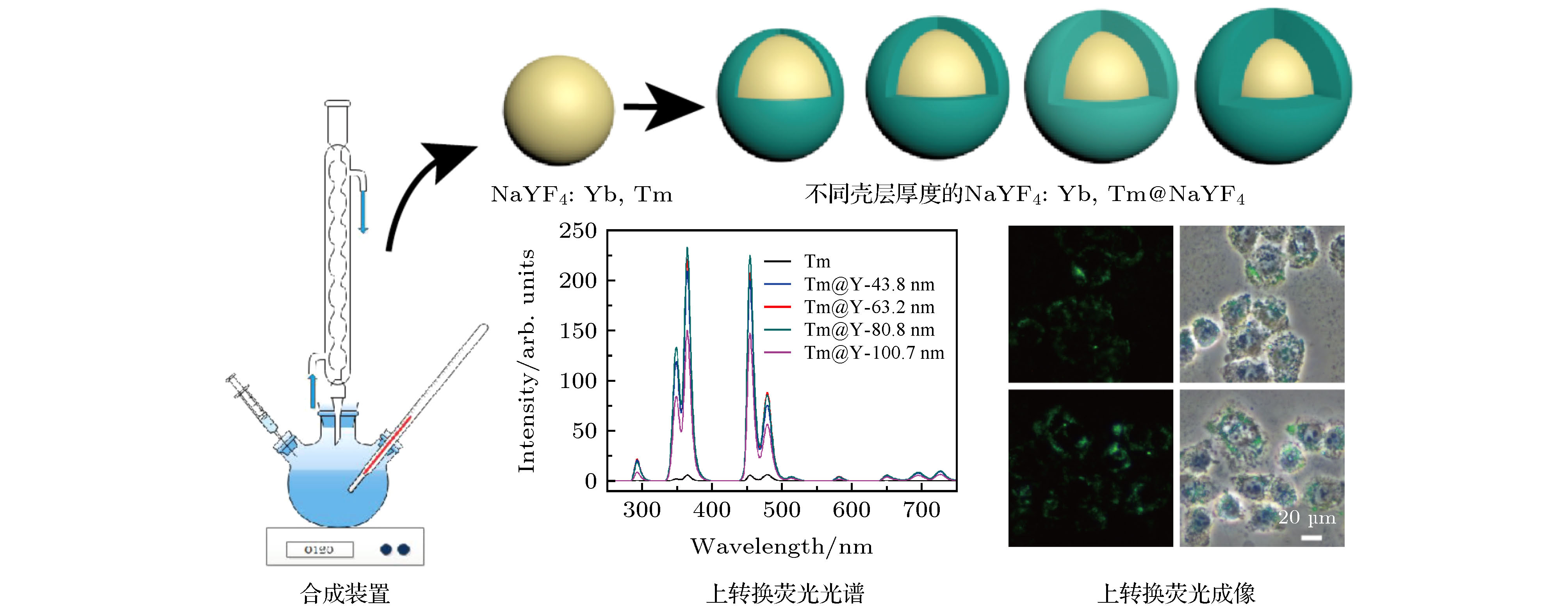

近几年来, 稀土上转换发光纳米材料凭借其生物组织穿透深度大、无组织损伤、无背景荧光干扰和成像灵敏度高等诸多优点, 在生物体荧光成像领域展现了巨大的潜在应用价值. 本文采用“一次热注射”高温溶剂热法制备不同壳层厚度的NaYF4:Yb, Tm@NaYF4上转换发光材料. 利用透射电子显微镜、粒径分析、荧光光谱等对产物进行表征, 探讨壳层厚度对纳米粒子上转换发光强度的影响. 结果表明, 在980 nm近红外光照射下, 上转换纳米材料能够发出紫外-可见光. 而且, 由于壳层包覆有效抑制了上转换发光的表面猝灭效应, 核壳结构的NaYF4:Yb, Tm@NaYF4纳米粒子发光强度比NaYF4:Yb, Tm提高了数十倍; 当壳层厚度为22.7 nm时, 上转换发光强度最强. 此外, 通过对上转换发光颗粒进行酸洗和聚乙二醇(PEG)修饰, 提高了纳米材料的生物相容性, 并成功将其应用于细胞的上转换荧光成像.In recent years, lanthanide-containing upconversion nanoparticles (UCNPs) have aroused the extensive interest in bioimaging due to their unique upconversion fluorescent properties, such as the high tissue penetration depth, good biocompatibility, low auto-fluorescence, and high imaging sensitivity. In this work, we synthesize a series of NaYF4:Yb, Tm@NaYF4 core-shell structured nanoparticles with various shell thicknesses. A “hot injection” strategy is introduced to fabricate the core-shell UCNPs through using high boiling-point mixtures (sodium/rare-earth trifluoroacetates dissolved in oleic acid and octadecene at 150 °C) as shell precursor solutions. The as-synthesized UCNPs are characterized by transmission electron microscope, particle size analysis and fluorescence spectra. The experimental results show that the shell thickness of UCNPs can be well controlled within a range from 4.2 nm to 32.6 nm by simply tuning the added quantity of the shell precursors. Meanwhile, the upconversion luminescence intensity of NaYF4:Yb, Tm@NaYF4 shows tens times higher than that of NaYF4:Yb, Tm owing to the effective suppression of surface quenching. The optimized thickness of the shell is determined to be 22.7 nm. An ultrathick inert shell (>22.7 nm) is not beneficial to upconversion luminescence mainly due to a strong scattering effect. In addition, the in vitro upconversion luminescent bioimaging application is demonstrated by using the as-synthesized core-shell structured UCNPs. Typically, the prepared OA capped UCNPs are dispersed in HCl solution to obtain hydrophilic ones, followed by polyethylene glycol (PEG) modification to improve their biological compatibility. The hydrophilic NaYF4:Yb, Tm@NaYF4@PEG nanostructures (denoted as UCNP@PEG) show a good biocompatibility with HeLa cells, as the viability of HeLa cells do not decrease obviously when the concentration of UCNP@PEG increases to 0.2 mg/mL. Then, we evaluate the upconversion luminescent signals of UCNP@PEG in HeLa cells under the excitation of 980 nm laser. An obviously increasing upconversion luminescent signal can be observed in HeLa cells with the incubation time increasing from 0.5 h to 6.0 h, indicating that the UCNP@PEG can be used as an excellent luminescence probe for cell imaging and monitoring the cell endocytosis process. All in all, we offer an efficient “hot injection” strategy of fabricating the core-shell structured UCNPs with various shell thickness for improving the upconversion efficiency of UCNPs, which will pave the way for new bioimaging and medical applications.

-

Keywords:

- upconversion luminescence /

- hot injection /

- core-shell /

- bioimaging

[1] Wen S, Zhou J, Zheng K, Bednarkiewicz A, Liu X, Jin D 2018 Nat. Commun. 9 2415

Google Scholar

Google Scholar

[2] Chen Q, Xie X, Huang B, Liang L, Han S, Yi Z, Liu X 2017 Angew. Chem. 129 7713

Google Scholar

Google Scholar

[3] Li X, Zhang F, Zhao D 2013 Nano Today 8 643

Google Scholar

Google Scholar

[4] Li X, Zhang F, Zhao D 2015 Chem. Soc. Rev. 44 1346

Google Scholar

Google Scholar

[5] Zhu X, Su Q, Feng W, Li F 2017 Chem. Soc. Rev. 46 1025

Google Scholar

Google Scholar

[6] Auzel F 2004 Chem. Rev. 104 139

Google Scholar

Google Scholar

[7] Dong H, Sun L D, Yan C H 2015 Chem. Soc. Rev. 44 1608

Google Scholar

Google Scholar

[8] Wang F, Deng R, Wang J, Wang Q, Han Y, Zhu H, Chen X H, Liu X G 2011 Nat. Mater. 10 968

Google Scholar

Google Scholar

[9] Hu F, Liu B, Chu H, Liu C, Li Z, Chen D, Li L 2019 Nanoscale 11 9201

Google Scholar

Google Scholar

[10] 丁庆磊, 肖思国, 张向华, 夏艳琴, 刘政威 2006 55 5140

Google Scholar

Google Scholar

Ding Q L, Xiao S G, Zhang X H, Xia Y Q, Liu Z W 2006 Acta Phys. Sin. 55 5140

Google Scholar

Google Scholar

[11] Haase M, SchäfTm H 2011 Angew. Chem. Int. Ed. 50 5808

Google Scholar

Google Scholar

[12] Rao L, Bu L L, Cai B, Xu J H, Li A, Zhang W F, Zhao X Z 2016 Adv. Mater. 28 3460

Google Scholar

Google Scholar

[13] Liu K, Liu X, Zeng Q, Zhang Y, Tu L, Liu T, AaldTms M C 2012 ACS Nano 6 4054

Google Scholar

Google Scholar

[14] Wang M, Mi C C, Wang W X, Liu C H, Wu Y F, Xu Z R, Xu S K 2009 ACS Nano 3 1580

Google Scholar

Google Scholar

[15] Nyk M, Kumar R, Ohulchanskyy T Y, BTmgey E J, Prasad P N 2008 Nano Lett. 8 3834

Google Scholar

Google Scholar

[16] Peng J, Samanta A, Zeng X, Han S, Wang L, Su D, Jiang W 2017 Angew. Chem. Int. Ed. 56 4165

Google Scholar

Google Scholar

[17] Liang L, Xie X, All A. H, Huang L, Liu X 2016 Chem. Eur. J. 22 10801

Google Scholar

Google Scholar

[18] Wang S, Fan Y, Li D, Sun C, Lei Z, Lu L, Zhang F 2019 Nat. Commun. 10 1058

Google Scholar

Google Scholar

[19] Lei X, Li R, Tu D, Shang X, Liu Y, You W, Chen X 2018 Chem. Sci. 9 4682

Google Scholar

Google Scholar

[20] Liu L, Wang S, Zhao B, Pei P, Fan Y, Li X, Zhang F 2018 Angew. Chem. Int. Ed. 57 7518

Google Scholar

Google Scholar

[21] H. Kobayashi, M. Ogawa, R. Alford, P. L. Choyke, Y. Urano 2010 Chem. Rev. 110 2620

Google Scholar

Google Scholar

[22] Liu X, Qiu J 2015 Chem. Soc. Rev. 44 8714

Google Scholar

Google Scholar

[23] Liu X, Yan C H, Capobianco J A 2015 Chem. Soc. Rev. 44 1299

Google Scholar

Google Scholar

[24] Park W, Lu D, Ahn S 2015 Chem. Soc. Rev. 44 2940

Google Scholar

Google Scholar

[25] Nadort A, Zhao J, Goldys E M 2016 Nanoscale 8 13099

Google Scholar

Google Scholar

[26] Liu B, Chen Y, Li C, He F, Hou Z, Huang S, Zhu H, Chen X, Lin J 2015 Adv. Funct. Mater. 25 4717

Google Scholar

Google Scholar

[27] Liu B, Li C, Cheng Z, Hou Z, Huang S, Lin J 2016 Biomater. Sci. 4 890

Google Scholar

Google Scholar

[28] Zhai X, Lei P, Zhang P, Wang Z, Song S, Xu X, Liu X, Feng J, Zhang H 2015 Biomaterials 65 115

Google Scholar

Google Scholar

[29] Ye S, Chen G, Shao W, Qu J, Prasad P N 2015 Nanoscale 7 3976

Google Scholar

Google Scholar

[30] Li W, Chen Z, Zhou L, Li Z, Ren J, Qu X 2015 J. Am. Chem. Soc. 137 8199

Google Scholar

Google Scholar

[31] Hao S, Yang L, Qiu H, Fan R, Yang C, Chen G 2015 Nanoscale 7 10775

Google Scholar

Google Scholar

[32] Chen D, Liu L, Huang P, Ding M, Zhong J, Ji Z 2015 J. Phys. Chem. Lett. 6 2833

Google Scholar

Google Scholar

[33] Gu Z, Yan L, Tian G, Li S, Cha Z, Zhao Y 2013 Adv. Mater. 25 3758

Google Scholar

Google Scholar

[34] Dou Q, Idris N M, Zhang Y 2013 Biomaterials 34 1722

Google Scholar

Google Scholar

[35] Liu X, Kong X, Zhang Y, Tu L, Wang Y, Zeng Q, Li C, Shi Z, Zhang H 2011 Chem. Commun. 47 11957

Google Scholar

Google Scholar

[36] Yi G S, Chow G M 2006 Chem. Mater. 19 341

[37] Wang F, Liu X 2008 J. Am. Chem. Soc. 130 5642

Google Scholar

Google Scholar

[38] Zhang S L, Li J, Lykotrafitis G, Bao G, Suresh S 2009 Adv. Mater. 21 419

Google Scholar

Google Scholar

[39] Cabral H, Matsumoto Y, Mizuno K, Chen Q, Murakami M, Kimura M, Terada Y, Kano M R, Miyazono K, Uesaka M, Hishiyama N, Kataoka K 2011 Nat. Nanotechnol. 6 815

Google Scholar

Google Scholar

-

图 3 (a)−(d) NaYF4:Yb, Tm@NaYF4纳米粒子(粒径约43.8 nm)的结构示意图, TEM图和粒径分布图; (e)−(h) NaYF4:Yb, Tm@NaYF4纳米粒子(粒径约63.2 nm)的结构示意图, TEM图和粒径分布图; (i)−(l) NaYF4:Yb, Tm@NaYF4纳米粒子(粒径约80.8 nm)的结构示意图, TEM图和粒径分布图; (m)−(p) NaYF4:Yb, Tm@NaYF4纳米粒子(粒径约100.7 nm)的结构示意图, TEM图和粒径分布图

Fig. 3. (a)−(d) The schematic core-shell structure, TEM images and size distribution of NaYF4:Yb, Tm@NaYF4 (about 43.8 nm); (e)−(h) the schematic core-shell structure, TEM images and size distribution of NaYF4:Yb, Tm@NaYF4 (about 63.2 nm); (i)−(l) the schematic core-shell structure, TEM images and size distribution of NaYF4:Yb, Tm@NaYF4 (about 80.8 nm); (m)−(p) the schematic core-shell structure, TEM images and size distribution of NaYF4:Yb, Tm@NaYF4 (about 100.7 nm).

图 4 (a) 980 nm激发下NaYF4:Yb, Tm@NaYF4纳米粒子的上转换机制; (b)不同壳层厚度的UCNPs的上转换发光光谱; (c)不同壳层厚度的UCNPs的上转换发光强度的柱状统计图

Fig. 4. (a) The energy transfer mechanisms of NaYF4:Yb, Tm@NaYF4 UCNPs; (b) the upconversion luminescent spectra and (c) the relative luminescent intensity of core-shell structured UCNPs with different shell thicknesses.

-

[1] Wen S, Zhou J, Zheng K, Bednarkiewicz A, Liu X, Jin D 2018 Nat. Commun. 9 2415

Google Scholar

Google Scholar

[2] Chen Q, Xie X, Huang B, Liang L, Han S, Yi Z, Liu X 2017 Angew. Chem. 129 7713

Google Scholar

Google Scholar

[3] Li X, Zhang F, Zhao D 2013 Nano Today 8 643

Google Scholar

Google Scholar

[4] Li X, Zhang F, Zhao D 2015 Chem. Soc. Rev. 44 1346

Google Scholar

Google Scholar

[5] Zhu X, Su Q, Feng W, Li F 2017 Chem. Soc. Rev. 46 1025

Google Scholar

Google Scholar

[6] Auzel F 2004 Chem. Rev. 104 139

Google Scholar

Google Scholar

[7] Dong H, Sun L D, Yan C H 2015 Chem. Soc. Rev. 44 1608

Google Scholar

Google Scholar

[8] Wang F, Deng R, Wang J, Wang Q, Han Y, Zhu H, Chen X H, Liu X G 2011 Nat. Mater. 10 968

Google Scholar

Google Scholar

[9] Hu F, Liu B, Chu H, Liu C, Li Z, Chen D, Li L 2019 Nanoscale 11 9201

Google Scholar

Google Scholar

[10] 丁庆磊, 肖思国, 张向华, 夏艳琴, 刘政威 2006 55 5140

Google Scholar

Google Scholar

Ding Q L, Xiao S G, Zhang X H, Xia Y Q, Liu Z W 2006 Acta Phys. Sin. 55 5140

Google Scholar

Google Scholar

[11] Haase M, SchäfTm H 2011 Angew. Chem. Int. Ed. 50 5808

Google Scholar

Google Scholar

[12] Rao L, Bu L L, Cai B, Xu J H, Li A, Zhang W F, Zhao X Z 2016 Adv. Mater. 28 3460

Google Scholar

Google Scholar

[13] Liu K, Liu X, Zeng Q, Zhang Y, Tu L, Liu T, AaldTms M C 2012 ACS Nano 6 4054

Google Scholar

Google Scholar

[14] Wang M, Mi C C, Wang W X, Liu C H, Wu Y F, Xu Z R, Xu S K 2009 ACS Nano 3 1580

Google Scholar

Google Scholar

[15] Nyk M, Kumar R, Ohulchanskyy T Y, BTmgey E J, Prasad P N 2008 Nano Lett. 8 3834

Google Scholar

Google Scholar

[16] Peng J, Samanta A, Zeng X, Han S, Wang L, Su D, Jiang W 2017 Angew. Chem. Int. Ed. 56 4165

Google Scholar

Google Scholar

[17] Liang L, Xie X, All A. H, Huang L, Liu X 2016 Chem. Eur. J. 22 10801

Google Scholar

Google Scholar

[18] Wang S, Fan Y, Li D, Sun C, Lei Z, Lu L, Zhang F 2019 Nat. Commun. 10 1058

Google Scholar

Google Scholar

[19] Lei X, Li R, Tu D, Shang X, Liu Y, You W, Chen X 2018 Chem. Sci. 9 4682

Google Scholar

Google Scholar

[20] Liu L, Wang S, Zhao B, Pei P, Fan Y, Li X, Zhang F 2018 Angew. Chem. Int. Ed. 57 7518

Google Scholar

Google Scholar

[21] H. Kobayashi, M. Ogawa, R. Alford, P. L. Choyke, Y. Urano 2010 Chem. Rev. 110 2620

Google Scholar

Google Scholar

[22] Liu X, Qiu J 2015 Chem. Soc. Rev. 44 8714

Google Scholar

Google Scholar

[23] Liu X, Yan C H, Capobianco J A 2015 Chem. Soc. Rev. 44 1299

Google Scholar

Google Scholar

[24] Park W, Lu D, Ahn S 2015 Chem. Soc. Rev. 44 2940

Google Scholar

Google Scholar

[25] Nadort A, Zhao J, Goldys E M 2016 Nanoscale 8 13099

Google Scholar

Google Scholar

[26] Liu B, Chen Y, Li C, He F, Hou Z, Huang S, Zhu H, Chen X, Lin J 2015 Adv. Funct. Mater. 25 4717

Google Scholar

Google Scholar

[27] Liu B, Li C, Cheng Z, Hou Z, Huang S, Lin J 2016 Biomater. Sci. 4 890

Google Scholar

Google Scholar

[28] Zhai X, Lei P, Zhang P, Wang Z, Song S, Xu X, Liu X, Feng J, Zhang H 2015 Biomaterials 65 115

Google Scholar

Google Scholar

[29] Ye S, Chen G, Shao W, Qu J, Prasad P N 2015 Nanoscale 7 3976

Google Scholar

Google Scholar

[30] Li W, Chen Z, Zhou L, Li Z, Ren J, Qu X 2015 J. Am. Chem. Soc. 137 8199

Google Scholar

Google Scholar

[31] Hao S, Yang L, Qiu H, Fan R, Yang C, Chen G 2015 Nanoscale 7 10775

Google Scholar

Google Scholar

[32] Chen D, Liu L, Huang P, Ding M, Zhong J, Ji Z 2015 J. Phys. Chem. Lett. 6 2833

Google Scholar

Google Scholar

[33] Gu Z, Yan L, Tian G, Li S, Cha Z, Zhao Y 2013 Adv. Mater. 25 3758

Google Scholar

Google Scholar

[34] Dou Q, Idris N M, Zhang Y 2013 Biomaterials 34 1722

Google Scholar

Google Scholar

[35] Liu X, Kong X, Zhang Y, Tu L, Wang Y, Zeng Q, Li C, Shi Z, Zhang H 2011 Chem. Commun. 47 11957

Google Scholar

Google Scholar

[36] Yi G S, Chow G M 2006 Chem. Mater. 19 341

[37] Wang F, Liu X 2008 J. Am. Chem. Soc. 130 5642

Google Scholar

Google Scholar

[38] Zhang S L, Li J, Lykotrafitis G, Bao G, Suresh S 2009 Adv. Mater. 21 419

Google Scholar

Google Scholar

[39] Cabral H, Matsumoto Y, Mizuno K, Chen Q, Murakami M, Kimura M, Terada Y, Kano M R, Miyazono K, Uesaka M, Hishiyama N, Kataoka K 2011 Nat. Nanotechnol. 6 815

Google Scholar

Google Scholar

计量

- 文章访问数: 15353

- PDF下载量: 274

- 被引次数: 0

下载:

下载: