-

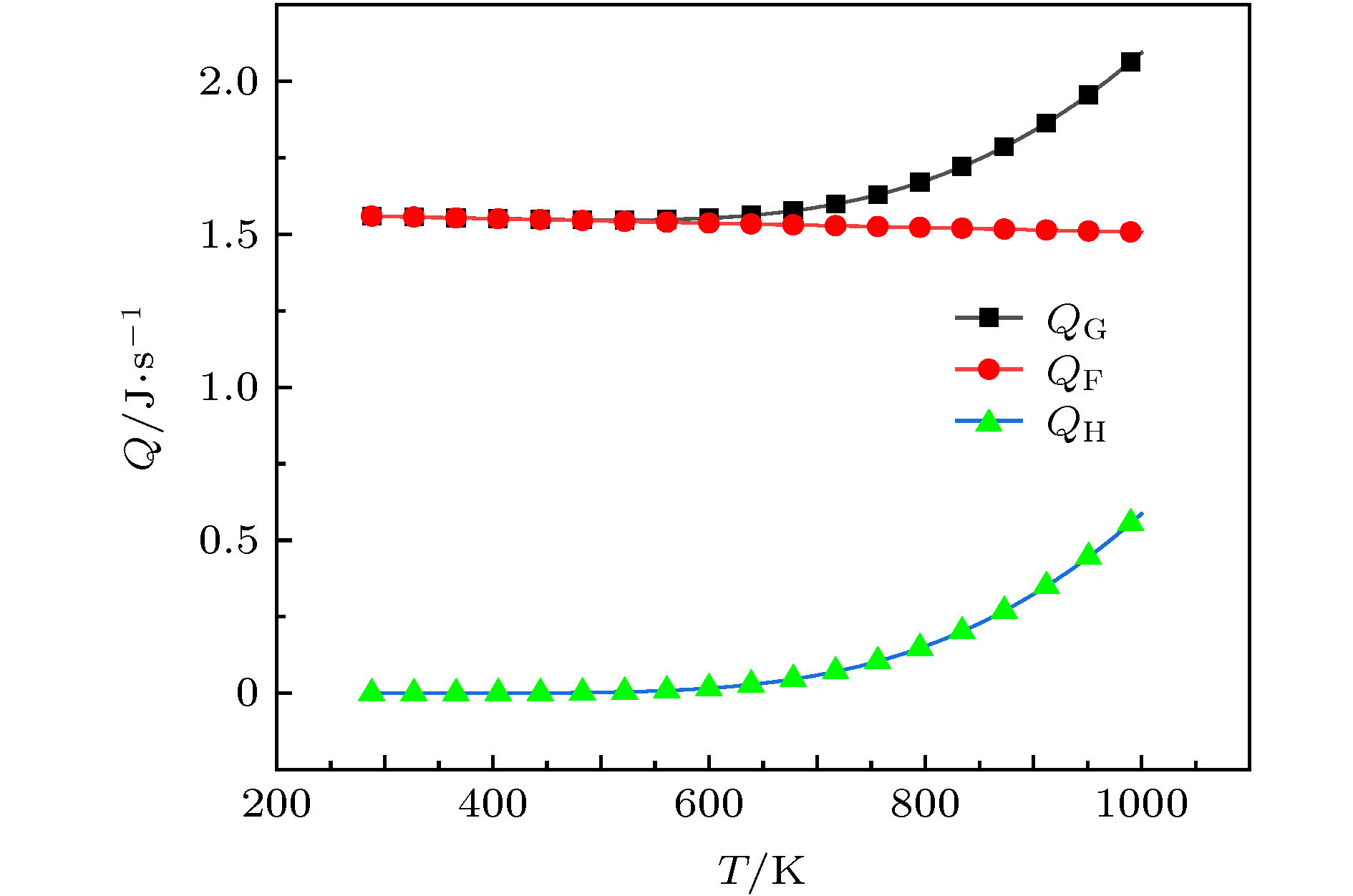

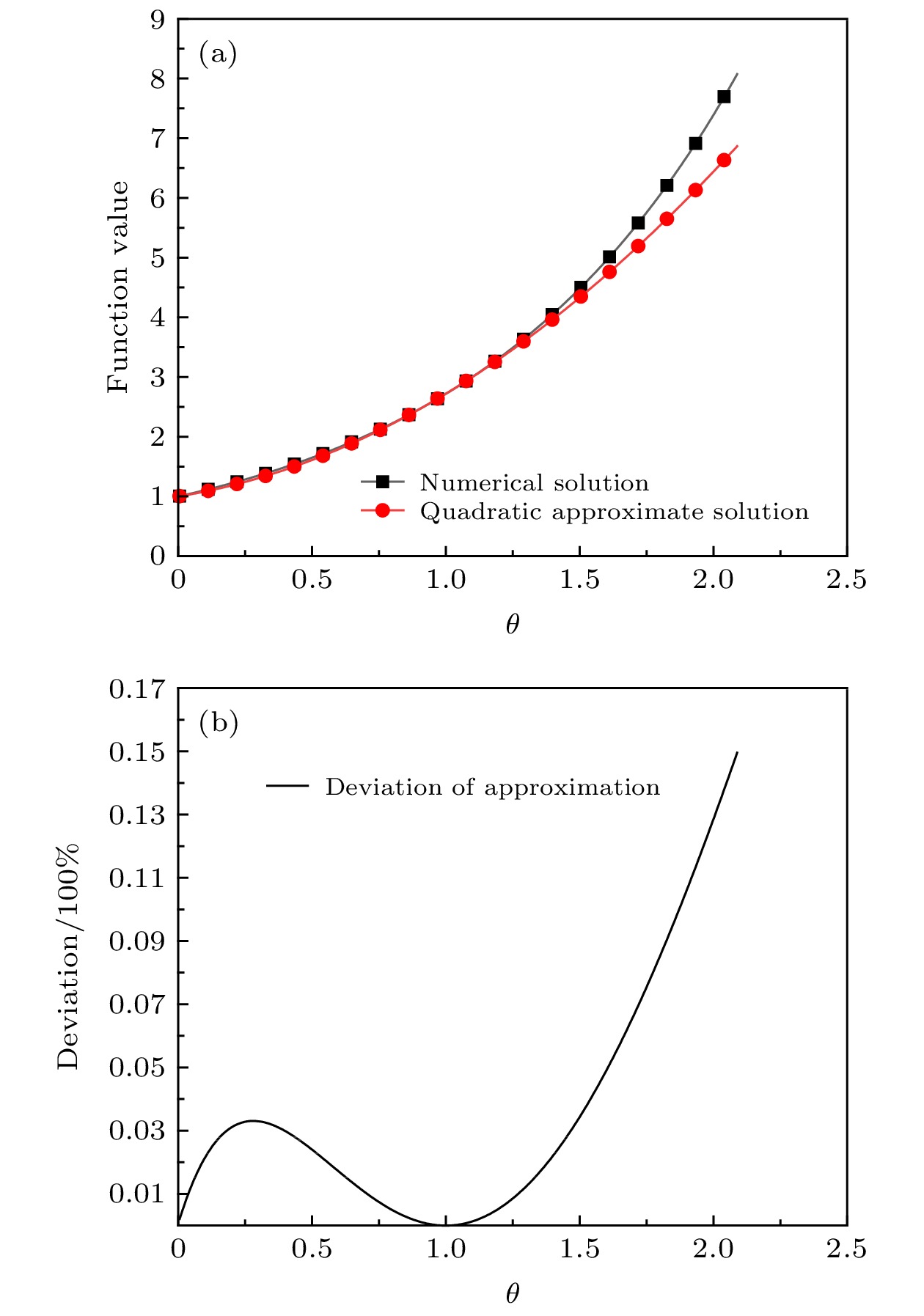

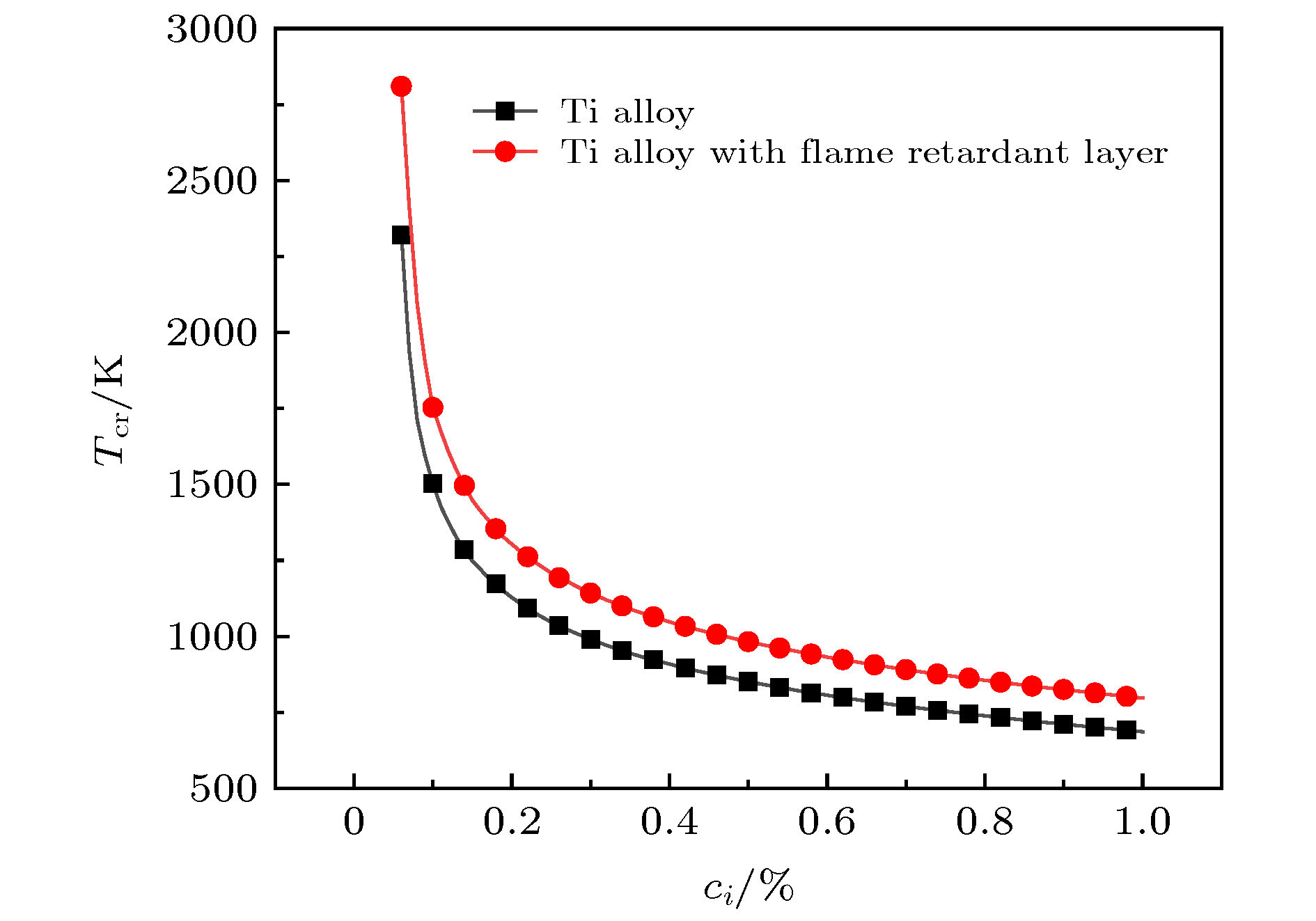

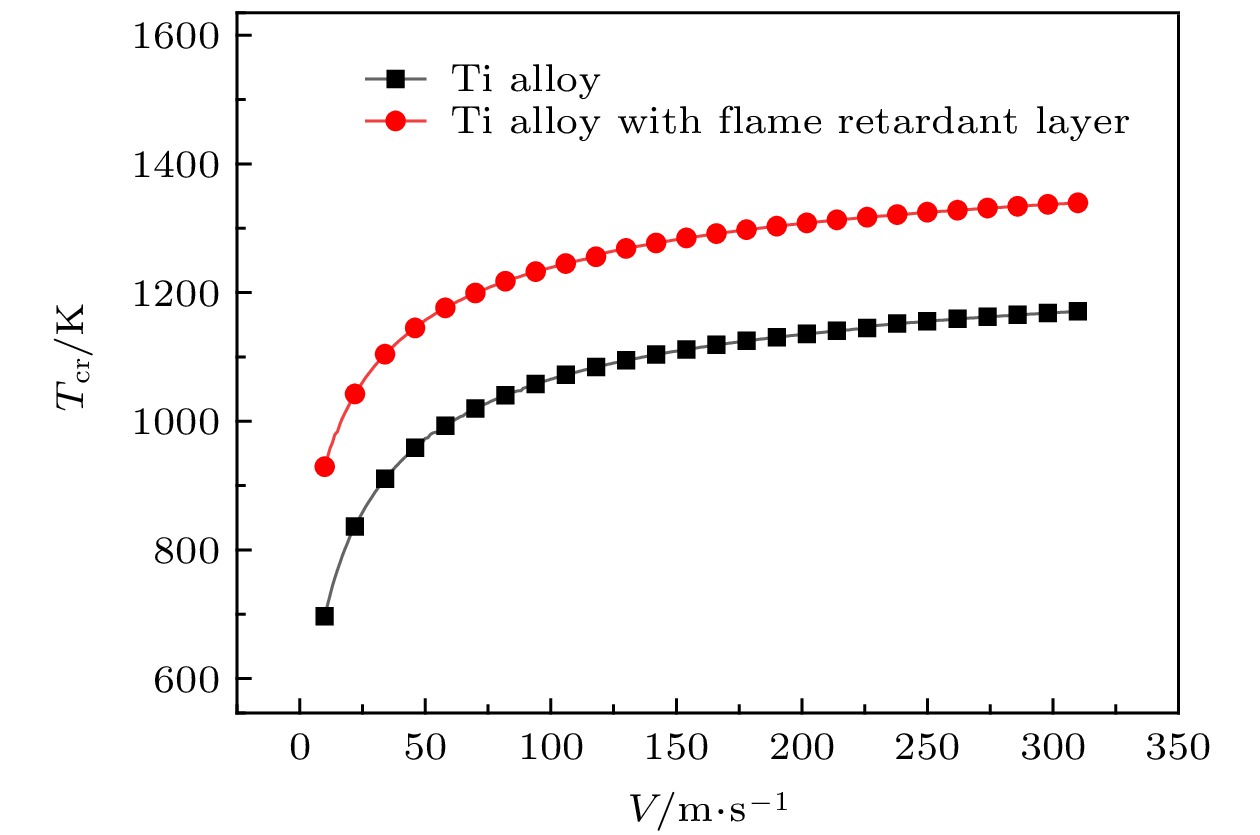

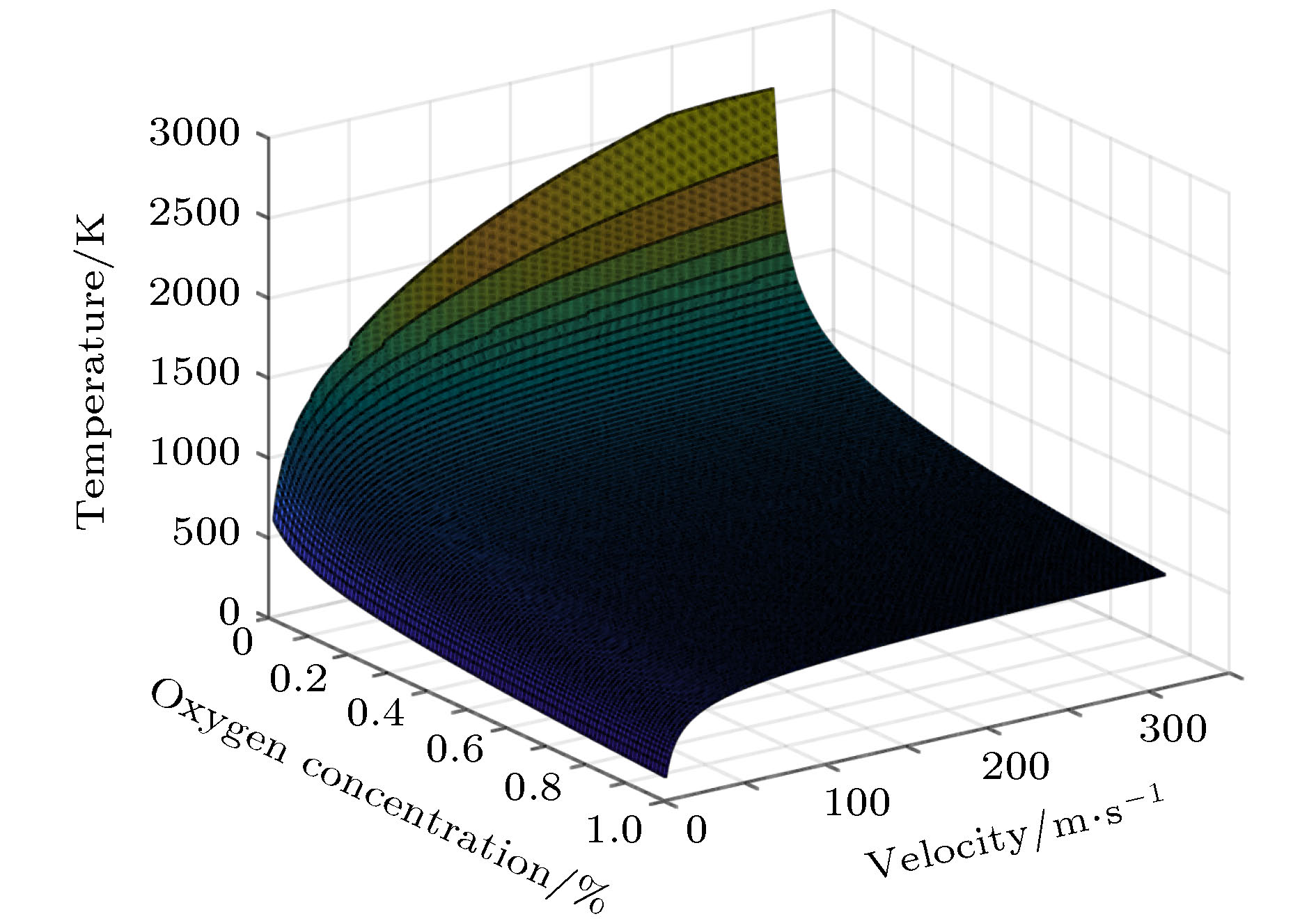

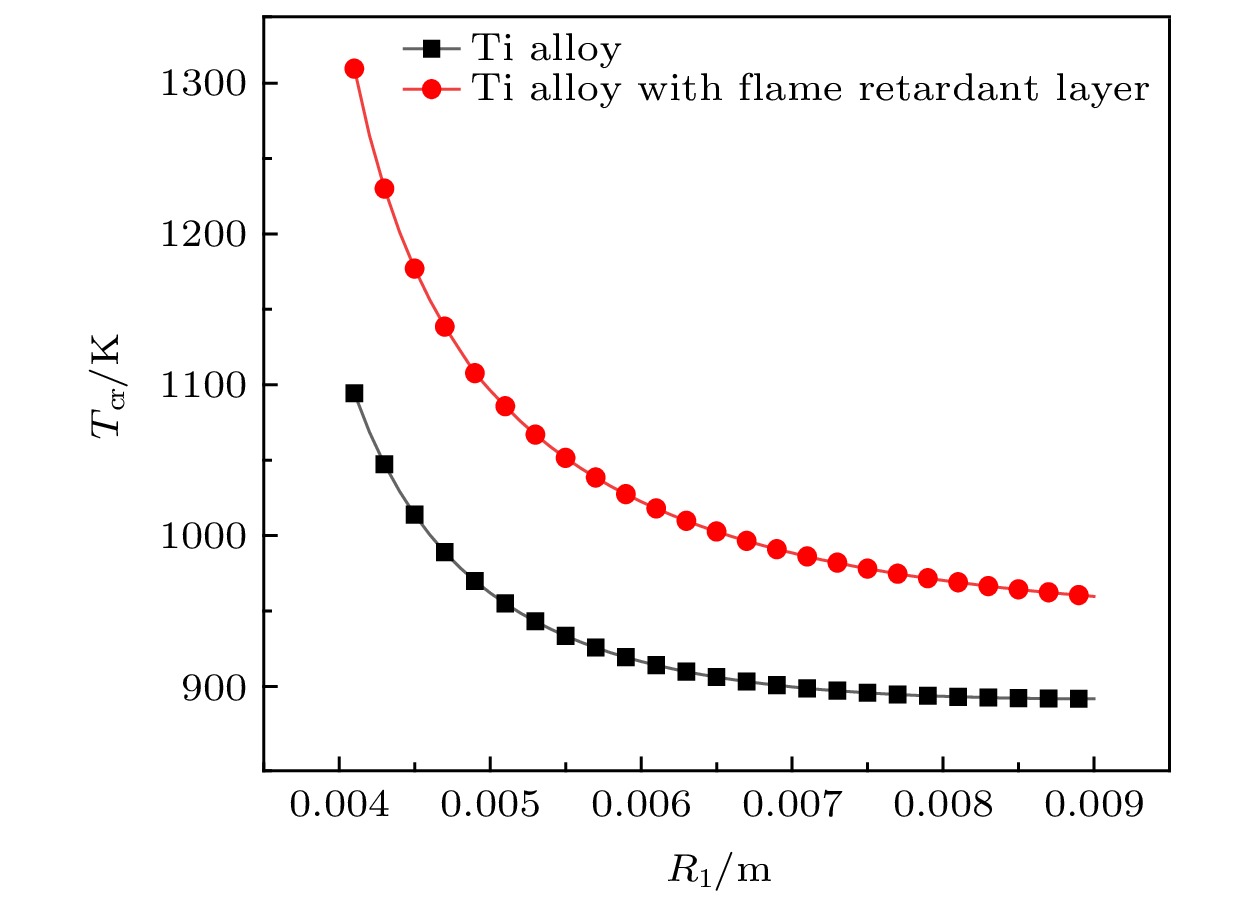

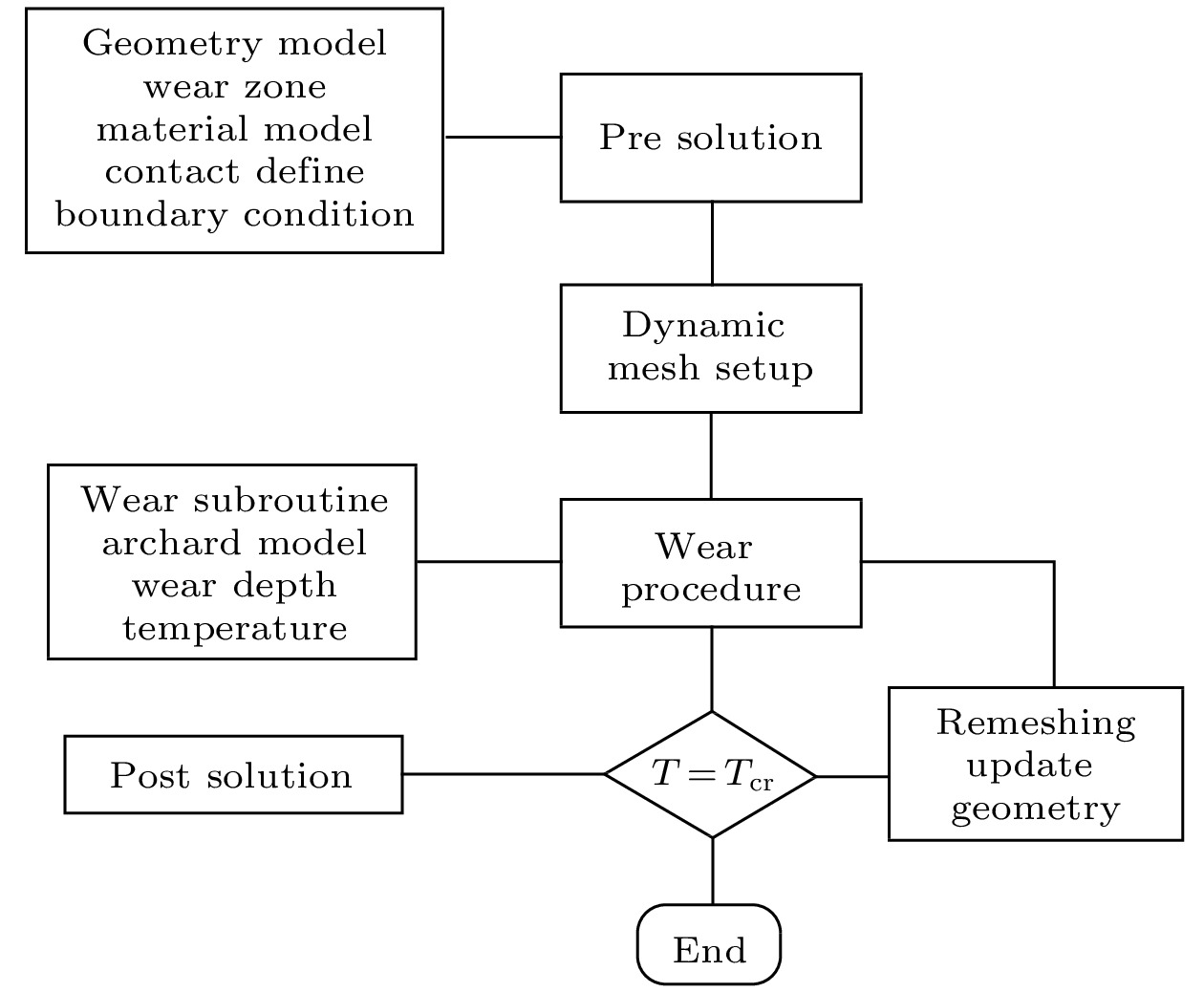

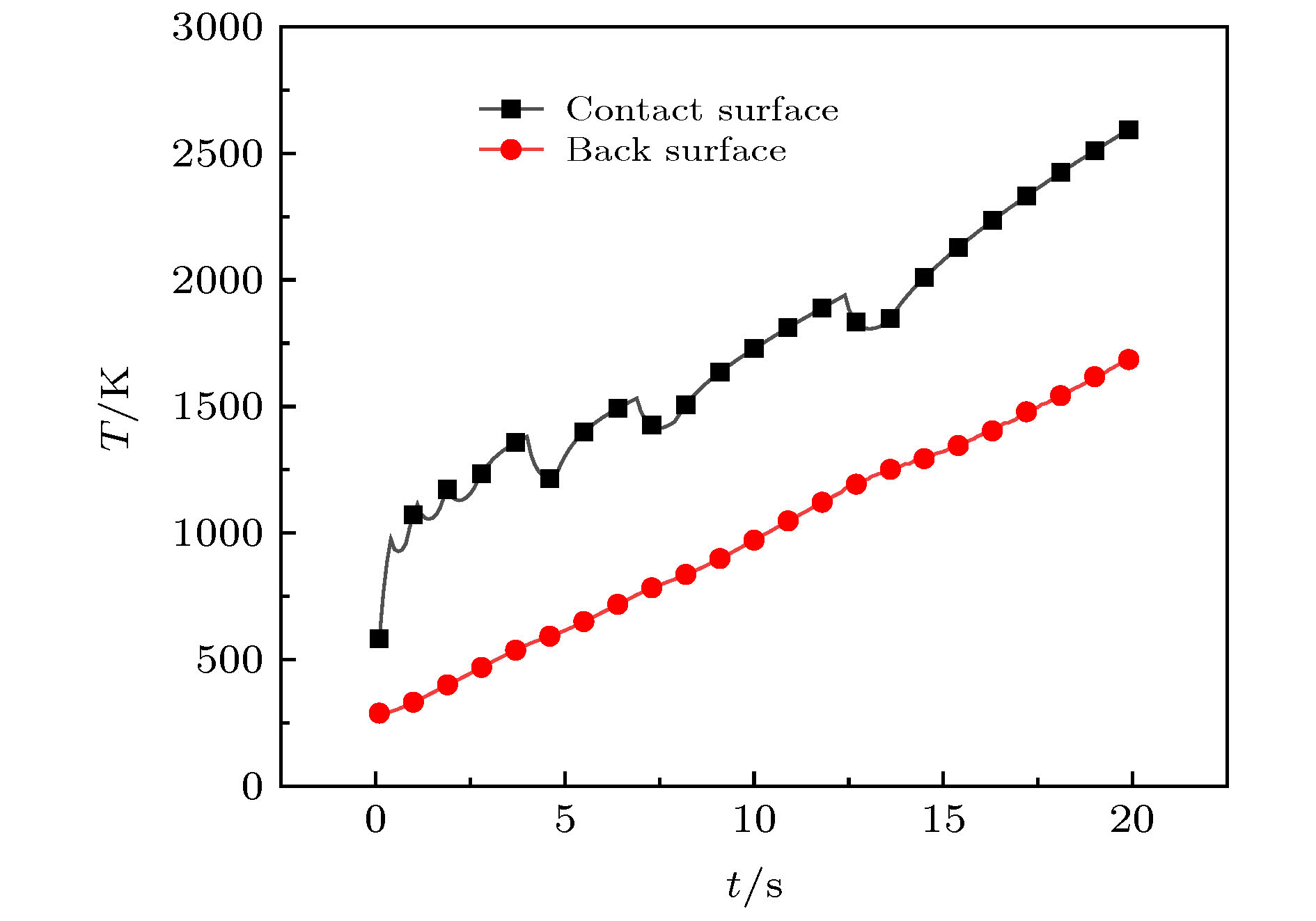

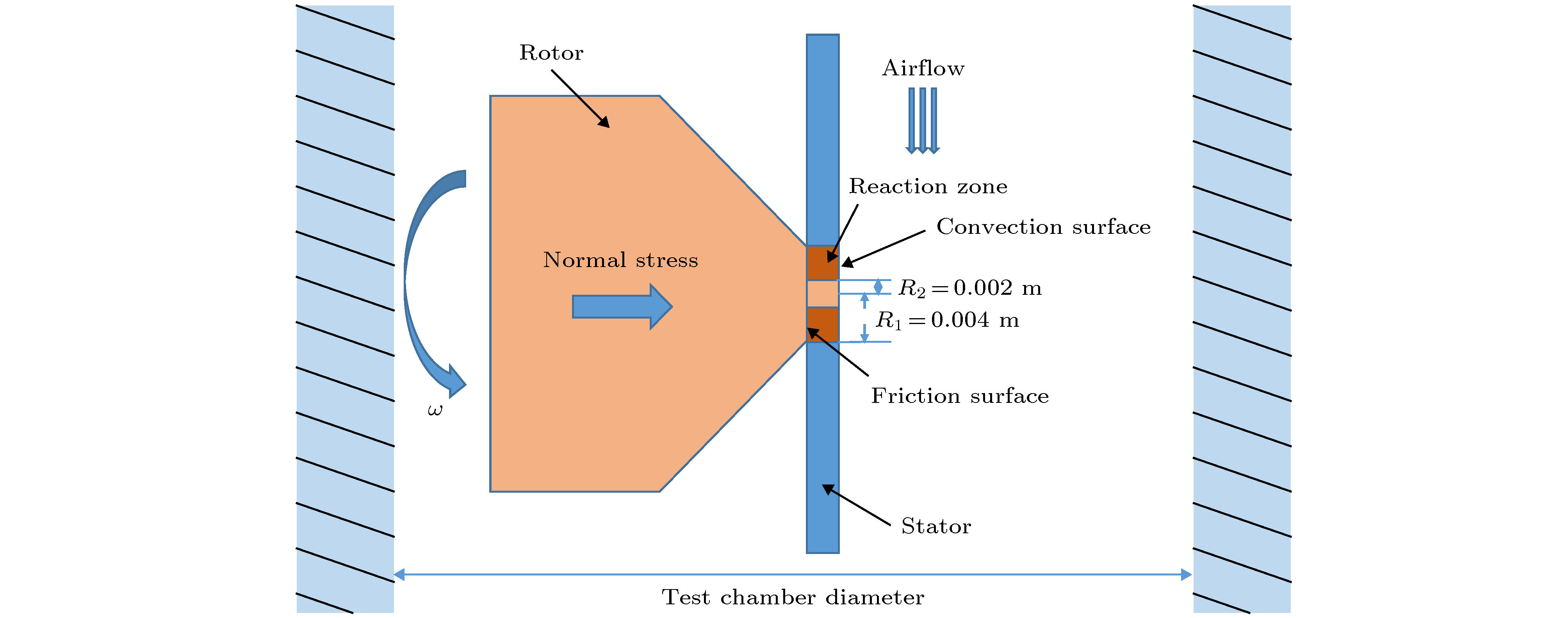

钛合金燃烧是现代航空发动机的典型灾难性事故, 压气机转子与静子的异常摩擦是主要的着火源. 本文基于非均相着火理论建立了考虑摩擦热源的钛合金着火模型, 推导了着火温度和着火延迟时间的理论计算公式, 进而分析摩擦系数、氧浓度、流速、接触半径以及阻燃层等因素对着火参数的影响规律. 结果表明: 当摩擦接触区的瞬时温度低于临界生热温度时, 生热过程由摩擦热主导; 当高于临界生热温度时, 生热过程由化学反应热主导. 降低摩擦系数可以显著提高着火温度, 而摩擦系数的变化对着火延迟时间影响很小. 着火温度随着氧浓度的增大和流速的减小均呈明显下降趋势. 当氧浓度从21%增加至42%、流速从310 m/s下降至50 m/s时, 着火温度分别降低约213 K和197 K. 实验结果与理论计算值的相对误差为8.3%, 验证了模型的可靠性. 阻燃层可以明显提高钛合金的着火温度和着火延迟时间, 带阻燃层的钛合金的着火温度提高约172 K, 着火延迟时间提高约3 s.Combustion of titanium alloy is a typical catastrophic failure of modern aeroengine. The abnormal friction between compressor rotor and stator is the main ignition source. A thermal theory model with friction heat source of titanium alloy is established based on the theory of heterogeneous ignition. The corresponding equation of critical temperature and ignition delay time are derived. The difference between the frictional ignition model and the classic model is discussed. The concept of critical heat generation temperature is proposed. The difference from the heterogeneous ignition model, and the effects of friction coefficient, oxygen concentration, flow velocity, contact radius and flame retardant layer thickness on the ignition parameters are analyzed. The research result shows that when the instantaneous temperature of the contact surface is lower than the critical heat temperature, the heat generation process is dominated by frictional heat, and when the temperature is higher than the critical heat temperature, the heat generation process is dominated by chemical reaction heat, that reducing the coefficient of friction can dramatically increase the critical temperature, but the change of friction coefficient has very little effect on the ignition delay time which can be ignored, that the critical temperature decreases significantly with the increase of oxygen concentration and the decrease of flow velocity. When the oxygen concentration increases from 21% to 42% and the flow velocity decreases from 310 m/s to 50 m/s, the critical temperature decreases by about 213 K and 197 K, respectively. The relative error between the experimental result and the theoretical result is 8.3%, which verifies the reliability of the model. The contact area has an effect on friction heat generation, reaction heat generation, and surface heat dissipation, and has a great influence on the critical temperature. The critical temperature decreases exponentially with contact radius increasing. When the contact radius increases to 0.007 m, the ignition temperature of the titanium alloy and its flame retardant layer are 899 K and 988 K, respectively. The increase of the thickness of flame retardant layer can effectively improve the critical temperature and ignition delay time. The critical temperature of titanium alloy with flame retardant layer is increased by about 172 K, and the ignition delay time is increased by about 3 s.

-

Keywords:

- titanium alloy /

- ignition model with friction /

- heterogeneous reaction /

- fireproof

[1] Borisova E A, Sklyarov N M 2007 Aviation Materials and Technologists: Production Combustion and Fire Safety of Titanium Alloys (Moscow: VIAM) p21

[2] 弭光宝, 黄旭, 曹京霞, 王宝, 曹春晓 2016 65 056103

Google Scholar

Google Scholar

Mi G B, Huang X, Cao J X, Wang B, Cao C X 2016 Acta Phys. Sin. 65 056103

Google Scholar

Google Scholar

[3] Frank-Kamenetskii D A 1955 Diffusion and Heat Exchange in Chemical Kinetics (Princeton: Princeton University Press) p288

[4] Merzhanov A G 1975 AIAA J. 13 209

Google Scholar

Google Scholar

[5] Elsayed S A 1996 J. Loss Prevent Proc. 9 393

Google Scholar

Google Scholar

[6] Khaikin B I, Bloshenko V N 1970 Combust. Explos. Shock Waves 6 412

Google Scholar

Google Scholar

[7] Aldushin A P, Bloshenko V N, Seplyarskii B S 1973 Combust. Explos. Shock Waves 9 423

[8] Chernenko E V, Griva V A, Rozenband V I 1982 Combust. Explos. Shock Waves 18 513

Google Scholar

Google Scholar

[9] Shafirovich E, Teoh S K, Varma A 2008 Combust. Flame 152 262

Google Scholar

Google Scholar

[10] Yuan C M, Amyotte P R, Hossain M N, Li C 2014 J. Hazard. Mater. 274 322

Google Scholar

Google Scholar

[11] Breiter A L, Maltsev V M, Popov E I 1977 Phys. Combust. Explos. 13 558

Google Scholar

Google Scholar

[12] Bolobov V I 2012 Phys. Combust. Explos. 48 35

Google Scholar

Google Scholar

[13] Bolobov V I 2003 Combust. Explos. Shock Waves 39 677

Google Scholar

Google Scholar

[14] Bolobov V I 2016 Phys. Combust. Explos. 52 54

Google Scholar

Google Scholar

[15] Ouyang P X, Mi G B, Cao J X, Huang X, He L J, Li P J 2018 Mater. Today Commun. 16 364

Google Scholar

Google Scholar

[16] 弭光宝, 欧阳佩旋, 李培杰, 曹京霞, 黄旭, 曹春晓 2019 航空材料学报 39 94

Google Scholar

Google Scholar

Mi G B, Ouyang P X, Li P J, Cao J X, Huang X, Cao C X 2019 J. Aeron. Mater. 39 94

Google Scholar

Google Scholar

[17] 弭光宝, 黄旭, 曹京霞, 曹春晓 2014 金属学报 50 575

Google Scholar

Google Scholar

Mi G B, Huang X, Cao J X, Cao C X 2014 Acta Metall. Sinica 50 575

Google Scholar

Google Scholar

[18] Li W Y, Ma T, Li J 2010 Mater. Des. 31 1497

Google Scholar

Google Scholar

[19] Darvazi A R, Iranmanesh M 2014 Int. J. Adv. Manuf. Technol. 75 1299

Google Scholar

Google Scholar

[20] Bohle M, Etling D, Muller U, Sreenivasan K R S, Riedel U, Warnatz J 2004 Prandtl’s Essentials of Fluid Mechanics (Heidelberg: Springer) (2nd Ed.) p428

[21] Thomas P H 1960 Trans. Faraday Soc. 56 833

Google Scholar

Google Scholar

[22] Gray P, Harper M J 1958 Sixth Symposium on Combustion New Haven, America, August 19–24, 1958 p425

[23] Boddington T, Feng C G, Gray P 1984 Proc. Roy. Soc. London 391 269

Google Scholar

Google Scholar

[24] 弭光宝, 曹春晓, 黄旭, 曹京霞, 王宝 2014 航空材料学报 34 83

Google Scholar

Google Scholar

Mi G B, Cao C X, Huang X, Cao J X, Wang B 2014 J. Aeron. Mater. 34 83

Google Scholar

Google Scholar

[25] 中国航空材料手册编辑委员会 2001 中国航空材料手册(第4卷) (北京: 中国标准出版社) p147

China Aeronautical Materials Handbook Editorial Committee 2001 China Aeronautical Materials Handbook (Volume 4) (Beijing: China Standards Press) p147 (in Chinese)

[26] Wang L, Zhang Q Y, Li X X, Cui X H, Wang S Q 2014 Metall. Mater. Trans. A 45 2284

Google Scholar

Google Scholar

[27] Chen K M, Zhang Q Y, Li X X, Wang L, Cui X H, Wang S Q 2014 Tribo. Trans. 57 838

Google Scholar

Google Scholar

[28] Elrod C W 1980 Proceedings of the Tri-Service Conference on Corrosion Boulder, America, November 5–7, 1980 p54

[29] 梁贤烨, 弭光宝, 李培杰, 曹京霞, 黄旭 2019 钛工业进展 36 1

Liang X Y, Mi G B, Li P J, Cao J X, Huang X 2019 Titanium Ind. Prog. 36 1

-

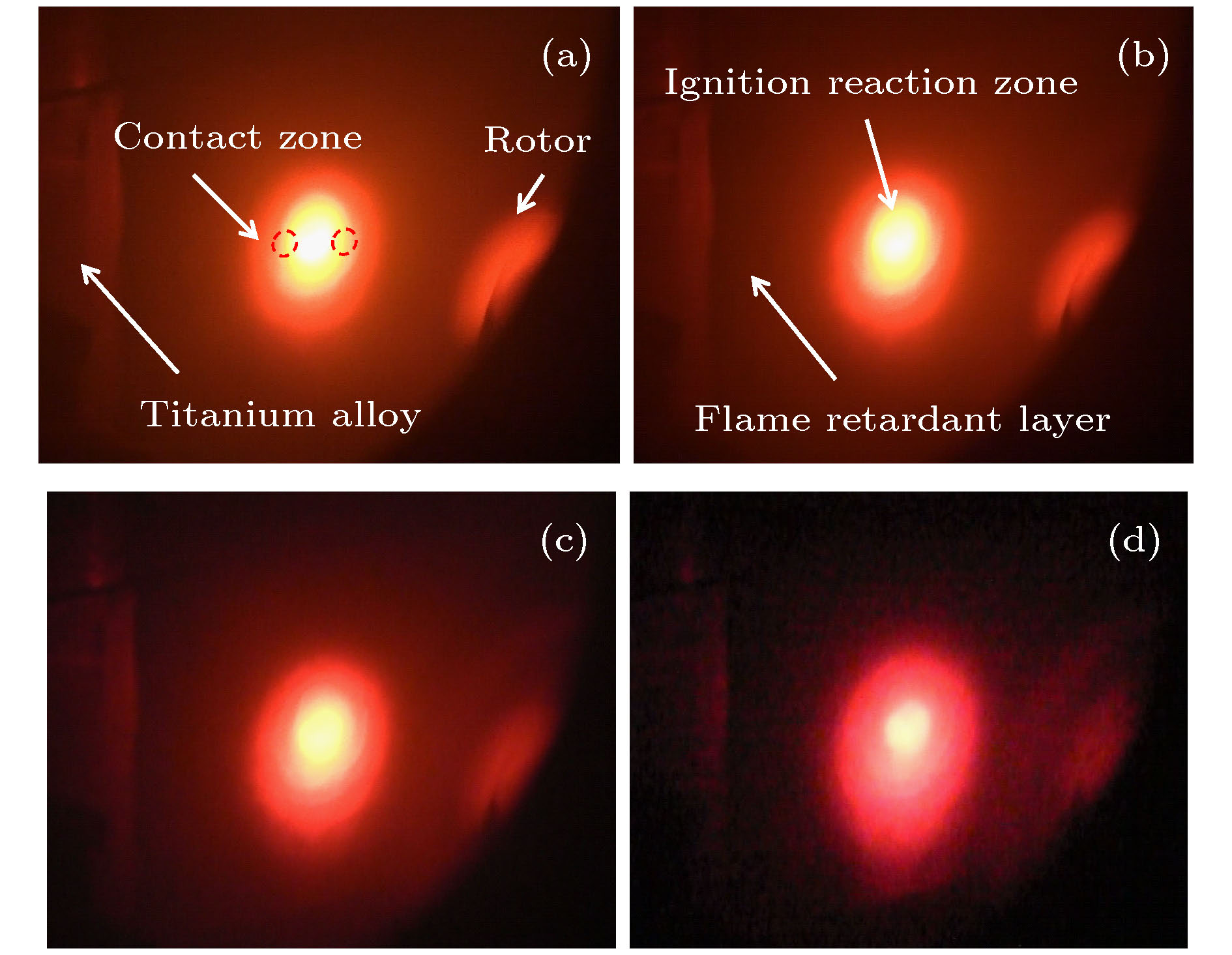

图 4 临界条件下摩擦着火过程的原位观察(I为静子背面反应区着火的镜像; II为反应区中心着火的放射状火花), 各子图分别对应摩擦结束后的不同时间 (a) 0.05 s; (b) 0.10 s; (c) 0.15 s; (d) 0.20 s; (e) 0.25 s; (f) 0.5 s

Fig. 4. In-situ observation of friction ignition process under critical condition (I, mirror image of ignition of reaction zone; II, spark of micro-bump near the centre hole of reaction zone): (a) 0.05 s, (b) 0.10 s, (c) 0.15 s, (d) 0.20 s, (e) 0.25 s, (f) 0.5 s after the rubbing ends.

表 A1 术语表

Table A1. Nomenclature

符号 物理意义 单位 λ 热传导系数 W·m–1·K–1 cp 比热 J·kg–1·K–1 q 单位反应热 MJ·kg–1 k 指前因子 kg·m–2·s–1 E 激活能 kJ·mol–1 f 摩擦应力 N·m–2 τ 着火延迟时间 s N 接触应力 N·m–2 φ 厚度 m d 试验舱直径 m R2 接触面内径 m R1 接触面外径 m ω 转子角速度 r·min–1 ci 氧浓度 100% v 流速 m·s QG 生热项 J·s–1 QH 反应热项 J·s–1 QC 对流散热项 J·s–1 QR 辐射散热项 J·s–1 μ 摩擦系数 / Sr 反应区面积 m2 a 吸附系数 / α 总传热系数 W·m–2·K–1 Nu 努塞尔数 / Pr 普朗特数 / Re 雷诺数 / 性能材料 密度

ρ/kg·m–3比热容

cp/J·kg–1·K–1反应热

q/MJ·kg–1指前因子

k/kg·m–2·s–1激活能

E/kJ·mol–1导热系数

λ/W·m–1·K–1吸附系数

a/MPa–0.5钛合金 4500 493 33 4.2 44.5 17.8 0.52 阻燃层 5600 560 — — — 0.62 — 初始摩擦正应力N/kPa 静子厚度φ/m 特征长度d/m 内半径R2/m 外半径R1/m 角速度ω/r·min–1 氧浓度ci/% 流速v/m·s–1 265 0.002 0.016 0.002 0.004 5000 21 50 -

[1] Borisova E A, Sklyarov N M 2007 Aviation Materials and Technologists: Production Combustion and Fire Safety of Titanium Alloys (Moscow: VIAM) p21

[2] 弭光宝, 黄旭, 曹京霞, 王宝, 曹春晓 2016 65 056103

Google Scholar

Google Scholar

Mi G B, Huang X, Cao J X, Wang B, Cao C X 2016 Acta Phys. Sin. 65 056103

Google Scholar

Google Scholar

[3] Frank-Kamenetskii D A 1955 Diffusion and Heat Exchange in Chemical Kinetics (Princeton: Princeton University Press) p288

[4] Merzhanov A G 1975 AIAA J. 13 209

Google Scholar

Google Scholar

[5] Elsayed S A 1996 J. Loss Prevent Proc. 9 393

Google Scholar

Google Scholar

[6] Khaikin B I, Bloshenko V N 1970 Combust. Explos. Shock Waves 6 412

Google Scholar

Google Scholar

[7] Aldushin A P, Bloshenko V N, Seplyarskii B S 1973 Combust. Explos. Shock Waves 9 423

[8] Chernenko E V, Griva V A, Rozenband V I 1982 Combust. Explos. Shock Waves 18 513

Google Scholar

Google Scholar

[9] Shafirovich E, Teoh S K, Varma A 2008 Combust. Flame 152 262

Google Scholar

Google Scholar

[10] Yuan C M, Amyotte P R, Hossain M N, Li C 2014 J. Hazard. Mater. 274 322

Google Scholar

Google Scholar

[11] Breiter A L, Maltsev V M, Popov E I 1977 Phys. Combust. Explos. 13 558

Google Scholar

Google Scholar

[12] Bolobov V I 2012 Phys. Combust. Explos. 48 35

Google Scholar

Google Scholar

[13] Bolobov V I 2003 Combust. Explos. Shock Waves 39 677

Google Scholar

Google Scholar

[14] Bolobov V I 2016 Phys. Combust. Explos. 52 54

Google Scholar

Google Scholar

[15] Ouyang P X, Mi G B, Cao J X, Huang X, He L J, Li P J 2018 Mater. Today Commun. 16 364

Google Scholar

Google Scholar

[16] 弭光宝, 欧阳佩旋, 李培杰, 曹京霞, 黄旭, 曹春晓 2019 航空材料学报 39 94

Google Scholar

Google Scholar

Mi G B, Ouyang P X, Li P J, Cao J X, Huang X, Cao C X 2019 J. Aeron. Mater. 39 94

Google Scholar

Google Scholar

[17] 弭光宝, 黄旭, 曹京霞, 曹春晓 2014 金属学报 50 575

Google Scholar

Google Scholar

Mi G B, Huang X, Cao J X, Cao C X 2014 Acta Metall. Sinica 50 575

Google Scholar

Google Scholar

[18] Li W Y, Ma T, Li J 2010 Mater. Des. 31 1497

Google Scholar

Google Scholar

[19] Darvazi A R, Iranmanesh M 2014 Int. J. Adv. Manuf. Technol. 75 1299

Google Scholar

Google Scholar

[20] Bohle M, Etling D, Muller U, Sreenivasan K R S, Riedel U, Warnatz J 2004 Prandtl’s Essentials of Fluid Mechanics (Heidelberg: Springer) (2nd Ed.) p428

[21] Thomas P H 1960 Trans. Faraday Soc. 56 833

Google Scholar

Google Scholar

[22] Gray P, Harper M J 1958 Sixth Symposium on Combustion New Haven, America, August 19–24, 1958 p425

[23] Boddington T, Feng C G, Gray P 1984 Proc. Roy. Soc. London 391 269

Google Scholar

Google Scholar

[24] 弭光宝, 曹春晓, 黄旭, 曹京霞, 王宝 2014 航空材料学报 34 83

Google Scholar

Google Scholar

Mi G B, Cao C X, Huang X, Cao J X, Wang B 2014 J. Aeron. Mater. 34 83

Google Scholar

Google Scholar

[25] 中国航空材料手册编辑委员会 2001 中国航空材料手册(第4卷) (北京: 中国标准出版社) p147

China Aeronautical Materials Handbook Editorial Committee 2001 China Aeronautical Materials Handbook (Volume 4) (Beijing: China Standards Press) p147 (in Chinese)

[26] Wang L, Zhang Q Y, Li X X, Cui X H, Wang S Q 2014 Metall. Mater. Trans. A 45 2284

Google Scholar

Google Scholar

[27] Chen K M, Zhang Q Y, Li X X, Wang L, Cui X H, Wang S Q 2014 Tribo. Trans. 57 838

Google Scholar

Google Scholar

[28] Elrod C W 1980 Proceedings of the Tri-Service Conference on Corrosion Boulder, America, November 5–7, 1980 p54

[29] 梁贤烨, 弭光宝, 李培杰, 曹京霞, 黄旭 2019 钛工业进展 36 1

Liang X Y, Mi G B, Li P J, Cao J X, Huang X 2019 Titanium Ind. Prog. 36 1

计量

- 文章访问数: 12181

- PDF下载量: 117

- 被引次数: 0

下载:

下载: