-

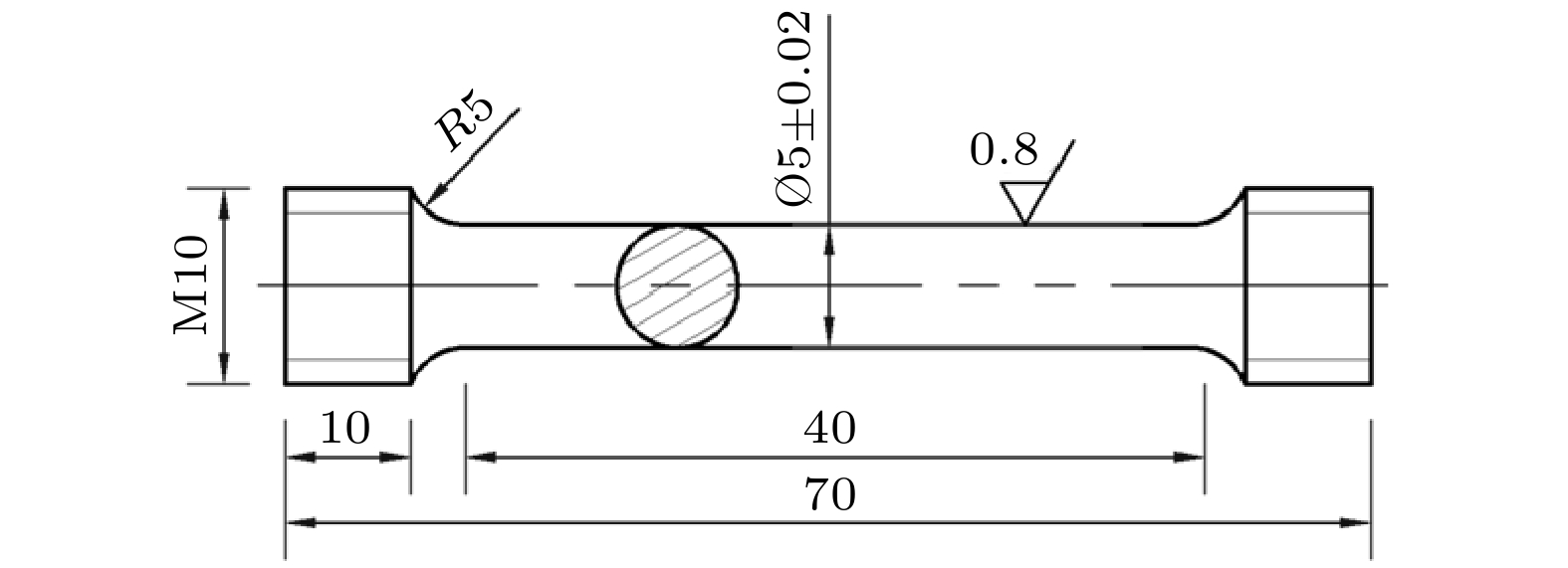

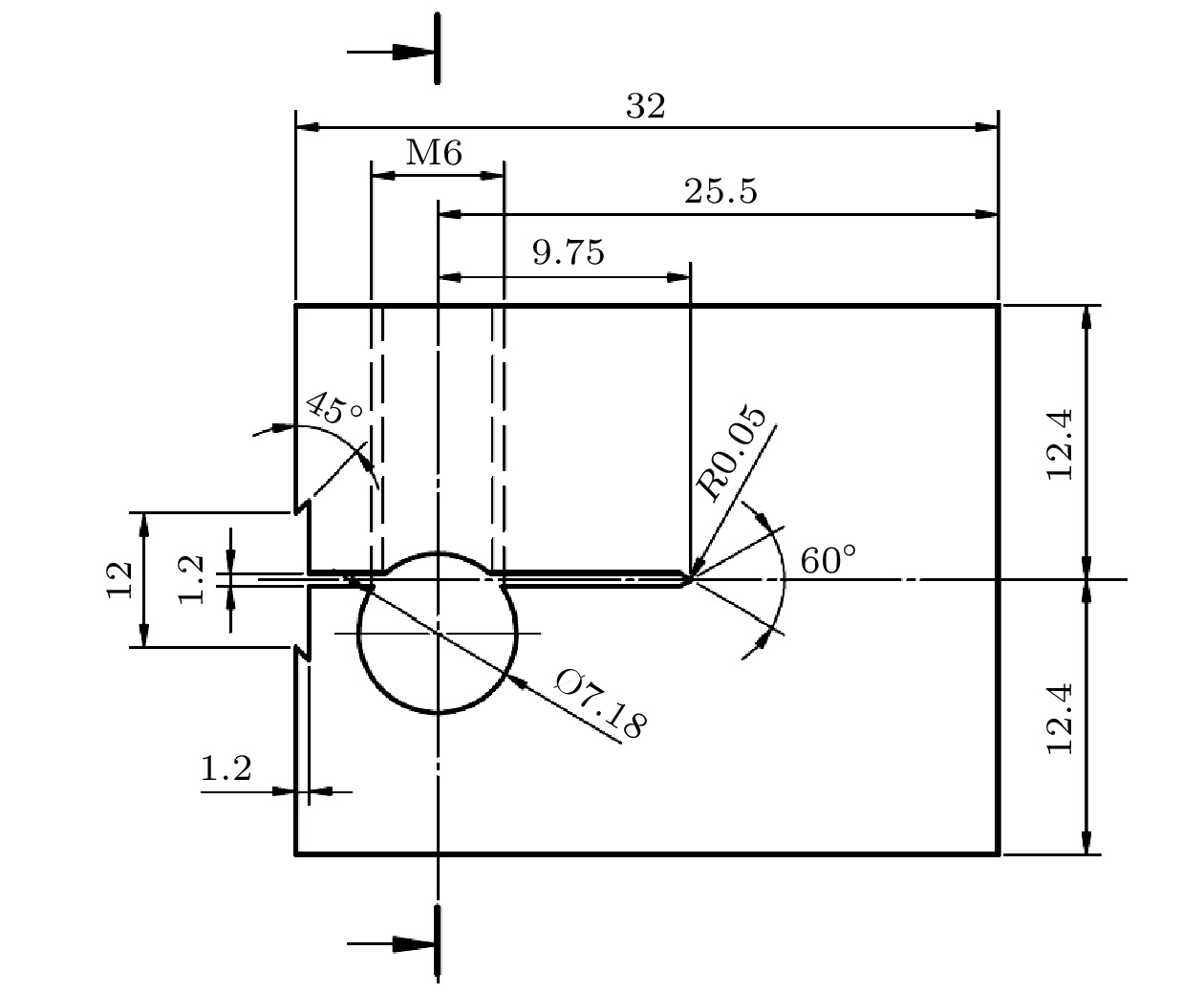

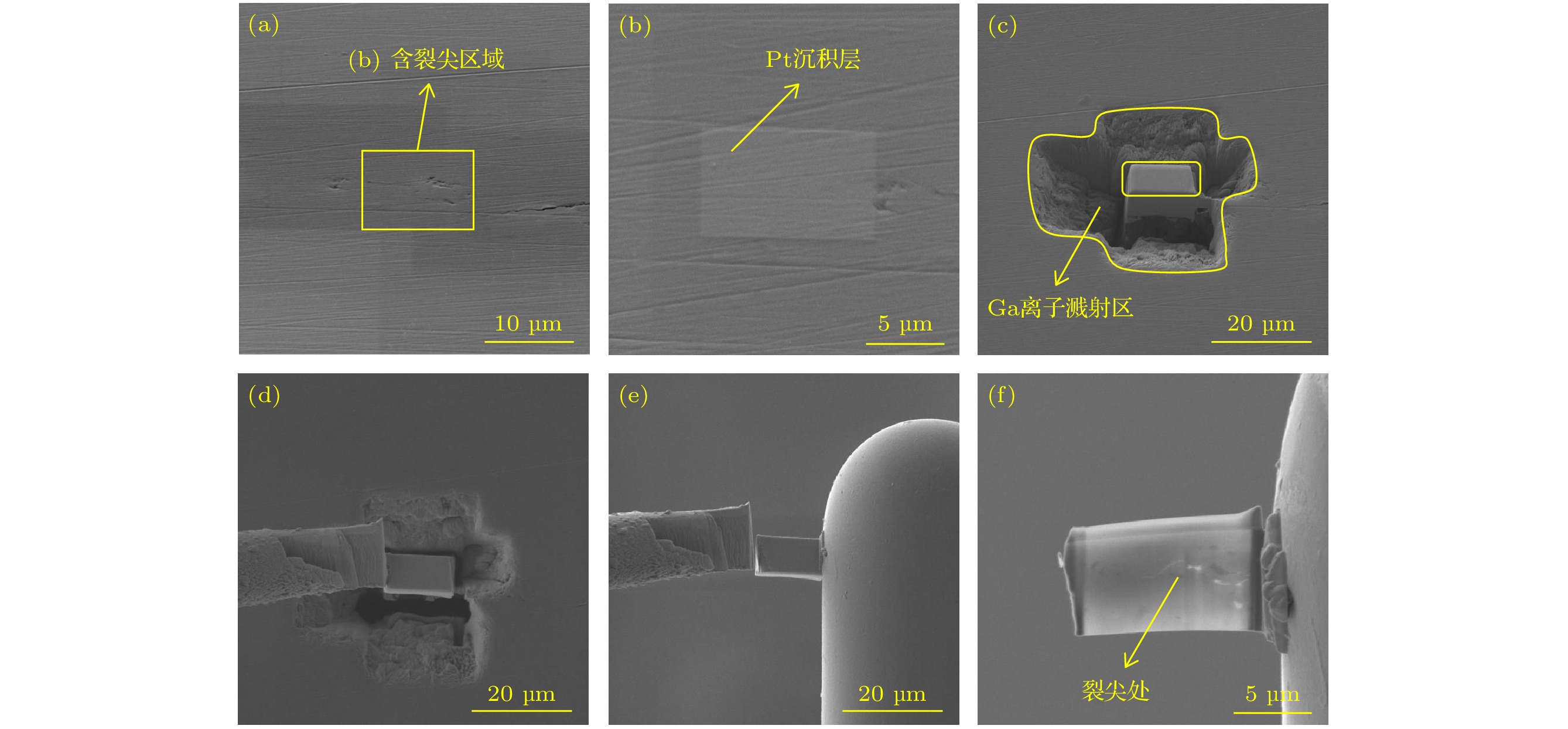

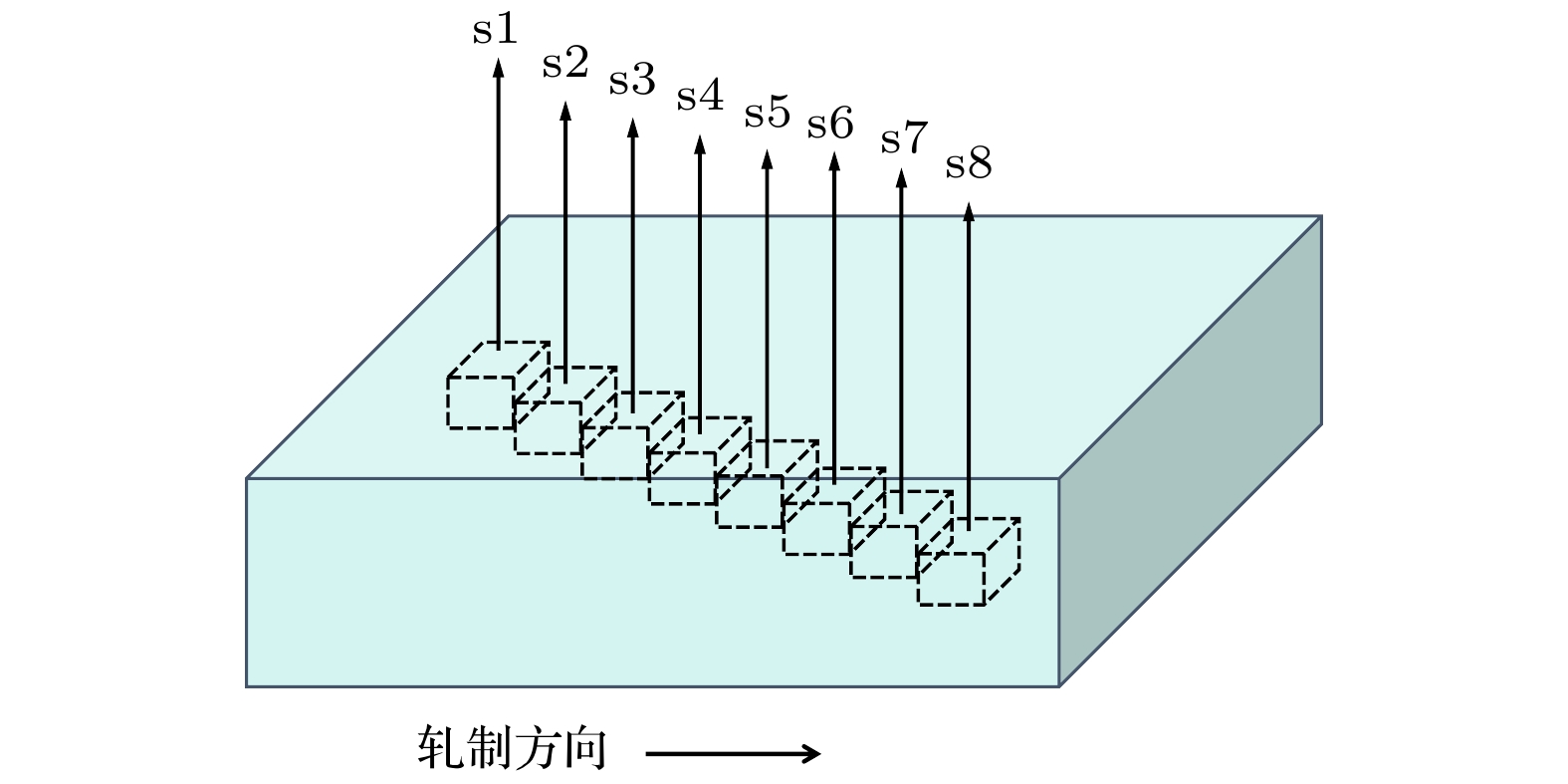

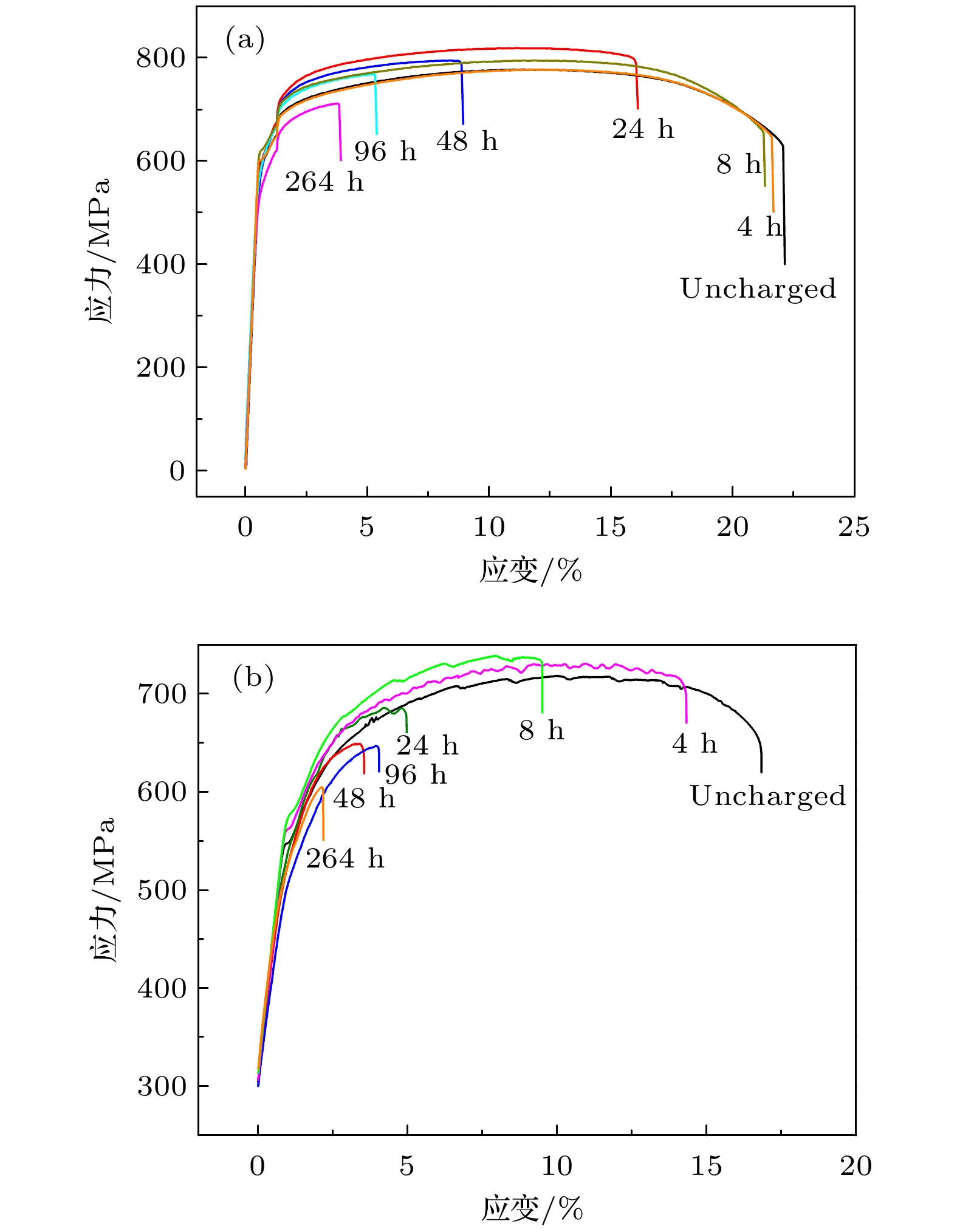

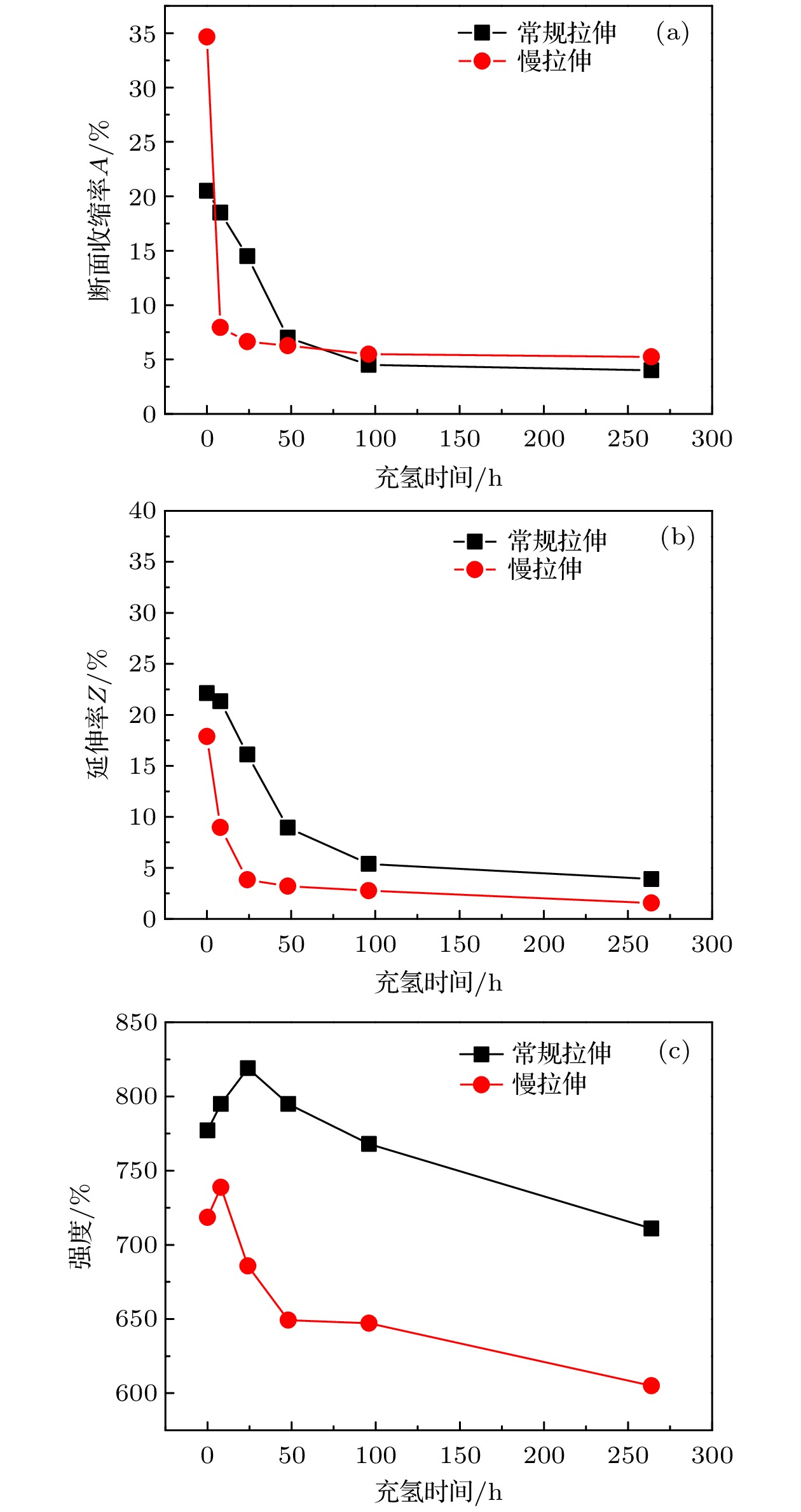

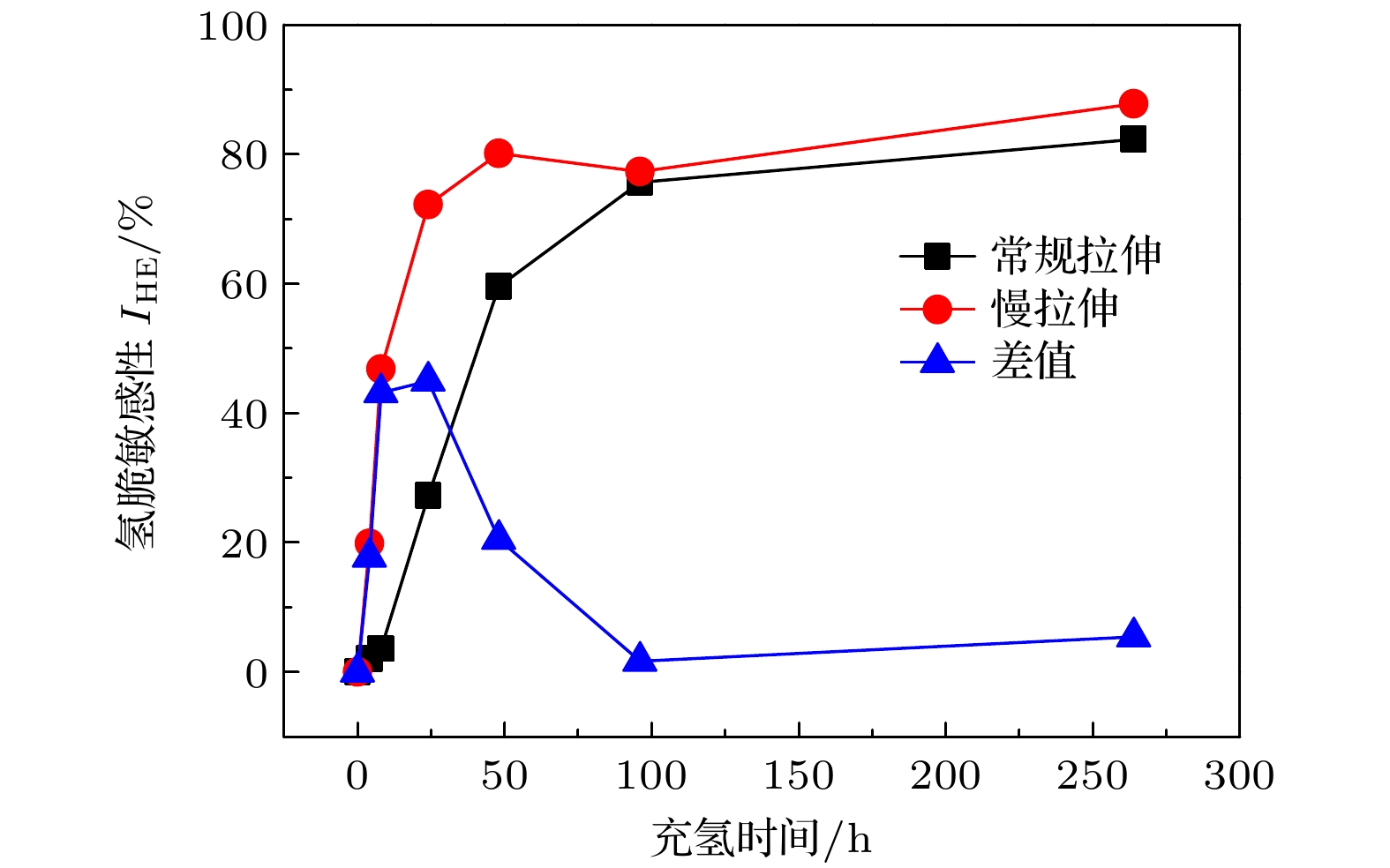

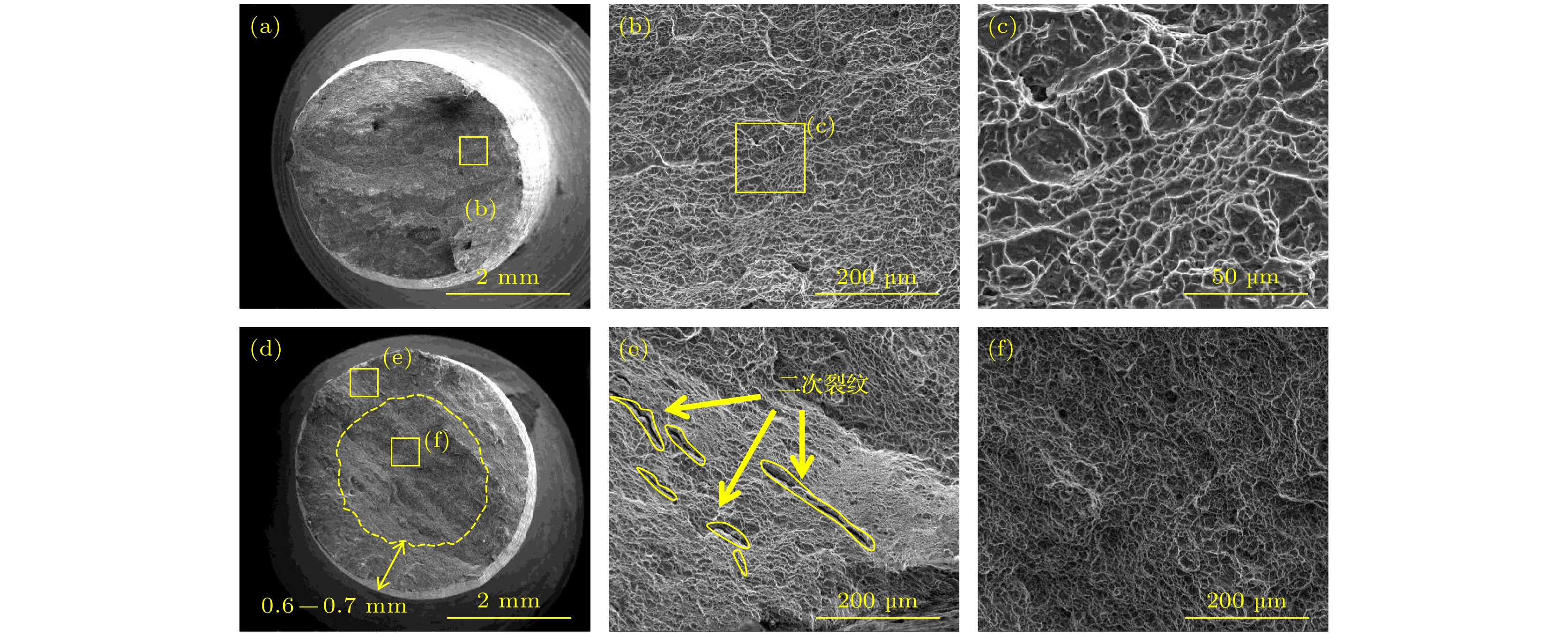

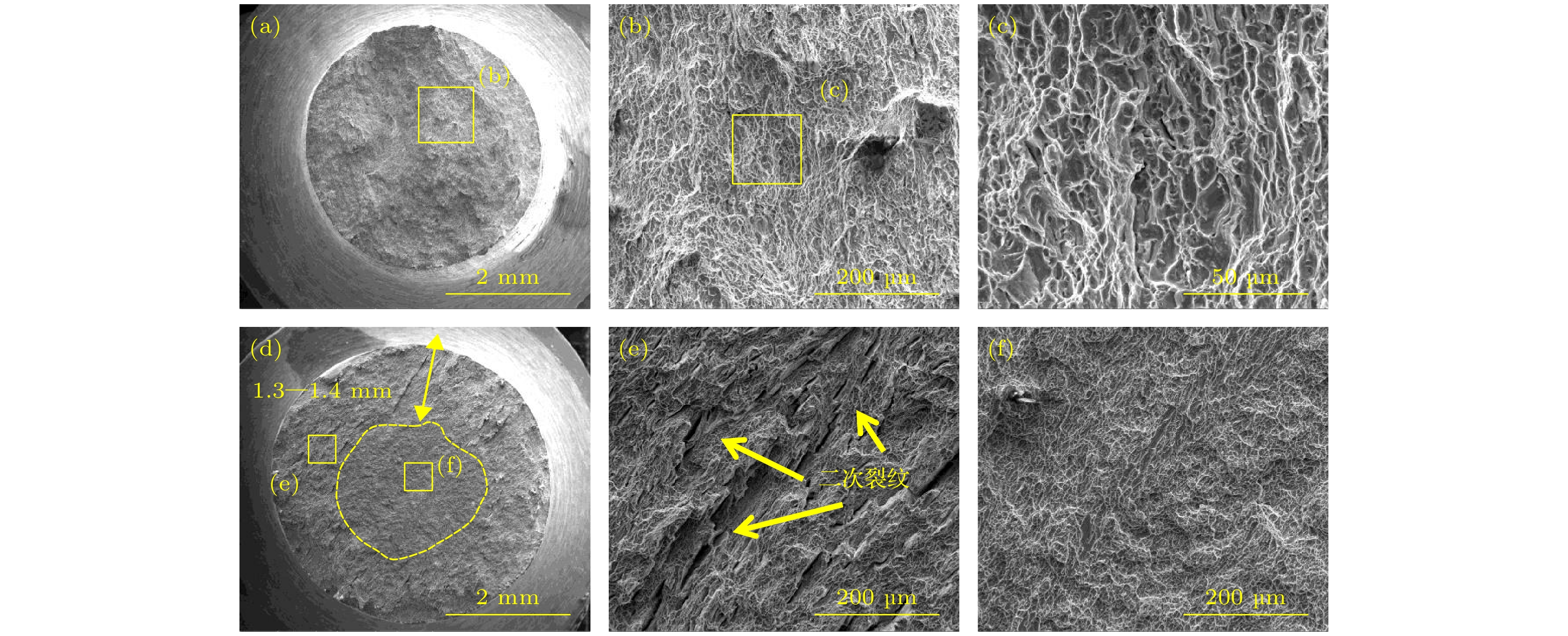

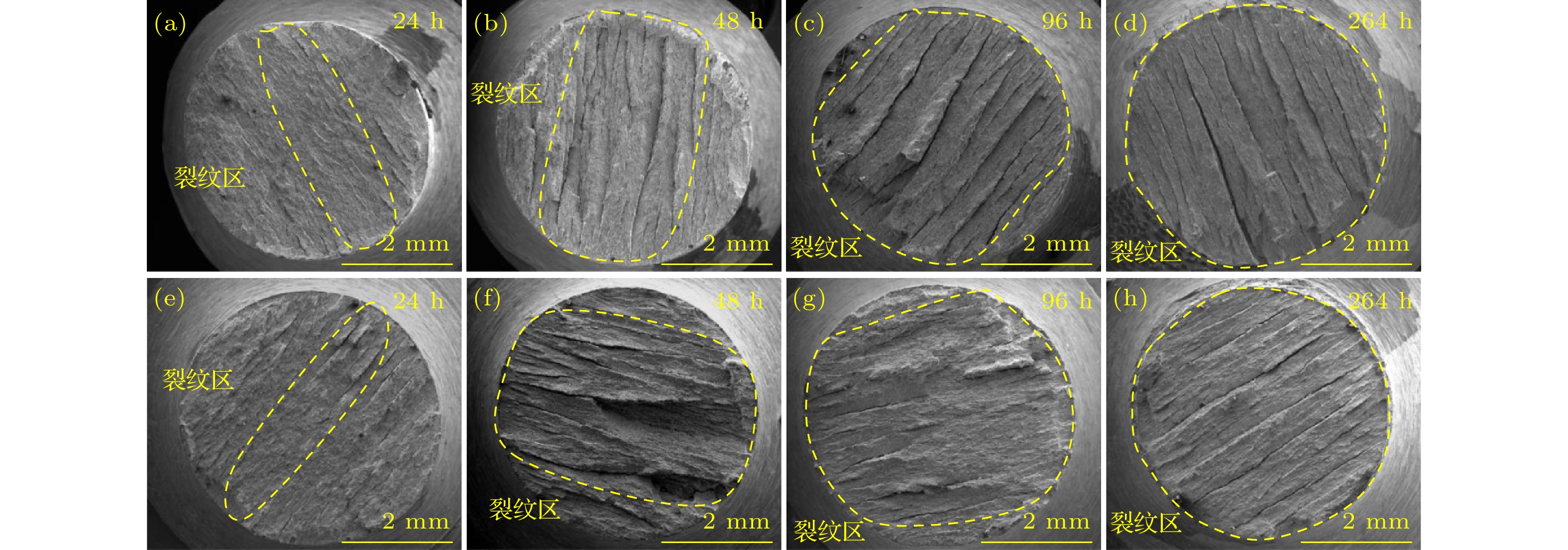

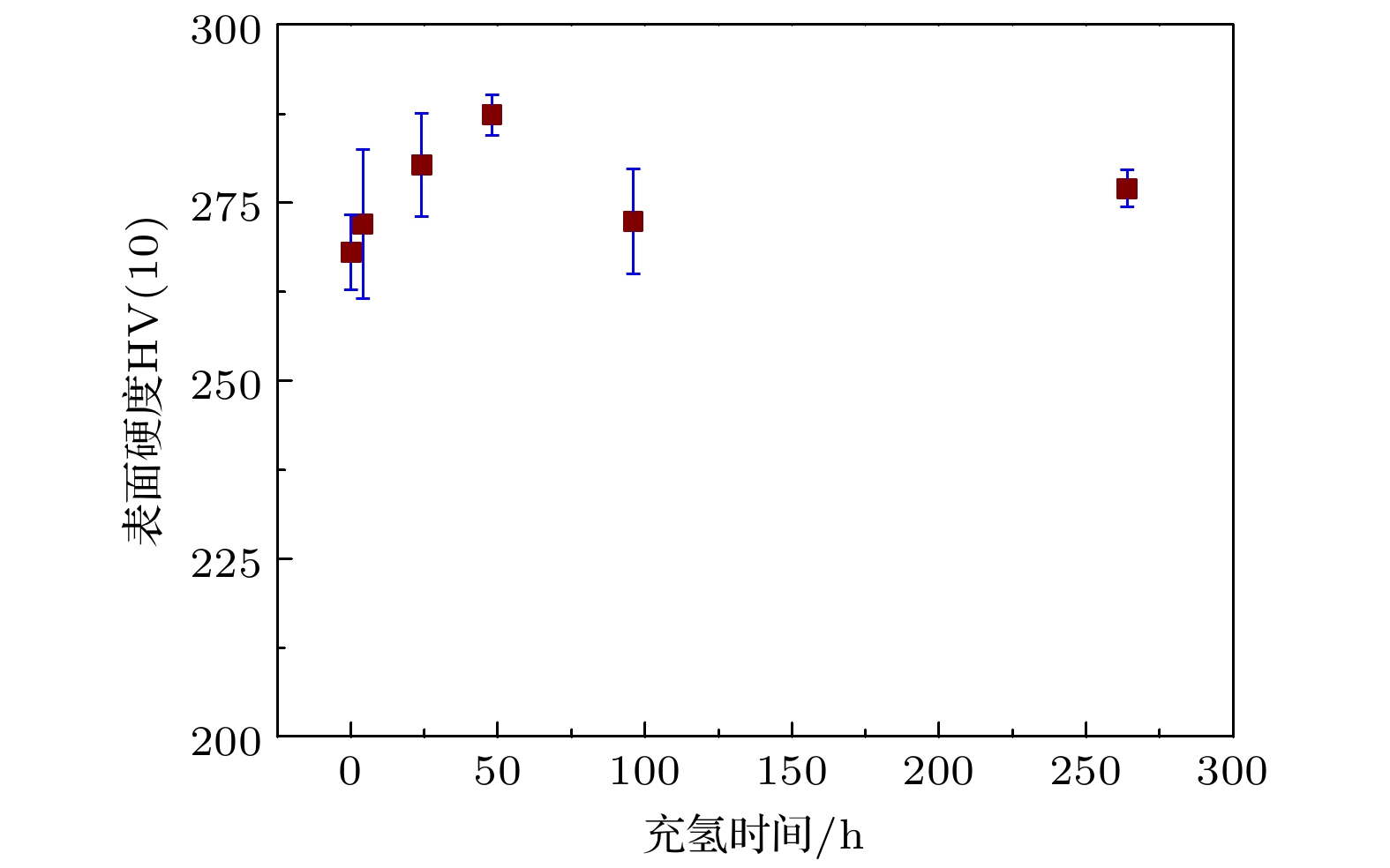

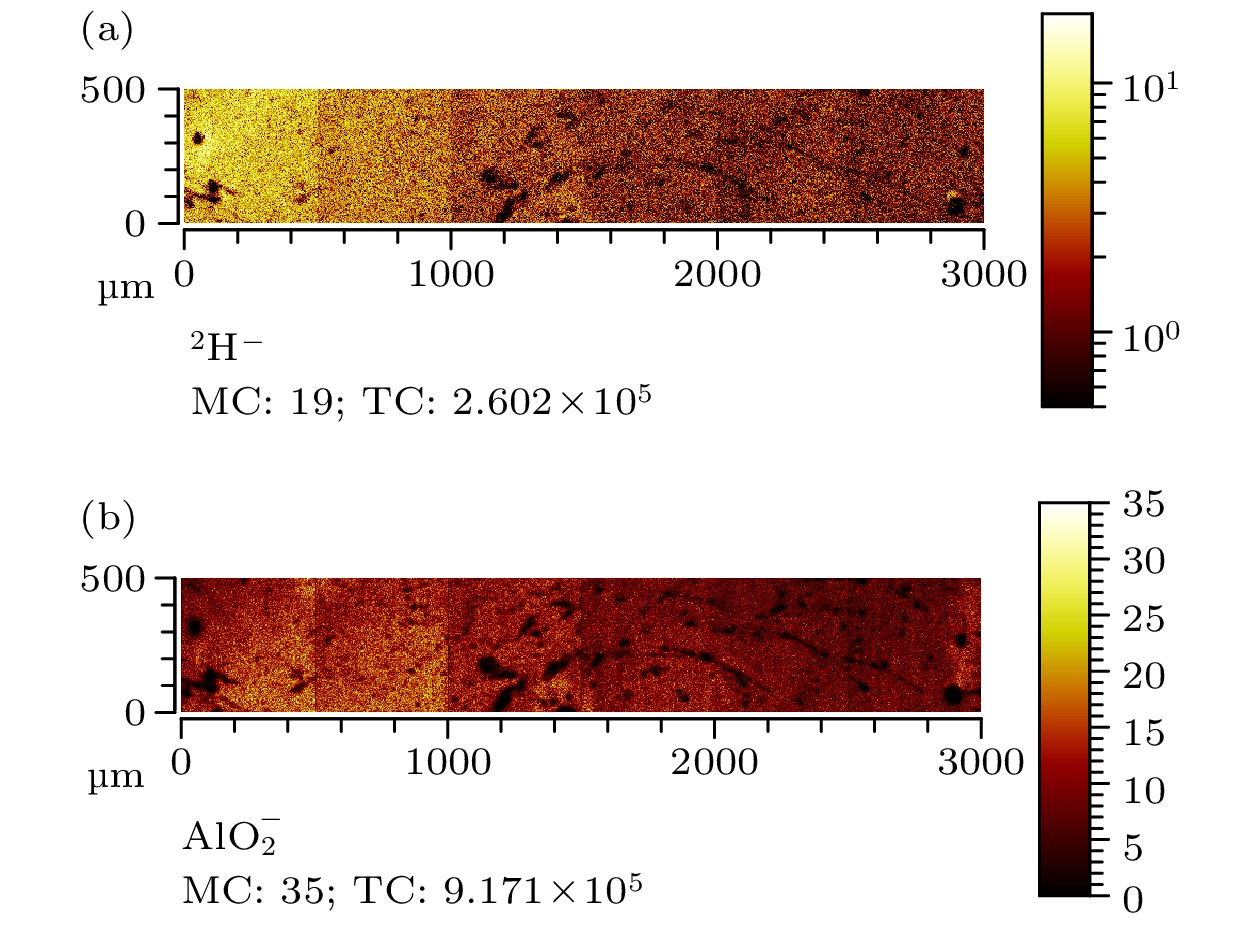

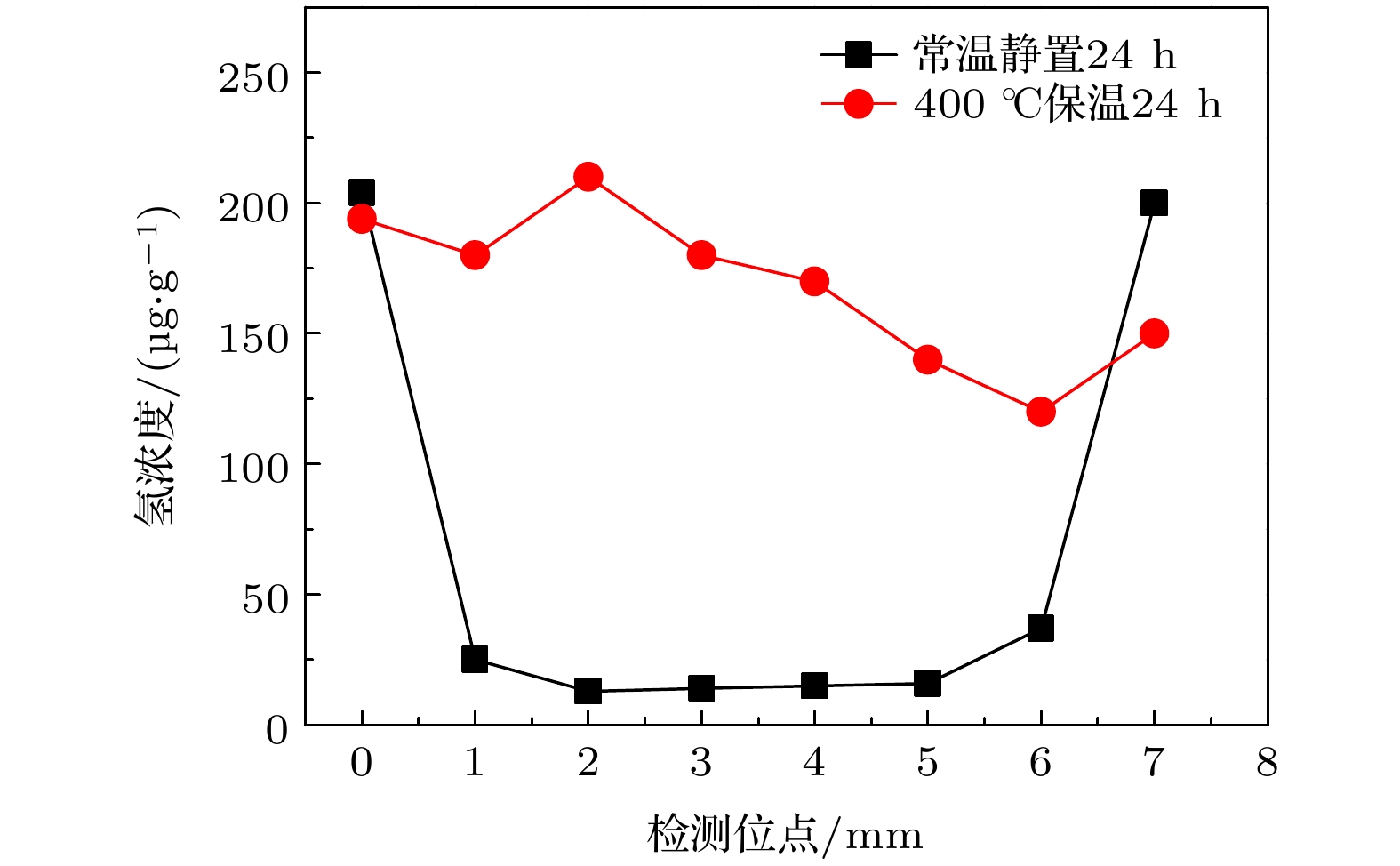

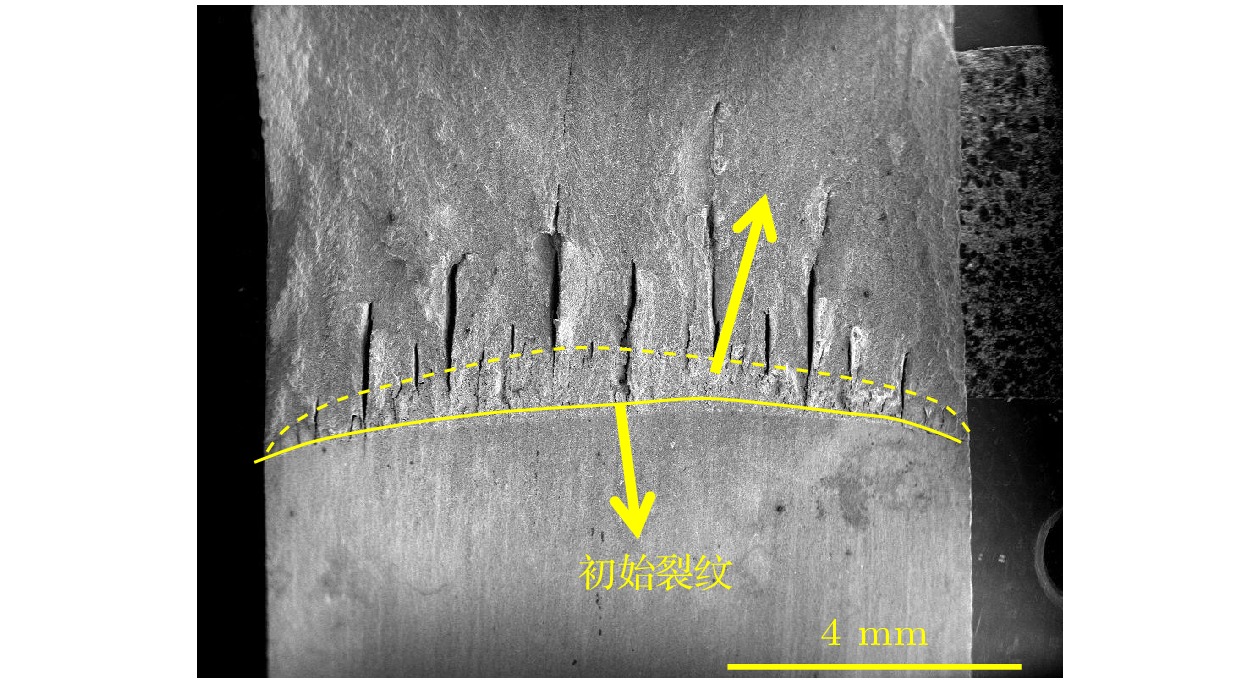

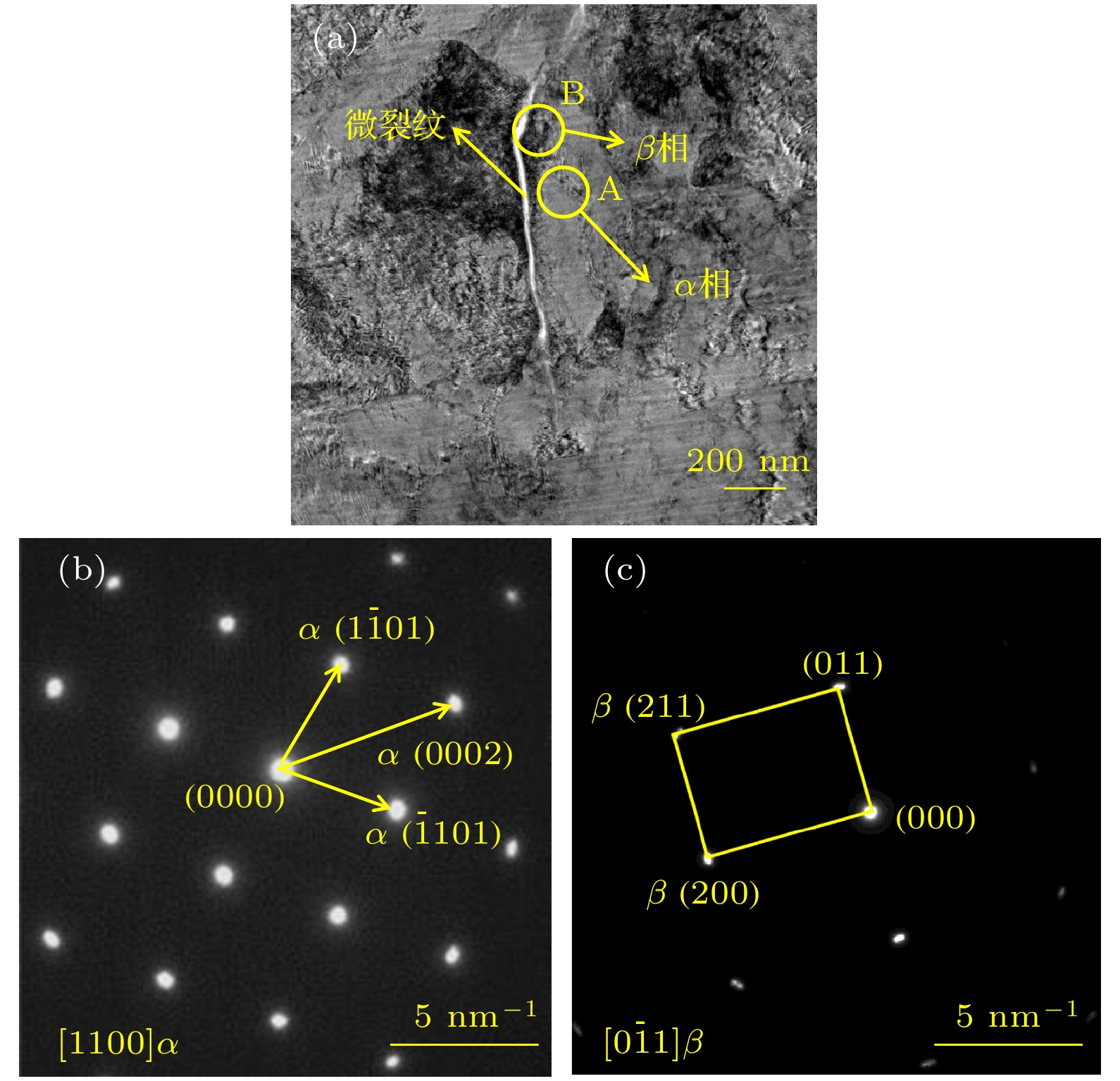

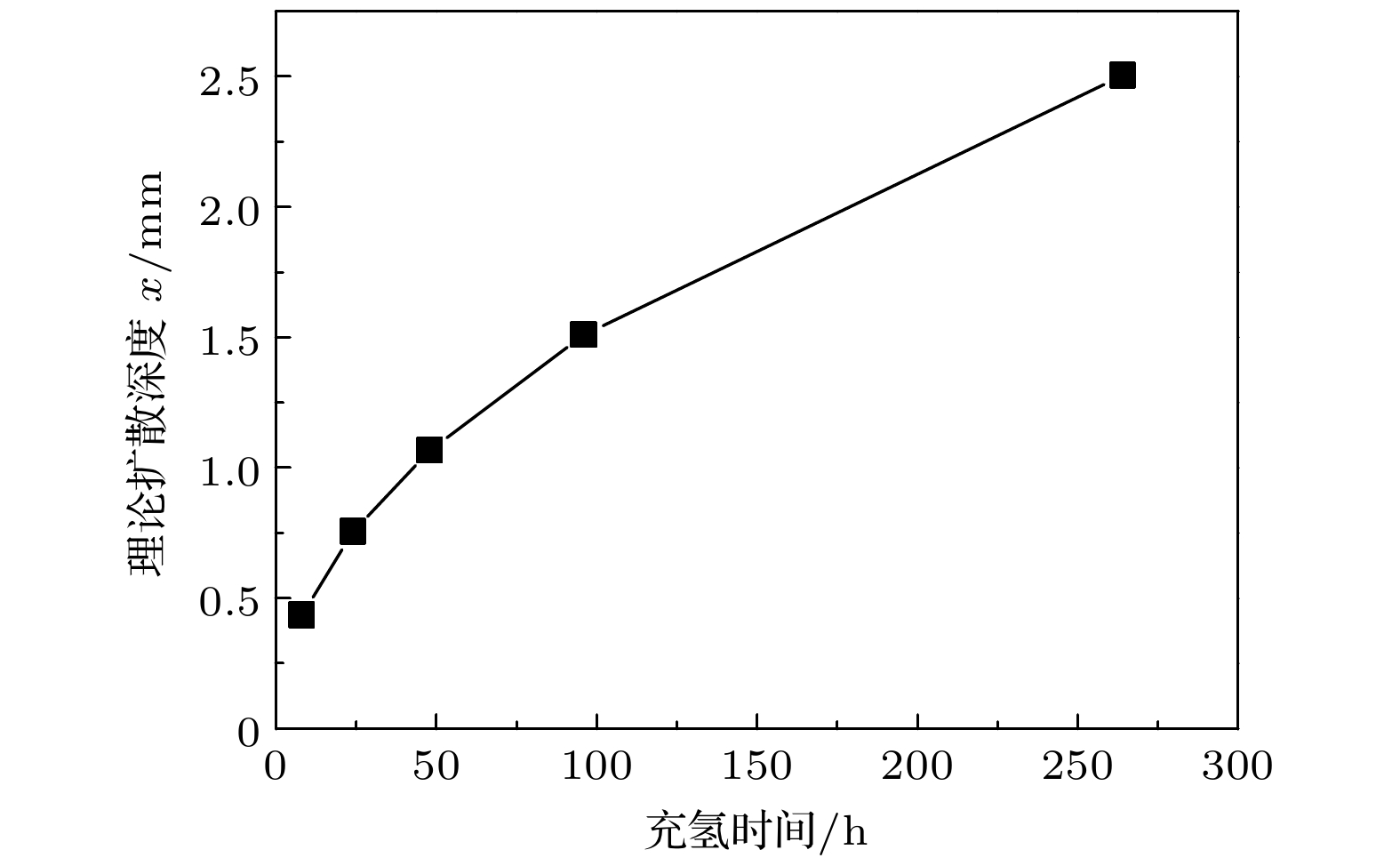

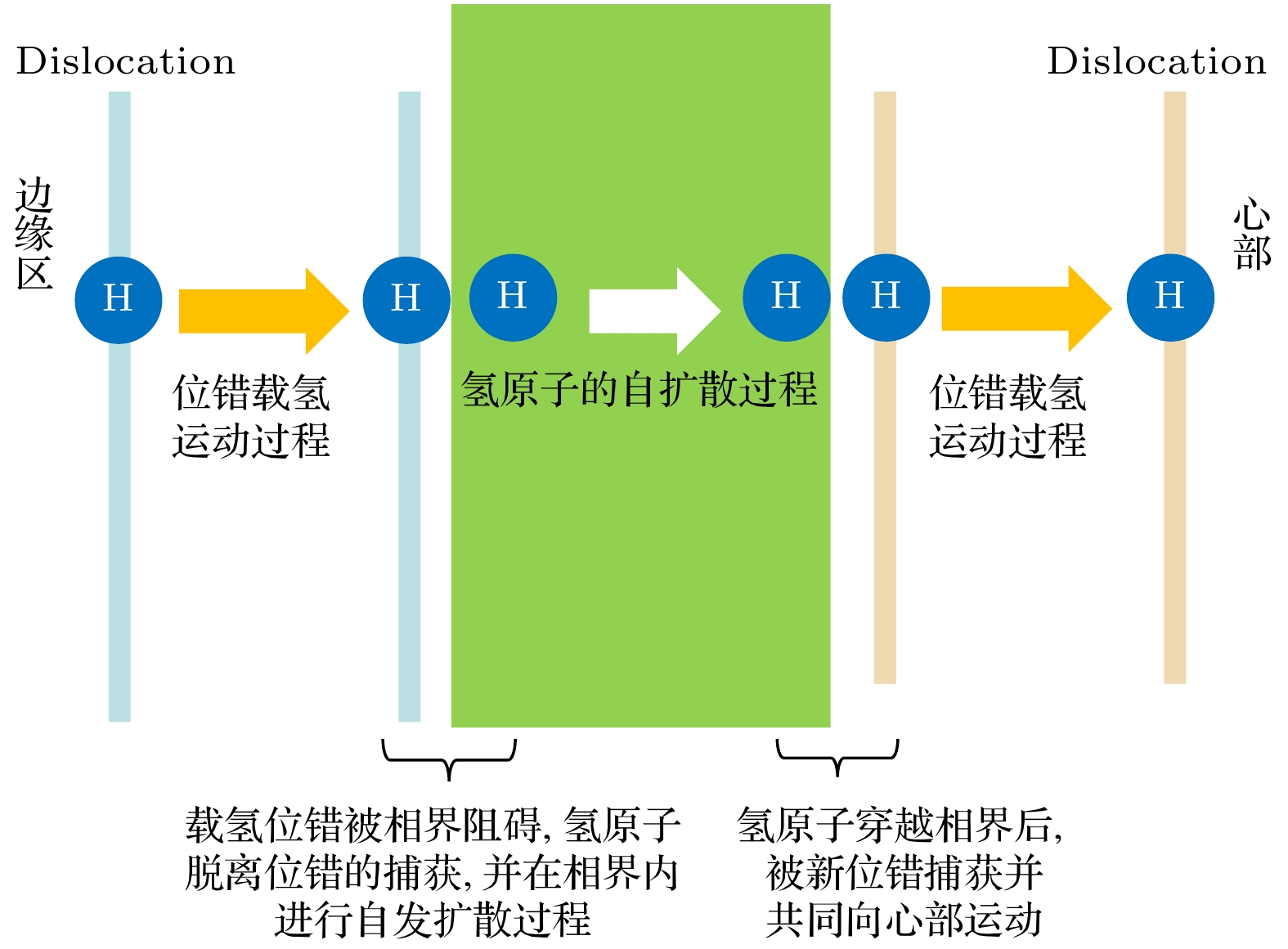

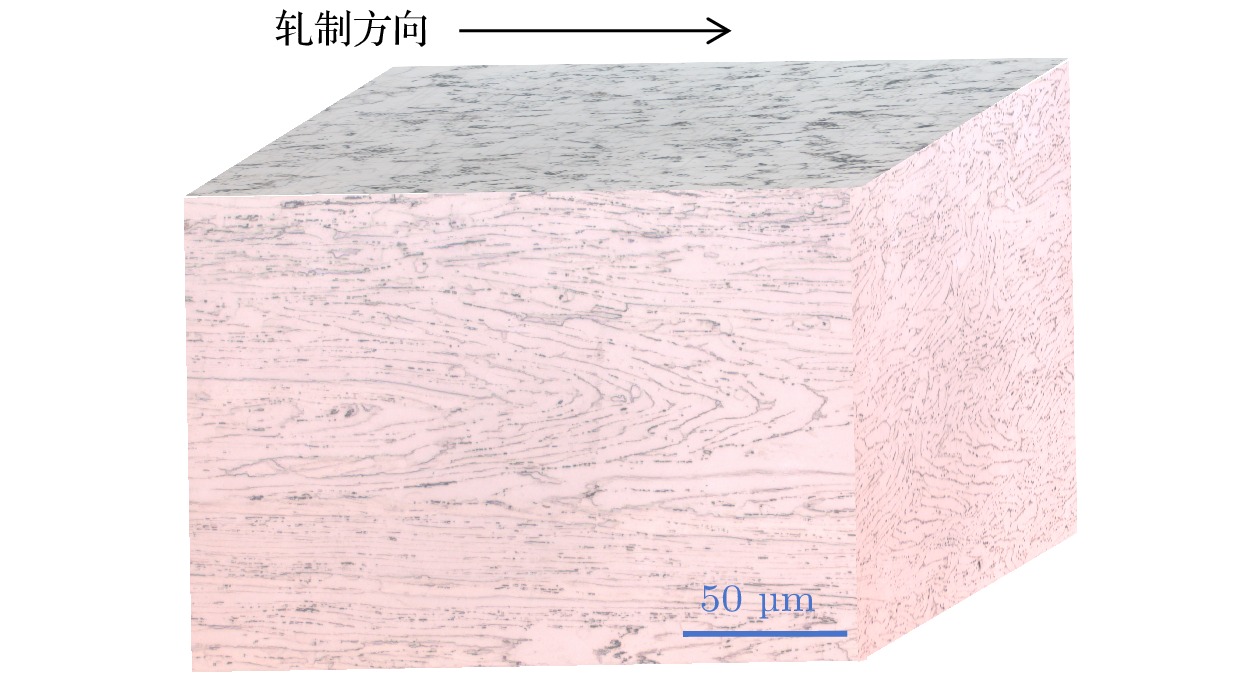

通过慢拉伸、恒位移等加载方法, 评估了含氢Ti-2.5A1-2Zr-1Fe合金的力学性能衰减行为及氢脆敏感性的变化. 利用扫描电子显微镜对断口微观形貌特征进行了分析, 并采用二次离子质谱仪对氢的宏观分布进行了表征, 揭示了断口脆性区域与氢宏观分布之间的内在联系. 此外, 结合位错载氢运动模型及扩散方程, 探讨了氢的扩散机制以及慢应变速率对氢扩散过程产生的影响. 为了进一步探索氢化物的存在性, 利用透射电子显微镜对表面高氢浓度层和裂纹尖端及其附近物相进行了表征分析, 最终未发现氢化物相的析出, 综合上述实验数据和微观物相结构分析, 对Ti-2.5Al-2Zr-1Fe合金的氢脆机制进行了探讨, 认为该合金的氢脆机制由HEDE机制主导.The Ti-2.5Al-2Zr-1Fe used as hull structural material, is susceptible to hydrogen embrittlement induced by corrosion and hydrogen evolution in marine environments. Considering the long-term service of ships, the hydrogen embrittlement behavior under slow strain rate is crucial for evaluating the alloy’s service performance and ensuring long-term ship structural safety. In order to investigate the hydrogen embrittlement mechanism of Ti-2.5Al-2Zr-1Fe alloy under slow strain rate conditions, this study combines slow tension and constant displacement loading techniques to systematically evaluate the attenuation of mechanical properties and the dynamic changes in hydrogen embrittlement sensitivity of hydrogen-containing Ti-2.5Al-2Zr-1Fe alloy. Employing scanning electron microscopy (SEM), we thoroughly analyze the microstructural features of fracture surfaces. Meanwhile, the close correlation between the brittle zone at the fracture site and the macroscopic distribution of hydrogen atoms is elucidated by using secondary ion mass spectrometry (SIMS). Additionally, theoretical analysis based on diffusion equations reveals a notable increase in hydrogen diffusion distance within the Ti-2.5Al-2Zr-1Fe alloy as hydrogen charging time increases. Further, using the dislocation-hydrogen interaction model, we derive a critical strain rate threshold $ {\varepsilon _0} = {{\left( {30RT} \right)} {/ } {\left( {\rho DE} \right)}} $ for dislocation-mediated hydrogen transport in titanium alloys. When the externally applied strain rate ε falls below this threshold, dislocations efficiently capture and transport hydrogen atoms, enhancing hydrogen diffusion depth and significantly augmenting the alloy’s hydrogen embrittlement sensitivity, thereby accelerating material embrittlement. The Vickers-hardness (HV) test further elucidates the dual nature of hydrogen’s influence on titanium alloy properties: although moderate hydrogen content slightly enhances surface hardness, exceeding a specific threshold leads to a major negative influence on plasticity, far exceeding the benefits of surface hardening, resulting in a substantial decline in overall mechanical performance. To comprehensively decipher the hydrogen embrittlement mechanism of Ti-2.5Al-2Zr-1Fe alloy, transmission electron microscopy (TEM) is employed to analyze the phase composition in regions of high hydrogen concentration, crack tips, and their vicinities. The analysis results indicate that no direct precipitation of hydrides is observed; instead, hydrogen atoms preferentially accumulate in the β-phase, prompting microcrack propagation along β-phase boundaries. According to the aforementioned experimental data and microstructural analysis, we propose that the hydrogen embrittlement mechanism in Ti-2.5Al-2Zr-1Fe alloy is primarily governed by the HEDE mechanism. Furthermore, when the strain rate falls below ε0, it synergizes with the dislocation-mediated hydrogen transport mechanism, vastly expanding the influence scope of the HEDE mechanism and exacerbating the alloy’s hydrogen embrittlement sensitivity.

-

Keywords:

- titanium alloy /

- hydrogen embrittlement /

- slow strain rate /

- hydride

[1] 杨锐, 马英杰, 雷家峰, 胡青苗, 黄森森 2021 金属学报 57 1455

Google Scholar

Google Scholar

Yang R, Ma Y J, Lei J F, Hu Q M, Huang S S 2021 Acta Metall. Sin. 57 1455

Google Scholar

Google Scholar

[2] 何燕, 周刚, 刘艳侠, 王皞, 徐东生, 杨锐 2018 67 050203

Google Scholar

Google Scholar

He Y, Zhou G, Liu Y X, Wang H, Xu D S, Yang R 2018 Acta. Phys. Sin. 67 050203

Google Scholar

Google Scholar

[3] 吴明宇, 弭光宝, 李培杰 2024 73 086103

Google Scholar

Google Scholar

Wu M Y, Mi G B, Li P J 2024 Acta. Phys. Sin. 73 086103

Google Scholar

Google Scholar

[4] 丁智松, 高巍, 魏敬鹏, 金耀华, 赵晨, 杨巍 2022 71 028102

Google Scholar

Google Scholar

Ding Z S, Gao W, Wei J P, Jin Y H, Zhao C, Yang W 2022 Acta. Phys. Sin. 71 028102

Google Scholar

Google Scholar

[5] Robertson I M, Sofronis P, Nagao A 2015 Metall. Mater. Trans. A 46 2323

Google Scholar

Google Scholar

[6] Venezuela J, Zhou Q J, Liu Q L 2018 Mater. Today Commun. 17 1

Google Scholar

Google Scholar

[7] Olden V, Thaulow C, Johnsen R 2008 Mater. Des. 29 1934

Google Scholar

Google Scholar

[8] Lynch S P 2007 NACE International Corrosion Conference Nashville, Tennessee, March, 2007 p07493

[9] Wang X, Zhu R T, Li C Y, Wang X, Huang P F 2020 Rare Met. Mater. Eng. 49 3769

[10] Zhang S Q, Wan J F, Zhao Q Y 2020 Corros. Sci 164 108345

Google Scholar

Google Scholar

[11] Xu Y L, Li L T 2021 Mater. Res. Express 8 046531

Google Scholar

Google Scholar

[12] 汪洋, 吴冰, 宿彦京, 邢焰, 王向轲, 高鸿, 李岩 2020 有色金属工程 10 33

Google Scholar

Google Scholar

Wang Y, Wu B, Su Y J, Xing Y, Wang X K, Gao H, Li Y 2020 Nonferrous Met. Eng. 10 33

Google Scholar

Google Scholar

[13] Sun Z G, Hou H L 2008 J. Alloys Compd. 476 550

Google Scholar

Google Scholar

[14] Liu X Y, Wang J, Gao L Q 2021 J. Alloys Compd. 862 158669

Google Scholar

Google Scholar

[15] Tien J, Thompson A W, Bernstein I M 1976 Metall. Trans. A 7 821

Google Scholar

Google Scholar

[16] 吴明宇, 弭光宝, 李培杰, 黄旭 2023 72 166102

Google Scholar

Google Scholar

Wu M Y, Mi G B, Li P J, Huang X 2023 Acta Phys. Sin. 72 166102

Google Scholar

Google Scholar

[17] 周伟, 姚泽坤, 谭立军, 郭鸿镇, 张建伟, 梁晓波 2011 稀有金属材料与工程 40 1230

Zhou W, Yao Z K, Tan L J, Guo H Z, Zhang J W, Liang X B 2011 Rare Met. Mater. Eng. 40 1230

[18] 赵晓丽, 张永健, 邵成伟, 惠卫军, 董瀚 2018 金属学报 54 1031

Google Scholar

Google Scholar

Zhao X L, Zhang Y J, Shao C W, Hui W J, Dong H 2018 Acta Metall. Sin. 54 1031

Google Scholar

Google Scholar

[19] 张滨, 郑华, 刘实, 王隆保 2005 原子能科学技术 39 522

Google Scholar

Google Scholar

Zhang B, Zheng H, Liu S, Wang L B 2005 At. Energy Sci. Technol. 39 522

Google Scholar

Google Scholar

[20] Chen C Q, Li S X, Lu K 2003 Acta Mater. 51 931

Google Scholar

Google Scholar

[21] 王艳飞, 巩建鸣, 蒋文春, 姜勇, 唐建群 2011 金属学报 47 594

Wang Y F, Gong J M, Jiang W C, Jiang Y, Tang J Q 2011 Acta Metall. Sin. 47 594

[22] 刘战伟 2009 桂林电子科技大学学报 29 108

Google Scholar

Google Scholar

Liu Z W 2009 J. Guilin Univ. Electron. Technol. 29 108

Google Scholar

Google Scholar

[23] 孙志杰, 王洋 2020 材料开发与应用 35 94

Sun Z J, Wang Y 2020 Dev. Appl. Mater. 35 94

[24] 刘晓镇, 韩恩厚, 宋影伟 2023 中国有色金属学报 33 307

Google Scholar

Google Scholar

Liu X Z, Han E H, Song Y W 2023 Chin. J. Nonferrous Met. 33 307

Google Scholar

Google Scholar

[25] 王秀英, 孙力玲, 刘日平, 姚玉书, 张君, 王文魁 2004 53 3845

Google Scholar

Google Scholar

Wang X Y, Sun L L, Liu R P, Yao Y S, Zhang J, Wang W K 2004 Acta Phys. Sin. 53 3845

Google Scholar

Google Scholar

[26] 孙永伟, 陈继志, 刘军 2015 金属学报 51 1315

Sun Y W, Chen J Z, Liu J 2015 Acta Metall. Sin. 51 1315

[27] 李洪佳, 孙光爱, 龚建, 陈波, 王虹, 李建, 庞蓓蓓, 张莹, 彭述明 2014 63 236101

Google Scholar

Google Scholar

Li H J, Sun G A, Gong J, Chen B, Wang H, Li J, Pang B B, Zhang Y, Peng S M 2014 Acta Phys. Sin. 63 236101

Google Scholar

Google Scholar

[28] Kan B, Wu W J, Yang Z X, Li J X 2020 Mater. Sci. Eng. A 775 138963

Google Scholar

Google Scholar

[29] Wang M Q, Akiyama E, Tsuzaki K 2007 Corros. Sci. 49 4081

Google Scholar

Google Scholar

[30] 王贞, 刘静, 张施琦, 黄峰 2022 中国腐蚀与防护学报 42 106

Google Scholar

Google Scholar

Wang Z, Liu J, Zhang S Q, Huang F 2022 J. Chin. Soc. Corros. Prot. 42 106

Google Scholar

Google Scholar

-

表 1 二次离子质谱测试参数

Table 1. Parameters of SIMS testing.

入射能量/keV 入射角/(°) 电流强度/pA 扫描面积/m2 极性及质量范围/amu 30 45 1.142 500×500 负离子模式 0—227 -

[1] 杨锐, 马英杰, 雷家峰, 胡青苗, 黄森森 2021 金属学报 57 1455

Google Scholar

Google Scholar

Yang R, Ma Y J, Lei J F, Hu Q M, Huang S S 2021 Acta Metall. Sin. 57 1455

Google Scholar

Google Scholar

[2] 何燕, 周刚, 刘艳侠, 王皞, 徐东生, 杨锐 2018 67 050203

Google Scholar

Google Scholar

He Y, Zhou G, Liu Y X, Wang H, Xu D S, Yang R 2018 Acta. Phys. Sin. 67 050203

Google Scholar

Google Scholar

[3] 吴明宇, 弭光宝, 李培杰 2024 73 086103

Google Scholar

Google Scholar

Wu M Y, Mi G B, Li P J 2024 Acta. Phys. Sin. 73 086103

Google Scholar

Google Scholar

[4] 丁智松, 高巍, 魏敬鹏, 金耀华, 赵晨, 杨巍 2022 71 028102

Google Scholar

Google Scholar

Ding Z S, Gao W, Wei J P, Jin Y H, Zhao C, Yang W 2022 Acta. Phys. Sin. 71 028102

Google Scholar

Google Scholar

[5] Robertson I M, Sofronis P, Nagao A 2015 Metall. Mater. Trans. A 46 2323

Google Scholar

Google Scholar

[6] Venezuela J, Zhou Q J, Liu Q L 2018 Mater. Today Commun. 17 1

Google Scholar

Google Scholar

[7] Olden V, Thaulow C, Johnsen R 2008 Mater. Des. 29 1934

Google Scholar

Google Scholar

[8] Lynch S P 2007 NACE International Corrosion Conference Nashville, Tennessee, March, 2007 p07493

[9] Wang X, Zhu R T, Li C Y, Wang X, Huang P F 2020 Rare Met. Mater. Eng. 49 3769

[10] Zhang S Q, Wan J F, Zhao Q Y 2020 Corros. Sci 164 108345

Google Scholar

Google Scholar

[11] Xu Y L, Li L T 2021 Mater. Res. Express 8 046531

Google Scholar

Google Scholar

[12] 汪洋, 吴冰, 宿彦京, 邢焰, 王向轲, 高鸿, 李岩 2020 有色金属工程 10 33

Google Scholar

Google Scholar

Wang Y, Wu B, Su Y J, Xing Y, Wang X K, Gao H, Li Y 2020 Nonferrous Met. Eng. 10 33

Google Scholar

Google Scholar

[13] Sun Z G, Hou H L 2008 J. Alloys Compd. 476 550

Google Scholar

Google Scholar

[14] Liu X Y, Wang J, Gao L Q 2021 J. Alloys Compd. 862 158669

Google Scholar

Google Scholar

[15] Tien J, Thompson A W, Bernstein I M 1976 Metall. Trans. A 7 821

Google Scholar

Google Scholar

[16] 吴明宇, 弭光宝, 李培杰, 黄旭 2023 72 166102

Google Scholar

Google Scholar

Wu M Y, Mi G B, Li P J, Huang X 2023 Acta Phys. Sin. 72 166102

Google Scholar

Google Scholar

[17] 周伟, 姚泽坤, 谭立军, 郭鸿镇, 张建伟, 梁晓波 2011 稀有金属材料与工程 40 1230

Zhou W, Yao Z K, Tan L J, Guo H Z, Zhang J W, Liang X B 2011 Rare Met. Mater. Eng. 40 1230

[18] 赵晓丽, 张永健, 邵成伟, 惠卫军, 董瀚 2018 金属学报 54 1031

Google Scholar

Google Scholar

Zhao X L, Zhang Y J, Shao C W, Hui W J, Dong H 2018 Acta Metall. Sin. 54 1031

Google Scholar

Google Scholar

[19] 张滨, 郑华, 刘实, 王隆保 2005 原子能科学技术 39 522

Google Scholar

Google Scholar

Zhang B, Zheng H, Liu S, Wang L B 2005 At. Energy Sci. Technol. 39 522

Google Scholar

Google Scholar

[20] Chen C Q, Li S X, Lu K 2003 Acta Mater. 51 931

Google Scholar

Google Scholar

[21] 王艳飞, 巩建鸣, 蒋文春, 姜勇, 唐建群 2011 金属学报 47 594

Wang Y F, Gong J M, Jiang W C, Jiang Y, Tang J Q 2011 Acta Metall. Sin. 47 594

[22] 刘战伟 2009 桂林电子科技大学学报 29 108

Google Scholar

Google Scholar

Liu Z W 2009 J. Guilin Univ. Electron. Technol. 29 108

Google Scholar

Google Scholar

[23] 孙志杰, 王洋 2020 材料开发与应用 35 94

Sun Z J, Wang Y 2020 Dev. Appl. Mater. 35 94

[24] 刘晓镇, 韩恩厚, 宋影伟 2023 中国有色金属学报 33 307

Google Scholar

Google Scholar

Liu X Z, Han E H, Song Y W 2023 Chin. J. Nonferrous Met. 33 307

Google Scholar

Google Scholar

[25] 王秀英, 孙力玲, 刘日平, 姚玉书, 张君, 王文魁 2004 53 3845

Google Scholar

Google Scholar

Wang X Y, Sun L L, Liu R P, Yao Y S, Zhang J, Wang W K 2004 Acta Phys. Sin. 53 3845

Google Scholar

Google Scholar

[26] 孙永伟, 陈继志, 刘军 2015 金属学报 51 1315

Sun Y W, Chen J Z, Liu J 2015 Acta Metall. Sin. 51 1315

[27] 李洪佳, 孙光爱, 龚建, 陈波, 王虹, 李建, 庞蓓蓓, 张莹, 彭述明 2014 63 236101

Google Scholar

Google Scholar

Li H J, Sun G A, Gong J, Chen B, Wang H, Li J, Pang B B, Zhang Y, Peng S M 2014 Acta Phys. Sin. 63 236101

Google Scholar

Google Scholar

[28] Kan B, Wu W J, Yang Z X, Li J X 2020 Mater. Sci. Eng. A 775 138963

Google Scholar

Google Scholar

[29] Wang M Q, Akiyama E, Tsuzaki K 2007 Corros. Sci. 49 4081

Google Scholar

Google Scholar

[30] 王贞, 刘静, 张施琦, 黄峰 2022 中国腐蚀与防护学报 42 106

Google Scholar

Google Scholar

Wang Z, Liu J, Zhang S Q, Huang F 2022 J. Chin. Soc. Corros. Prot. 42 106

Google Scholar

Google Scholar

计量

- 文章访问数: 3655

- PDF下载量: 100

- 被引次数: 0

下载:

下载: